___________________________________________________________________________________________________

“It’s not a party until the fire department shows up.” –Thom Filicia

___________________________________________________________________________________________________

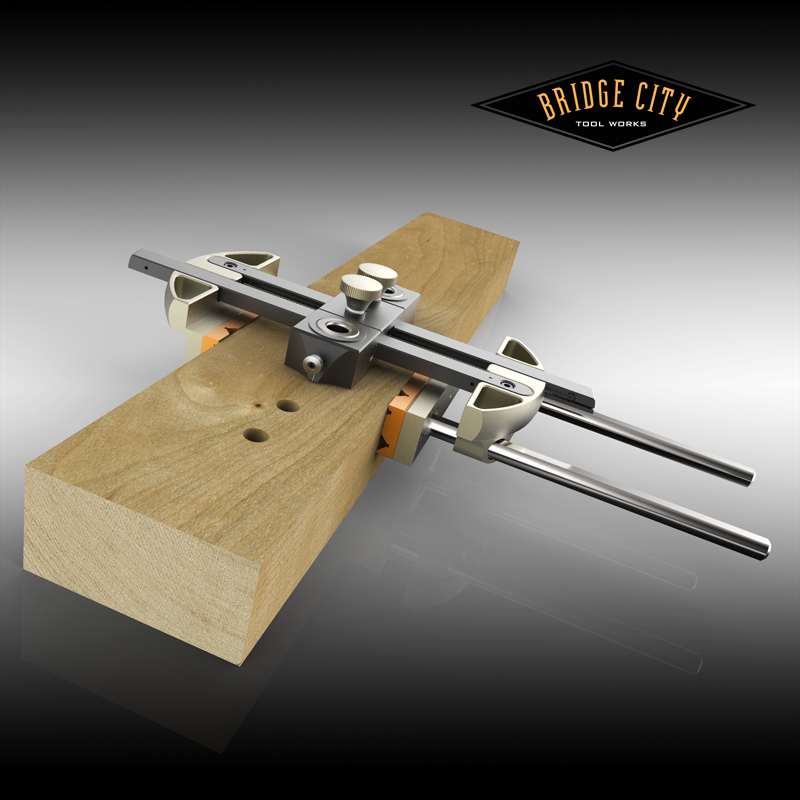

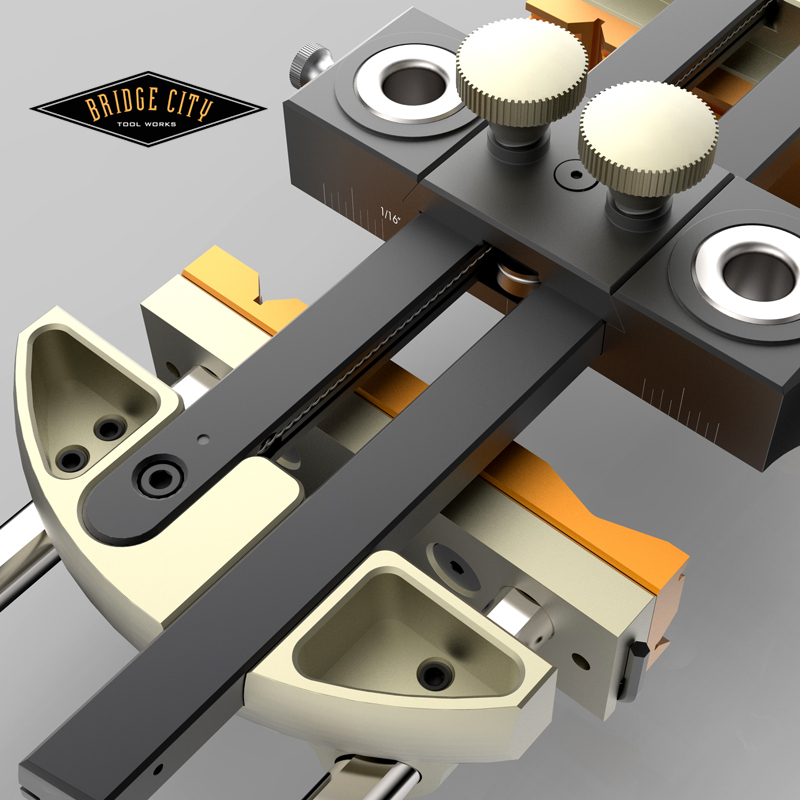

Last week I shared the new offset attachment for the DJ-1 Drilling Jig.

Certain vocal members of the Drivel Starved Nation insisted that I not sleep until “I get it right.”

One such member (name rhymes with Rutager Savatteri) suggested that if I were a Jedi Knight, the Force would abandon me.

