____________________________________________________________________________________________________

“You don’t get harmony when everybody sings the same note.” – Doug Floyd

____________________________________________________________________________________________________

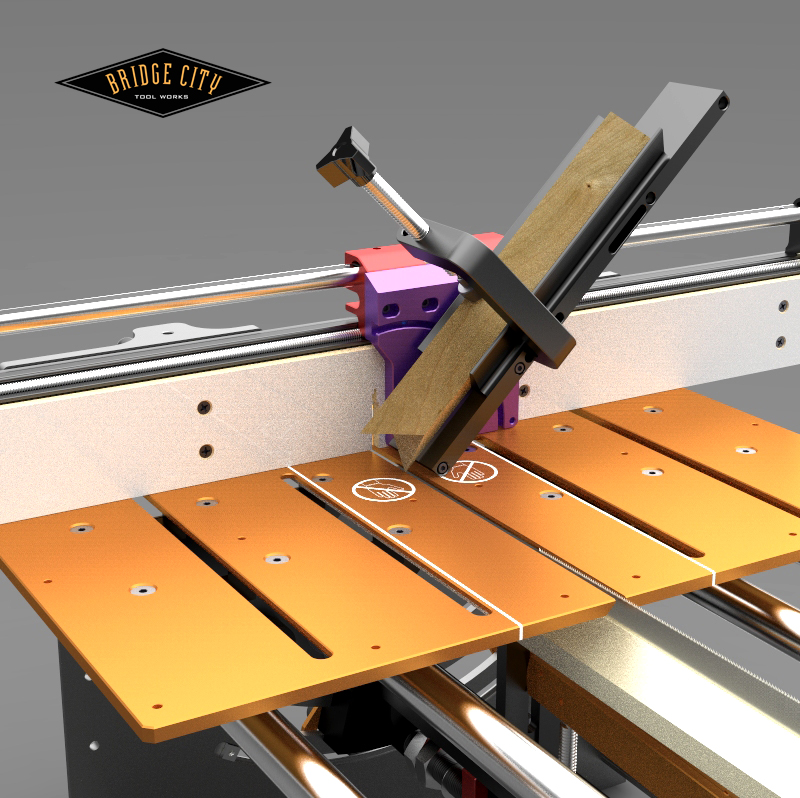

Below is an image of the bias arm–this is a really cool looking cut and makes a beautiful looking joint–needs a dowel for sure and what better way to center drill an end grain dowel hole perfectly every time? Why the DJ-1 of course… and that Drivel Starved Nation is a shameless plug.

We made a lot of these cuts at WIA with the stock vertical and blade tilted. I am now of the belief that tilting the stock, when possible, is superior to tilting the blade. With our new AngleMaster setting these arms perfectly can be done in one take. No trial and error. Period. Assuming of course that the blade is at 90 degrees.

Lots of questions so let’s get to it;

Will the Precision System fit the Jointmaker SW?

It will. I am not sure we will offer the fence in the same length however, most likely we will do a shorter version as an option.

When will this be available?

We are shooting for March, 2012 and hope to open the pre-order window sometime next week.

How will the new pivot clamps work on small stock?

This was a great question and prompted me to redesign the clamp so the swivel pads can be removed. So the anwser is they will great on small stock!

There were a couple of comments about the locking knobs so here are my thoughts.

First, I can’t stand looking for a hex key when I want to adjust the wood fences on my saws. So that has been fixed (remember, this is my dream solution). In order to conserve table space which equates into cutting capacity, this is as compact as I can make it.

Will the fence tilt to 45 degrees and can you cut a miter on stock 5″ in width?

No. And you can’t do this on the original either. Face miters on stock up to 3″ in width require the fence bridge to be removed and the cut is made using either table but not both. With the new system, it is possible to take one of the original fences and set it forward on the table at 45 degrees. This will allow both 90 degree cuts and 45 as long as your stock width will fit between the two. The entire fence will pivot enough to cut single pass dovetails, just like the original fence.

It appears that edge miters need to be cut to length first–is this true?

Almost. If both ends are to mitered, which is very common, then you need to cut your stock oversize by 1/8″. This will allow you to miter one end and then use the stop for the second end. For longer pieces you will need to affix a shop made extension stop to the end. We will tap a couple of holes to make it easy for you.

