Tomorrow I am heading out to the factory that is producing the CT-17 to supervise the final assembly of this long overdue job. Finally, all of the components are built. It will feel great for all involved to get this tool shipped because the CT-18 is…. oops, I am not saying another word.

If my inbox is any indication of pent up demand, we are long overdue to make the HP-3 and HP-4–we haven’t made them in a decade. So I pulled out my old files, and decided to completely re-engineer these two little planes. (They are both bevel up planes, one low angle and the other standard.)

Clearly these are small planes and their function is primarily for accurate detail work. That said, the new fences and skids bring added functionality that I cannot wait to use for some of my own projects. We will make a limited run of these in stainless and will also make them in either brass or aluminum, maybe both. No news on pricing as of this writing.

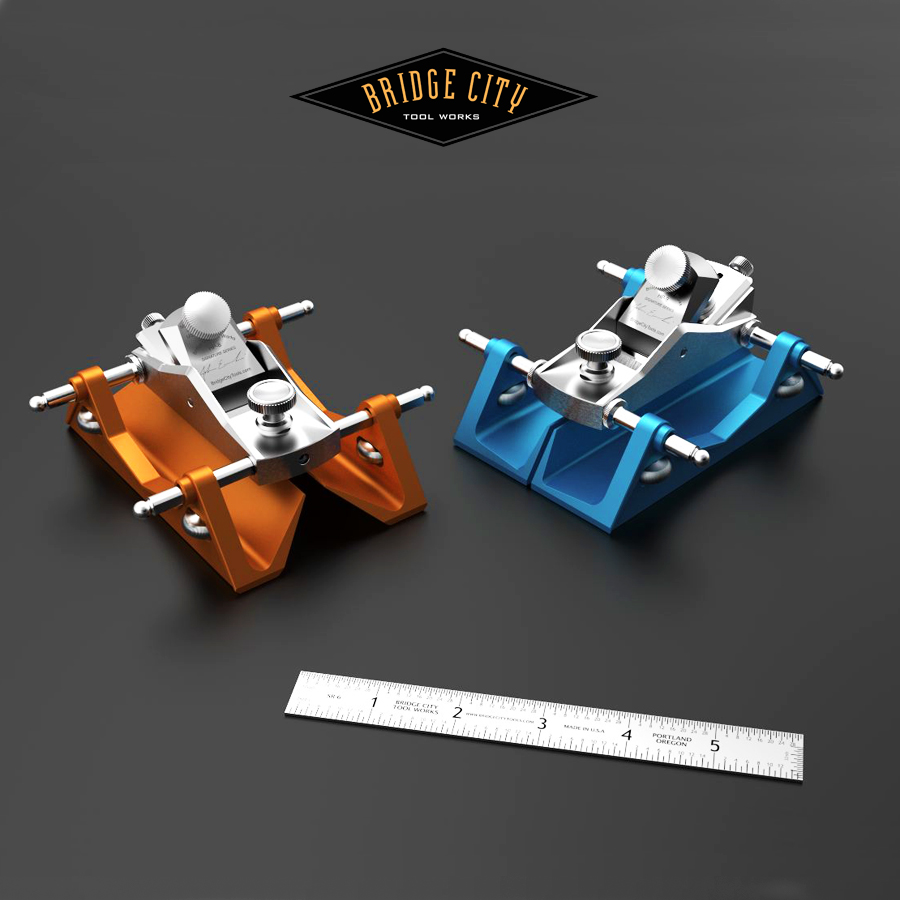

The HP-8 and HP-9 in stainless steel side by side…

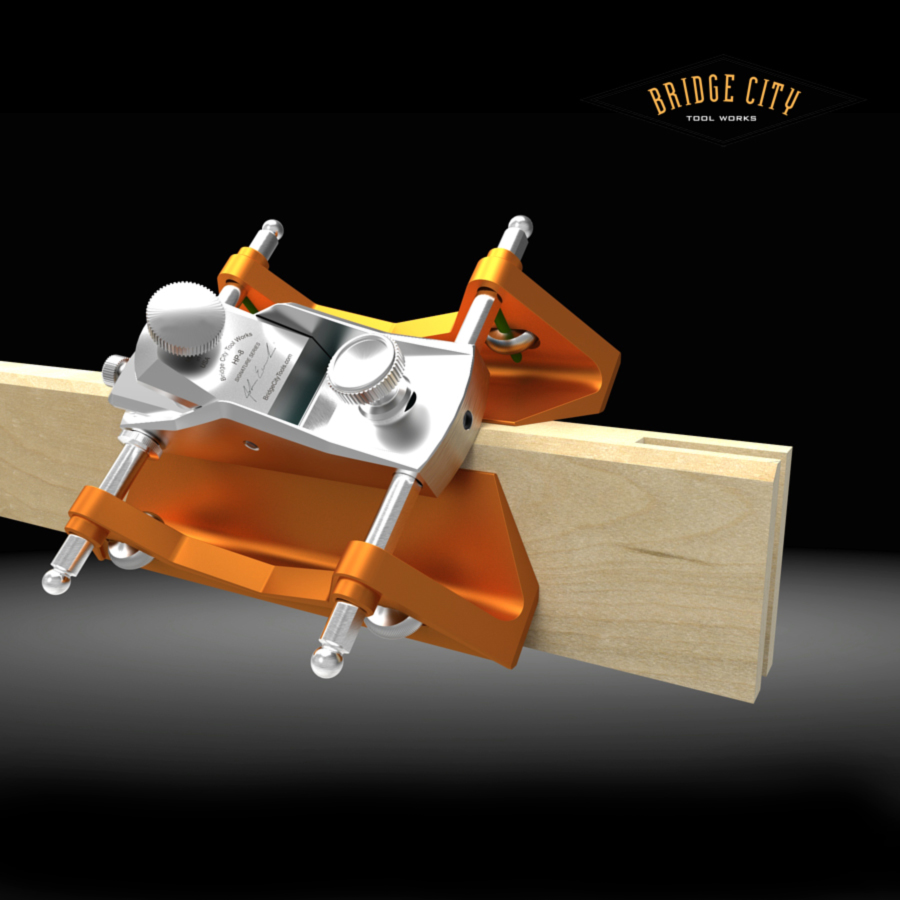

I always enjoyed a stand alone chamfer plane. Now you can adjust both miter fences simultaneously without changing the width of your chamfer (when you need to move to a sharp section of the iron). In addition, the low angle of this this plane makes it an ideal choice for flushing small protruding tenons or dovetails.

