The video below shows our new surface cove kits (should be available next week). Auto orders have been shipped.

This profile is really interesting. Not only does it do what it is designed to do, which is create a surface profile wherever you choose, but when used in conjunction with the miter fence, it is also a small rabbet plane, and creates two unique molding profiles depending on when you stop cutting. (We included a stop motion clip to illustrates how this works.) This profile would make cool tambours and adds a rich detail to a myriad of projects. It also cannot be replicated with a router. Check your inbox next week for the introductory special.

We finished shooting video of our next “Silent Woodworking” invention and I think you will find this to be an amazing new tool. Hopefully we will have pricing done next week as well.

And, I just finished the design of Commemorative Tool #16!

I think I need a break…

John

Add new tag

Ouch. Yippee!

March, 30th, 2009

Life is all about perspective. I dislike putting our tools on sale–this is the “ouch” part of my business life. And the “yippee” part of yours.

One hand saw to seriously consider (particularly since it is on sale–Ouch!/Yippee!) is our JS-7 Combination saw–it is an adjustable back dozuki and an adjustable back rip saw. What makes this saw a joy to use is the adjustable back. In short, it completely prevents accidental overcuts–one of the ugliest repairs in the joinery world. This saw is ridiculously fast–and on sale.

The short clip below shows this unique saw in action–and if you would like to save $50 bucks (I can’t believe I just said that), click here. (This price is good through the end of this week or until this batch is gone.)

–John

Economaki Economic Stimulus Plan For Woodworkers Who Hate Sanding!

December, 2nd, 2008

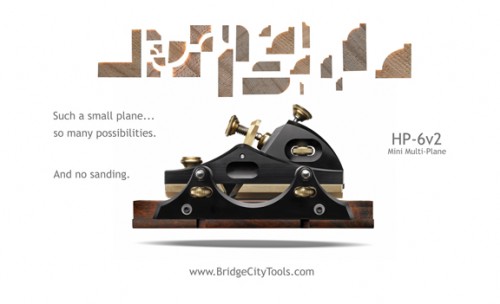

Today (Tuesday, Dec 2, 2008) we are unleashing the Economaki Economic Stimulus Plan for Woodworkers who HATE Sanding–EESPWHS (pronounced “Holy Cow!)

This plan is based on the fact that the really cool tools sitting in our warehouse are doing you no good. Actually, they are not doing us any good either–a classic lose/lose proposition.

Our Plan to Eliminate Sanding for the Holidays!

Starting today, when you purchase 3 HP-6 sole/iron kits at the regular price, add two more for FREE! (Equal or lesser value, of course).

But wait–there’s more… When you purchase 4 HP-6 sole/iron kits at the regular price, add three more for FREE! (same rules as above)

But it gets better… When you purchase 5 HP-6 sole/iron kits at the regular price, add FOUR more for FREE! (same rule again).

We’re not done… If you buy 10 HP-6 sole/iron kits at the regular price, add NINE more for FREE! This is not a typo!

NOW FOR THE FINE PRINT: As you now know, the free items you select must be of equal or lesser value and all selections are limited to stock on hand (no back orders). The two newest sole/iron kits (1/2 & 3/8″ Face Bead kits) are excluded. Other than that, this is an awesome deal. Be prepared with a couple of alternate ideas–or better yet, call early. The Economaki Economic Stimulus Plan for Woodworkers Who Hate Sanding EXPIRES ON DECEMBER 9th.

IMPORTANT NOTE: This is a phone order sale only (our new website has some goofy limitations). This means one of the smiling faces I get to see every day will gladly take your order. Patience please if you are placed in a queue–it will be worth it. 1-800-253-3332. OR, you can email us (sales@bridgecitytools.com) your order if we already have your address and current payment info on file (do not email credit card information).

There is yet another cost savings to mention! These items should arrive in time for you to make a couple of gallery-quality holiday gifts–did we mention no sanding?

Below are a couple of ideas and a few pics to start you dreaming…

Have fun–

John

The planter box above can be made in an afternoon. We ebonized the ash and then infilled the pockets on each side with cut moldings. It is simple and beautiful.

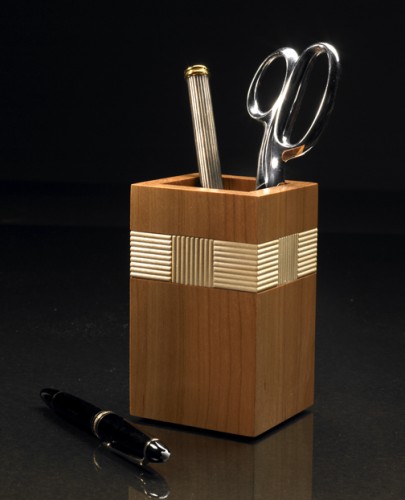

This pencil box is a variation on a theme. An entire desk accessory system can be made with this simple theme.

