___________________________________________________________________________________________________

“I think animal testing is a terrible idea; they get all nervous and give the wrong answers.”

— A Bit of Fry and Laurie

___________________________________________________________________________________________________

Yikes, have we been busy around here. The Drivel Starved Nation must be…starving!

This is a friendly reminder that for those of you who are making pieces for possible inclusion in the “Quality is Contagious” exhibition, you have until July 1 to get your piece to the Museum. For those who submitted work for the book, I have been told that one piece was accepted. Nicole is sending out notifications this week and making arrangments for the safe return of the submissions.

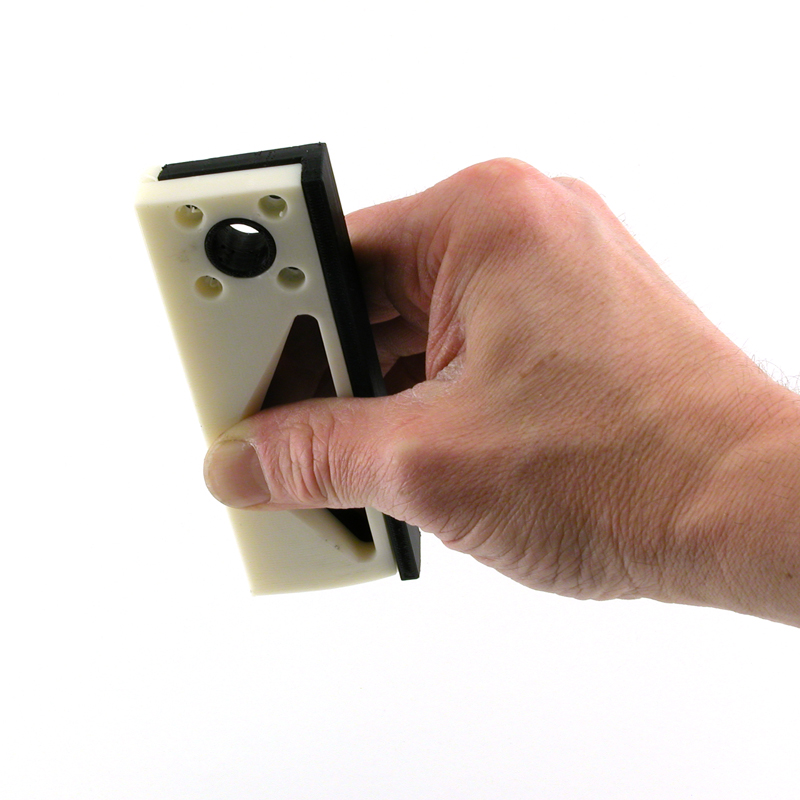

We are 30 years old this year and are busy making presents that you can buy for yourself (we are always thinking of you). What better place to start than with a new version of the TS-2? Please meet the TS-2v2;

We are making two versions, all aluminum and all stainless steel. The later will be a limited edition.

We invented a whole new way to make a precision square (which as you can see, doubles as a dovetail square) and you can get the idea by looking at the non-stainless version in the image above. The two aluminum squares in the image above are actually the same tool, it has a split personality.

After making well over 100,000 try squares we have learned a few things. One of those “things” is when a square hits the floor, the corners of the blade frequently flare. We solved that little annoyance by rounding the corners, and it makes all the sense in the world, there is no function for a square corner on a square blade. Oh, and the blade is field adjustable.

That said, the grip on this tool is off the charts, maybe it will never hit the floor…

We will open up pre-orders next week, but here’s a pleasant surprise: The aluminum version will be under $100. Want to know how cool this is? The original TS-2 sold for $45 in 1983. This inflation calculator tells us that the TS-2 would sell for $104.89 today. How cool is that?

-John

John,

Very cool, that’s how cool.

That’s one beautiful square and I think the market has a very limited selection of accurate square available for under $100, I hope you’re ready for a flood of orders.