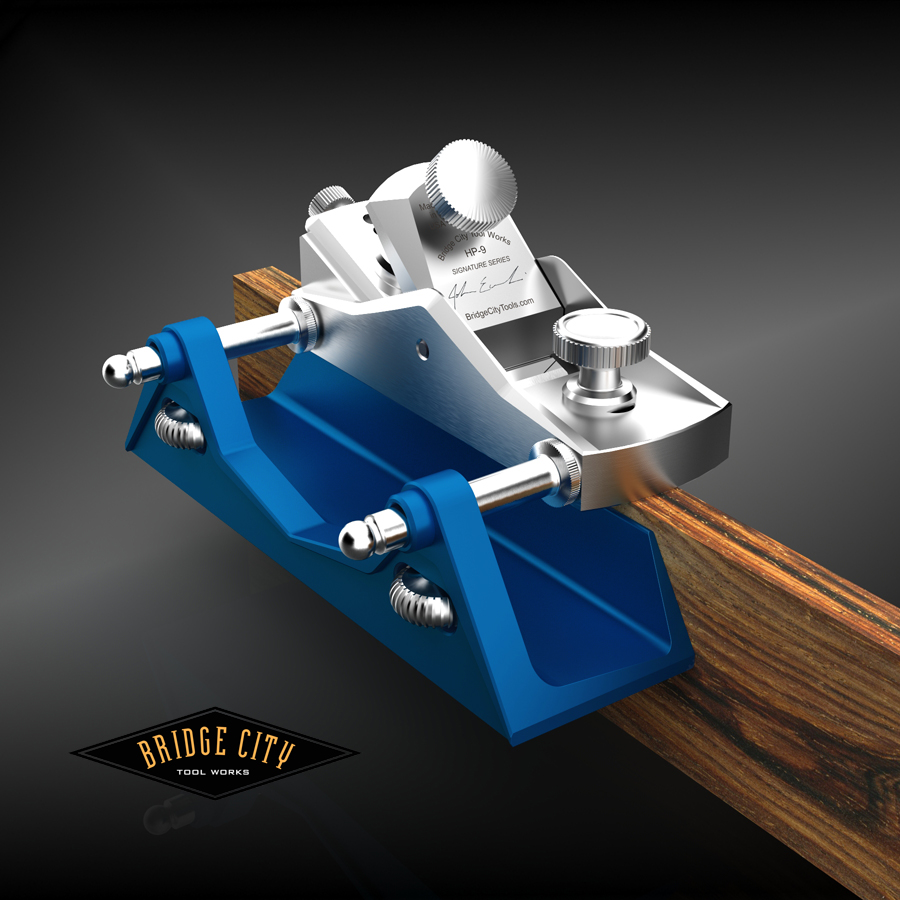

The 90 degree fence is really handy for putting a square edge along thin stock–not easy to do with a larger plane.

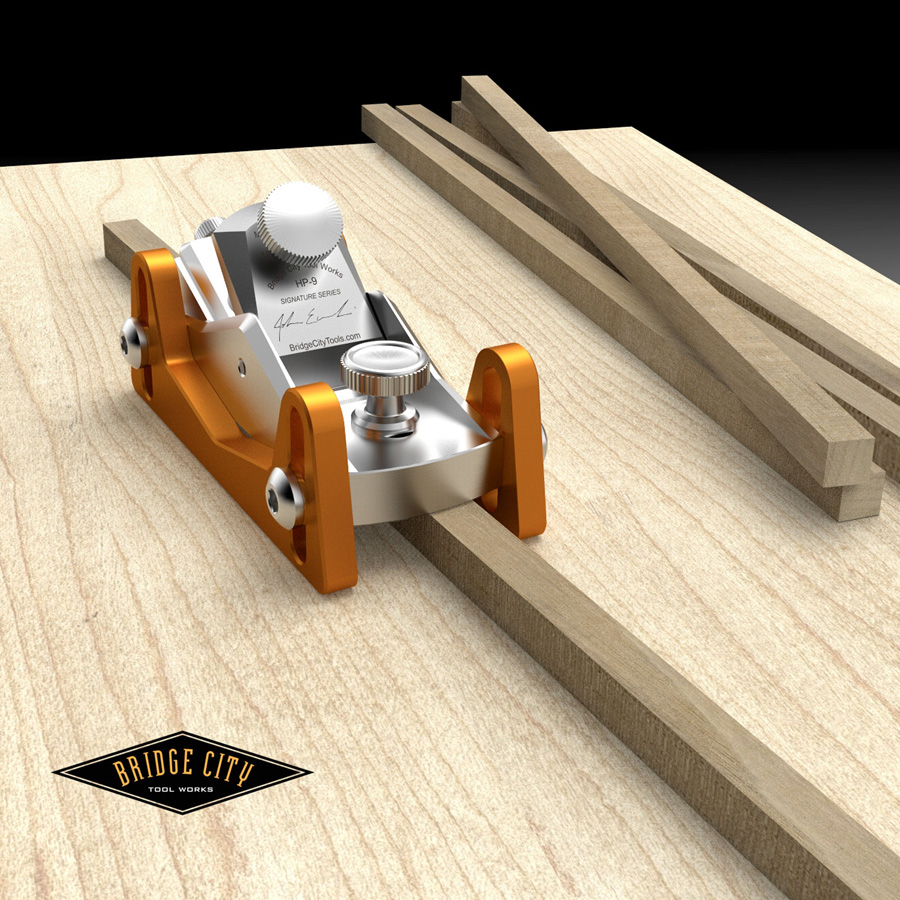

What is new is the ability to attach depth skids. Now you can use either of these planes as thickness planes for small cross-sectional stock. You know I have a fetish for coffee stirrers…(you will eventually see what I am doing with them). I have an inexpensive set of gage pins I use to set the skid heights. For example, I can put a .050″ pin under the front of the plane, and a .051″ under the rear and lock the skids against a flat surface.

Don’t know when, and don’t know how much. But I do know we are going to build them.

Remember-you saw it here first.

–John

Bravo John,

I absolutely love my HP-4 chamfer plane; reminds me of a catamaran! These two are awesome and I can’t wait to have them in my arsenal.

-Rutager

Too cool! As Gillian said when she saw them, “They’re like little racing cars. I like the blue one!”

