____________________________________________________________________________________________________

“”When I examine myself and my methods of thought, I come to the conclusion that the gift of fantasy has meant more to me than my talent for absorbing positive knowledge.”

– Albert Einstein

____________________________________________________________________________________________________

For those of you (all 150,000,000 plus) who follow this totally awesome and worthless blog with fervor and wonderment, you know this weekend was a busy one for this space.

During the weekends I have my iPad lying around on the kitchen table. Whenever I walk by, I check it and needless to say, I did not get much done this weekend. Actually, that is not true–I gave both Louie Dog and Jitter Dog treats around 3pm on Saturday.

Last night when I sat down to dinner, my wife gave me a boiled turnip for dinner. WHOOPIE!

I said, “What is with the boiled turnip dinner–and why no plate?”

“Who are you married too–me or Roger Savatteri?”

So Roger, it looks like I get half your stuff when I file for divorce.

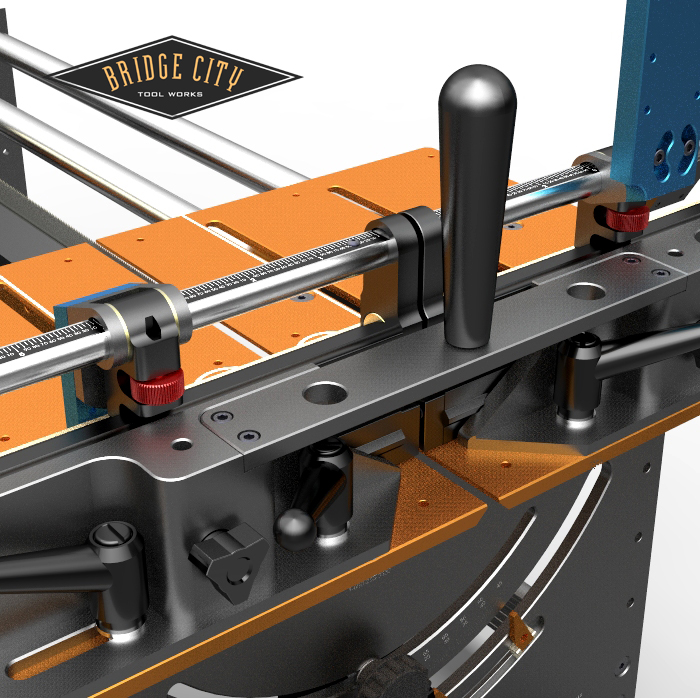

Made a couple of changes to the new Precision Fence System from when Roger and I were on better terms. His suggestion of adding a horn to the bridge was a good one… so consider it done–image below.

I wish my life were less complex.

–John

John,

Are those extra holes so the handle can be used off center too? I would think it would be easier to use if your hands weren’t real close together. Maybe the handle could mount to the mounting block or the bridge.

-Rutager

Rutager,

Those holes you see are access holes to the quick action lever clamps.

From the inventor’s perspective, one hand on the crank, one hand on the tables…

– John

John,

Now that Rutager has you talked into one handle, he is shooting for two! Kind of like the dual buttons on a punch press………

The handle looks good by the way!

DJ

Oh sure. I ask you where you put your fingers for pushing, and you say there’s plenty of places. Roger waltzes in with his artistic JMP-owning flair, and you put a horn on your fence. Typical male. Boiled turnip for you, buddy.

.

Actually, I quite like boiled turnips. Especially when they’re in a really nice chicken soup. Kudos on giving the dogs a treat. I’m sure your wife really appreciated it. I know mine does, when I go out of my way like that. The key is to keep the expectations low. That way they’re surprised when you do ANYTHING.

.

Kudos also on the horn – I like it. Do you have any old totes from the CT-12 lying around? They’d look pretty cool on there. I agree with Rutager (!) – it would be nice to be able to offset the horn to one side or other.

.

Who gets Michael in the divorce?

.

– Peter

Can I get one in Metric?

John,

Maybe your wife is actually giving you a hint, she may want her own Ipad.

So does this mean I could only blog back on office hours? I mean, whatever it takes to help for marriageable bliss.

If it will help I’ll send you a life size cardboard cutout so you could sit me down at dinner.

.

ps. my guest house should be ready by Spring.

.

-roger

John,

What! the handle is not made from Coca-bola? (just kidding)

Nice horn! I’ll take one.

.

Concerns:

If one rests one hand with the pinky finger towards the bridge plate – will it get a little tight between the horn and the holder for the rails on the fence?

A possible solution may be to bring the bridge plate a bit closer to the user by either V-ing the plate out (like the bow of a ship) And place the the horn out a little more. Just a thought.

