____________________________________________________________________________________________________

“After a time, you may find that “having” is not so pleasing a thing, after all, as “wanting.” It is not logical, but it is often true.” –Spock, “Amok Time” Stardate 3372.7

____________________________________________________________________________________________________

From the quote above, it looks like Bridge City will be around for awhile…

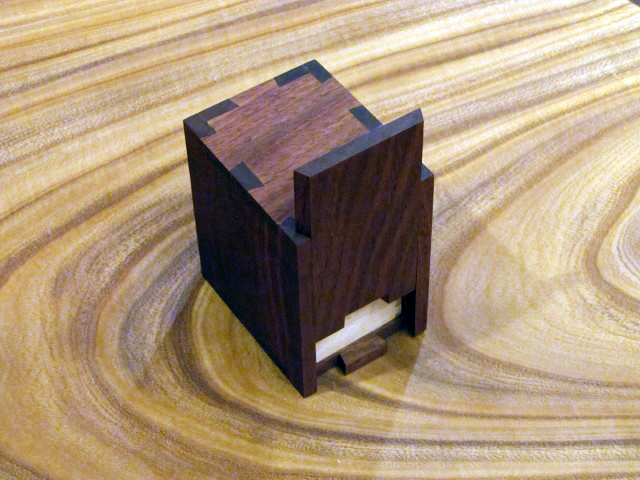

A couple of weeks ago I received an email from fellow DSN member “DJ”, aka “Dennis”. He is a JMP owner and had a couple of cuts that he felt did not lend themselves to the JMP and I wanted to see exactly what he was talking about. He sent me the following pics and with his permission I am pleased to share them with you–it is a cool project.

This project is a gift for a friend of his in Japan and I don’t know if he is back yet, but I think you will agree, this would be fun to receive. More on the difficult cuts at the end.

“I used the JMP for the length cuts, dovetail cuts, etc. on the trays. These went very quick and easy. I stacked several and zipped them out. The only problem was the sliding dovetail cut for the cover. I had to enter the wood on the corner of the edge and cut at an angle into the side piece. Couldn’t make that cut happen..”

Dennis was correct, the JMP will not do the puzzle cuts…just kidding. I do believe sometime next year the accessory to make that sliding dovetail cut on the JMP will be available. For those of you who have been working in wood for awhile, you know it is harder to do smaller projects well than large. There are very few bail out options when you don’t have much material to work with. Cool project Dennis!

Feel free to comment, but I can see several spin offs for his idea and I am keeping them to myself.

Lastly, one of you DSN folks needs to be honest with yourself and send me some pics so we can pick the 2011 Sh!t Bunny Recipient.

Oh, one more lastly thing—I do believe Fred West is still living with his Entertainment Center. Ouch.

-John

Dennis,

WOW! That is some very nice and small work. I built a 90 degree fixture and I posted it in the JMP section of the forum and I think that it would work for the sliding dovetail cuts, unless I’m missing something.

John,

I have a wood putty filled coffee table that I’ve been meaning to photograph for the Sh!t Bunny contest- it is actually serving as an entertainment center right now as my stereo is sitting on it.

-Rutager

Rutager;

You can’t win if we can’t see your Sh!t.

Did I just say that?

Oh well–the rest of you were thinkin’ it.

-John

Fred is indeed still living with his award-winning entertainment center. On the other hand, he has almost as much nice wood in his shop as Konrad. The only thing standing between him and a new entertainment center is … well … a plan. And lots of sawdust and shavings. And time. Lots of time.

.

But I hear he has lots of nice tools to build things with!

.

Dennis, wonderful work! I love the puzzle stamps. What a fun idea. My sister is really into hand-made jigsaw puzzles. She gets them custom-made with little pieces that look like animals or flowers. It’s a fun detail in the larger puzzle.

.

Don’t you love how John’s posts always allude to something new coming down the pipe? No wonder he put that epigraph to this post. Want? Yes, I want!

.

– Peter

Rutager,

Thanks! It was a fun piece to do. Your jig might work. The hardest thing for me was holding the piece rigid and straight enough to get a 60 deg cut started “right on the corner” of the entire length of the rip cut. It is a really tricky cut to make. I’m looking forward to seeing what John comes up with on this one!

John,

While doing this piece I was thinking the next (obvious) evolution of this is to make the box a puzzle as well.. I have some ideas about that as well….It might be a fun contest to take a basic shape and see what unique puzzle boxes could be derived using JUST a JMP, wood, and a touch of glue.