Best,

Rutager

John,

The stocks look amazing. I don’t have use for the dovetail square feature in the blade and have to wonder if other cutout shapes will be an option.

Chris

John,

How is the re-squaring adjustment accomplished?

-Rutager

Chris-

What did you have in mind?

-John

Rutager,

Loosen the four screws and re-square. Fast, easy and accurate.

-John

John,

Chronologically, this is what I thought of:

-a 1:6 dovetail taper;

-an ice cream cone (just round the top);

-flames;

-a stylish flourish; or

-a solid blade without a cutout.

Chris

Chris,

We could do 6:1.

I designed the tool with an anthropomorphic theme; you are looking at a little cheerleader yelling “Do perfect work!”

How about we cut out the letter “F” for your version? The ex-teacher in me has just graded your suggestions. 🙂

-John

John,

If I’m looking at the “cheerleader” part right, it appears she’s pregnant; I suppose for some, that would be considered doing perfect work!

How limited is the stainless version going to be?

Thanks,

Rutager

Man, I wish I’d had that square today! It’s stunning!

— Peter

Rutager,

Does under 10,000 work?

Don’t know as of this writing to be honest.

-John

John,

I understand your position. If you would cut out an F on my version, I’ll order one for sure. But I’ll tell people it stands for Flair.

Chris

Hot stuff- Happy anniversary!

N

I hate to be a pill, but are you considering doing a version in metric?

— Peter

Metric? Absolutely. The blog is a DSN snack, not the whole meal.

-John

Burp.

And speaking of essential tools, what has happened with the BCTW Essentials? I believe that Rutager did a count some months/years ago, and discovered that we’re still a few tools short of an essential complement. It strikes me that a TS-2 is pretty essential. You might want to save yourself some work and just declare it so.

Just sayin’…

— Peter

Mr. Economaki, (my aren’t we formal) you stated that the price of the aluminum version of the TS-2v2 will be under 100 dollars, which, when compared to the price in 1980, hasn’t risen much when inflation has been calculated in. My question is have you got a price for the stainless steel version locked in yet? My suggestion is that you keep it around the same price as the aluminum square. I don’t think that will happen, though.

Paul,

The last time somebody called me Mr. there were blinking red and blue lights in my rear view mirror…

The price of the stainless version will be between 3x and 4x of the aluminum version. We are waiting for the quotes to come in. That is my best “thumb in the wind” guesstimate. So you surmised correctly.

-John

Speaking of essentials; when is the TB-2v2 going to be introduced?

Alex-

What a group of task masters the DSN has become! Geez…

Oh, the TB2v2 is…drum roll please……….. NEXT!

There you have it. Don’t ask the date either.

-John

That’ll be great!!! (Especially if it’s field adjustable….)

Great square John!

I hope this is the beginning of a long list of “presents” that will be available!

.

hmmm, one thought (request?)

I hope I’m not stepping out of line here,

but at the short end of the blade wouldn’t it be handy (at those odd times & just because) to have a center-line marking when you are doing your etching. One just below the ratio mark at the short end of the dovetail marker would (could) be handy as well.

;-/

roger

hey,

While your at it, perhaps some incremental marks on either side of the center line at 1/16th increments would be handy as well.

(not to mention the same for the metric version)

.

Did I go too far that time?

.

Roger;

Thanks for the comments, but I don’t agree. The dovetail cutout exists so that you can layout pins and tails of infinite size.

You always go too far. That is your strong suit!

-John

Striking while the Schwarz iron is hot. I approve.

Totally unrelatedly, I just finished resawing a roughly 6″ x 18″ piece of ugly figured maple (sold as “character grade” birdseye) into two roughly .25″ boards using a JS-8. It only took about a month and probably 80% of the useful life of the blade. It was totally the wrong tool for the job (although it is “rip-crosscut”) and if I try such a fools errand in the future, it will be with something longer and more rippy–and I have ideas on starting and maintaining the kerf… Still, I felt like Arthur pulling Excaliber from the rock when the board came apart this morning! Why mention? I felt like crowing!