.

Will the horn also be included in the optional “adjustable” bridge plate that will take into account the different angles the fence(s) will go, yet hold the two tables in unison?

.

-roger

John,

Regarding the Table-saw sled.

hmmm, how should I put this gently?

A while back you made a video for a parallelogram jig for a table-saw sled, this one…. http://www.youtube.com/watch?v=Vmp2x5VxKhM (thank you Paul Marcel for the link)

I’m not seeing how the upside down “V” bridges on both the front and the back will take into account of the “swing” that will occur between the two tables.

It would seem as if the base of either side of the “V” would be further out (towards the middle of either board) from where they are now.

You “are” including the function of the parallelogram sled with your new sled/fence,,,,,,,,,,,,,,,,,,,,,,,,,aren’t you?

(It’s 3:30 in the morning, I’m glad I got that off my chest, now I could go back to sleep.)

.

roger

Possible use of the JMP pivot clamp with the table saw sled,,,,,,,,

http://www.youtube.com/watch?v=AMRIQib4JHU&feature=related

Roger,

This sled will not accommodate our parallelagram concept…for one, the index system would need to be recalibrated after shifting.

Secondly, is the method by which the fences attach to the sled stock, they are screwed down.

Regarding the horn, there will be plenty of room for the pinky finger. And we are including it with the fences.

You can drill and countersink a shop made bridge for canted fences…

Please do book me for the guest house…I would like to stay there for a month or two before I take full ownership after our divorce…

And you are spot on about my wife wanting her own iPad!

@Paul-Marcel,

Would you like a metric Crescent wrench too?

@Peter, you can have the turnips-I am sticking with sushi.

@DJ: When you get a chance, email me pics of the cut you struggled with…it may be already addressed by something you don’t know about yet… 😉

-John

John, Oh mighty tool pontificate!

.

So, call me stubborn or not being able to let go of a vision…..

But last night I had a vision of you and Michael and your soon to be made Tablesaw Sled Video,

where you do all your normal operations on the sled,

and then,

you go into “Parallelogram mode” and wow the socks off of everyone not in the JMP choir,

You’ll buy your island with fields of Turnips for your wife,

And happiness will spread over the land.

.

How? You may ask?

Ok, let’s break down your objections….

Starting with the second one, something about the fence being screwed down to the sled stock.

Let’s say your sled stock is made out of Applyply or Europly rather than Mdf.

(Anyone ordering your fence system can afford to splurge on either option)

So now that you have a strong base there would be the structure to embedding a T-track along where the fences would sit.

So,,,,,,

The fences are now movable along the T-track.

.

Next,

“The index system would need to be re-calibrated after shifting.”

I have a couple of responses to that,

a.) So let’s re-calibrate, I rather do that than to have two huge sleds hanging about my smaller workplace,

(one being the Parallelogram Sled, the second being the Precision Sled)

b.) Who cares? (If one doesn’t micro-adjust in parallelogram mode – it would be very nice if we could, but not at the expense of not having parellelagram mode if not.)

Also, one could always embed forward of the fence on either side a measuring rule for when in parallelogram mode.

.

c) Perhaps your thinking that if I add the Parellelaogram mode now it will bump up the price,,, well – make it an option. We’ll pay the difference,

(I could probably speak for Ron, Paul Marcel and Rutager as well)

.

d.) I would be rather sad if you came out with a Precision / Parallelogram Fence a year after buying the Precision fence.

ok, So where did I put my coffee?

-roger

Roger;

How about this idea, cooked up especially for you…and anybody else that would like the ability of the Precision Sled Kit fences to be angled to the blade…

Take your sled material and sink a couple of t-nuts in the bottom strategically placed to accept your original JMP fences; the extrusions will attach via the dovetail nuts. Now you can independently tilt either fence while employing what would be obsolete parts assuming you own the Precision JMP fence.

No need for the parallelogram in this case, and the original sled kit bridges will do just fine. As mentioned, you will need to recalibrate.

Furthermore, the fences will now quickly slide on and off… you could put one 18″ fence on the JMP when needed, or put a 12″ fence on the sled kit….

And the best part is, no extra parts required outside of 4 t-nuts.

For those that do not have the original JMP fences, we can make them available.

-John

John,

I always have one hand on my crank; I was just thinking that it might be nice to have options on where the handle is mounted especially if only one table was in use.

Next question: on the next JMP run, what will it have for a fence?

-Rutager

Rutager-

Next JMP run will have the standard fence like the previous runs-we will offer a “Works” version too.

