When I arrived at the exhibition hall in Chiba two days ago I learned this show used to be three times the current size as recently as five years ago. So how big is it?

It is not quite as big as the National Hardware show in Vegas each year (which used to be much bigger when it was in Chicago). In many ways, a woodworking/DIY trade show is a trade show the world around…they are all shrinking.

I asked for the reasons and the popularity of pre-fab houses was at the top of the list. Also, IKEA is hugely popular here–young Japanese families can buy an entire room of furniture for the cost of ONE high-end plane or chisel set. Lastly, it appears the people here don’t have much time for anything but work and family. Sound familiar?

I am having fun demonstrating the Jointmaker Pro and I would say there is a profound appreciation for the accuracy and the clean cuts. Don’t get me wrong, we are not on our third order book, or second…you get the idea, but the reactions are genuine and many can’t believe how easy it is to do accurate work. The soulfulness of the process (very little noise) is greatly appreciated. Lots of gasps and smiles.

My demo unit is set for my height which is radically different from most here. We rigged a step stool and now I can coax just about anyone to try the JMP. The reactions on peoples faces is worth the trip. I am trying my best to be a good Yankee ambassador and we are having fun. Here’s an amusing story…

I stopped by an educational booth and made my very first pair of chopsticks with hand planes. Elapsed time was maybe two minutes. The booth attendant asked me my occupation and I replied “business executive”. This created quite the stir because they have never seen such a “confident” business executive use hand tools. They really struggled with this and through an interpreter I explained that I used to be a woodworker. This knowledge put everyone in the booth at ease and there were many smiles and sighs of relief. Afterword I invited them all over to the Jointmaker booth and this was the highlight of the day for me and I would like to think for this group as well.

Even in Japan, businessmen are presumed to be incompetent…

–John

My cell phone does not work here but the camera does. Here are a few (crude) tradeshow pics from the Land of the Rising Sun…

Trade shows all look the same. Not as many pony tails here however…

This lady could not cut dowel with her hand strength. She was so excited when I showed her how to use the clamps. She must have made a half-dozen passes, each drawing a big smile from the onlookers.

This creature caught my eye–it is made entirely of woodworking tools.Wingspan is close to 10 feet! The feathers are hand saw blades, the legs are auger bits and the face and face feathers are all knives. If this thing ever fell over on a cow…instant hamburger.

Jointmaker Pro Stationary Hand Saw

Posts, comments and questions regarding the Jointmaker Pro Stationary Hand Saw

Jointmaker Pro Updates…

August, 14th, 2008

I am pleased to share that we are now accepting web and phone orders for the Jointmaker Pro! Here is a pic of the new stand for those that want a stand-alone machine. It is laser cut and will fit the production model perfectly–the legs are height adjustable so the sliding tables can be precisely set to hip height.

Two noteworthy tidbits; we plan on shipping in late fall and our special introductory rates will only last a couple of more weeks. (Late fall means before the holidays using the Economaki calendar.)

The next stop for the Jointmaker Pro is the International Woodworking Fair August 20-23 in Atlanta. I will be demonstrating in the booth of the firm we contracted to make the Jointmaker Pro components–booth number 8874. Please stop by and introduce yourself–this should be a fun show.

The following week the Jointmaker Pro debuts in Toyko. I will be demonstrating in the booth of the company that makes the Jointmaker Pro blades–I am looking forward to the trip and some good sushi. I am a bit troubled about leaving because I have a 14 year old dog that…well, you dog people know where this is headed. I love my dogs and I sure hope my trip is trouble free in this department.

If you followed all the buzz regarding the Jointmaker Pro on the internet a few months back you undoubtedly came across the bile of many who had a great laugh at our expense regarding this new tool. Here is a refreshing update;

I have been contacted on two separate occasions by web forum participants who were actively leading the chorus of boo’s regarding the Jointmaker Pro…and get this–they both apologized!

This occurred after seeing the Jointmaker Pro in action during one of my demonstrations. Both agreed that their behavior was sophomoric and/or irresponsible. Now get this–both of these folks placed orders for the Jointmaker Pro! I know this is a little thing but sometimes the smallest gestures have the largest significance. One thought my blog rants about the “Woodworking Taliban” was funny but also dead-on and he wanted out. I thought to myself, this is just like raising kids, you have no clue they are listening until years later. Anyway, their sincerity was moving.

