________________________________________________________________________________________________

“Trust that little voice in your head that says ‘Wouldn’t it be interesting if…’ And then do it. ” — Duane Michals

________________________________________________________________________________________________

There is no progress without screw-ups, and I must be going somewhere fast because I have made too many mistakes the last two days. OK, last 30 years.

We just concluded our little caulking gun contest on this Totally Awesome, and Worthless Blog. Each of the Drivelite finalists won a whopping $50 gift certificate as a reward for their participation and creative spirit.

Here’s the oops part: if your entry was one of the finalists and your name is not Peter F., Mike B., Chris W., or Gary P., you need to send me your contact info (john@bridgecitytools.com). In my haste to rid my PC of clutter, I nuked the contest participant folder this morning. (I remember the names above because of the graft I proudly accepted by agreeing to include their entries…)

NEW TOOL DEPARTMENT:

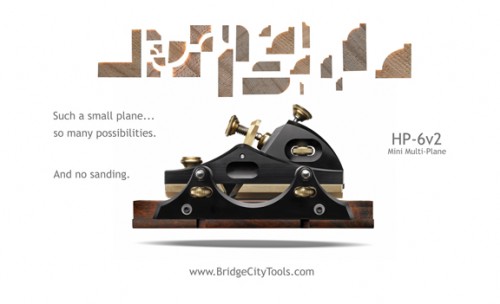

The HP-6v2 Mini Multi-Plane is about to get a major versatility injection. We are pleased to announce the addition of two new dado/groove kits; 3/8″ and 1/2″.

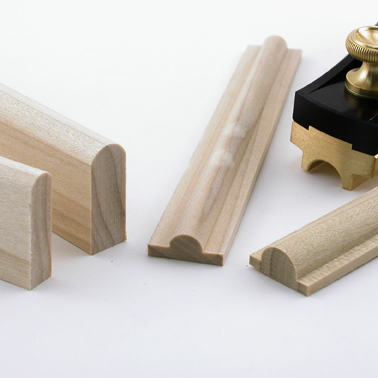

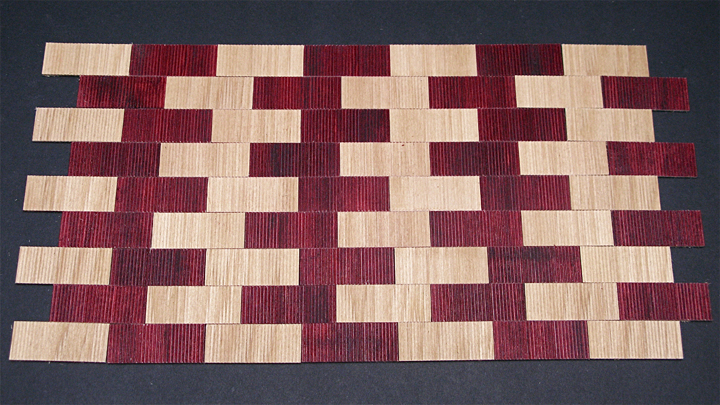

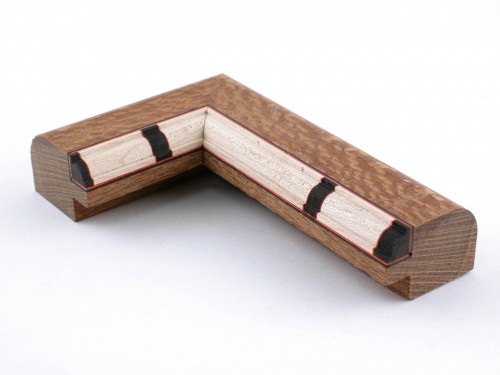

Like all of the dado/groove kits, these new sizes will also cut with the grain, across the grain, and on end grain with zero tear-out (yes, you need a sharp iron). The reason they work so well is our unique scoring cutter which does two things; scores ahead of the iron, and determines the precise width of the cut. They are reversible, depth adjustable, and easily sharpened on our “V” hone. Here is a close-up;

Both of these new sizes will cut grooves, dados and rabbets (attach wooden shims to the bottom of the sole with double stick tape to restrict depth of cut). One or both of these dado profiles will be required when we introduce the sliding dovetail profiles in 2012. OOPS! That slipped. The maximum depth of cut is equal to the width of cut for both.

