___________________________________________________________________________________________________

“A gentleman is a man who can play the accordion but doesn’t.”

— Unknown

___________________________________________________________________________________________________

First, for those that follow this Totally Awesome and Worthless Blog (about 2/3 of the total population of Earth last count–amazing isn’t it?) you are likely aware of Drivel Starved Nation member, Rutager West. Besides being a great customer, he is a fervent contributor to our forums and is likely the world’s foremost authority on our DJ-1 Drilling Jig and perhaps the Jointmaker Pro–and of course, bacon.

Rutager is also an avid bicyclist and commutes 20 miles each way to work in St. Paul, MN. Friday, while riding to work in frigid weather, he hit a patch of ice, crashed, and broke several bones in one leg–not unlike a compass needle that points both North and East. Not good. He has had surgery and now will have a difficult time passing through airport screening. The good news: He has not lost his sense of humor–and I am guessing as he re-cooperates he may enjoy hearing from fellow DSN members. rutagerwest1@gmail.com Sorry Rutager, had to do it.

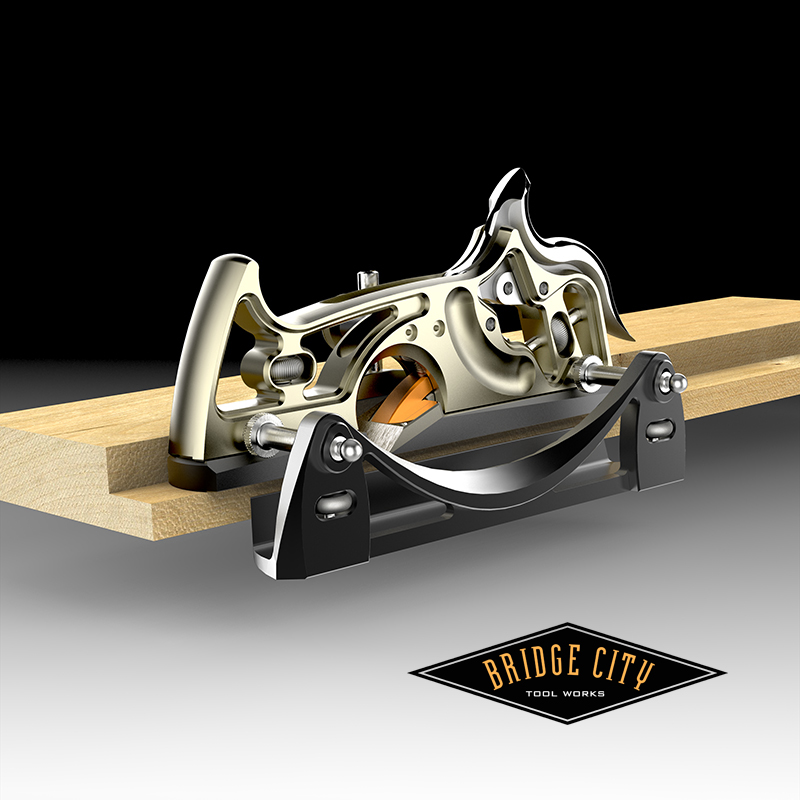

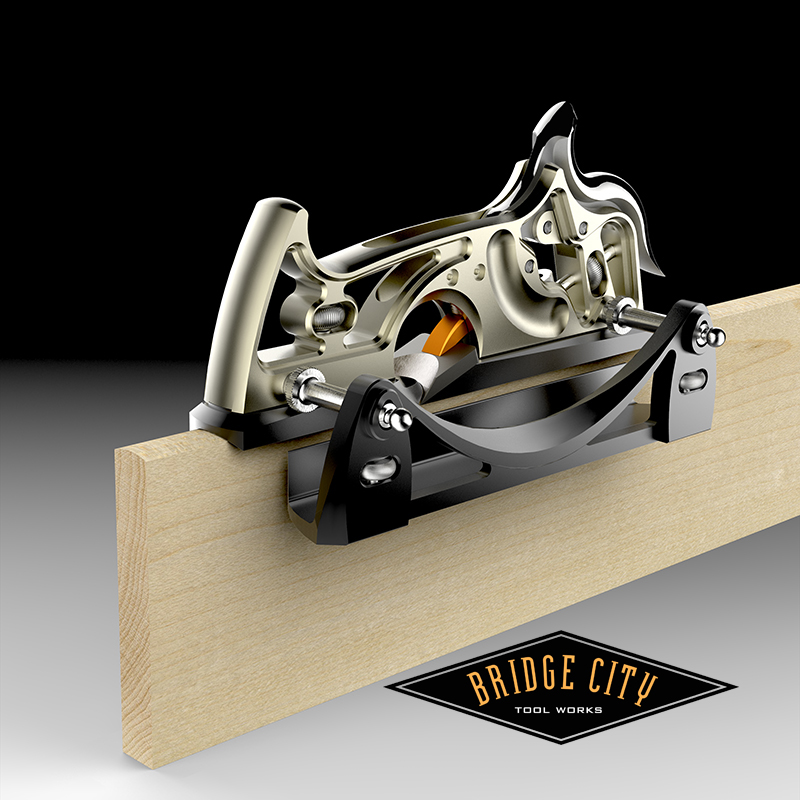

I am really excited about adding our newest creation to our Bridge City Essential family of tools. As mentioned in previous posts, our focus is creating tools that not only work, but take up very little space. The value proposition of this new tool should be enticing to many. Please meet the HP-10 Foxtail “Convertible” Plane…

The HP-10 Foxtail is primarily an all aluminum plane, and we will reveal full specs in a couple of days. Since I have been gone much of the year, and you are likely starving for more drivel, here are a few pics illustrating the many functions of this versatile plane.

Here is the setup to precisely cut rabbets;

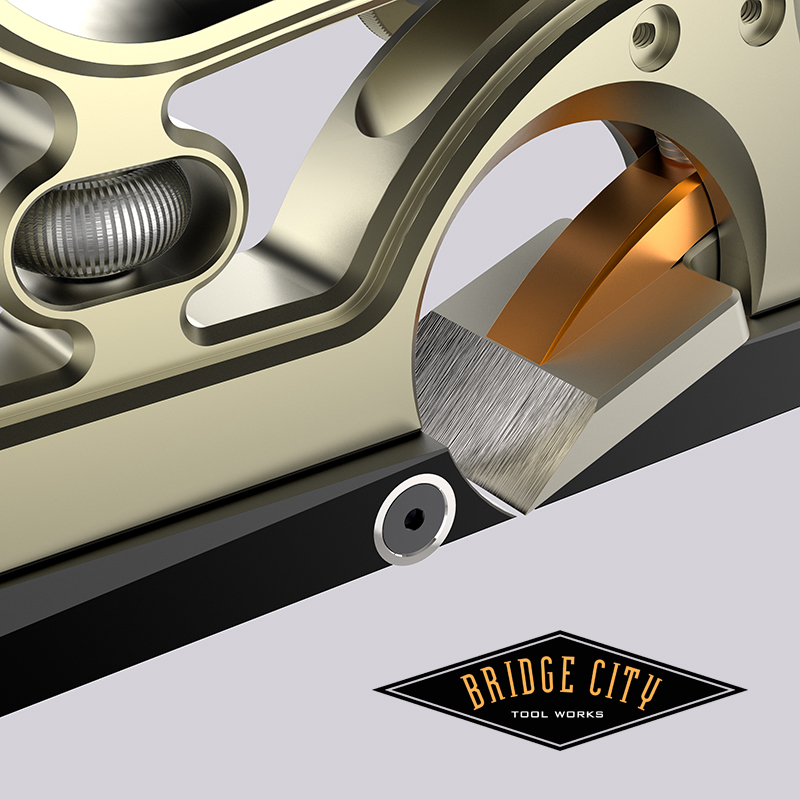