So, not knowing what that really meant, I set out over the weekend to redesign the offset attachment. In short, the new design offers the following;

1.There is no minimum offset

2. Works with the Universal Jaws

3. Locks in place with set screws, integrated hex key wrench stores in jaw.

4. Will work in a wood vise

5. No need to attach/re-attach

To attach, you remove one screw on your existing DJ-1 outrigger, and attach the new offset jaw assembly.

Now let it be known that I listen.

–John

John,

Functional and SEXY! Hallmarks of a great tool.

In order to calm my guilt of you working the weekend, I’ll buy two. I’m still feeling a bit guilty, so Roger,Fred, Masood and Paul-Marcel will buy two each also. You’re welcome guys.

Best,

Rutager

Meekly he asks: how tough would it be to add a micro adjust feature for fine tuning?

Thanks,

Rutager

Too cool, John. What a beautiful re-design. I’m very impressed. You’ve really added a lot of functionality to both the DJ-1 and the offset attachment.

Hope you’re having fun stuffing decks of cards into bottles. Now, if you could get, say, a CT-18 into a bottle, I’d be really impressed…

— Peter

… and I’m particularly impressed with how you ditched the original design, and started anew. That takes a lot of guts – and inspiration. Kudos. Very impressive.

— Peter

… but how do you measure the offset? Calipers?

— Peter

John,

That Peter fellow is brilliant; since you know where zero is, maybe you could machine two flats that the caliper jaws could register on.

Best,

Rutager

Peter-

My magic class starts next week, but thanks for reminding me–been on DJ-1 mode.

Setting offsets from the centerline is easy-use a pocket rule. I will post an image tomorrow.

Changing designs in mid stream is easy if the “force” is going to make me a creative orphan. Besides, without Rutager’s orders we would go bankrupt… Actually, since we lose money on every order, Rutager is bankrupting us.

-John

PS: I like this variation-may change the CS-1v2 and build the offset into the CS-1 v3. Think Rutager would bite?

John / Michael,

Home Run guys!

That Italian Design blood is showing through!

I love it that it works with the Universal jaws.

I’ll take two as well!

I think I have just one question,

When DJ-1 gets seated in the table vise,

Looking at the new outrigger side below the new rods,

the part that would “shelf” on to the table vise…..

has less height than the other outrigger side.

If just left to itself the entire Dj-1 would sit crooked because of the imbalance of heights. With a shim on the non-jig side – all would be good. Is this a “Design moment”?

Should there be an aluminum shim that mimics the non-jiged outrigger? Or should I just be quiet and count my blessings? 🙂

May the Force be with you!

cheers,

roger

Yes

Roger-

I remember the day I quit wetting the bed, I think I was 28. It was a joyous moment.

Your approval, and blog binding order for two (accepted) is, imagine this, more momentous.

Knowing this, your silence to count your blessings is deserved.

–John

Roger,

Don’t count your blessings, count to two outriggers- put them on both sides, DJ-1 sits flat- you’re welcome again.

Rutager

Roger,

Rutager is on commission.

FYI.

–John

Regarding the aluminum shim,

this may be low tech-

but it could just be double-face taped to the bottom of the non-jiged outrigger-and blend right in.

.

:-/

Rutager,

.

Ouch!

Your right!

.

Shameless plug here…just learned that we have about 20 AS-24 v3s left.

Soon as they sellout we will unleash the DSS-6 for pre-order.

Did I mention that I have tamed sliding dovetails? 🙂

–John

Hmmm.

John?

Now that I have two new outriggers on both sides of one DJ-1, meaning I have double capacity potential…..

Would it be possible to order longer square tubes between outriggers to turn that double capacity into reality?

.

roger

Good Job everybody,

I am in for 2 as well. I was not going to get the last one. I am sure it was just a teaser knowing you and you were just playing.

but I think the new one should have a sexy Cam-Look and Micro dial.

Just my 2 cents..

-Masood

Sorry I mean Cam-Lock.

-Masood

John,

The redesign looks great.

Chris

I love the idea of a CS-2v3 having the same offset capability built in. But I have to echo Rutager and Masood: I’d love a microadjust. And a built-in scale. Using a ruler seems so… so… antiquated.

The microadjust wouldn’t have to be difficult. You could have a horizontal screw with two set screws. You put the offset near where you want it, and lock the microadjust to the rod. Then turn the screw (which bears on the outside of the jaw) to microadjust, and then lock the second screw to stop the rod from moving (or the screw from turning). Kind of like the one on some marking gauges, or the Festool router microadjuster.

— Peter

BTW, the horizontal screw would be a hollow tube, and the rod would pass through it. I don’t think I was clear.

