___________________________________________________________________________________________________

“A perfection of means, and confusion of aims, seems to be our main problem.”

—Albert Einstein

___________________________________________________________________________________________________

Yesterday we actually built this version. I can’t speak for Michael, nor would I want to, he disagrees with me too much, but I know he likes this version as much as me.

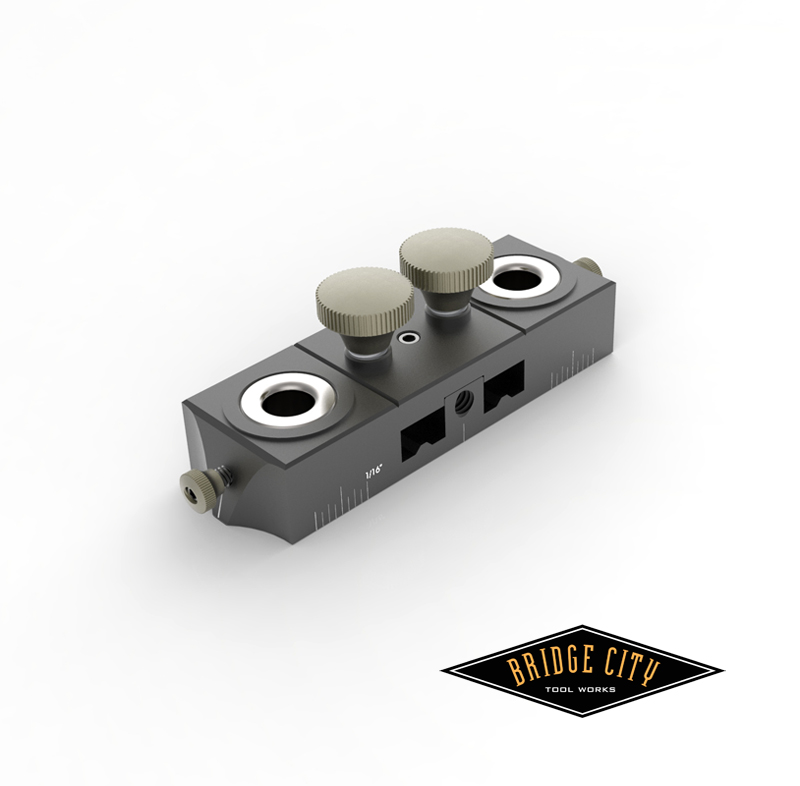

It all starts with a revamped bushing holder–it can be used by itself and we have added tapped holes in the side for what ever contraption you conceive to hold the bushings over a surface.

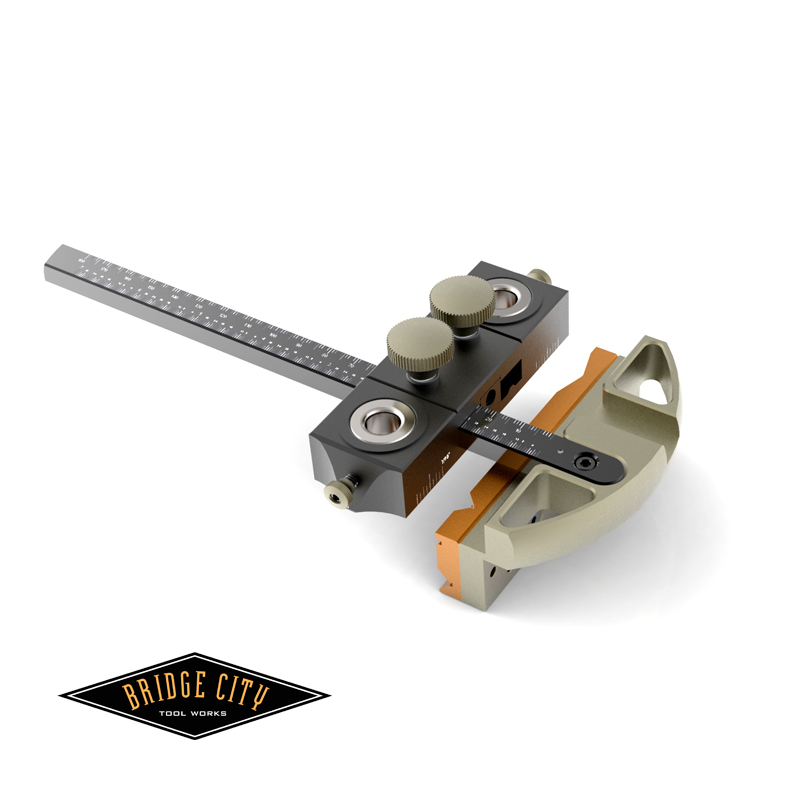

If you want to drill a hole on a plank (bookshelf holes for example), slide in one arm and set the jaw to your desired center line from the edge using either the imperial or metric rules.