I spent a great deal of time in July trying to reduce the cost of the Jointmaker Pro and was successful by almost $50. Guess what happened? During that same time the price of the metal increased $45. Go figure. For those of you who may be in the world of manufacturing, I have NEVER seen such a market. Between daily price fluctuations and all out shortages, it is very troublesome.

I won’t be posting again until the first week of September and my first post will be a Sneak Preview of Commemorative Tool #15. It is a never-before-seen device that …

–John

More fun with the Jointmaker Pro

July, 17th, 2008

Yesterday I spent the afternoon playing with our Jointmaker Pro prototype. Here’s a short video of a couple of ideas I pursued–as you can see, the accuracy of this tool is incredible. We are all marveling that I can work in our office doing these things without disturbing anybody. It was one of the best days I have had in a long time!

Here’s a direct link to the YouTube video; http://www.youtube.com/watch?v=UTVKQgOqZSo&fmt=18

Also, the Bridge City forum is now open. This is a moderated forum where you can ask woodworking questions or share information regarding our products. The location for entering the forum is at the bottom of our home page. Click on “Community Forum”.

We are Close to Launching the Jointmaker Pro!

July, 9th, 2008

Over the past eleven months we have been working on what may be the most important new tool in our 25 year history. The Jointmaker Pro is a new and safe way of working wood that yields terrific results (unbelievable in some cases), without power or dust collection and is as quiet as sanding by hand.

Last month we released a short video that showed a sampling of this tool’s capabilities. That video has been seen the world around and is the subject of more internet discussions than any woodworking tool that I can remember.

We don’t participate in woodworking forums, so we never respond to criticism or praise. That changed last month when Michael Berg (one of our designers) informed me of a civil woodworking forum that was also intelligent and fun. Simultaneously, I received an email from Matthew Schenker, (who is responsible for this forum) inviting me to participate in a lively discussion regarding the Jointmaker Pro and to answer the many questions already posed by participants.

The Festools Owners Group (FOG) is an avid and highly passionate collection of woodworkers who simply believe in quality tools. They too are vilified by the Woodworking Taliban, so I decided to briefly join their forum to invite one of their members to Portland for an unfettered couple of days with one of our Jointmaker Pro prototypes.

And that is how we met Roger Savatteri.

Roger is a full time woodworker/sculptor whose work is stunning. Unlike many woodworkers, he designs first and figures out how to make his designs later–this is how it always should be.

You can read Roger’s detailed review of the Jointmaker Pro here. In order to see his detailed photographs you must join the FOG forum–I think it is a decision you will not regret, and it is free.

(I particularly enjoyed the section on how to trash a blade..)

There are also a couple of interesting shots of our ball-bearing model of the Jointmaker Pro (since rejected because of price) that you will see only in his review. Most importantly, if you think the Jointmaker Pro has a future in your shop, this is likely the most in-depth review available.

We are planning on taking orders on our site within the next 10 days. If you would like to be informed of the introductory promotion, go here and fill out the info at the bottom of the page–we will then be able to email you when the introductory period begins.

Below are a couple of pics from Roger’s visit in early June.

-John

Roger setting the Jointmaker Pro fence to 90 degrees.

Here Roger cuts his first single pass dovetails.

Our moment for posterity–John, Roger and Michael forcing smiles for the camera.

Dovetail Joints and the Jointmaker Pro

July, 7th, 2008

Light-tight dovetail joints are a hallmark of craftsmanship. The video below illustrates how we make through dovetails using the Jointmaker Pro. In the interest of saving a few megabytes of bandwidth, a little background information is in order…

“Traditional methods” are important, perhaps pertinent, but often times I feel the urge to try ideas that are not 300 years old. That said, the only aspect of dovetailing in this video that is “traditional” (it is such a regressive word) is waste removal by chisel. The rest should be an enlightening combination of speed and accuracy–and easily replicable.

When setting the blade (or the fence) of the Jointmaker Pro to a particular angle, we make practice cuts on wide stock until the stock nests perfectly to a reference (t-bevel or square). All of the prep work for this video was done off camera.

Regarding pins vs tails first, I embrace “whatever works for you”. However, with the Jointmaker Pro we are definitely pro tail (socket) first. The reason is simple, we did not need to layout the tails. You will see us using a stop block for joint symmetry. We also made all of the tail cuts by cutting from both faces of the stock with the blade set at the same angle–this ensures the single pass cuts are also dead symmetrical–this is much faster incredibly accurate…more on this at the end.