Cutting both with the grain, against or across is a breeze with the circular scoring cutter;

Here’s a view of the rabbet depth stop, which like the fence or the scoring cutter, can be attached to either side of the plane body;

The first of the many conversions possible with the HP-10 is the obvious shoulder plane;

And my favorite decorative cutting plane of all time, the crown cut conversion;

This plane is heading where the capacity of the HP6 leaves off–because of the larger body and improved grip, we will be able to add conversions down the road. AND, we are going to add them in a really fun way, we will decide here, on this blog!

Lastly, before anybody has a cow, there is an HP-9 plane, it needs more work so this plane skipped ahead.

–John

John maybe I’m being paranoid but that second-to-last statement seems to imply that the HP6 will be dropped or abandoned or worse. The statement that this “…is heading where the HP6 leaves off…” has me quite nervous. I was not aware that the HP6 actually left off.

Is bad news in the future of HP6 owners?

NO! The HP-6 is here to stay!

What I meant to say is there are some profiles that we cannot do with the HP-6 and this has to do with the ratio of the width of the cuts and the length of the plane. For example, the smallest multi-bead sole kit for the HP-6 is pushing the limits of the capacity of the tool. If you flattened that profile you will see that the actual cutting width of the shaving is significantly wider than the HP-6 body. Basically, this is the main reason larger moldings are made with a combination of hollows and rounds–you would need a locomotive to pull the plane shaped to make the entire profile.

Another example; the HP-6 is a great rabbet plane for small rabbets, but not for larger rabbets. Make sense?

Sorry for the panic attack–I would have felt the same way, I love the HP-6–there has never been anything like it.

FYI: We would be committing corporate suicide if we torque our HP-6 owners.

