Some of what you are about to read is true.

For the past 25 years I have had numerous encounters with Bridge City Tool antagonists. My therapist says that by talking about it, I will begin the healing process.

But I don’t have a therapist, I just made that second sentence up–it is fake and a lame attempt for sympathy. I created a mental image of a therapist in my mind and while walking to my favorite Bento lunch spot we had a compelling and somewhat heated discussion which led to the creation of this blog entry–I had no choice.

OK, that is not true either. I did see an episode or two of the Soprano’s … all I know is I now feel great.

And I hope you will feel better too.

wood·work·ing /ˈwʊdˌwɜr kɪŋ/ Pronunciation Key – Show Spelled Pronunciation[woo

kɪŋ/ Pronunciation Key – Show Spelled Pronunciation[woo d-wur-king] Tal·i·ban [tal-uh-ban]

d-wur-king] Tal·i·ban [tal-uh-ban]

-noun

1. A small, loosely organized, and wildly dispersed group of individuals (including homo erectus and descendants of the Huns) who (by virtue of a personality flaw) collectively preach, primarily via internet forums, a singular and myopic vision of woodworking exactly as it occurred between the years of 1659 BC to 84AD, which of course is the end of Ancient Times. (Modern Times begin with the death of the first horse [her name was Apricot] which correspondingly began a 1500 year reign of hide glue.)

2. Individuals with basic woodworking skills and internet access who make, wear, and swear by banana leaf shoes.

3. Any woodworker who supports the “free wood” movement by removing every other ceiling joist from one’s home (or hut) and uses the material for a hemp trellis or cooking fuel.

4. Those who vehemently debate the merits of flint over carbon steel–more than once.

Another Real Life, I-Swear-This-is-True, Encounter with the Woodworking Taliban

Most of my encounters with the WT (you guessed it!) are passed on by irate customers after their real life, I-swear-this-is-true, encounter with the WT on internet forums. What I am about to share occurred three weeks ago to John Economaki (that would be me) IN PERSON! The story begins…

I was in a very large Midwest city… I can’t remember the name but I am positive it rhymes with Chicago. Actually, it could have been Chicago but I am not a good rhymer (should I run for office?). We were in the shop of Jeff Miller (this was a TLN Hand Tool Event and Jeff is a very talented designer/craftsman who also teaches). I was excited to be there, my favorite road compatriots were there (in no particular order); Tom Lie-Nielsen, Chris Schwarz, Denib (the official Lie-Nielsen PRO ATHLETE that flattens hard-rock maple workbench tops with a hand plane FOR FUN…do the math on that one) for two straight days of high-level tool talk. DETOUR: I had so much fun at dinner I put on a Lie-Nielsen tattoo that Denib swore would rub off in the shower. It did, and what was left of my arm looked like the lead-in clip to the Six Million Dollar Man, only instead of gears, lights and pulleys beneath my skin, there was real bone, for which I am thankful.

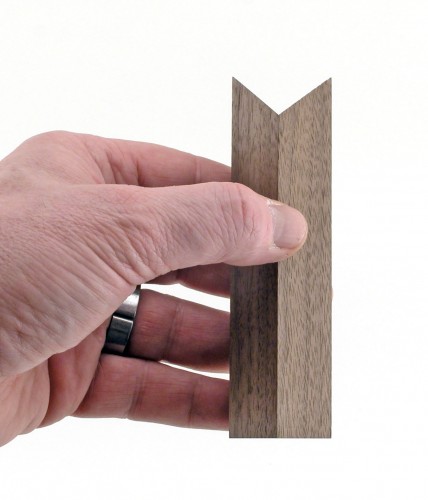

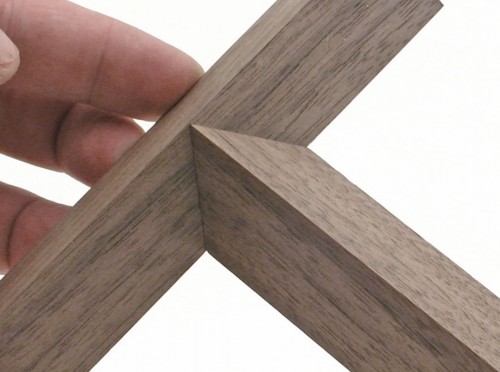

The real purpose of my trip was to introduce a new sawing machine that uses no batteries or electricity. One demonstration involves cutting hardwood dovetails with one pass of the saw in 5/8″ thick material. ( I have been working wood since 1968 and I have never seen anything like this–it is a very impressive demo.) And it is fast. And perfect, as in P-E-R-F-E-C-T. That is not me talking, others will agree. Except…

“That’s cheating!” the man screamed over the small crowd.

“How is this cheating?” I asked.

“That’s cheating!” he replied, and “It is not FAIR!”

Immediately recognizing him as a likely CHARTER MEMBER of the WT, I asked him to clarify his position. (My favorite weapon against the WT is a logic question–very similar to exposing a vampire to sunshine.)

“Those are NOT HAND CUT DOVETAILS!” Of course he was getting louder.

Pretending to be concerned that I violated an unknown sacred rule, I grabbed our Kataba handsaw from the workbench to my right, offered it to him and asked him to share how he cuts dovetails.

“I can’t cut dovetails with that saw–it has no back on it,” he confidently stated.

“Back? You need a BACKSAW to cut dovetails?

“Yes, I use a backsaw.”

“That is cheating!” I loudly proclaimed.

There were smiles around the room as he stomped off, and yes I was a jerk, but it is O.K. to be a jerk when one encounters the WT!

The WT have a set of unwritten RULES that only they understand. Never to be concerned with anything but THEIR technique, their always-unsolicited-opinions are NEVER to be questioned. I dare you to mention proportion, harmony, texture, grace or anything that has to do with the appearance of SOMETHING.

And there is something about perfect work (insert full moon analogy here) that really sets them off.

But I exaggerate.

kɪŋ

kɪŋ