By making a zero clearance throat plate, we can make single pass cuts to either side of a line with ease–and so can you. We used 1/8″ aircraft plywood for the false tables and the throat plate. (You only make these once, they can be used over as often as needed.) The video shows minimal layout to mate the pins to the tails–that is all that is required and pencil tic marks worked fine. Of course, you can use whatever method you prefer–we only care about a light-tight joint.

I think you will agree, the saw cuts cannot be improved–by any method. And if you had a complete project (as opposed to our single sample joint) we believe there is not a faster way to hand cut dovetails. Of course layout can be expanded for more complex joints but you don’t need much–the saw does the work perfectly without the need for a thorough visual reference. The saw (assuming a sharp blade) cannot cut crooked unless your set-up was crooked. In short, the Jointmaker Pro reliably cuts your intent, cut after cut without you worrying about accuracy.

It is incredible to think that EVERY cut is exactly the same depth and perfectly angled. Lastly, this was a first take video and we spent no effort on the proportions of the half and full pins. We just made cuts and chiseled away and you will never guess what happened. I could fit the tails onto the pins from either direction, and that has NEVER happened to me before.

What fun!

–John

PS: I am working on a way to cut half-blind dovetails. I will let you know if I succeed…

If you have a woodworking friend who would like to see this video and not wade through my ramblings, here is the YouTube link:

http://www.youtube.com/watch?v=l_eyFENlSQ0&fmt=18

Free Food and Dead Cicadas…and that is the truth.

June, 19th, 2008

Well, it’s a little after midnight and AGAIN I find it hard to go to sleep. I just spent almost 12 hours on the Popular Woodworking campus talking about the Jointmaker Pro. Although this trip was all about business, I would not dare call it work, only because there was free food, and plenty of dead cicadas… DETOUR: We don’t have cicadas in Oregon (if we do I am sure someone will correct me) and this much dead biomass is fascinating. And loud. Before they die that is. Do the math here–17 years as a hibernating nymph buried next to a big, fat tree root, wake up hungrier than a teenager without a refrigerator, munch on tree sap until the libido overwhelms, spend a couple of hours at the screaming mimi cicada bunny ranch and then croak from exhaustion… This isn’t so bad when you think about it…no SAT tests, background checks, or exit polls–just an incredible, one week, no-strings-attached love fest. Reincarnation requests anyone? How about a Jamba Juice Tree Sap Smoothie?

I digress. Approximately 60 people ventured into Cincinnati to eat free pizza and listen to my Silent Woodworking spiel. (Not quite as bad as one of those guilt ridden timeshare meetings…I hope.)

It is hard to tell if people had a good time, but I found it fun. As many of you know, Chris Schwarz claimed that the cut from the Jointmaker Pro was the cleanest saw cut he has ever seen–by any method. Of course the Woodworking Taliban pilloried him for such nonsense and I believe, if any of the attendees step forward, his critics will join the cicadas in the belly of a street sweeper.

After my presentation, the Jointmaker Pro was moved to the shop and all interested were allowed to make cuts. There were plenty of smiles–and frankly that was worth the trip. I am leaving the prototype with the Popular Woodworking crew for the next month for further play and testing. Oh, and a small detail — nobody lost any digits.

I was treated like a dignitary (I am not, and NEVER want to be) so I had four pieces of pizza, two of which were onion–without which we would still be talking about the Woodworking Taliban at a local watering hole. Smart people, those Popular Woodworking folks.

–John

The Jointmaker Pro and FREE Food-June 19

June, 2nd, 2008

Thanks to a gracious invite from Chris Schwarz and the Popular Woodworking staff, I will be heading out to Cincinnati for a June 19 presentation on “Silent Woodworking”. This will be an informal, up-close and personal affair centered around our new Jointmaker Pro and several new profiles for the HP6-v2 Mini Multi-Plane. These folks are passionate about hand woodworking and Chris and staff are terrific hosts. The event is F-R-E-E and includes a buffet of real food. Everybody is welcome to give the Jointmaker Pro a go before I go–you will be amazed at what can be done without a power cord.

We are limited to the first 60 attendees because the Cincinnati fire marshal just does not get the concept of free food and woodworkers. Dinner begins at six and if you can make it, I would love to meet you in person (Chris too). In addition to a couple of surprises I have up my sleeve, these things have a habit of spilling over to a local bingo hall afterwards for more serious discussions.

RSVP ASAP via email to Megan Fitzpatrick; Megan.Fitzpatrick@fwpubs.com

I hope to see you there!

