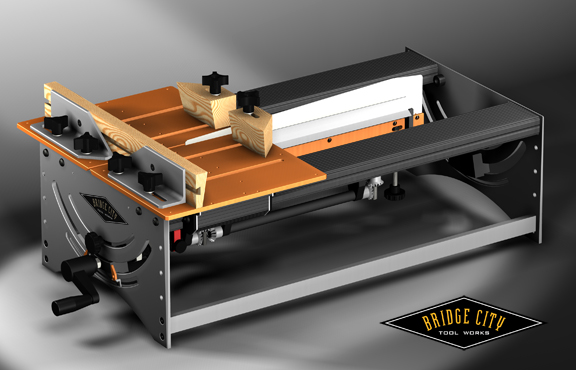

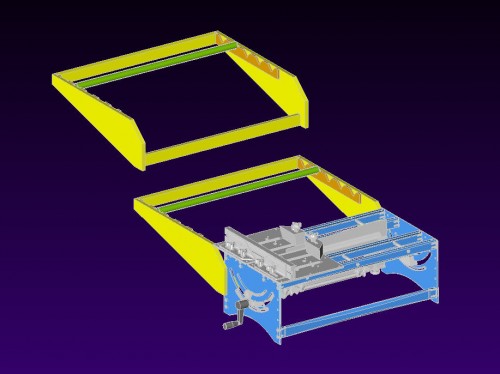

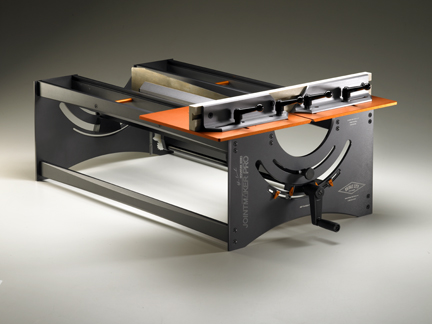

Here are a couple sneak images of our new Jointmaker Pro v2 and the brand new Jointmaker SW. Don’t tell anybody you saw them here first–I could get fired.

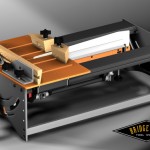

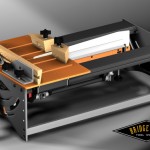

The image below is the Jointmaker Pro v2. The difference between the JMP and the v2 is in the linear table mechanism–the JMP v2 uses linear ball bearing sliders for a more efficient (less effort) user experience. In addition this version runs dry, meaning there is no lubrication required. Full info will be posted on our web catalog in the next couple of days. The retail price will remain at $1195 and the optional stand is $195.

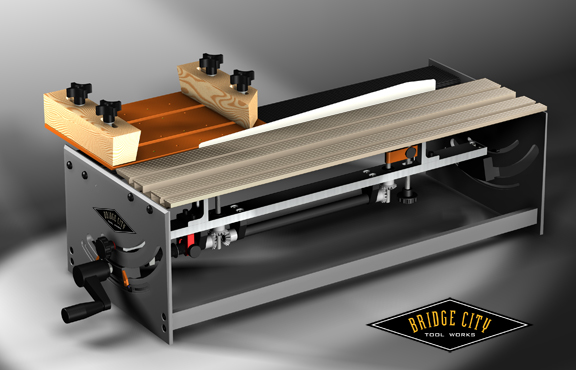

The Jointmaker SW is pictured below. This version employs one linear table and one static table. It will make all of the cuts of the JMP (some not as convenient) for much less $$$. The JM-SW will retail for $795 and the optional stand is $189.00 More details will be posted on our web store in the next couple of days and most of the Q & A regarding our entire Jointmaker line can be found on the JMP user forum.