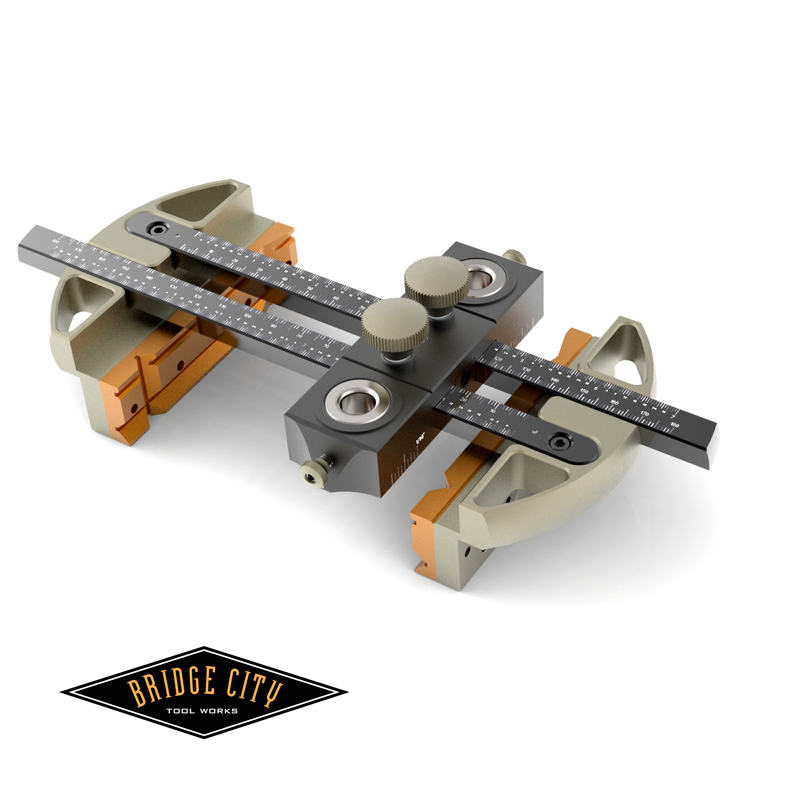

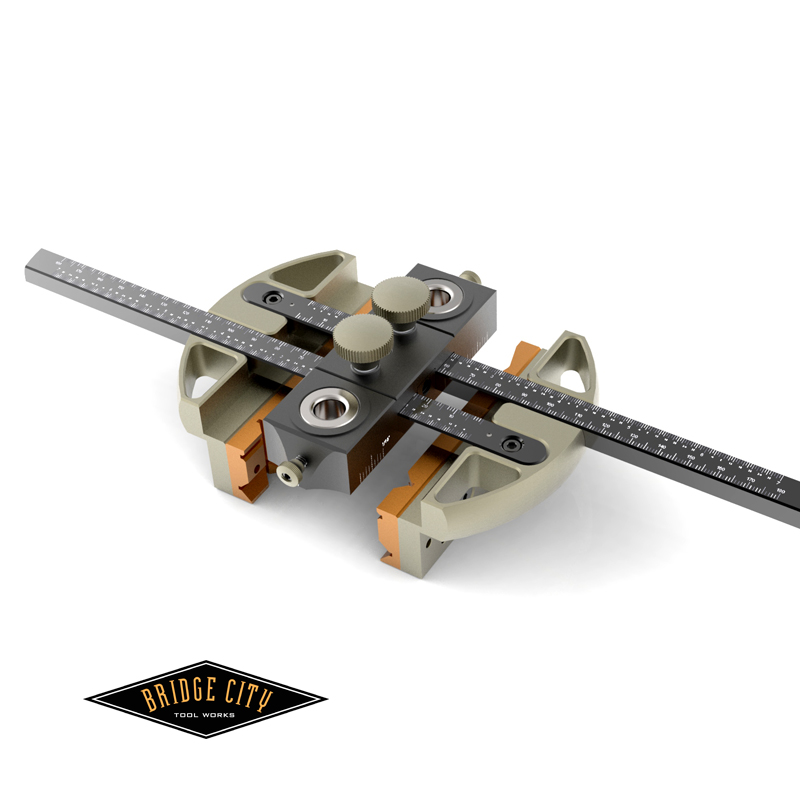

Off center holes are easy, slide in the other arm-the graduations indicate the distance of the jaws from the edges. The bushing housing slides so effortlessly across the beams… so smooth in fact Michael guarantees you will have an uncontrollable desire to call an 800 number that charges by the minute… Did I just say that?

To center drill, I recommend using the metric scale, you are not measuring, you just want the same number on the left as on the right. Your center will be within .005-.01″; it is easy and fast.

The answer to off center drilling was under our noses the entire time. This will work with the Universal Jaws, and our new lock system locks 100%–no give or wiggle anywhere.

I am sending this out for pricing, but in my opinion, this makes the DJ-1xxx a better tool for less cost.

What is not to like?

Thanks for all the cool feedback–especially from the Thursday happy hour bunch…

–John

John,

I like this for a couple reasons: one it will allow for the offset; and two, allow more people to achieve DJ oneness. Having more DJ-1s in woodworkers hands should make it more feasible for you folks to offer more attachments to do yet to be determined cool stuff.

