Last summer while demonstrating the Jointmaker Pro in Japan, I visited several artists who created extraordinary mosaics from wood tiles. This got me to thinking how I would approach this art form using the Jointmaker Pro.

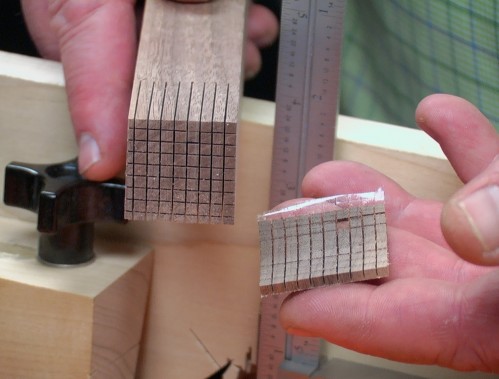

The results are incredible. Using the equivalent of a 1-1/8″ cube of maple, I made 648 smaller cubes (.0117″)–with only 24 cuts! The photo below speaks for itself…

and the quality of each cube is amazing…

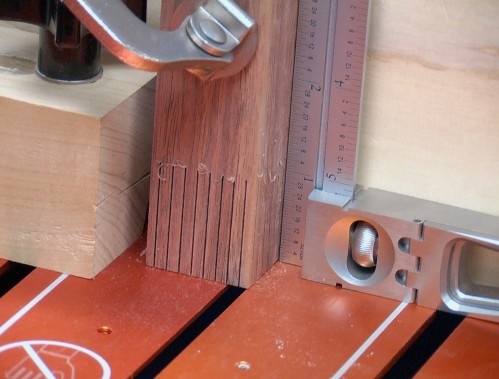

The whole process is way easier than one might imagine. The set-up for each cut is illustrated below;

All of these cuts were made by eye just to test the idea. As you can see below, it would have been smart to check that my stock was square before I started, but then again, this was just a test using scrap.

Once all the vertical cuts were made, I stuck a piece of packing tape to the end so I would not end up with little pieces of wood all over the place when I made the crosscut. This worked just fine.

This is about as small as you would want to go. This created about 8 square inches of surface area.

Using readily available software (Google: mosaic software) you can do amazing things. Briefly here’s how it works;

1) You decide on a tile size (doesn’t have to be a cube, just square).

2) You need an array of colors from light to dark. You could use natural wood tones (they all change with sunlight exposure however) or you could use one light toned species that dyes well and use aniline dyes (alcohol based) available in many colors.

3) The program needs to know what colors you are using–there are ways of scanning them in or approximating the colors using a RGB chart or other methods.

4) You scan your artwork/photograph into the program and tell it how big you want your piece.

5) The program creates a tile by number (each color is assigned a number) plan for you.

You need to have the desire and inclination to undertake such a project but none of what you need to do is hard.

I like this idea because it is a project that could involve the entire family–from kids to grandparents. Using the sizes in my example above, ONE BOARD FOOT of material would be enough material to make a mosaic 25″ x 32″–now that is almost unbelievable.

It’s a pretty slick idea and one I hope somebody embraces.

–John

JMP

JMP Feedback and 1 Idea;

March, 11th, 2009

We are about half-way done shipping the Jointmaker Pro’s as of this writing and the feedback (so far) has been positive. You never know with something so new and controversial–today is a good day.

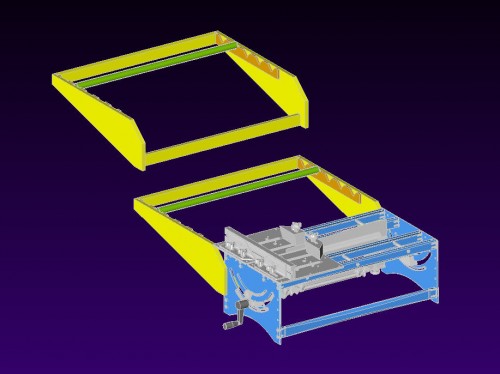

One of the changes we made to the production version of Jointmaker Pro is the ability to add user designed jigs and fixtures. Below is a quick concept of a dead man to keep from loading the linear tables when cutting longer stock. This idea would fasten directly to the front and rear plates and offers minimal resistance to stock traversing.

I would likely make this from 1/2″ baltic birch ply and design around any stiff round stock (pvc, conduit, dowel, closet rod, aluminum tube, etc). Perhaps include another brace with a lip on the down legs of the wings for blade storage. This is a seed idea for our customers–more ideas and feedback can be found on the Jointmaker Pro forum on our website.