I might take the liberty to also ask our friends who visit this site a question? I was using a 2/0 blade to cut the puzzle pieces but on something this small, it seems like I used WAY too big of a blade. Are there recommendations for a very fine scroll saw blade to use?

Thanks for sharing this John! I will show this to my friend here in Japan tonight.

DJ

Fantastic piece Dennis. How did the recipient like it? Were you able to make it to the tool museum?

I look forward to such small scale work after the next run of JMPs.

Dennis:

Thinking out loud here… Would your rip cut been doable if you had not cut to net first or glued a small strip of scrap to the parent stock to avoid starting on a corner?

-John

Dennis,

Beautiful box, beautiful presentation!

You might want to check out Lee’s jewelry saws over at – http://www.knewconcepts.com/

Btw, I don’t think I’m seeing the end view of the wood the stamp is mounted on?

.

Regarding clamping down a thin stock I have a thought that could very well work with the new elbow and pivot clamps. Think of the squigy

….that is used in silk screening, it’s a hard rubber that is held by a long wooden holder. If John’s new fence could be parked on the jmp tables parallel to the blade the elbow clamps with an accessory interface – holding the “squigy device” – holding the workpiece/thin stock.

…but John may very well be ahead of me with his next image update!

-roger

…. In the meantime I concur with John’s suggestion above.

.

I don’t like blogging with an iPhone and big thumbs!

Ok,

I think I have this figured out; I’ll try it this weekend to see if it works out.

-Rutager

Webb,

Yes, it was well received. If I had made 10 such gifts, it would not be enough to repay the generosity being shown to us on our visit here. I was not able to get to Keoto. Maybe next trip, but this one has been action packed. I have seen more than you can imagine – GREAT trip! I just finished a night time drive through Tokyo and have seen the “big buddah” today. Amazing…

The stamps are simply glued to some 1/8″ dark hardboard. I would suggest using a thin film of white glue rather than just licking the stamps..

Thanks for the hint on the blades.

finally, I have to go right now, but I will think about gluing on a piece – that would help me, but I was having most of my problem just holding the piece tight enough to engage the blade well.

DJ

John

I think it’s time to produce the first Jointmaker Pro project book. I think it would write itself with input from all the users and publishing a dozen or so projects that you would shop test. It could be a formal book or something to buy through the website to download and print at the local Kinko’s or what ever form is appropriate.

For the best project I would be willing to sponsor a new fence system for the Jointmaker Pro as the grand prize.

What do you think?

John,

Awesome idea. I want to cogitate on the concept for a couple of days…. Your sponsorship offer is not only generous, but a real motivator….

I know one thing…we will throw in the Earthquake After Detector to really shake things up…

-John

Guys,

I figured out the sliding dovetails and ran a couple test joints and will post it to the forum when the forum will let me. I can’t log in today- had the same problem last week and Michael got me up and running, but same issue today. I have pictures and everything.

Best,

Rutager

Ok,

Michael got me back in the game and I posted my solution in the forum under “Jigs and Fixtures” in the Jointmaker section.

Best,

Rutager

Wow!

Thanks for going to all of the work to proove the method for sliding dovetails! I like that the blade will be held firmly as it enters the piece. Also, with your jig the piece can be securely fastened to avoid movement. This will work!

Have you started on a jig for the puzzle cuts yet?

Your help is really appreciated. This cut is very useful for small boxes etc. I think a lot of JMP users will find this post very beneficial.

DJ

Another potential issue is how sharp the blade is? Blade “wandering” occurred as it entered the rip cut (I did not change to a rip blade) this may also have contributed to my problems. I am probably due for a blade change and haven’t taken the time to do it.

John, Do you have some pointers on this? I know you probably have more “saw time” than anyone and I have been wondering about how closely I need to pay attention to this. What indicators do you use to determine when a blade change is in my best interest?

Dennis

Dennis,

I judge blade wear primarily by the quality of the cut. When I see, or feel a surface that no longer amazes me, I change blades. Blade drift is an automatic change out–defeats the intent of needing no further work.

The best discipline for blade longevity is to force oneself to take little bites and lots of passes. The rip blade can create an incredible finished cut but is prone to clogging so I don’t use it much since the cc blade does an OK job.

-John

OK,

It is time for a blade change on my saw for sure. Do you leave the blade cut inclination at the lowest level normally or do you adjust this frequently? I normally have left this at a low setting (at the bottom of the adjustment). Thanks for your pointers on this!