Almost every single profile for the HP6 can be used for frames. Here are two simple versions that demonstrate the power of texture. Frames are not limited to pictures – boxes and cases can benefit from texture, too!

The modular design of all the HP6 sole/iron kits allows for structured nesting opportunities. Here you can see the incredible detail you can add to your projects.

Never underestimate the power of no sanding. Can you imagine sanding this multi-bead profile? We can’t. And our profiled aluminum “stones” allow you to put a factory edge on any of the profiled irons in a matter of minutes–sharpening has never been easier.

Without question, the HP-6v2 is the most versatile tool in our stable of heirloom products. It is also a significant percentage of our overall business–but more important is the fun you will have creating ideas that are uniquely you!

The CT-15 is Coming Together!

October, 9th, 2008

The best part of my job is when components of a new tool arrive for first article inspection–and in this case it is really a big deal because the parts on my desk today are for Commemorative Tool #15, our limited edition multi-square.

As mentioned earlier, I have developed a fetish for stainless steel. It is tough, durable and likely will not rust (all stainless steels will rust under the right conditions–as dumb as that sounds.)

Over the past couple of weeks we have been testing various bead-blasted finishes and have settled on a matte finish that feels just plain sexy. Below are a couple of pics of some parts–the t-bevel lock lever/pocket clip is really cool.

–John

PS: I have actually gone two days in a row without making Squiggle Wood. I think I need help.

The image above is a computer rendering of the CT-15 Multi-Square, it is five layout tools that fit in your apron pocket.

The finish and form of this cam lock/clip is really cool!

When this tool is completely assembled it is really going to be fun to use.

News from the Sticks and Stones Will Break Bones but Words are Worse department: We used Michael as a hand model because I was informed by my staff that my hands are not as photogenic as my knees or elbows.

Atlanta and Japan JMP Summary…

September, 2nd, 2008

I could only work half the day today as I have a major case of jet lag… To give you an idea how tired I am, I came home too tired to sleep and almost watched C-Span. Still can’t believe there is a C-Span II.

The attendance in Atlanta was spotty, I am not sure about the value of big trade shows anymore…my local connection of friends suggested it was a poor show for sales.

I left Atlanta encouraged regarding the JMP. There was very strong interest from power challenged countries and we are going to ship units to India, Bahrain, Guatemala and one other country I can’t remember at the moment. These are all for programs to put people to work in the tourist industries so I am excited to see where this leads. Also sending a couple of units to Britain. So in many ways the word is getting out. Everybody liked the internet videos that Michael produced in our office and we plan to do another one this week.

I did get a chance to talk at length with yet another internet woodworking expert who has changed his views regarding the JMP after seeing it work. Amazing what first hand knowledge will do for opinions.

Japan was simply exhausting. I couldn’t sleep, the toilets scared me (and I played ice hockey for 20 years…I would rather get hit in the face with a puck (again) than sit around and find out what those toilets do.) The language barrier was no big deal, cutting wood is easily understood, and many of the visitors spoke English. The JMP is an ideal tool for shoji screen work and I want to make a video demonstrating this capability. The people were very warm, excited and enthusiastic and just like in the States, nobody could believe the quality of the cuts. We have several customers in Tokyo and couple of them stopped by to say hello which was great.

As expected, the food was fantastic.

Tomorrow I will let the cat out of the bag and introduce Commemorative Tool 15–stay tuned.

–John

More fun with the Jointmaker Pro

July, 17th, 2008

Yesterday I spent the afternoon playing with our Jointmaker Pro prototype. Here’s a short video of a couple of ideas I pursued–as you can see, the accuracy of this tool is incredible. We are all marveling that I can work in our office doing these things without disturbing anybody. It was one of the best days I have had in a long time!

Here’s a direct link to the YouTube video; http://www.youtube.com/watch?v=UTVKQgOqZSo&fmt=18

Also, the Bridge City forum is now open. This is a moderated forum where you can ask woodworking questions or share information regarding our products. The location for entering the forum is at the bottom of our home page. Click on “Community Forum”.

We are Close to Launching the Jointmaker Pro!

July, 9th, 2008

Over the past eleven months we have been working on what may be the most important new tool in our 25 year history. The Jointmaker Pro is a new and safe way of working wood that yields terrific results (unbelievable in some cases), without power or dust collection and is as quiet as sanding by hand.

