Final prep is being done to the CAD files now.

Delivery is estimated for November.

9-15-11 – We have our final quantities now, so production will commence next week!

11-17-11 – Well sorry it has been a while since I’ve updated this one. The bodies are being made now. Programming took longer than anticipated. At this point, I am hoping to get these out by the end of the year. Sorry for the last minute change in schedule. Still trying to get this worked in to our methods here.

12/1/11 – I took one for the team and spent my entire Thanksgiving weekend combing through Extrusion videos. I’m sure you have all seen this one, but I believe it illustrates the process of extrusion rather well.

Parts are being machined as fast as possible! Aluminum for the fences is being extruded.

12/8/11 – Stainless steel little buggers…how slow you are to go. Uh oh, did someone request a CT-18 prototype to be made at the same time? I did not say that.

12/15/11 – The bodies and throat plates are just about complete. We then mate them together and grind them at the same time to create the flat sole we all strive for.

12/22/11 – Fence extrusions deliver next week. Aluminum machines a gazillion times faster and more easily than 303 stainless. Next week, the machines slow down a bit. I will get a more accurate timeline next year when all is full speed again.

1/5/12 – Packaging is being finalized for all of these parts. Dies are being made for the foam cut outs.

1/12/12 – I got word late this afternoon that our long lived radial knurl may be wearing out a bit. This affects the knobs on the fences. I will find out more tomorrow and see if I can get a new knurl made quickly. These are custom made to order.

Foam packaging has been designed and the die is being made. (these are quick to make). The packaging will contain spots for all of the parts but also will have one big empty spot so that you can stow the plane with the fences attached. There won’t be a need to disassemble to put it back in the box.

1/26/12 – Apparently, machine shops are busy these days. Since we don’t have the pull or might of Apple (who actually has a similar business model to BCTW of being a design and marketing house without any in house manufacturing..) things seem to go slowly. Check out this article in the New York Times about the current state of manufacturing in the US: article . Things are happening at our shops, just not as fast as I’d like. Once one finds good shops it is easy to load them with work, which seems to delay all of them.

It looks like the current estimates of shipping these things out will be in mid-February.

2/2/12 – As a follow-up to the above post; I submitted drawings (for a yet to be released tool..) to a vendor this week and they replied back that they just could not bother even quoting it. They were just too busy to even consider taking on new work right now. Amazing stuff. Don’t worry, I have the drawings submitted with 4 other shops right now. Back to HP-8. Picked up some knobs this week, and other odds and ends. Looking good. Still a couple of weeks out though.

2/23/12 – Lots of boxes of parts on hand, grinding operations on the plane soles will be starting next week. The bodies ended up being incredibly tedious and time consuming. Yikes. I have a sample of the whole lead screw assembly and it works amazingly well. I’d tease you with a picture, but at this point it may just be mean to do that!

3/1/12 – Final bead blasting to the bodies is happening on both the brass and stainless. Fence extrusions go in to final anodizing next week. It looks like things are back in motion after finally getting through the bodies. Things should be good to go in 3 weeks.

3/8/12 – Everything is looking great here. The end of the month things will get out the door.

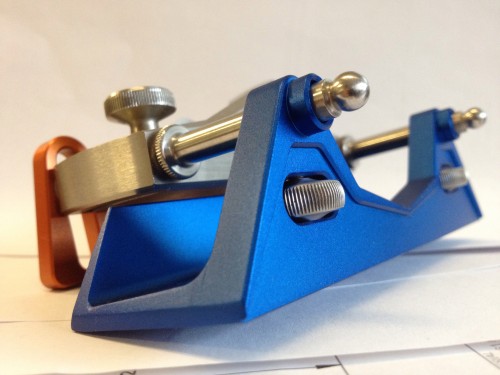

3/15/12 – These little things are sweet. Check out this finish on this.

Can’t wait to see the anodized fences!

3/22/12 – A bit of bead blasting is happening on the fences prior to anodizing. All parts are in hand now. We’ll do some final finish work on the bodies and and assemble it all up. Laser etching the caps takes place next week.

3/29/12 – Laser etching is done, assembly and finish work is moving along. I would say we start shipping these the week of the 16th. The 72 threads per inch adjustment knob is sweet!

4/4/12- Some fences are in. Graining and assembly is full steam ahead now.

4/12/12 – These should be starting to ship out on the 24th. Man those 8 knobs for those fence kits took a while to put together!

4/19/12 – Packaging is complete for most. Auto Orders will be starting to process tomorrow. Product starts shipping out Monday and Tuesday.

4/26/12 – Shipping is underway, more to go next week.

5/3/12 – Wait list people are being contacted now.

I couldn’t get John to leak any CT-18 information. Hey, I could tell you a lot about the CT-17.5; trade?

Do we think the CT-18 is going to be stainless steel?

Cool aluminum extrusion video, John. I’ve always wondered how they did that. I’m still not clear on how you get hollow extrusions. Is it like hollow pasta, where the edges join after passing through the die?

Why extruded aluminum for the fence, and not milled?

I just got word that the CT-18 may be made from Unobtainium. I need to find a good source for it now.

Yes, like pasta, the aluminum forms at a seam for hollow cut-outs.

Milling the fences from solid would require a lot of time. Granted the extrusion die costs money, but nowadays extrusions become cost competitive pretty quickly. By starting with an extrusion, we are able to cut down on machine time which is costly.

Interesting. Thanks Michael. Best of luck finding an Unobtainium source. I bet that John has a mine on his island…