Last summer while demonstrating the Jointmaker Pro in Japan, I visited several artists who created extraordinary mosaics from wood tiles. This got me to thinking how I would approach this art form using the Jointmaker Pro.

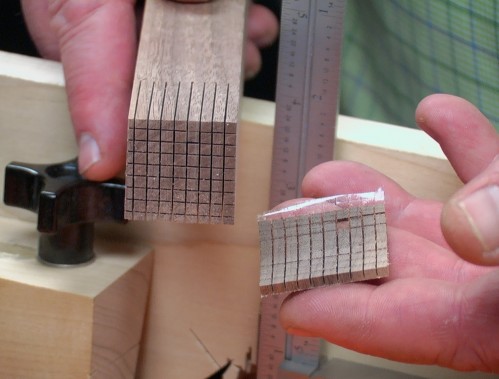

The results are incredible. Using the equivalent of a 1-1/8″ cube of maple, I made 648 smaller cubes (.0117″)–with only 24 cuts! The photo below speaks for itself…

and the quality of each cube is amazing…

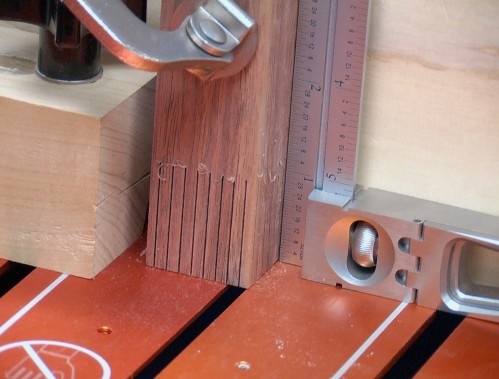

The whole process is way easier than one might imagine. The set-up for each cut is illustrated below;

All of these cuts were made by eye just to test the idea. As you can see below, it would have been smart to check that my stock was square before I started, but then again, this was just a test using scrap.

Once all the vertical cuts were made, I stuck a piece of packing tape to the end so I would not end up with little pieces of wood all over the place when I made the crosscut. This worked just fine.

This is about as small as you would want to go. This created about 8 square inches of surface area.

Using readily available software (Google: mosaic software) you can do amazing things. Briefly here’s how it works;

1) You decide on a tile size (doesn’t have to be a cube, just square).

2) You need an array of colors from light to dark. You could use natural wood tones (they all change with sunlight exposure however) or you could use one light toned species that dyes well and use aniline dyes (alcohol based) available in many colors.

3) The program needs to know what colors you are using–there are ways of scanning them in or approximating the colors using a RGB chart or other methods.

4) You scan your artwork/photograph into the program and tell it how big you want your piece.

5) The program creates a tile by number (each color is assigned a number) plan for you.

You need to have the desire and inclination to undertake such a project but none of what you need to do is hard.

I like this idea because it is a project that could involve the entire family–from kids to grandparents. Using the sizes in my example above, ONE BOARD FOOT of material would be enough material to make a mosaic 25″ x 32″–now that is almost unbelievable.

It’s a pretty slick idea and one I hope somebody embraces.

–John

Hand Cuts

Insomnia has its rewards…

May, 5th, 2008

I don’t know why, but I wake up in the middle of the night so frequently I wonder why I go to bed in the first place. Last August, while you were likely asleep, I was wide awake fretting how woodworkers tend to put their fingers at risk when sawing small stock. Then an idea came upon me…

With patents pending, we will soon introduce a completely new way to crosscut wood and make joinery entirely by hand. And although this saw really shines with small stock, it will cut hardwood or softwood up to 6″ in width and 1-5/8″ thick, which is the vast majority of crosscuts for most. It is quiet, accurate, and the cut is so smooth no further work is necessary for cleanup. It is rather remarkable because accuracy like this has never been possible without power. There is also no need for hearing protection, dust collection and it is very safe.

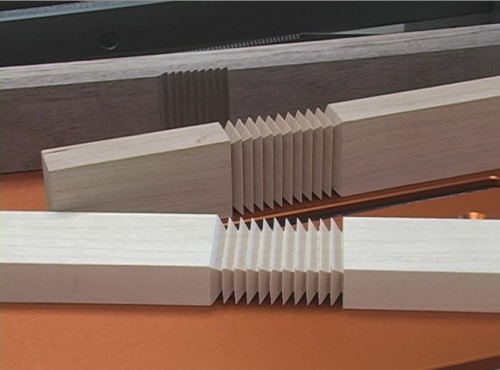

Many woodworkers view new ideas with a bias towards their own skills and techniques and are slow to embrace change–woodworking is the most anachronistic hobby in America. So, over the past four months I have given demonstrations to several different groups of woodworkers to determine interest in this new way of cutting wood. We also demonstrated the saw in Cologne, Germany in March. I will write more later, but until then, check out the two images below – all of these cuts were hand sawn! We think you will agree, these images are strong indicators of a tool that rivals, and exceeds in many cases, the capability of power-hungry alternatives.

-John

These two boards were cut entirely by hand with a new handsaw from Bridge City. The cuts are smooth, accurate and depth is consistent within .002″ on every cut. Each board took about 10 minutes and is comprised of 88 individual cuts.

In an effort to fully understand the capabilities of our new saw, we quickly cut angled cuts into two pieces of wood and nested them. This is amazing when one considers no power was used. Each piece was cut in approximately 5 minutes and consists of 42 individual hand cuts.