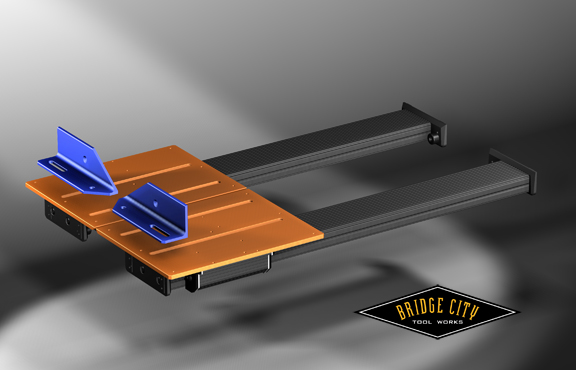

Existing owners of the JMP can upgrade to the JMP v2 by purchasing the upgrade kit below. It will be available for $395.

We are excited about the continued development of the Jointmaker line. All of the above are “Make to Order” items and will be available in March/April, 2010. Full ordering details will be available on our web store early this week.

And if I get fired for leaking these images it’s your fault.

–John

Jointmaker Pro Stationary Hand Saw

Posts, comments and questions regarding the Jointmaker Pro Stationary Hand Saw

The Jointmaker Pro v2, the NEW Jointmaker SW and More…

November, 18th, 2009

Sometime tomorrow or Friday (Nov. 20th) we will update our website to accept pre-orders for the new JMP v2 and the new Jointmaker SW. In addition, we will also be able to take orders on upgrade kits (JMP to JMP v2) for existing JMP owners. Here’s a little behind the scenes info…

The original design criteria of the JMP was to create a tool that was capable of gallery quality cuts without dust collection, and with so little noise one could listen to music. And the original JMP could do this and more. However, no product is perfect and no designer/engineer can rest until all little details are addressed…

The original JMP linear motion tables used sliding dovetails and one aspect of sliding dovetails are the incredibly tight tolerances–the parts are expensive to make and the sliders need lubrication. In addition, the sliders were ever so slightly hygroscopic which means combined with tight tolerances, the tables needed to be adjusted with humidity swings. The JMP v2 addresses these areas.

The Jointmaker Pro v2 is identical to the JMP in every way with the exception of the linear table design–the JMP v2 features a recirculating linear bearing system (the bearings follow a closed loop). They do not need adjustment (factory assembled) and they do not require lubrication. The main advantage is they are easier to use (much less friction) at the expense of a bit more noise. The bearings are acetyl which are much quieter than steel bearings–we are thrilled with the results. This version feels effortless and is easily used with one hand working the tables.

About the upgrade kits: They will cost $395 (delivered) and include new rails, adapter plates, tables, and fences. They fasten perfectly to all existing JMP’s. Installation involves removing the screws that hold the original dovetail rails in place, lift out the old rail system and replace with the new–a ten minute chore. Add another ten minutes to align the two new tables planer with each other. We will post a detailed video of this process on the JMP forum on our website.

I would like to add that NOBODY needs to upgrade–the cuts and results are identical on both versions. That said, we are only going to make this upgrade kit available once.

The JMP v2 will retail for $1295 and we are forecasting delivery in April, 2010. The inclined stand (a great accessory) will remain $195.

The JMP SW (Single Wing) is big news. Rather than utilizing two sliding tables that are bridged (for most cuts), this saw works similar to most sliding table saws–there is one sliding table and one static table.

The JMP SW blade will tilt 45 degrees in one direction, and 15 degrees in the other (for dovetail work). It will make all the cuts of the JMP and the JMP v2. The difference is in the jigging–edge miters for example, can only be cut accurately with the long face down. And there is a bit more thought for some cuts where the falloff needs to be supported. The video we are going to release should address most of these cuts. The JMP SW has the exact same cutting capacity of the JMP but occupies a smaller footprint.

We are targeting the JMP SW for $795 delivered (unassembled). The accessory stand is DIFFERENT than the JMP but will be available for $195. All will be delivered next April.