— P

Round 6 here we come.

The force is strong with this design. Props for returning to square one. I love that I can use it with the existing jaws and is vise friendly. Dj-1 is perfect tool to keep a hand brace in line…literally.

Wow, I get busy for a couple days and this place blows up! 🙂 but in a good way!

Outstanding design, John. Also glad to see you basically scrapped the old design and started anew; bolting something onto the old one wouldn’t have worked well.

I’d like to see the CS-2 get a version of this although arguably the current offset plate isn’t bad.

Will you be incorporating this into future DJ-1 runs? I could see the DJ-1v2 coming out with this already part of the package.

Go ahead and put Roger down for two for me, too. 🙂

ok,

It’s past midnight, waking up and I’m staring at the new design and running the DJ-1 video and imagining the new jig in place. Both with one and two jigs attached. It’s a wonderful sight.

.

.

.

.

but,

.

.

there is still one thing gnawing at me as I run the operations shown in the video there are times when the Dj-1 is clamped to the workpiece using a quickclamp at 1.09 and 1.52 timemarks, where having a tad more holding space may be useful. Right now the new base that holds the orange jaws is the same height as the orange jaw. If you were to increase the height by about a 1/4″ (below the new bars) this may be an advantage in such a set up.

.

ok,

Now that I got that off my chest I could go back to sleep.

.

roger

“Shameless plug here…just learned that we have about 20 AS-24 v3s left.

Soon as they sellout we will unleash the DSS-6 for pre-order.

Did I mention that I have tamed sliding dovetails? ”

So John, does this mean that we need to buy an AS-24 v3 to be able to do our tapered dovetails? Seems llike a warning…………..:-)

The next morning,

Well, i think Rutager talked me out of the longer square tube options I spoke about above. But a larger clamping area below the new rods is still dangling like a carrot before me.

.

roger

Econ, fantastic re-design. I also very much like the idea of the microadjuster and Roger’s idea of longer square tubes so as to add to the potential of having an offset on both sides. Now and unlike Rutager who should have jumped all over this once he added the second offset for ONE DJ-1, those of us with TWO DJ-1’s need FOUR offsets. Please put me down for four and add Rutager, Roger, Masood and Paul-Marcel for the same. Just for helping out please charge Peter for two offsets as well. Now, you will be starting down the road out of bankruptcy on this product. 😮 😮

Fred

PS Yes, I am serious about four offsets.

Folks,

What use can you imagine where two of these are needed on one DJ-1? It subtracts about 3/4″ of capacity. FYI

What the heck am I missing? Are you worried about vice use?

The “force” is clearly not with me this morning.

-John

John,

Roger pointed out that the new outrigger bars wouldn’t allow the DJ-1 to sit flat on the top of a vise, I jokingly replied that he should buy a second one to balance it out- now apparently I have singled handedly doubled your sales!

The only reason a second one would be helpful, in my opinion is if you are so lazy that you don’t want to flip the DJ-1 around to offset the other direction- being that lazy would probably get in the way of even owning any tools at all.

Best,

Rutager

I think they’re asking for *both* more cowbell *and* fewer notes, Herr Mozart.

Rutager/Roger/Mozart, et al;

OK-we will throw in a spacer for you folks to balance the jaws on top of your vice jaws. One last thing-

anodizing is more art than science when it comes to colors other than black. The odds of this attachment matching the champagne static jaw color perfectly is likely zero. Is this going to be an issue? If so, then we will change the color completely.

–John

John,

No problem with color, especially if it sports a nice micro-adjust. Like a third threaded rod in the center with micr dial on it. with a cam lock on top no set screws needed.

Masood

“PS: I like this variation-may change the CS-1v2 and build the offset into the CS-1 v3”

I think the existing blue plate works great with the cs-2:

— You don’t have the clamping concerns with the CS

— it’s quick and easy to install

— it keeps the whole tool small.

— integrated offset scale is very convenient. Set your mortise width and go.

The new design which works so well for the DJ, would be overkill on the CS-2

Slight color change is not an issue for me (though if you use more of that blue on your tools in the future, you’ll see more green from me. That blue is far an away my favorite of the anodized colors.)

John,

Thank you for the spacer-lift, I didn’t know earlier that we lose 3/4″ with the new jig- so that will help with my dedicating one off set jig for both Dj-1’s.

Regarding the champagne question, it’s a non-issue-it all sizzles the same.

.

What about rutager’s micro adjust?

🙂

.

Roger

John,

Not super concerned about the color being off a tad, although, maybe instead of using a spacer, just include a matching static side with spacer built in, so they will match for sure. Not sure what that would add to the cost- maybe offer that as an option, or toss out the price and see what the interest level is. Roger, Fred, Masood and I will each take two.