We are going to drill and tap a hole to receive a horn in both fence bases, this horn has an external thread. The bridge horn has a female (the Bridge is not thick enough for male threads and there is no room to make it any larger than it is) The horns are about $10 from McMaster Carr.

Happy? 🙂

John

John,

I’ve been happy since I bought my first Bridge City tool; and they keeping better. Thanks for over reaching. This will be a silly wicked upgrade.

-Rutager

Rutager;

Thanks.

I am not done–you earlier birds are getting a deal–and I am going to get what I want. More to announce later.

–John

John –

Is there a turnip-slicing attachment for the new JMP fence?

Segmented turnips might bring your wife around and becoming a member of this drivel (and turnip-starved nation). Volume may be low, but much less costly than a move to Roger’s.

John

In all seriousness, thanks for the ‘real-time’ feedback in evolving and enhancing the design. The new handle looks like a great addition.

Now one question on the tablesaw sled…

How do you angle the fence? In looking at the photo, I don’t see anything that allows the fence to move – no slots through the wooden base to angle the fence. With the bridge the two sides won’t offset. Am I missing something?

neil

Neil-

The original aluminum angle fences for the JMP can be used to mount the extrusions to your sled stock. I will post imagery before weeks end. So rather than fastening direct to the sled stock at a permanent 90 degrees, both fences will now pivot. Two “t”-nuts per sled is all it will take.

Also, regarding the horn–it fastens to the bridge. For those with the SW, we are going to provide the identical horn that replaces the three wing lock knob of the overarm clamp. This will also work for those with the pro when cutting angles on one table only.

The feedback from you folks is awesome–and now, thanks to Roger, I am a bigamist!

-John

PS: When we get a chance, and just for fun, Michael and I are going to make our first parody video–we are going to use the JMP to cut a hot dog for lunch. 🙂

I love it! You could call your hot dog-cutting saw the “Don’t Stop”. Make sure you count your fingers when you’re done!

– Peter

John, good morning

.

Thank you for the modifications and the upcoming imagery (360 view?,,,, lol) (Does that include the adjustable bridge for the JMP version that you spoke about a few days ago?)

Question regarding the slot guide for the sled,

I’m considering making a rather long sled in order to accommodate wider stock and to prevent sled fall off/tipping pulling out further.

Will longer stock be available? (I think I’d rather set them one piece elements than setting one after the other.)

.

-roger

Roger-

I am suggesting that you gang shorter guide bars–longer bars have a straightness issue that it not worth us chasing economically. By standardizing the bar length, we can offer an optimal solution (for most) at the best price.

-John

360 View? Hang on, it’s coming!

John,

thank you for that “instant” reply’

One more thing,,,,,,,

.

Now that you got me taking a fresh look at my table saw.

I’d like to run by you my “Gull-wing” sled concept.

This would enable one to make an angled cut using the sled on a board size piece, let’s say a 12 inch wide piece for this discussion.

In building the sled you would need to picture a 1/2 inch euro ply base with a 3/4 euro ply top hinged along the (just before) blade on either side.

(yes, there is a little sacrifice to the max height of the blade) The slot guides would be attached to the 1/2 inch layer thru the top.

If one wanted to make a compound cut one would have to make the first flat angled cut and then the secondary cut in “Gull-mode”.

There would be two very shallow rabbets cut into both the top of the bottom layer and the bottom of the top layer perpendicular to the blade. (on both sets)

Into these slots would be inserted precut triangle (wedges?) set at different angles. (one would make a set of these, and custom ones should the need arise)

If necessary one could make two sets of these if one wanted to have a Gull-Wing carriage – if one had a large cylinder that you wanted to run vertical cuts into.

Or any myriad of sculptural forms.

Ok, back to my 12 inch board that we are cutting at 45 degrees, the board would be fastened down to the fence with the elbow clamps. (after having cut a clean edge)

On the back side one would use a pivot clamp to hold it securely (along two slots cut into the top 3/4 layer, similar to the slots on the sled in the video on post #9 above)

Before one were to angle the left board up into Gull-mode, you need to first take the right fence and slide it to the right to get it out of the way of the left fence tipping over.

At this point you would then raise your left wing and insert your triangle wedgey supports. (being mindful of the position of the blade of course)

And proceed with your cut.

If at any time one would want to use the “Gull-Wing carriage” one would have to slide to the left and the right the two fences a little bit.

your thoughts?

-roger

john-.

postscript,

Since actually both fences would need to be slide aside. ( when using one wing in Gull-mode, first being to avoid the blade, the second side to avoid the fences hitting),,,,,,

how adjustable will the rule atop the rail be?

Are they adjustable to fix increments or free floating?