-John

The Jointmaker Pro can do things without power that are unimaginable. It is an impressive tool that you can try yourself on June 19th in Cincinnati.

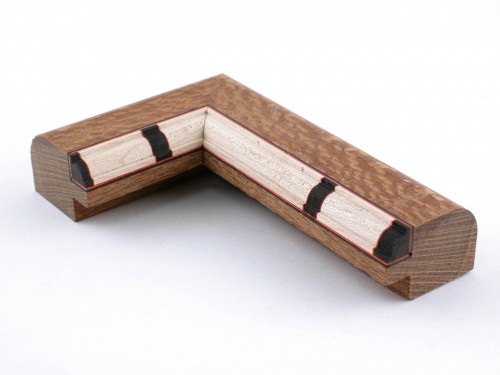

This image vividly illustrates the accuracy capabilities of the Jointmaker Pro. The material is hard-rock maple and was made with 10 strokes.

HP6v2 and the Jointmaker Pro, Silent Woodworking–Endless Possibilities

May, 21st, 2008

Our HP6v2 owners are a passionate group. The really smart customers take my summer classes at the Marc Adams School of Woodworking and upon completion enter the enchanted world of creativity and return home a woodworking genius. (I hope my kids are reading this…).

Take Rutager West for example. He bicycles twenty miles to work each and every day, all year long, in MINNESOTA! Yikes! Rutager also happens to be an equally dedicated woodworker who cannot stand the noise, the dust and the risks associated with power tools, particularly routers. Rutager makes boxes and cases. He recently told me in my “CAD for Woodworkers” class that our HP6v2 has changed his life–and cannot wait to receive his Jointmaker Pro. Now that is pretty cool, and speaking of cool, check out some of the things he has been making with the amazing little HP6v2 Mini Multi-Plane… these are details of the frames and components he shows prospective customers–all without sanding! And if you are as impressed as we are, I am certain he would appreciate reading your comments.

The above frame used HP6v2 Mini Multi-Plane corner bead and rabbet kits. It is stunning craftsmanship.

The multi-bead soles (available in four sizes) are a great way to add texture. These shavings in ebony and an unidentified hardwood speak volumes for the capabilities of the HP6v2.

Using the V-groove sole, Rutager plowed a recess to receive the molding made with the corner cove sole which also made the cove on the edge–beautiful work. I don’t know how he makes his laminations!

This frame detail uses the following sole/iron kits for the HP6v2; rabbet, corner bead, and corner radius–all without a grain of sandpaper.

Another view–THANK YOU Rutager for sharing your work!

If you have an HP6v2 story to share, please do!

-John

Jointmaker Pro In Action

May, 8th, 2008

Here’s a little clip that shows some amazing capabilities of the Jointmaker Pro.

–John

“Indiana is the veneer capital of America…”

May, 7th, 2008

I’ve been teaching classes at the Marc Adams School of Woodworking for about 187 years now–give or take a few weeks. Mainly I enjoy the free lunches. And my students. And Marc Adams. And the occasional blank check he sends me–in that order.

Tuesday evenings feature an informal dinner where teachers respond to woodworking questions with their mouths full of food. Around 7:00 post meridian time, instructors share their work with overly satiated students who need sleep. It is really interesting and if you don’t believe me, take a class–it’s a great school.

This year I shared a working prototype of our new Jointmaker Pro saw. It is a hybrid tool, part miter box/chop saw/table saw. It requires no power, is unbelievably accurate and conversationally quiet. I was a bit nervous because I really needed live feedback by real woodworkers–hopefully positive feedback. Afterwards, in my tent by the freeway, I faded believing the demonstration went well.

The next day, Marc Adams, who ironically goes by the name of Marc Adams, shared that my presentation went well. I asked him what he thought about the new saw.

DETOUR: Marc has informed me on numerous occasions that he lives in Indiana and it is no coincidence that Indiana is the largest veneer producing state in America. It’s a long story–take my word for it and don’t bring the subject up in his presence.

So he blurts, “I bet it won’t cut veneer.” (Hallmarks of friendship include confrontational challenges, brute honesty and the assumption that your friend is listening…)

Imagine my surprise when Marc supplied me with a stack of veneer, and taught me AGAIN that IF this works, it would be called PARQUETRY, not MARQUETRY. Thanks Marc.

The picture below illustrates how cutting veneer on the Jointmaker Pro is not only fast but dead-on perfect.

I asked Marc what he thought of the results…

“They are perfect. But we don’t do it that way.”

This made me smile.

-John