My candid impressions comparing the two versions? Thanks for asking–having lived and breathed with this device over the past three years, I really like the JMP v2 for all the obvious reasons, not the least of which it carries our “Pro” designation (less jigging hassles, better opportunities for sub-tables). However, for the casual user, the JMP SW is clearly 90% of the JMP v2 and $500 bucks less expensive. I suspect we will sell 3-4 JMP SW’s for each JMP v2. Both do gallery quality joint cuts (ZERO chisel paring or router plane work). The blades are the same.

That’s all for now–if you have questions or comments, feel free to ask them here but we would prefer you use the JMP forum for the benefit of those who don’t follow my incredibly hilarious blog.

Thanks–

–John

This is Almost Unbelievable…

April, 7th, 2009

Last summer while demonstrating the Jointmaker Pro in Japan, I visited several artists who created extraordinary mosaics from wood tiles. This got me to thinking how I would approach this art form using the Jointmaker Pro.

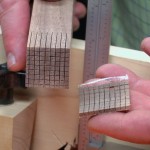

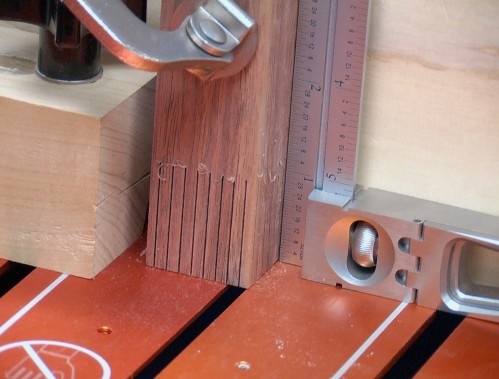

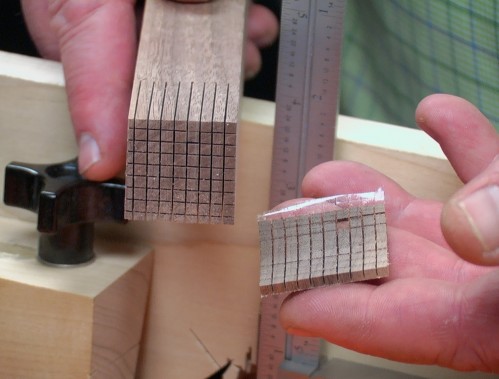

The results are incredible. Using the equivalent of a 1-1/8″ cube of maple, I made 648 smaller cubes (.0117″)–with only 24 cuts! The photo below speaks for itself…

and the quality of each cube is amazing…

The whole process is way easier than one might imagine. The set-up for each cut is illustrated below;

All of these cuts were made by eye just to test the idea. As you can see below, it would have been smart to check that my stock was square before I started, but then again, this was just a test using scrap.

Once all the vertical cuts were made, I stuck a piece of packing tape to the end so I would not end up with little pieces of wood all over the place when I made the crosscut. This worked just fine.

This is about as small as you would want to go. This created about 8 square inches of surface area.

Using readily available software (Google: mosaic software) you can do amazing things. Briefly here’s how it works;

1) You decide on a tile size (doesn’t have to be a cube, just square).

2) You need an array of colors from light to dark. You could use natural wood tones (they all change with sunlight exposure however) or you could use one light toned species that dyes well and use aniline dyes (alcohol based) available in many colors.

3) The program needs to know what colors you are using–there are ways of scanning them in or approximating the colors using a RGB chart or other methods.

4) You scan your artwork/photograph into the program and tell it how big you want your piece.

5) The program creates a tile by number (each color is assigned a number) plan for you.

You need to have the desire and inclination to undertake such a project but none of what you need to do is hard.

I like this idea because it is a project that could involve the entire family–from kids to grandparents. Using the sizes in my example above, ONE BOARD FOOT of material would be enough material to make a mosaic 25″ x 32″–now that is almost unbelievable.

It’s a pretty slick idea and one I hope somebody embraces.