Best,

Rutager

Very elegant. Looks great, works great. What’s not to like? Nice work you two.

.

“…but I know he likes this version as much as me.”

Are you saying that Michael likes you as much as he likes the new DJ? I’m not sure I’d know how to take that.

.

— Peter

John,

I think you (& Micheal) really did it this time.

I’m holding my original version in my hand as I look above and I say,,,,,,YES!

Ok, some “optional” questions,

.

1. Are you going to make the bushing holder available?

You know if u wanted to get crazy and have the option for set “sets” of holes. (yes, I know one would have to have two sets of bushings)

.

2. Now that we don’t have cables to contend with, can you make longer lengths of the bars available?

btw, nice move there with the tapped holes on the side!

.

have a great weekend and week away!

.

roger

Ps. When I said make the bushing bar available I meant as units by themselves – in addition to the one in the set.

It’s a handsome tool, John. Tell Michael those numbers have 976 prefixes…

It looks like a DJ-2 to me. I use my DJ-1 for drilling the center of rounds as much as anything so the self-centering cables are very handy. Rather than switching the tool back & forth perhaps consider making this the DJ-2 offered as a complete set. The offset feature will be great however looking at it now (no cables) you are just a “braining session” or two away from enabling the bushing CL’s to be adjustable for drilling various drawer pull CL’s, etc. If not a variable spacing bar perhaps offer the bushing bars in fixed spacing of different lengths.

“Set the jaw…using…the…rules.” “The graduations indicate the distance of the jaws from the edges.” The beams/rules will obviously be inside the bushing holder, so will the scales on the beams be “slid over” to show distance of the jaw from the center of the bushing holder?

Oops, my mistake. The grads indicate the distance from the edge of your stock to the drilling centerline.

@Ron: Working on a body that does some interesting things…. Won’t be this year though.

–John

I like it. Somtimes simpler really is better. I do really like the idea of offerring longer bars.

dmarkowi,

976 numbers are pretty cheap and lots less exciting compared to 1-800-253-3332; that one always cost me more than $4.95 a minute, although I don’t ever recall being asked what I’m wearing.

John,

My understanding is you will be in class with Marc Adams; the two of you together could be pretty disruptive in any class. Question is: what office can you guys be sent to if the principal is one of the troublemakers?

Best,

Rutager

P.S. be wary of sushi joints in strip malls.

John,

Really beautiful solution. Count me as one more for the longer bars. Can’t wait to see what you do with the body next year as I love Ron’s idea especially if the bushing center lines can be on a variable spacing bar. 😮

The good news is that apparently Rutager will eat at a Sushi bar as long as it is not in a strip mall. I am pretty sure that we can accommodate Rutager to a “high class” sushi bar in either Pasadena or Cincinnati. 😮 😮

Fred

Elegant simplicity! If we could only tap that brain power at BCTW as an alternative energy source….. Longer bar option would be nice.

Dear Mr Magician, opps John,

.

One little thing,,,,,,,I was having a conversation with someone here about the DJ-1 (who has two names for a first name – French Influence) ;-).

And we both mentioned, one little, itty bit, possible room for improvement on the next generation DJ-1’s.

And that’s the way the bushing is held in the bushing bar.

Is there something that could be done to prevent it from more than occasional slippage? That indent works, but I feel it needs just a little bit more magic.

.

thanx

roger

Wow! I like the results.

I have a couple thoughts.

1- How difficult would it be to add a scoring blade/scribe bit to the bushing set?

2- If you made the bars longer, I think everything would need to be scaled up. I’m not sure it is worth it.

3- Micro adjusters are cool.

4. I can see a tool being built that does more than just scribe lines and fix drill bits. Maybe something to help with hand cut mortises.

5. I need a better job to pay for these toys.

Charles,

“2- If you made the bars longer, I think everything would need to be scaled up. I’m not sure it is worth it. ”

.

Them’s fighting words.:-(

Why would everything need to be beefed up?

All u are doing is positioning a bushing somewhere on a work plane in order to drill a hole. Once u start that hole there is a “mechanical” connection between bit and workpiece, literately at that point the DJ-1 is just along for the ride.

.

The longer bars would enable one to position the DJ-1 over a wider location then it can at present.

cheers,

roger

I like #4, Charles. But I think it’s a different animal.

— Peter

Leverage-multiplied stress on teensy connectors and threads comes to mind as a problem with longer posts.

Tool Potentate Here;

We can add a couple of inches and that is it, and we will. For longer offsets, you will make your own trammel bar . Or we can make one…

Hmmm…

–John

Does this mean that the one I just purchased will not work with future accessories or will you continue to support the old format?

The cable version is not becoming obsolete from an accessory perspective.

–John

It would be nice if a “bare bones” option would be available – no jaws or bushings, that we can attach all our DJ-1 stuff to.

Alex-

Completely agree!

–John