Last month we released a short video that showed a sampling of this tool’s capabilities. That video has been seen the world around and is the subject of more internet discussions than any woodworking tool that I can remember.

We don’t participate in woodworking forums, so we never respond to criticism or praise. That changed last month when Michael Berg (one of our designers) informed me of a civil woodworking forum that was also intelligent and fun. Simultaneously, I received an email from Matthew Schenker, (who is responsible for this forum) inviting me to participate in a lively discussion regarding the Jointmaker Pro and to answer the many questions already posed by participants.

The Festools Owners Group (FOG) is an avid and highly passionate collection of woodworkers who simply believe in quality tools. They too are vilified by the Woodworking Taliban, so I decided to briefly join their forum to invite one of their members to Portland for an unfettered couple of days with one of our Jointmaker Pro prototypes.

And that is how we met Roger Savatteri.

Roger is a full time woodworker/sculptor whose work is stunning. Unlike many woodworkers, he designs first and figures out how to make his designs later–this is how it always should be.

You can read Roger’s detailed review of the Jointmaker Pro here. In order to see his detailed photographs you must join the FOG forum–I think it is a decision you will not regret, and it is free.

(I particularly enjoyed the section on how to trash a blade..)

There are also a couple of interesting shots of our ball-bearing model of the Jointmaker Pro (since rejected because of price) that you will see only in his review. Most importantly, if you think the Jointmaker Pro has a future in your shop, this is likely the most in-depth review available.

We are planning on taking orders on our site within the next 10 days. If you would like to be informed of the introductory promotion, go here and fill out the info at the bottom of the page–we will then be able to email you when the introductory period begins.

Below are a couple of pics from Roger’s visit in early June.

-John

Roger setting the Jointmaker Pro fence to 90 degrees.

Here Roger cuts his first single pass dovetails.

Our moment for posterity–John, Roger and Michael forcing smiles for the camera.

HG-1 Honing Guide in Action

June, 2nd, 2008

It is always fun around here when an idea becomes reality. Later this week our new honing guide will be in stock. Although I designed this tool with the specific needs of sharpening our HP6 profiled irons in mind, it will work on just about every tool in your shop. Here’s a peek of the tool in action…

As you can see, the rear roller is flat. We have had several inquiries regarding a roller that is crowned to facilitate relieving the corners of wide plane irons. Although this sounds like a good idea, the math makes no practical sense. For example, if one wants to relieve the corners of a plane iron by .002″-.003″, the crown in the honing guide roller would be around .001″. This is just not a practical idea (in our opinion) when the same results can be achieved with finger pressure applied to each corner during honing. If a more severe crown is required, a barrel shaped roller might make sense, and if you have that need, you can easily remove the stock roller and insert a shop made roller (wood will work) for your needs.

Lastly, it is not clear in this clip but the clamping bridle pivots and will accommodate aggressively tapered tools–the most common of which are Japanese chisels.

Thanks for watching.

-John

Ideas are everywhere when you’re hungry…

May, 1st, 2008

Last fall I crossed paths with a sandwich board on my walk to lunch (O.K., I tripped). As I walked around the sign I had one of those moments where I saw something that wasn’t there (typically I imagine IRS agents—they’re everywhere you know…) The offending culprit is pictured below.

Empirically we understand concrete is a painful abrasive (knees never forget) and while regaining my balance I imagined the sidewalk as an endless… abrasive… honing stone… and I was tripping over a… crude honing guide! Sounds weird, but a ray of light leaked into my cranial garden and in that instant, an idea germinated.

I returned from lunch, grabbed a chisel and mocked up the idea using my Razr cell phone. That was all the validation I needed to pursue the development of our HG-1 Honing Guide. And we are thrilled with the results. (In a pinch, a cell phone makes a crappy honing guide, but as you can see, schematically it worked out very well. Don’t be surprised if the “Woodworking Taliban” embraces this ridiculous cell phone alternative …)

The HG-1 is completely different than previous designs. Most significant is the built-in squaring guide which will keep cutting edges that have to be square to the sides in perfect alignment (shoulder plane irons are one example). The other new development is the infinitely adjustable micro-bevel system controlled by the knob at the back of the plane. This was a crucial development for this tool because of the profiled irons our HP-6 Mini Multi-Plane employs.

We will formally announce this new product (and the reference set-up guide for precise primary bevels) in a couple of weeks, with many more details and pricing. Needless to say, it will work well for chisels, irons and really shines when used on our aluminum profiled stones for HP-6 molding irons. Below are a couple of pics to see how the guide unfolded.

Oh, and I forgot, the yakisoba was delicious.

-John