–John

Thanks John. All better now… Sorry for the palpitations.

John,

Too bad you where unavailable when I called you from the hospital (BCTW is my emergency contact) I was just lying there bored and looking at a couple hour wait for surgery, I was also “hopped up” on morphine from the paramedics- dang man, you probably missed some interesting conversations!

As long as it’s included in a blog by a tool as cool as this one, you can give out my SSN# and bank PIN too.

Being a member of the DSN and therefore smarter than most people, I’m guessing that the Fab 50 Crowning Plane and Rabbet Plane will also accept any of the new soles, correct? Your answer will not change my HP-10 order.

While I’m asking questions, is this new plane going to eliminate the skeletized HP-7 bronze plane that was talked about a few years back?

Great tool, as usual, of course letting us know that there is an HP-9 sitting in the que, is just going to get you multiple phone calls from Fred begging for info.

Best,

Rutager, the guy who broke the cardinal bike rule of “rubber side down.”

Rutager-

I did not include your address because your refrigerator is not big enough for all the free bacon the DSN would send your way.

Yes, this plane replaces the skeletonized HP-7.

The soles will fit the fab 50, but the plane wont work. I had to change the internal guts of the plane, and the body, to house a modified clamping mechanism that addresses irons with different lengths.

Wishing you well, we can’t imagine what it would be like here if you were to miss a paycheck.

Lastly, if you need additional MORPHINE, contact Fred West–he has to have plenty of that stuff to live with his Entertainment Center…

–John

John,

I’m supposed to use my tools?

No worries, Michael can get his boy new shoes still, I’m sitting on 500 hours of unused vacation/ sick leave and hopefully will be able to do a couple days of office work each week.

Please only give out my address to available pretty women- Peter or Fred in skirt and heels don’t count.

Thanks,

Rutager

john, how are the galvanic issues with aluminum and dissimilar metals resolved. can the iron be left in the plane without issues?

i’ve got an old airstream i want to renovate down the road and i’ve noticed that there is significant fastener erosion where the sides are fastened through the floor. the aluminum and steel have just eaten each other up over time.

thanks for the heads up re: rutager’s fridge. i just cancelled the bacon delivery.

Whoa Dave,

Let’s not be so hasty about canceling that bacon, just see if they’ll deliver inside, I just got groceries delivered and just moving 4 bags about 15 feet has left me hurting and winded, I’ll move the rest later.

Now back to planes, John,

How are dovetails looking for this baby?

-Rutager

Dave-

The really short answer is I don’t personally know, but I do know that your experience is possible. According to this resource, galvanic corrosion in dry conditions is not possible.

http://www.aluminiumdesign.net/design-support/aluminiums-corrosion-resistance/

-John

DSN!

Rutager has some time on his hands… FYI.

Rutager;

Because of the iron pitch, I cannot make a dovetail iron for this plane. Yet.

Working on a couple of novel approaches! I for one would like it a lot!

BTW, the first-article the HP-6 dovetail irons came in and YIKES! You are going to like it!!! I am changing the width of the iron to track in the center channel of the HP-6 body, and yes, it still maintains lateral adjustability.

-John

Yes, lots of time, one working leg and a shop at the bottom of a circular staircase. In a day or two, I’m going to investigated going up and down the stairs by butt, if it works, I should be able to get a bit of stock prepared and lucky me, I have JMP with precision fence in the living room to work with. Wish me luck and if you live nearby, your phone number so I can call you to get me out of the basement!

Best,

Rutager

rutager, hesitant to try to order the bacon again. afraid i might get into an order loop like the bctw clearance sale fiasco. sorry. however, as an alternative, you can at least catch up on the missed episodes of the united states of bacon to see what you have missed.

are you in john’s april masw class and will you be healed by then?

John,

WOW, what a great couple of days. First there was Rutager’s good news. You know, about his new bike being ready and now the HP-10. 😮 Now, if only there had not been that disparaging remark about my morphine, I mean EC. I have to say it has really grown on me and has to date generated TWO mascots in the Sh!t Bunny & Ecoli, plus $200.00 in BCTW gift certificates. I have decided that until I know that the spigot has turned off, I may as well keep it, eh? 😮

Great plane John.

Fred

John, the HP-10 looks like a great plane! I think a popular new profile for it in Minnesota would be the VTB (Variable Thickness Bacon) – used to slice bacon off the bulk slab in varying thicknesses, depending on the severity of the needed fix. Of course that would require special jaws in Rutager’s leg vise.

And Rutager, get back on your feet soon!

Yes, I’m signed up for the JMP class in April and am very much looking forward to it. It will be right after my 8 week recovery. I have almost no pain now and barely touch my Tylenol and haven’t had the Oxycodone in several days. I hope to be healed earlier than normal so I can make the drive.