NEW HP-6v2 FENCE SYSTEM…

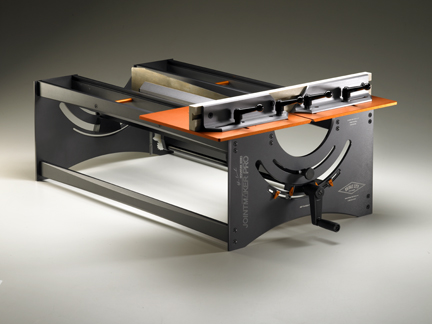

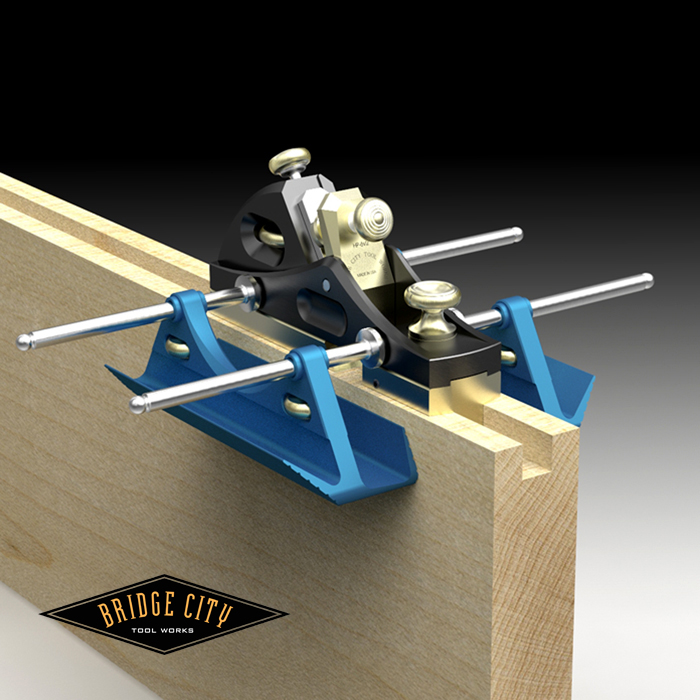

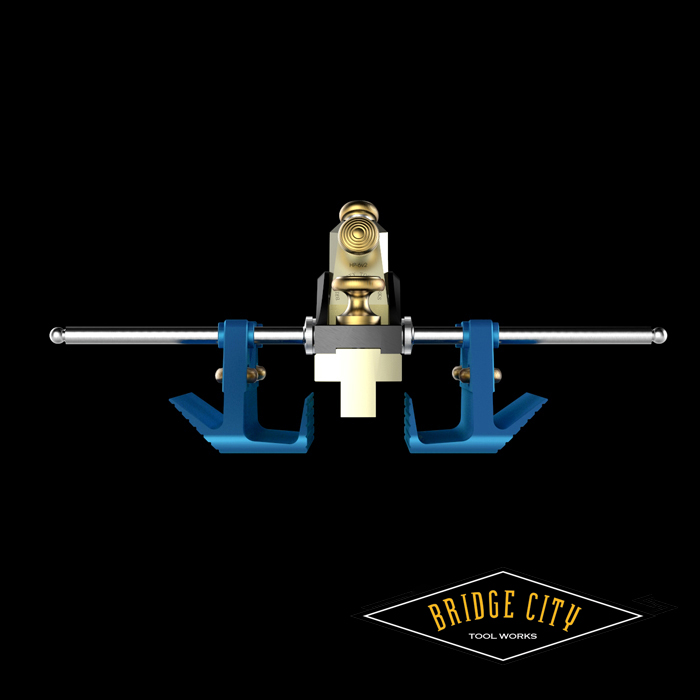

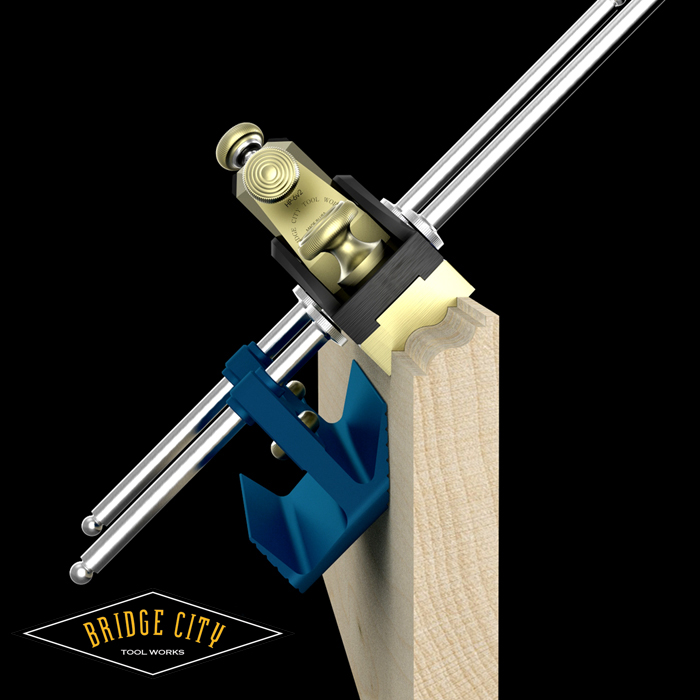

We are discontinuing the original fence system and replacing it with a new, dual purpose fence. (NOTE: If you have the original fences, you DO NOT need this fence system.) Milled from aluminum, these fences will work with all of our profiles, either with the miter guide option or as a side guide. FYI, by using two straight fences for grooves (the set-up pictured below) assures your cut will be parallel to the sides.

Also visible in the image above (and below) are the new accessory long posts. They work great when added capacity is needed. (If you haven’t visited our HP-6 Forum lately, check out Rutager West’s latest HP-6v2 project)

Lastly, your Tool Potentate is far from perfect. We are now going to discontinue the original clamp pad with a magnetized version. I don’t know how many times I have dropped that part…

If you don’t have an HP-6v2, we are doing our annual manufacturing run this fall and we are now accepting pre-orders. Delivery will be late December/early January.

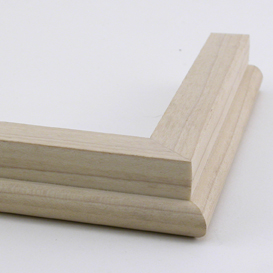

3/8″ and 1/2″ grooves are two of the most common cuts in the woodworking community. From drawers to cases to whatever, you can now make flawless cuts while listening to Rocky II (Rachmaninoff’s Symphony no. 2).

It doesn’t get any better than that.

–John

PS: The email announcing pricing and availability should be in your inbox before weeks end.