Best,

Rutager

@Roger-

Actually I was mistaken-there is no loss of capacity with this jaw replacement. That said, nobody needs two on a single DJ-1. The spacer will work fine, and if we decide this is going to be a permanent change to the DJ-1v2, we will mill new static outriggers with the step built in. At that time we will offer it those who want it.

Regarding Rutager; He has bought 82% of every DJ-1 we have made, so guess we have to have the micro adjuster. Film @ 11. Or tomorrow.

–John

John,

I agree with Webb on the CS-2; the current offset attachment works wonderfully in that tool. That said, putting the new version in it would visually “rock,” and I would buy it- Roger, Fred, Masood and Paul-Marcel would buy two.

-Rutager

John,

Micro adjuster? Be still my beating heart, better duck next time you see me, because I might try and kiss you on the lips!

The ability to micro adjust right to the line will be sweet- thanks!

Best,

Rutager

P.S. Just kidding on the first comment; trying to make Fred jealous.

Rutager/Fred;

I listen but I ain’t kissin’.

–John

John,

I just want to say that I’m very happy with all the final adjustments to the DJ-1 Sidekick Jig.

My hat is off to you and that magical Portland Air.

hmmmm,

So the question remains, if I combine this with my JMP will it also allow me to do Rip Cuts?

😉

.

cheers,

roger

That was an “ewwwww” moment.

“I just want to say that I’m very happy with all the final adjustments to the DJ-1 Sidekick Jig.”

Roger: Final? But… WAIT–there is more!

–John

John,

.

Hmmm,

Round 6 here we come.

Ok,

I’ll start the volley of what will come next,

🙂 😉

In the top picture the DJ-1 is set up for a 90 degree hole drilling. Let’s say you wanted to make that an 80 degree hole in relation to the above surface. (Right to left of the workpiece, not end to end) With the present set-up now one would have to fiddle with shims against the universal jaw in order to angle the work to fit for the bushing to drill an 80 degree hole.

What if,

.

.

The bushing itself would be able to pivot like the hands of a clock against the travel bars and lock into segmented positions?

.

always,

roger

What if,,,,,,

.

.

There would be a “flag-pole” like reference point that would be set into the new jaw outrigger (the part that is holding the orange jaw) in order to use the AMP-V2 to set the workpiece within the DJ-1 and would then the flag-pole be removed once the setting is locked.

.

What if,,,,,,,,,,,,,,,,,,,

.

.

Recessed into an optional orange-like jaw would be two mini-rollers (or ball-bearings) into each jaw to help facilitate placement as you are positioning the workpiece for a series of holes.

As you tighten the jaws the rollers or bearings would recess into the jaw.

.

What if,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

.

.

When making repetitive holes,

Attached to the bridge element (the bar holding the two bushings) was an “element” that would peg into the previous hole to act as a self indexer . (Think of the Festool Domino and it’s peg system for the same task.)

.

What if,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

.

.

After the two present out-riggers are replaced, they would then be serving as bases for the DJ-1 when doing work and you didn’t have a table vise at hand, and needed two hands to operate your hand brace.

Into the bottoms of the new outriggers would be two female threads machined on either side of each outrigger. Then you would insert two pole elements into each threaded hole for each outrigger. All of this would somehow be attached to the old outriggers. There could be different size pole lengths.

.

Gotta love that peg/indexing system for a series of holes. Nice one, Roger!

Okay – they’re all pretty fun ideas. You must have had some good coffee this morning!

— Peter

Peter; Would you please drive up to Roger’s and disconnect his internet service?

Thanks!

–John

Peter,

Actually I was drinking an afternoon Hayles Valley Expresso by http://store.bluebottlecoffee.com/categories/Coffee/, and sitting by my Koi pond.

I think there is a primal thing going on with the Koi.

.

cheers,

roger

.

The indexing thought bubbled up in the rush of Koi.

All awesome ideas, Roger… quick! roll on the floor! you’re on fire! 🙂

I don’t know john – you could easily imagine what might happen if I go up to Roger’s. I’d get sucked in, and you’d get twice the crazy ideas…

— Peter

Ha, Ha.

.

opps.

the dizzy spell is happening again,

.

.

What if,,,,,,,,,,

.

Now since we have those bars that extend outward from the new outrigger –

The DJ-1 could very elegantly mesh with the Festool rail system. So one could very accurately drill holes over a larger field.

.

How?

Not dissimilar from a clunky jig I made a while back, that used the Festool rail. But this time we have those new rods, another sleek element could be clamped between the two rods on the outside of the outrigger and ride (and lock) onto the Festool rail.

later,

gotta run,

roger