What is the TB2V2? I can’t seem to find a TB or a TB2 anywhere on the web site.

Jim

Jim,

The TB2v2 has not been announced yet – it is a month or two away. It is our 30th Anniversary t-bevel.

-John

Crow Away!

John,

TB-2v2; I hope it will be sporting one of those wonderful cam locks, best method for securing a blade I’ve ever come across.

Regards,

Rutager

Yup.

The cam lock was what I had in mind, also. If you designed that after the first of the year, we must have experienced a NY wine mind meld. (inside joke!)

Perhaps it’s my computer screen, but I see an orange-looking layer inside the handle cut-out. Is that actually there, or just an optical illusion?

— Peter

Your screen is fine. It is a splash of orange.

-John

And is the orange part of the tool? How do you get it in the stainless handle? Is it anodized aluminum? Does it have a function other than color contrast?

Inquiring minds want to know. And me too.

— Peter

Peter,

The quest for answers has placed man on top of the tree of evolution. If I told you want to know, you might quit climbing branches.

Discuss the mystery of the orange amongst yourselves! My lips shall remain sealed!

Am I hilarious or what? 🙂

– Your friendly and elusive Tool Potentate

Okay, I’ll take a stab at the orange; unless it is another layer of the tool, I don’t think it is anodized. It might be painted though. As far as purpose, it is there to inspire and possibly make for a quick visual reference when picking up the tool.

John,

Yes, you do think you’re hilarious and there is a lot of what too!

Definitely “or what”.

I’m thinking you used leftover JMP tables, sliced them up, and inserted them into the slot you needed to mill to insert the blade.

Rutager – do you really think that painted metal would wear well in the handle? I could see it in places that wouldn’t get touched, but I’d think it would wear out if handled all the time.

— Peter

I’d think it is a layer in the tool; perhaps orange rubber or some other grip-friendly material.

The hilarious part must be due to the wine. Not that there’s anything wrong with that.

Hi there guys. Sorry to throw water on you Rutager. REALLY I AM… But John wouldn’t sell us paint. I’m just sure of it. It is actually quite easy to insert an orange colored layer between the two halves of the handle. Now the real question is: “is it for aesthetics or functionality”?

I do have a comment about the TB2v2: I’m sure everyone has their preferences on T bevels, but I have always preferred the type that have a lock at the bottom of the handle (like the TB-5) because for me it is most functional. When using a T bevel with a side lock the hardware gets in the way when flipping it over to make dovetails, etc. I think a new T bevel should be the SIZE of the TB-2, but with a lock like the TB-5. One man’s opinion only here, but I would be interested in hearing what others prefer on this subject also. Actually, I have every one of BCT’s T bevels, but the one I always grab is an old Stanley bevel because of the two things I just mentioned. It bugs me, because I get more endorphins when using Bridge City Tools so I’m depriving myself of that good feeling every time I use the Stanley…

DJ

Observation: orange covers the interior lip/chamfer on the tan half of the handle and stands a bit proud of the black side, but leaves the interior lip/chamfer on the black side exposed. I’m guessing it provides a cover for the seam between the two sides, improves the grip by creating a ledge, and provides some added stability in the joint between the two halves.

Dave “Wild Ass Guesses” Markowitz

Dave (Sherlock) Markowitz,

NICE job! I think you’ve got it!

DJ

Peter and Alex

I don’t believe that the scale of the tool would lend itself to having much wear on the orange area; might be able to get a finger or two in there, but most likely you wouldn’t hold it that way. Milling a slot and inserting a orange anodized inlay would work well, so I rescind my painting comment and agree with Peter on the insert; the handle is already in two pieces, so an inlay would be fairly easy to do.

Best,

Rutager

John,

No where in the description did you say this tool is damn sexy, it is damn sexy, isn’t it?

-Rutager

John,

Love the orange in the aluminum version; did you try black or another color in the stainless to see how it would look?