Is the plan that you’d be able to get the chamfer and right-angle (and elevation) shoes for each of them (low and regular angle)?

Why do you need both of the (blue) right-angle shoes?

– Peter

P.S. Love the stainless!!!!

John,

Those are really great but I would really like mine before Rutager. 😮 Sign me up man, I can’t wait. Thank you for the good news on the CT-17 and I am dying to see what the CT-18 will be. Will Peter know this one as well? If not I volunteer. :o)

Fred

John, it looks like you’re intending to use an Allen wrench/screw to hold the rods in place, and that you access the grub screw through the front and rear of the sole.

What if you made the front finger rest into a grub screw that would hold the front rod in place? It would be easy to access, no need for tools, and it would look pretty. You’d have to move it forward a bit (or move the rod back). Maybe something similar at the rear? A thumb screw, perhaps?

– Peter

Peter;

Both the HP-8 (42 degree attack angle) and the HP-9 (50 degree attack angle) feature blind, adjustable mouths which are locked by the front tote.

Only the HP-8 has the pass through front post which is secured by a hollow lock socket screw (substantially different than a grub screw but similar function). To relocate a known chamfer width to a sharp area of the iron, the hollow lock screw needs to be loosened as well as the rear two thumb wheels–now both fences will move in unison (they are locked to the front post by thumb wheels). I find it really annoying to have to reset my chamfer every time I need a sharp iron so I can’t wait to use this plane.

The reason this feature is exclusive to the HP-8 is that many chamfers are done on end grain, and a 50 degree attack angle on end grain is generally not ideal and in some woods, down right ugly. Hence, the HP-8 to the rescue!

Lastly, there are no lock screws in the rear of the planes–there is no room unless we eliminate the blade depth adjustor.

–John

Ah – I see the problem with having the front tote lock the through-rod. Bummer.

How come you went with the thumbscrew front knob rather than the cool clip that you have on the CT-17? It might look nice with the new, linear side profiles.

There was a suggestion on tF that you put an angled chamfer (is that redundant?) on the tail of the plane to take an angled knob that would hold the rear rod. It might just fit in under the blade adjustment knob.

Very cool design. I’m looking forward to holding one. Or two.

By the way, shouldn’t you have put “Coming Later this Year” more like: Coming Later “this Year”? 🙂

– Peter

How come you went with the thumbscrew front knob rather than the cool clip that you have on the CT-17? It might look nice with the new, linear side profiles.

The scale of the cam lock tote does not port to this size of a plane–actually looks awful in my opinion.

There was a suggestion on tF that you put an angled chamfer (is that redundant?) on the tail of the plane to take an angled knob that would hold the rear rod. It might just fit in under the blade adjustment knob.

There is zero room in the back of the HP-8 (there is almost not enough room for the pin nut that advances the blade)… a 12 degree bed does not leave much room in the rear for a plane of this length and only slightly more in the HP-9–the OAL is approx. 3.6″ for both.

–John

Oh well – it was worth asking. It would be fun to know some of the other things you considered, but rejected, as you designed these tools.

– Peter

I rejected rosewood fence cheeks forever! They are too oily and although they look cool, they leave marks on light colored woods. I rejected the old side profile in favor of the less sinuous side introduced with the CT-17. Also rejected the open nose throat for a blind throat plate. I rejected the old blade clamp pad for a magnetic clamp pad…no more dropping these.

The new extruded fences will eventually be standard on the HP-6v2 as well as the magnetic clamp pads. FYI, on the redesign of these little planes I have about 150 hours invested yielding about 20 revisions. This may sound incredibly selfish, but I have an immediate need for a plane with thickness skids. Moving forward, I don’t think we will ever make a plane without the ability to add depth skids…this feature allows for the ability to make modular components and this really interests me at the moment. And I suggest this will also be of interest to some of the DSN when I unveil the project.

That is about all for now.

-John

Thanks John. Those make a lot of sense, though some are just aesthetics. I kind of like the curvier side profiles…

Maybe it’s because I don’t have one, but I’m not sure what the “magnetic clamp pads” are…

As I was looking at the fences and thickness skids, I was wondering how difficult it would be to make a pair of fences that had hinged flanges. Then you could set them to any angle (45-90, or perhaps even 180), and lock them in. That would allow you to do your chamfers and jointing (and perhaps skid-thickness planing) with one set of fences. You could set the angle by setting the hinged pieces flush with the wood to be planed, and then angling the plane to the appropriate angle, and lock down the hinge.

