Drivel Starved Nation-

As mentioned earlier, we are short-staffed here until sometime in March due to my travel schedule. Tomorrow I leave for my annual work retreat and I have so many ideas to persue…can’t wait to get started!

First, we are shipping the final 25% of the TS-2v2 Try Squares and here are a couple of answers to the most asked questions;

1) The inserts (either orange or black) float in the handle, they wiggle by design. Besides the cool decorative element, they serve as a flange to help in dis-assembly.

2) The stainless blades, because of the dovetail cut-out, are laser cut not ground. This creates an edge that is dead straight but not quite as smooth as a ground edge, so that too is by design.

3) The finish on the blade is a semi-matte finish to help with the readability of the laser etched graduations, it also is much more fingerprint resistant.

We have assembled about 1/2 of the FC-1v2 Flushing Chisels and they are gorgeous. We are waiting for the last batch of irons to arrive (next week) and those will all go to our fulfillment facility and will soon be shipped.

All of the components for the HP6v2 Male Dovetail Kit are complete. We are waiting on the adapter clips for our sliding parallel (they are at the anodizer) and that job will ship.

Lastly, the HP6-FX is waiting for a couple of turned parts and it looks like it will ship in three weeks. The CT-18 is finally coming to fruition. I saw the first-article of the body last week and it is stunning. The rest of the stuff we have in the pipeline I will update later.

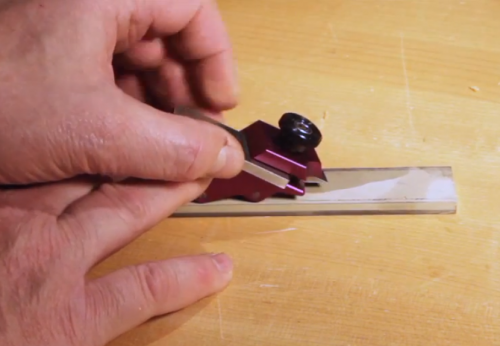

Regarding our tapered sliding dovetail system, below are two videos regarding the irons. They should help you understand how this works. If not, holler back and I will do my best to explain.

Here’s how to sharpen both irons;

httpv://youtu.be/nKK-0Pwl4p0

Here’s how I set up the female cutter;

httpv://youtu.be/bAlRvCmZJlw

Happy New Year DSN, I will be back in three weeks.

-John

Tapered Sliding Dovetails: Setting and Sharpening the Irons…