The articulated stops look good for wider pieces, but what if you’re cutting 1/2″ wide stock?

I would not use these clamps for narrow stock if I had a choice. But assuming one doesn’t have a choice, I would put a block of wood on top of the narrow stock and use the articulated clamp to pinch them to the tables.

Will you make extensions for longer stock?

Not as of this writing. But there is a quick work around. You can fasten a myriad of ideas to one of the stops and one idea is to fasten a shop made arm to one of the stops that would allow you to still use the micrometer adjustors. Before we address longer stock I need to make the dead man wings–that will come later next year.

How long will it take to re-index the system once removed?

It will be faster than you think. Square it back up, center the gap between the rules over the gap in the tables and lock down. Next, take a 3/8″ dowel, cut one end and use one of the stops to cut to any length around 1″. Measure with a caliper and adjust the appropriate micrometer dial to your reading. That’s it.

This is a significant, game changing accessory for the JMP family. And it is going to make me really happy using it! And please, keep the questions and comments coming–they are really helpful.

-John

Instead of a dead man wings for longer stock, an alternate approach could be an unconnected freestanding dead man. A simple adjustable polished bar would do and could be placed at any appropriate relative position, hight, angle and distance from the JMP. Such an accessory would be simple to produce and less likely to put undue stress on the JMP.

A single bar is the approach we are taking and actually posted images of a DIY version on the JMP forum. A single bear is the wau to go, although we are going to use tube, which is lighter and stiffer.

-John

John,

In the spirit of possible improvements on your wonderful design –

Concerning the clamp portion in the photo above, specifically the round head of the clamp that contacts the workpiece – are you considering giving the option of changing those heads?

Such as an inverted “V” head for round stock, or a wide inverted “U” shape that would snug up against the sides of various angled stock rather than pressing down on corner. (such as it appears above)

And,,,,,,

Is the C – clamp like devise (above) detachable? – so one might be able to attach a shop built jig hold down devise that would attach to the cradle devise holding the workpiece. – For those oddball works where the distance allowed under the c- clamp hold down might prove a limitation.

cheers,

Roger

John,

Will there be any set up for the fence to rip small narrow pieces? I hate to use big equipment for small pieces. I think someone else mentioned the need to rip stock on the jmp.

Thanks for considering this.

Allan

Beautifully conceived and executed John. Very nicely evolved and refined since your preview at Roger’s.

Allan,

The new pivot clamps should help if the parent stock is big enough. Limited ripping is not off my radar.

-John

@Gary: Thanks!

Roger-

Yes, the clamp pads on both the c-clamp and the pivot clamps are removable. We gave a “V” groove pad for the cut where the stock is clamped on the bias.

-John

PS: Finish your shop yet or are you too busy enjoying the view?

Love the new fence system and will order one for sure. I was thinking that there is still one item missing. It would be cool to have a part that would attach flat to the sliding table kind of like a miter sled for a table saw. I guess the two independent fence halves could be set that way pretty easily but I’m impatient .

Can’t wait to order one!!!

Bob-Your wish has been granted-will post an image of the new miter arm hopefully tomorrow-it attaches to the index heads.

-John

John,

Wonderful set-up! I’m thinking about other ideas, but you have been very thorough. One thing I’m planning to do and you are working on something similar; is a way to index multisided objects, in your case gears, in my case more of a beveled rip cut- the closest thing I can use to explain what I’m trying is an octagon chisel handle like shape. My current hurdle is how to use an index wheel without slicing it too.

-Rutager

John,

Hmmm,

Nit-picky question,,,,

As the fence is set up in the photo above,

let’s say one wants to perform a straight forward crosscut without the purple/orange clamping devise.

a. how easy is it to just take it off?

and/or is it possible to flip it out of the way

without it rattle-ing around as one makes a

cut.(and if so, do u see embedding a magnet

to hold it in place at some point on the flip

side?)

b. if one were to place sticky sandpaper on the

working side of the fence in order to firmly

hold the workpiece – does the purple/orange

clamping device have enough clearance to

slide about with the sandpaper in place?

thanks,

roger

Roger-

Any setup can flip out of the way for a crosscut-“rattling will not be an issue.

Yes, there is room on the fence for grits should one choose.

–John

P.S. I really like your epigraphs. Is Doug Floyd Pink’s brother?