–John

The Prices of Progress

March, 17th, 2009

And now for today’s lead-in quote;

“Karate is a form of martial arts in which people who have had years and years of training can, using only their hands and feet, make some of the worst movies in the history of the world.” –Dave Barry

OK, I am not going anywhere with that, but it brightened my day–yours too I hope.

Amid all the controversy that surrounds the Jointmaker Pro, the opinion most befuddling to me is the one proffered by “purists” who claim that cuts made with the JMP are “cheating”–whatever that means.

Today I was reminded (thanks to one of our forum members) of a different day in a different discipline not that long ago…

Do you remember the first hand held calculators–the ones introduced in the early 1970’s that only did arithmetic functions? They sold for $395 (that’s a whopping $2087.59 in today’s dollars!) Here’s a tool that purists vigorously defended just a couple of presidents ago;

Remember these?

Ironically, this site is rather fun. It works on screen, instructions are included. Imagine using one of these in a 400 level physics class with the bull horns of war protesters outside…

“WHAT DO WE WANT?”

“PEACE!!!”

“WHEN DO WE WANT IT?”

“NOW!!!”

A bit oxymoronic don’t you think? Now, don’t the bullhorns echoing around the internet regarding “how” a cut is made in wood seem rather silly?

Oh, and imagine how abacus owners must feel.

–John

PS: The Jointmaker Pro would have retailed in 1970 for $226.00. If you want to have fun with price comparisons, click here.

JMP Feedback and 1 Idea;

March, 11th, 2009

We are about half-way done shipping the Jointmaker Pro’s as of this writing and the feedback (so far) has been positive. You never know with something so new and controversial–today is a good day.

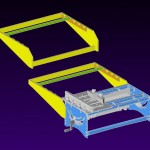

One of the changes we made to the production version of Jointmaker Pro is the ability to add user designed jigs and fixtures. Below is a quick concept of a dead man to keep from loading the linear tables when cutting longer stock. This idea would fasten directly to the front and rear plates and offers minimal resistance to stock traversing.

I would likely make this from 1/2″ baltic birch ply and design around any stiff round stock (pvc, conduit, dowel, closet rod, aluminum tube, etc). Perhaps include another brace with a lip on the down legs of the wings for blade storage. This is a seed idea for our customers–more ideas and feedback can be found on the Jointmaker Pro forum on our website.

Now here is some good news for us, we have 7 JMP’s left. (Actually we have 17, but 10 are reserved for my Silent Woodworking class at Marc Adams School of Woodworking in May). We anticipate beginning the wait-list for round two in about two weeks or less.

Monday we begin the video shoot on my secret new controversial tool that will challenge how you think about another aspect of woodworking. Silence is golden! (Stolen from that 60’s song by The Tremolos or Tremeloes…which in turn was originally recorded by the Four Seasons I believe.) Damn I am getting old.

Stay positive, engaged and enthused!

–John

Jointmaker Pro Updates, Misc. News

February, 6th, 2009

Each year I leave Portland’s rainy winter for a solo, two week work retreat. Despite what you may be thinking, the emphasis is on work. This year I parked my rear in St. George, Utah.

The sequence of each day is as follows; shower, coffee shop/New York Times, banana, CAD work, lose track of time, (including when to eat) and around 10-12 hours later I heat up a bowl of soup and watch (when it is on) “How It’s Made” on the boob tube and then retire. I repeated this routine 14 straight days on this trip. With the exception of the banter at the coffee shop, I am isolated from people and all of their annoying habits.

Or maybe it is the other way around…

I have a list of objectives that I barely dent–which is always disappointing to me. I routinely overestimate my capabilities and although this is difficult for me to admit, I also have a life-long habit of underestimating–the delivery dates for the Jointmaker Pro are a fine example. I think I am caught in some kind of weird dimension trapped between under and overestimating because in this strange world things are done before they start yet they are never finished.

