As many of you know, we are wrapping up the best sale we have ever had on the HP6v2 Mini Multi Plane. This has precipitated many questions about sharpening profiled irons. Hopefully this totally awesome and worthless blog will set the record straight.

It has been suggested that the Bridge City profiled hones are not necessary, that one can make their own hone simply by planing a profile in a hardwood, and hone using diamond paste.

True or False?

Let’s start by assuming that however the iron is sharpened, the intent is to maintain the decorative, factory profile over time.

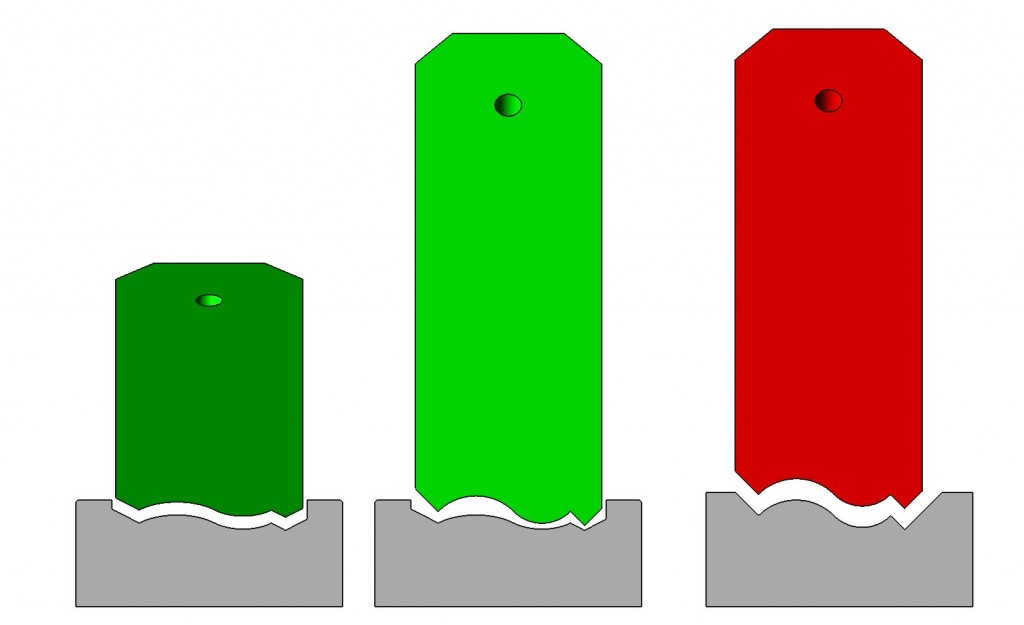

The illustration below is a front view of the same profiled iron. On the left, you can see the relationship of the iron to our custom hone when held in an invisible honing guide at 30 degrees to the hone surface (which is identical to the factory grind).

On the far right, you see the iron pitched at 55 degrees (in the same invisible honing guide). Because the iron was used to create the profile of the wooden hone, the edge of the iron and the surface of the hone are an exact match.

The center image illustrates the difference of the iron pitched at 55 degrees and the hone which was designed for the iron to be pitched at 30 degrees for sharpening. Quite a difference.

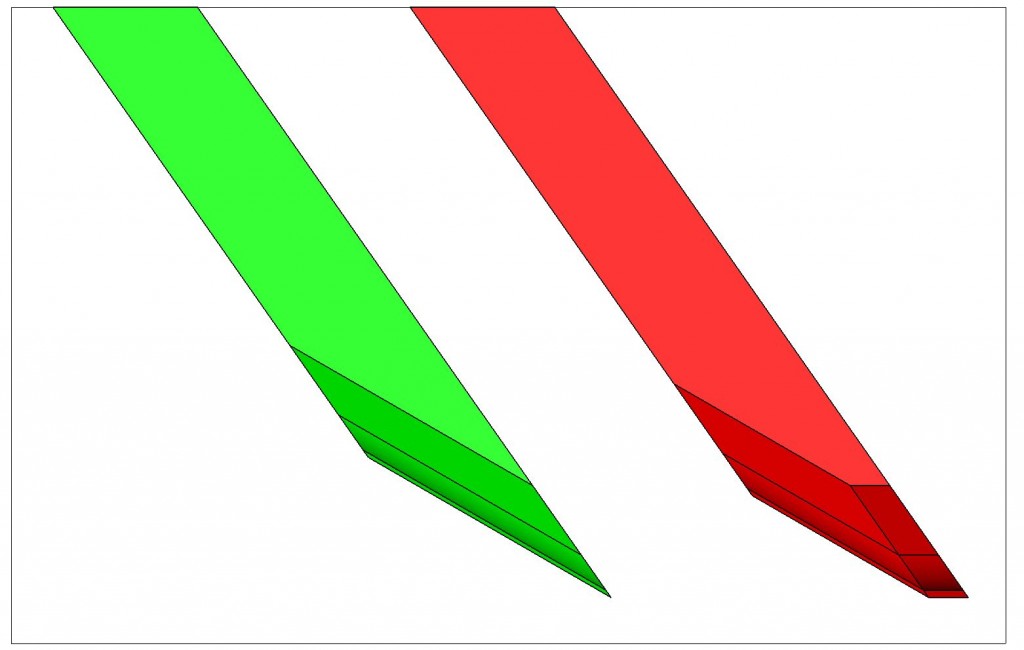

Take a look at the illustration below. The green iron has an attack angle of 55 degrees and the iron is sharpened to 30 degrees. The red iron is also pitched at 55 degrees. Look what happens to the factory edge after sharpening on a homemade hone that used the iron for the hone profile. This iron has been “dulled” 25 degrees. A 55 degree edge is not very sharp.

But what does this really mean?

First, the good news: the red iron will cut the exact same profile as the green iron.

But consider this; you will immediately notice the added force required to cut, your cuts will need to be more shallow and you will need to make more of them–obviously.

Now imagine the edge of the red iron over time. At some point (after enough sharpening) the factory grind will completely disappear leaving zero clearance between the cutting edge and the metal that follows (which occurred after the very first sharpening using this method). Zero clearance is rarely good but ignoring that, drag increases (again) and burnishing will occur (burnishing can really mess with some penetrating finishes) but–it will cut the identical ogee profile. It might be reasonable to expect that the edge will last longer because it is not as sharp…but when you factor in the added passes due to the added resistance–I don’t know if that claim is logical.

So–true or false?

I say tr….

Hope this helps.

–John

Thanks for info on the honing issue. I had the Hones in my favorites list for a few days. I Just ordered them. One note on the diagram. I got the explanation but I think the middle diagram should show the home made Hone and the 30 Deg Iron. Unless I am completely confuse.

By the way I recently discovered BC. your staffs are great.

Masood

John,

Is there a hone for the surface cove profile?

Regards,

Guy

@Masood: Pleased to have you join our family of crazy tool folks. Regarding your illustration comment, If you can imagine the middle diagram upside down, the image would be as you suggested.

‘

@Guy: We have not made them yet and we are going to make them in the next couple of months.

-John

This would be a great moment to announce you are planning another run of the HG-1 honing guide. I am admittedly biased in thus matter, but gladly so.

Those lucky few who purchased that big bundle actually beat employee cost!

Also, for you folks who bought the bundle but missed the deadline on the two new profiles, we are making a small over-run, but not 50. Call 1-800-253-3332 and see if Natasha can get you on the list ASAP.

Now about the hones…

-John