But perhaps you couldn’t lock the hinge strongly enough to ensure that the flanges didn’t move?

Let me know if this doesn’t make any sense…

– Peter

John,

I’m also interested in the planing skids; I’ve re-read your Blog entry on “Tolerance Stack” several times and am anxious to put it to use on a couple of ideas.

Quick question: How many of these new planes would I need to order to guarantee that I would get mine before Fred got his?

-Rutager

I’m with Rutager on the planing skids. I have a Japanese smoother just for that use. In my case, it is a shoji window I want it for; this would be amazingly useful for the kumiko.

aaarggg, my project list stalls when I read this blog… I have the material and design for an entertainment center (that won’t win microbe awards), but is all compound angles… a week after I got all that, the AMPv2 was announced and there’s no way I’m starting this without it!!

Now, I wonder if I should keep the shoji for these planes… hmmm

Oh, and I was thrilled to see that these new fences will become available for the HP6v2 plane; bravo!

Hi John,

Those little planes look fantastic and I’ve really enjoyed reading the questions and comments and your responses. Are those images renderings? I really look forward to seeing more about the HPs-8&9.

Gary

@Peter; …I’m not sure what the “magnetic clamp pads” are…

It is the pad that sits on the back of the iron that the blade lock screw presses against. When you remove the blade it will stay stuck and not fall into a heat vent.

I was wondering how difficult it would be to make a pair of fences that had hinged flanges…

I spent about 10 hours exploring such a concept and it adds much complexity. Sometimes simplicity, at the expense of less common, perhaps esoteric functionality is the ideal value proposition. There is another aspect of these fences that I haven’t bothered to share (because I was really just giving the DSN a sneak peek down the road…) is that these planes need to be able to work upside down held in a vice… imagine putting a chamfer on all 12 edges of a 1/2″ cube… only way to do it is with the plane upside down and these fences are relieved in the middle so the corner of the vise jaws can hold the plane body.

@Gary: …Are those images renderings?

Yes*. *They are hybrid images. Lot’s of fun to make but but more important, they effectively communicate our intent without spending $2-4K on professional photography.

@PaulMarcel: I was thrilled to see that these new fences will become available for the HP6v2 plane; bravo!

Me too–thanks! In the interim, you can always attach skids to most any smoother with double sided tape–it is what I have always used.

–John

Ok, I have looked at the planes, read all the questions and I still don’t get it. What do these planes do that a HP-6 can’t do? The planes looks a bit wider, but for chamfers and small pieces it seems to me this is a duplicated effort.

I like the idea of the magnetic pads, though.

Jorge;

It is a matter of scale and cut quality. For example;

Say you have a 1/2″ dia. round tenon that needs to be flushed. The HP-8 is pitched at 42 degrees and will do a much better job from both a control and cutting perspective than a 55 degree pitched HP-6.

Many chamfers are on end grain. You can chamfer with the HP-6 but again, it is pitched at 55 degrees–cutting end grain in soft woods with this plane is not going to leave an optimal (no work) surface finish.

As mentioned, we last made these 10 years ago, and they are the most requested item in my mailbox, so it is time to make them again.

Others who frequent this board own the predecessors (HP-3,4,and 5) so perhaps their view will be more believable than the words from an evil capitalist…. 🙂

All said, there is duplication in almost every flat bottomed plane, detail work and smaller scale work are simply easier with tools sized for the task. Hope this helps.

-John

PS: We will make magnetic pads available for the HP-6 when we run these.

Thanks for the explanation John, I see your points and I certainly do not want to be argumentative, I just want to define what my hp-6 and hp-6v2 can do. Wouldn’t a back bevel on the rabbet blade achieve the same as lowering the incidence angle?

As to the evil capitalist thing, no need for additional explanations. The tools I buy from you I know will work as advertised, are flawlessly made and that any trouble I have with them will be addressed, all of this costs money. I rather enjoy my woodworking than have money in my wallet and keep fighting a POS piece of equipment.

Jorge: because the HP-6 plane is a bevel down plane, it will always be pitched at 55 degrees. If you back bevel this face you will increase the attack angle, not decrease it. 55 degrees is a great pitch for moldings, and that is what this plane does best.

Make sense?

– John