Good thing I have dogs–they appear to understand me. However, they are English Setters…

Good news regarding the Jointmaker Pro, the saw blades will arrive towards the end of this month and that is all we are waiting on! What a great journey this project has become and I can’t wait to see it unfold in other ways.

Years ago, I used to be a studio furniture designer/maker and from this experience I have frequently used the term, “gallery quality work” when describing the capabilities of the Jointmaker Pro. But what does this really mean?

There are four basic elements to working wood (which is different than woodworking), dimensioning stock, sawing, drilling, and shaping. All of the other ancillary process of shaping wood fall into these base categories–including joinery. Gallery quality work implies that as you progress through any of these four basic zones, your efforts are as intended and yield predictable results. Cuts are clean, holes are true, faces are parallel (if that is your intent) and you have no need for putty, filler, or other back peddling activities that hammer at your productivity or the quality of your efforts.

Of course, this is easier said than done, but I am committed to finding ways to pursue this philosophy without the need for an ear-busting, headache-inducing dust collection system. The Jointmaker Pro was the first leg on my quest.

In a few weeks we will unleash the second leg of this quest with another revolutionary idea that will equally broaden your understanding of what it means to to do gallery quality work without power… actually you will need some source of power to play music.

Stay tuned (pun intended).

-John

PS: I will be demonstrating a PRODUCTION VERSION of the Jointmaker Pro on Feb 13th and 14th at the Crucible in Oakland, CA. It is free (sponsored by the fine folks at Lie-Nielson Toolworks) and just maybe, I may have a surprise with me…

Jointmaker Pro Update

January, 27th, 2009

Two weeks ago we received all of the components for the Jointmaker Pro–holy cow, I have never seen a BCTW project with so many parts! Prior to anodizing the aluminum parts, we assembled one unit and the results are…

Spectacular—in every sense! For those that have seen the prototype in action, the production version features over 80 changes and all I can say is I thought the prototypes were cool, but now, like everyone else waiting for delivery, I CAN’T WAIT to get mine!

Parts come back from the anodizer this week and they are off to the laser house next week. Packaging for both versions (unassembled and assembled) are finalized, and we have decided to forgo a written assembly manual for a DVD or web-based assembly tutorial which we will finish next week. Lastly, the saw blades should arrive from Japan any day now (it took 4 months to make all of these blades).

We also decided to do a little bit of sub-assembly work for the unassembled versions for those who have limited assembly experience. Now, all one needs is to be able to do is insert and tighten screws.

While the components were being manufactured I took the JMP on the road to a couple of the Lie-Nielson Hand Tool Events (if you can go to one of these, they are intimate, fun and educational). One thing became apparent to me after demonstrating this tool for eight hours straight—my back ached.

As a result, we redesigned the stand so the back of the Jointmaker Pro is now 3” higher than the front. This accomplishes two important things, it shortens the sawing stroke and it makes it easier to see your cuts. It is one of those counter-intuitive decisions that really makes using the tool fun. I demonstrated this change to show attendees and everyone agrees this is an awesome improvement. Whether you use our stand, or make your own, we recommend inclining the Jointmaker Pro without hesitation.

As those patiently waiting know, we have taken our time to make sure the user experience is going to be as flawless as possible. We can’t wait to learn how our owners use this transformative tool—it truly changes your perspective on project ideas.

Lastly, I am on the second week of my annual two-week work retreat. I would have posted this update last week but I am in Utah and forgot the password into my blog…

This whole password thing is really getting to be an issue for my aging brain.