Man-on-man divorce + cranks + hot dogs + parody movies=Brokefence Mountain

I forgot the horn…

Roger-

One step ahead of you. 🙂

Keep thinking!

-John

“Man-on-man divorce + cranks + hot dogs + parody movies=Brokefence Mountain…”

“I forgot the horn…”

Clearly the DSN are spending too much time on this totally awesome and worthless blog. GET BACK INTO THE SHOP!

John

PS: That was funny so you are excused.

John,

.

On your revamped sled will there be an adjustable back brace to support tapered rips?- forward of your upside down back “v” brace. (think a floating back fence that’s adjustable forward to lock in a workpiece against the front fence – with perhaps one pivot clamp midway if the work is rather large) Such a set-up is sometimes used on sliding tablesaws to accommodate odd rips.

This combined with a gull-wing type sled should prove to be a very useful option.

.

-roger

Roger-

I am not sure I get your idea-the sleds are constrained by the guide bars–they move backward and forward only (assuming you keep the thing screwed together).

I have had the rip guide for the JMP on the dwg board for over a year and it indeed works as a gull wing. I had to to the fence first because I need this fence for my own work, and, this device will fasten to the micrometer adjustor.

Let me know if I am being dense–or more dense than my normal denseness.

-John

John,

Not a matter of denseness, it’s more of a matter that I’m painting pictures with words, where words fall short.

This evening (later) I’ll have more time and I’ll approach it in a different manner.

Cheers,

Roger.

John,

Check your email, pictures of a mock up of what I talked about are included.

.

One thing that hasn’t been discussed to date in the blogs or in your product descriptions is the world of “JMP accuracy” that will be opened up by the table-saw sled for composite materials, plastics etc. that can’t be done on the JMP.

.

cheers,

roger

John,

There is another thought I just caught as I’m pulling out of a parking space, Starbucks in hand starring at the roof rack of the car in front of me.

By using two sets of rails front and back with a support brace riding on top of both rails one could then use that top brace as plateform to suspend holddowns. Thus freeing up the sled top in a particular set up.

Till later,

Roger

I’ll try and get a mock-up picture to u by tomorrow.

Roger-

Between coffee, and our pending divorce, are you getting any work done on your new shop?

🙂

-John

I’m multiple-tasking.

Today’s my last day of moving. Between the upcoming interior remodel of the guesthouse and “setting up” of the new space I should be ready by the arrival of the new fences!

.

Roger

Hoping this iPhone reply works.

Roger, buddy, will you stop it with the suggestions? If John keeps adding stuff you suggest I might not get my fence till next xmas….and if he gets a divorce I might not get it at all!! :)) So quit it!!! 🙂

Jorge,

I can’t.

It’s a condition I have.

I think it had something to do with a visit to Portland some time ago.

Anyhow, haven’t u realized yet?

This blog is actually a black hole in regards to anything outside of it.

That includes time!

– roger

John,

0n late lunch break,

But not a Jmp break!

Taking my focus off Gull-wings and overhead clamps, (for a moment) I’d like to draw your attention to the stops on both the Jmp and sled systems. Outside of a pencil mark is there going to be a way to store multiple settings on the fences? Something that one could set the flip stop against. Something along the lines of what u provided for multiple recordings on the Jmp for when angling the blade.

If not, could one order the fence with extra flip stops? Like u already have on there? And how difficult is it to add them?

-roger.

Roger;

Thanks to you, this Totally Awesome and Worthless Blog has now progressed to become the Totally Awesome and Worthless Black Hole of a Blog. Nice.

Regarding extra stops; NOTE: It should be obvious; only the L an d R blue stops index direct to the micrometer system. HOWEVER, you can use them to “nudge” the black stops in .001″ increments since this stop now floats (they lock to the traverse bar, whereas the blue stops lock to the lead screw). Originally I had the black stops on the lead screw and determined that was not very bright. So…

It is possible to have a total of 4 stops set precisely where you want–all systems will be able to do this. You can add extra black stops but you will lose about 1-1/2 of capacity for the blue index stop. So, yes it is easy to add them and we will make some extras.

Have you told your bride about us yet?

-John

Ok.

Click.

40 Comments.

This black hole blog seemed to have been frozen at 39.

Wow, that felt better.

Dang Roger,

I saw the 40 post and thought it was the surprise hinted at in #16.

Oh well the wait will be worth it I’m sure.

-Rutager

Rutager,

.

The follow-up from post #16 was exactly the one I had in mind when I attempted to “shake the tree” with post #40.

.

While we are on the subject, don’t forget post #22 – “(360 View? Hang on, it’s coming!”)

heh, heh.

.

-roger

Like you said I’m sure the wait will be worth it!