Now here is some good news for us, we have 7 JMP’s left. (Actually we have 17, but 10 are reserved for my Silent Woodworking class at Marc Adams School of Woodworking in May). We anticipate beginning the wait-list for round two in about two weeks or less.

Monday we begin the video shoot on my secret new controversial tool that will challenge how you think about another aspect of woodworking. Silence is golden! (Stolen from that 60’s song by The Tremolos or Tremeloes…which in turn was originally recorded by the Four Seasons I believe.) Damn I am getting old.

Stay positive, engaged and enthused!

–John

Henry Ford would be proud….

March, 2nd, 2009

As promised last week, we began shipping the Jointmaker Pro kits today. Concurrently, we are preparing the assembled versions and thought you might enjoy this picture. (It will take us about 10 days to fill all of our orders so check your email for shipment confirmation and tracking number).

As a reminder, the manual is posted here.

–John

Nobody Has Ever Seen Wood Like This…

September, 16th, 2008

Last week I shared our latest Jointmaker Pro discovery; Squiggle Wood. Check out one afternoon’s experiments–wood is just not supposed to act this way. By the way, this is European beech. Oak and ash work too.

It’s hard to imagine woodworking being more fun…let me know your thoughts!

–John

YouTube Link: http://www.youtube.com/watch?v=eq8O3uUilM8&fmt=18

YouTube Link: http://www.youtube.com/watch?v=eq8O3uUilM8&fmt=18

Atlanta and Japan JMP Summary…

September, 2nd, 2008

I could only work half the day today as I have a major case of jet lag… To give you an idea how tired I am, I came home too tired to sleep and almost watched C-Span. Still can’t believe there is a C-Span II.

The attendance in Atlanta was spotty, I am not sure about the value of big trade shows anymore…my local connection of friends suggested it was a poor show for sales.

I left Atlanta encouraged regarding the JMP. There was very strong interest from power challenged countries and we are going to ship units to India, Bahrain, Guatemala and one other country I can’t remember at the moment. These are all for programs to put people to work in the tourist industries so I am excited to see where this leads. Also sending a couple of units to Britain. So in many ways the word is getting out. Everybody liked the internet videos that Michael produced in our office and we plan to do another one this week.

I did get a chance to talk at length with yet another internet woodworking expert who has changed his views regarding the JMP after seeing it work. Amazing what first hand knowledge will do for opinions.

Japan was simply exhausting. I couldn’t sleep, the toilets scared me (and I played ice hockey for 20 years…I would rather get hit in the face with a puck (again) than sit around and find out what those toilets do.) The language barrier was no big deal, cutting wood is easily understood, and many of the visitors spoke English. The JMP is an ideal tool for shoji screen work and I want to make a video demonstrating this capability. The people were very warm, excited and enthusiastic and just like in the States, nobody could believe the quality of the cuts. We have several customers in Tokyo and couple of them stopped by to say hello which was great.

As expected, the food was fantastic.

Tomorrow I will let the cat out of the bag and introduce Commemorative Tool 15–stay tuned.

–John

The Jointmaker Pro and FREE Food-June 19

June, 2nd, 2008

Thanks to a gracious invite from Chris Schwarz and the Popular Woodworking staff, I will be heading out to Cincinnati for a June 19 presentation on “Silent Woodworking”. This will be an informal, up-close and personal affair centered around our new Jointmaker Pro and several new profiles for the HP6-v2 Mini Multi-Plane. These folks are passionate about hand woodworking and Chris and staff are terrific hosts. The event is F-R-E-E and includes a buffet of real food. Everybody is welcome to give the Jointmaker Pro a go before I go–you will be amazed at what can be done without a power cord.

We are limited to the first 60 attendees because the Cincinnati fire marshal just does not get the concept of free food and woodworkers. Dinner begins at six and if you can make it, I would love to meet you in person (Chris too). In addition to a couple of surprises I have up my sleeve, these things have a habit of spilling over to a local bingo hall afterwards for more serious discussions.

RSVP ASAP via email to Megan Fitzpatrick; Megan.Fitzpatrick@fwpubs.com

I hope to see you there!

-John

The Jointmaker Pro can do things without power that are unimaginable. It is an impressive tool that you can try yourself on June 19th in Cincinnati.

This image vividly illustrates the accuracy capabilities of the Jointmaker Pro. The material is hard-rock maple and was made with 10 strokes.

Jointmaker Pro In Action

May, 8th, 2008

Here’s a little clip that shows some amazing capabilities of the Jointmaker Pro.

–John