–John

Next Week We’ll be in Berea, KY: Woodworking in America

November, 6th, 2008

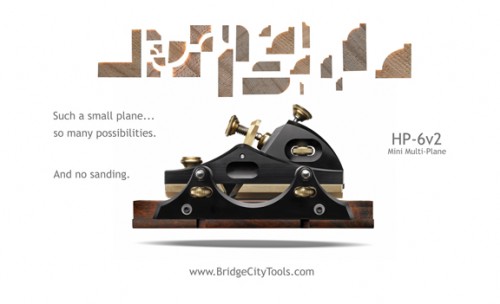

In preparation for the upcoming Woodworking in America conference, I decided to make a display featuring all of the cuts possible with our HP-6v2 Mini-Multi plane. This turned out to be quite fun and, enlightening.

Every week my fondness for working without noise grows–this little display project was done in our front office on the workbench in our modest showroom. I was so happy with my mess I deemed it noteworthy. See pic below.

While making the different cuts (about 60 two foot strips) it became apparent to me that these samples are a great way to play. I was goofing off, combining different moldings together and I felt like a kid playing with Lego pieces. It was really interesting and a great way to discover new, distinctive forms. When Michael and I get back from WIA, we are going to produce a video on this very activity.

Now for something completely different:

The Jointmaker Pro was recently named one of the best new products of 2008 by Popular Woodworking.

Everybody is working their tail off on the initial run and we will hopefully ship before the holidays.This is a big job! We have about 20 units remaining in this run and then we will begin a wait list for run #2. We hope to sell the remaining units at the Woodworking in America Conference–we’ll see…

Commemorative Tool #15, will begin shipping within the next two weeks! Tomorrow I will have a first article for final inspection! This is exciting.

The NEW and IMPROVED CenterScribe will ship in the next week or so as well!

The original CenterScribe was one of the top 5 tools we ever produced. This one is much better! Holds a pencil in addition to the scribe, finds centers on dowel ends, rectangular or square stock and has ZERO backlash, and will cost less!

That’s all for now.

Oh wait! Did I mention that I am working on Commemorative Tool #16?

–John

Nobody Has Ever Seen Wood Like This…

September, 16th, 2008

Last week I shared our latest Jointmaker Pro discovery; Squiggle Wood. Check out one afternoon’s experiments–wood is just not supposed to act this way. By the way, this is European beech. Oak and ash work too.

It’s hard to imagine woodworking being more fun…let me know your thoughts!

–John

YouTube Link: http://www.youtube.com/watch?v=eq8O3uUilM8&fmt=18

YouTube Link: http://www.youtube.com/watch?v=eq8O3uUilM8&fmt=18

Atlanta and Japan JMP Summary…

September, 2nd, 2008

I could only work half the day today as I have a major case of jet lag… To give you an idea how tired I am, I came home too tired to sleep and almost watched C-Span. Still can’t believe there is a C-Span II.

The attendance in Atlanta was spotty, I am not sure about the value of big trade shows anymore…my local connection of friends suggested it was a poor show for sales.

I left Atlanta encouraged regarding the JMP. There was very strong interest from power challenged countries and we are going to ship units to India, Bahrain, Guatemala and one other country I can’t remember at the moment. These are all for programs to put people to work in the tourist industries so I am excited to see where this leads. Also sending a couple of units to Britain. So in many ways the word is getting out. Everybody liked the internet videos that Michael produced in our office and we plan to do another one this week.

I did get a chance to talk at length with yet another internet woodworking expert who has changed his views regarding the JMP after seeing it work. Amazing what first hand knowledge will do for opinions.

Japan was simply exhausting. I couldn’t sleep, the toilets scared me (and I played ice hockey for 20 years…I would rather get hit in the face with a puck (again) than sit around and find out what those toilets do.) The language barrier was no big deal, cutting wood is easily understood, and many of the visitors spoke English. The JMP is an ideal tool for shoji screen work and I want to make a video demonstrating this capability. The people were very warm, excited and enthusiastic and just like in the States, nobody could believe the quality of the cuts. We have several customers in Tokyo and couple of them stopped by to say hello which was great.

As expected, the food was fantastic.

Tomorrow I will let the cat out of the bag and introduce Commemorative Tool 15–stay tuned.

–John