Best,

Rutager

I’m going to insert my personal opinion here: I’m not a big fan (without having seen it in real life) of the orange accent on the stainless square. I LOVE my DSS-6, and I think that having this TS-2 match the DSS-6 in its simplicity would be a nice complement. Let the curves and metal speak for themselves. Now, if the orange accent is functional, I might be persuadable that it should be there…

— Peter

P.S. It took a great deal of sublimating my Canadian-ness to actually state an opinion here. I hope you appreciate it! 🙂

Orange and black are a classic look, but I’m kind of thinking like Peter on the stainless steel piece. A black insert would be all of the color I would want on this one. P.S. that was quite brave of you peter 🙂

DJ

John,

Are there any more thoughts on creating a left side extended table for the JMP to fit two fence sections on one side for cutting rips on a bias?

Don’t overlook that the stainless version could get the black chrome accent and be the CS-12v2’s little brother.

-Rutager

Whoa Rutager! Now THAT would be DAMN sexy! Peter would have to agree I think. but then, I’m not sure I have the authority to make that classification stick. I’m not the most potent tool potentate here…

I LIKE your idea Rutager 🙂

Dennis

I agree – very sexy. Hard to believe it came from Rutager. He must have been surfing the internet again…

— Peter

Peter and Dennis,

Thanks for the votes of confidence- probably best not to admit to it in writing, but we all make mistakes. Don’t be too surprised with my insights into great tool design; I am after all, a three time Tool Making class attendee, still no diploma, but I’m sure that is just a coincidence.

Best,

Rutager

Rutager,

If from dumb luck, honed skills, or just raw talent, Your Idea is still a good one :o)

John,

I was thinking after the August bash I might take a drive down to the coast. is there any particularly great place to go / stay for an evening along the coast? I would love to experience some quiet beach with breathtaking beauty at sundown. Maybe reflect about life and the fun of living in this world. 🙂

Dennis

Dennis-

It’s cool you are coming to Oregon!

My tip is to drive south on 101 and you can make all the scenic turn-outs without crossing the opposing lane.

The entire coast is freakin’ awesome and all of the shoreline is publicly owned… No chain link fences running into the surf like I saw in CA.

Depending on your time, I would drive far enough south so you can head east and visit Crater Lake. Awesome!

-John

This sounds great John!

I’m trying to rough out my trip. I’m planning to come from Idaho down the Columbia river to Portland. I think the Mount Hood day trip is just before Portland and I thought that would be fun to take in. Probably a good day just to see that?

Since several DSN are going to be there like Fred, Rutager, Masood, etc. I really couldn’t miss it!

DJ

If you have never been here before, get a giant rubberband to keep your jaw attached to your skull–the Columbia gorge is beautiful.

If you turn left at Hood River to come around Mt. Hood, you will miss all the waterfalls. I would do Mt. Hood another day.

-John

Well, I ordered my stainless TS-2v2 with a black insert today. I’m betting that between Rutager and Fred, almost all the 300 of each are sold!

— Peter

Peter, Fred bought all 300. We can’t fill your order.

Fred has an eBay listing for $1200 apiece. Apparently they are all sold too.

Sorry!

-John

John: an update on your e-bike experience would be interesting. I’m bike shopping, almost certainly for a conventional bike, but I’m due-diligencing. Many thanks.

LOL!

Guess I’ll just have to get one from Woodpeckers. They’re the same, right?

🙂

— Peter

My e-bike rocks! I have over 1K on it now (saving three tanks of gas…almost $200) I have since taken another old Trek, stripped it, powder coated the frame white, converted it to a FWD e-bike, added oak fenders and gave it to my wife. She then added an iPhone holder to the handlebars. Go figure.

I will try to do a post on it soon.

-John

Thank you. My current pipe dream bicycle is a Brompton folder converted to a Rohloff Speedhub (you should look up Rohloff–they’re like the BCTW of bicycle drivetrains–14 internal gears and a 500% ratio bottom to top 😀 )