Best,

Rutager

First, let me add my sympathies to those directed at Rutager. Hope your leg mends well and quickly.

John,

So none of the sole/iron combinations for this new plane will work with the SE Crowning Plane? I thought you indicated there would be additional profiles when it was introduced. (Or was it just a hint?) That was certainly a big factor in my decision to purchase one.

John

Rutager/John, and other SE 2012 future owners;

I was mistaken–the SE version of the Rabbet Plane and the HP-10 are 100% compatible. Me getting old I guess…

John

Wow Rutager, sorry to hear about your leg. You were always my hero for the miles you put on with your bike. (Still are!) Hopefully you will be back to normal by the time the snow is gone.

I’m still confused about the new plane. Did you say there is going to be a bacon slicing attachment???

Honest to God, I spent the weekend designing some furniture that needs this plane. I was frustrated when I couldn’t find what I needed in a hand plane instead of router bits.

I had a $150 solid carbide router bit come flying out of my router table the other day. Looks like a bad collet. I literally hid behind my board when I saw what was going on until it hit the Sawstop (it does stop things!) and went crashing to the floor. I can now verify that solid carbide is brittle and will break when it hits saws and concrete, so no need for any of you to repeat this experiment.

I lost part of my thumb to a router accident 17 years ago. I am now officially afraid of routers, and need many more hand planes. Or i need to quit making stuff with wood; my health is having a hard time with my hobby.

John: that’s a handsome hunk of aluminum!

I got thinking: given that this is aluminum, and not brass or stainless (or iron), some thought has to be given to mass and weight distribution. A quick Googling established the relative densities of aluminum and brass as 2.70 g/cm^3 and 8.4 g/cm^3, making brass more than three times as dense (I’m accepting someone’s entry on Yahoo answers for this, so YMMV).

I love the skeletonized look, but physics being physics, something’s gotta give.

You being you, I’m sure this has all been taken into account.

Dave “Doubting Thomas” Markowitz

rutager, glad to hear you are not planning to ride your bike to masw. however, with the new modified electric model and a sidecar you might have cut quite a picture tooling on down the road.

Dave-

You keep doubting–you are good at it. 🙂

We won’t dissapoint–aluminum is much “stiffer” than brass. Here is some brain food for you;

http://en.wikipedia.org/wiki/Young's_modulus

–John

If your are talking about making crown cuts with and oversize radius bit in two passes, been there done that. This is way better, and no sanding!

-John

John: I was more thinking the thing would be too light rather than that it wouldn’t be stiff enough. A rabbeting plane seems like the sort of application where the “oomph” of a dense metal would be desirable. Perhaps you mean a stiffer material better transmits energy from the user than a more flexible one?

FWIW, and I’m no expert when it comes to such things, but you’re one of two plane makers I’ve ever heard of using aluminum for the body of any sort of hand plane.

I’ve had a lot of thoughts about density lately (call me “dense”!) relative to mallets–if you ever make a new model of the DB-2, I’m in line. The options out there range from light to ugly. I’m thinking of getting something and trying to turn a nicer handle.

Dave-

Some of the finest planes in the world have wooden bodies. As long as you know how to sharpen, you will like the results. AND, not having a lot of mass comes in handy for long planing sessions.

Mallets are indeed a fun tool to ponder, and I think you can design e a dandy one that fits your hand perfectly. And if you do, post a pic!

-John

Point taken about wood…but wooden planes seem to substitute bulk for density. Having doubted enough for a day, I’ll take your word that it works out.

I’ve been drawing mallet handles on my phone for two weeks. Your Android users might have fun with an app called draw(er). I am. It isn’t CAD, but I don’t know how to use CAD, so I’m perfectly satisfied. 😀

John,

I think we need a new award… In honor of Rutager’s accident we should have the $hit, I’ve fallen and can’t get up award. You can design a custom BCTW tool made of bacon. It will not plane or chop wood, but you can wood fire grill with it.

That’s good wintersedge,

I did lay there for awhile figuring the pain would go away and would continue my ride, then after a quick leg inspection realized that the pain was not going away and I better wiggle over to my bike and get my phone, because at 5:30 am at single digit temps, The trail wasn’t going to have too many users.

Okay, back to planes, I think that so many of our beliefs about what makes a plane work well may or may not be valid. I suspect that aluminum wasn’t readily available and certainly not anodized when metal planes started coming into their own; by then, brass and steel had become tradition and accepted and strictly followed. Thinking about the HP-6, the brass body is much heavier than the aluminum, but both plane equally well, even with wide profiles. I’m looking forward to seeing what this one can do, and we even have similar brass and stainless versions for comparison.

-Rutager

John,

Got any pictures of 45 degree fences or planing skids?

Thanks,

Rutager

John,

Are the handle and adjusting knobs stainless, or will they be aluminum too?

Thanks,

Rutager