DJ

Just one other detail for what it is worth: The trays were made with a 1/8″ dado to hold the bottom of the trays. This can easily be done with the JMP by making the dado side cuts and a couple of center cuts and then just cleaning out the dado with a narrow chisel. The tray dovetails were made with a shoulder so that they could cover up the dado slots. I find it always the best option to make a shoulder on dovetails – especially on small work. This really helps to reference the piece accurately for marking the cuts. I made the dovetail cuts 1/32″ long for cleanup after gluing. You can also make a cut (to establish the dovetail shoulder) on the JMP, then clean out the rest on a scroll saw leaving the “tail” ready for assembly. You can imagine how the new fence system will augment the ability to perform a series of cuts like this – I can’t wait to get this mounted on my saw!

This piece surprisingly was made very quickly in a couple of evenings. I was somewhat focused since I had a deadline, but I could not have done this nearly as well using any of my other shop tools (and I have too many). The JMP is custom made for accuracy on small pieces. I’m just learning how valuable this tool is to my arsenal. I’m looking forward to making some other pieces soon! I saw one very promising design in a Tokyo gallery we visited. More on that later!

DJ

Dennis,

We recommend taking the deepest cut possible without feeling resistance from the saw. Let the saw (and you) do the work. Yes, we play with pitch before each use and it is variable that changes by species and stock width (number of teeth engaged per stroke). There is a cutting guide at the back of the manual…You do read manuals don’t you? 🙂

I agree, this is a phenomenal tool and all of my JMP’s are sitting idle waiting for the new fence system. This is going to change my life as I fully plan on getting back into the gallery woodworking world with what I have planned.

Thanks for sharing your thoughts-the JMP community is a fun one.

Others can chime in here-more is better!

-John

Geez,

READ the manual? Last resort…..

Great to know you are thinking of more gallery work! Be sure to bring us DSN junkies along on the voyage!

DJ

John,

When are you coming out with a dado blade for the JMP? I know, I know, …. Use the HP-6…. But it WOULD be fun….

DJ

Actually, the more I think about this, a dado clean out tool mounted on the JMP would be an interesting attachment! You could cut the side walls of the dado to depth and a couple of center cuts to weaken the fiber, then use the clean out tool to bring the dado to a precise depth! What do you think about this idea? It could be used for dados, rabbits, etc. Hmmm….

DJ

Dennis,

At WIA this past fall we did gang a couple of rip blades and it appeared to work at first…

It did make a double wide kerf which could be handy, but because the teeth location on both blades is identical, the crests of each tooth hit each other, so the identical set created a void between the bodies which soon filled with dust.

If we can find a way to stagger the set of the teeth, I am certain this would work.

Anyway, we are working on it…meanwhile, after the Precision Fence System is attached, you won’t find time to dream about dado cuts!

-John

Ok Everyone,

I sent John pictures of my “Coffee Table of Shame” for possible inclusion in the Sh!t Bunny award contest- It’s your turn now, don’t let me walk away with an easy win.

-Rutager

For dados, why not put two saw blades a certain distance apart, and put one of the HP6-v2 dado blades (or a chisel blade, or something) between them to clean out the space between the blades. If the system could be set so that the chisel blade was exactly the same height as the saw blade, and the whole set moved together, it could cut dados lickety split (a technical term). I guess the problem would arise form the fact that the saw blade can take a much deeper cut than a chisel or plane, so there might be a lot of jamming.

– Peter

Peter-

The governing factor which limits converting the JMP into something it was never designed to be is the saw spine. That slot will only allow about .060″ of saw blade material. In addition, the saw guides (which is why the JMP cuts as smooth as it does) will also only open up to the same .060″ width.

That said, there are other ideas that would work….

Patience folks!

–John

Rutager-

I am in receipt of the images of your table. It is bad, but… how should I say this… it doesn’t stink enough?

Here are the requirements for receiving the coveted Sh!t Bunny Award;

1. Maker must have a sense of humor.

2. Maker must recognize that they have made something that only their mother would love.

3. Maker understands that design is a much deeper discipline than woodworking techniques.

4. Maker agrees that he/she has learned from said entry and would never repeat whatever it was that should have caused the piece to never leave the cutting room floor.

5. Maker agrees that as a Sh!t Bunny Award winner, your name will forever be associated with, er, Fred West.

6. Maker understands that our promises of TV shows, red carpet appearances and yet to be named benefits were exaggerated a little. Maybe a lot.

7. Maker understands that the coveted Sh!t Bunny Award is recognized by the IRS as $19.95 of unearned income. FYI.

–John