________________________________________________________________________________________________

“The key question isn’t “What fosters creativity?” But it is why in God’s name isn’t everyone creative? Where was the human potential lost? How was it crippled? I think therefore a good question might be not why do people create? But why do people not create or innovate? We have got to abandon that sense of amazement in the face of creativity, as if it were a miracle if anybody created anything.” — Abraham Maslow

________________________________________________________________________________________________

With the help of Drivel Starved Nation members (who might get FIRED if they don’t get back to work and off the web…) I am pleased to pass on the following works in wood;

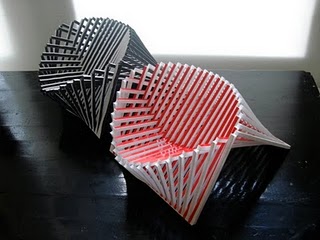

This from DSN member Peter Franks who would like to share the work of Robert van Embricqs (video link) ;

I will admit, I am addicted to art. In my home I have a couple of spaces that are patiently waiting for their ability to serve their master by hosting an art piece. One such space is my covered front porch. I think this piece by Jeroen van Laarhoven would be great!

The metaphors, and whimsy of this piece make my day–what looks haphazard is really an inspired bit of thinking. If you look at this piece for a minute or so you will feel it. It is fun. It is joyous–and in its simplicity there lurks a rare, emotional gratification. And the one thing it isn’t: plain vanilla. Works for me.

Now…who would want to sit next to me? The most obvious and easy choice is …

OK! I had a major relapse–could be worse!

–John

PS: What is the biggest perk of working at Bridge City? May through October each year our office is open Mon-Thurs. The customer service staff is here 8-5 and the rest of us 7-6. Oregon is paradise (most of the time) during these months and rainy Nov-April. You know what I do on Fridays for the next six months? Yup, come in to the office. For the past 5 years I have been trying to change with the exact same results I had when I dumped Megan Fox…

Hey John,

After seeing pictures of the machining of the ct-17, I know you can appreciate this table from Jeroen Verhoeven. It’s a favorite of mine. This version was milled out of a solid block of Carrara marble. Definitely not flatpackable!

http://www.artnet.com/Galleries/Artwork_Detail.asp?G=&gid=424521042&which=&aid=424915125&wid=425930946&source=inventory&rta=http://www.artnet.com

Cheers,

Niels

Niels: That is incredible–AND, he made 6 of them. I would love to see it in person.

Thanks for sharing!

–John

I love that van Laarhoven ice bucket, too.

Why not get the three-person chair? Then you could get Megan Fox and, say, Cameron Diaz to join you.

Wow, but that carved marble table is astounding. It’s amazing that the marble has enough tensile strength to not break after so much has been removed.

Thanks for sharing. Cool stuff!

– Peter

The van Embricqs chair reminds me of a garage door designed by Santiago Calatrava. You can see it at http://kibsgaard.se/CALT/EW/EW.htm. (The second row of photos shows the door opening; you can click on them to enlarge.)

-Steve

Love it, Steve! That’s wonderful.

Now I have to go and remodel my house to get that door. It would work so much better than the panel door that I have – I’d be able to put lights over my workbench where they’d be otherwise shaded by the door when it’s up. Brilliant!

– Peter

Steve,

The concept of that door is closely related to the container McDonald’s uses for French fries…in a loose way of course, but the similarity is uncanny.

-John

It’s all parabolas and hyperbolic sections. A hyperbolic surface is an incredibly strong and rigid structure, even when made of flimsy material. That’s why we always “cup” the page a little bit when we’re holding a magazine. We’re shaping it into a hyperbolic surface so that it won’t flop over.

– Peter

Here’s a video of Los Tres Juanes – http://vimeo.com/22647179

It prompts thoughts of how any tool can be used for good or evil, a chisel or a 5-axis mill. There was a time when I’d have resisted mightily the notion that machinery that I associate with hands-off serial production could be used to express craftsmanship, but I’m thinking that a more open philosophy fits me better as artists and craftsmen learn to use cad and cnc machines expressively. It’s a fuzzy line, however, tweaking other sensibilities when a guy in Bahrain or Greenwich wants an ornate coffered ceiling that can be made by hands over the course of years or with the aid of cnc machines in weeks. I understand how design becomes constrained by the specific capabilities of a machine and like it when machinability is enhanced by a craftsman’s comfort with other tools to make something more than what’s described in a .dxf file, but what about when a design that I deem perfect requires nothing downstream of the vertical machining center more than a little paring, deburring and assembly? I’ll stop here, for now, because this becomes a rabbit hole for me and I’m interested in what you thoughtful people have to say.

Gary

Gary;

Great link-thanks for sharing–this is a nice tangent to follow…

Speaking only for myself, I could care less about how something is made unless it becomes a constraint.

The machines in the video make all the sense in the world to me, because at the end of the day, the product is the result of somebody’s brain/spirit, and for that matter, so are the machines. And the argument could be made that such work in our world today would not exist without the capacity boost of the machines–for all the obvious fiscal reasons.

When I go to an art museum, or a sculpture garden, the thought of how the objects were made never enter my mind. I enjoy/crave the internal dialog/debate/emotional response with the pieces. Every once in a while I will see a piece where the technique must enter the dialog because of the meticulous passion/obsession of the artist, and this adds to the appreciation in a much smaller way than the overall presence of the piece.

I think as a woodworker, the vast majority of American woodworkers are completely brainwashed about the importance of technique over the substance of form…

I mean come on, man has been making dovetails for several thousand years–who gives a hoot about whether the pins or tails are cut first? All that really matters is that they are tight–unless of course one is constrained to making machine made dovetails only. And at that point the joint most often loses the height/width aesthetics of hand-made dovetails that as of today, are not replicable by machine–and if and when the day comes that I can replicate the narrow grace of a handmade dovetail by machine, I will certainly calculate the value proposition of doing so.

We will be remembered by what we made, not how we made it.

–John

Hi John,

It’s interesting that you bring up sculpture and your response to the object with rarely a thought about how it was made, and that it didn’t occur to me in this context. Much of what I do for a living is build sculpture for other artists including Ellsworth Kelly, Jeff Koons, Claes Oldenburg, Robert Therrien and others. A response that I often get from people unfamiliar with the art world is; Well then how can he be called the artist when he didn’t make the piece? And not for a millisecond have I ever thought that building the sculpture made me the artist or that there was anything unnatural or tricky about me building a 27′ tall, 13,000lb., very technically-demanding stainless and aluminum sculpture, rather than the 88 year-old sculptor. So, for this thread, I am the machine and it’s my job to faithfully understand and execute the artist’s vision. The fact that the artist hasn’t touched the piece does not diminish it’s significance. If that’s true for fine art, as I’m saying it is, then how can it not be for craft? Here’s how (maybe): Comfortable as I am channeling an artist’s vision, I don’t think that craftsmanship can be considered

as separate from the craftsman. I could make a Sam Maloof chair – perhaps a bad example since I don’t like the design and the attendant mass-hysteria does not increase its value, to me – and it would be my craftsmanship that resulted in the copy, but the vision of that chair would not have come from me, from my experience or desire or sensibilities. In that case, as in the case of Maloof chairs being made without Sam, the craftsman (Sam) is not the craftsman but just a designer and what the collector gets is not a product of his craftsmanship and, to me, that is significant though maybe unimportant, if I may make that distinction. I’ve got lots more to say on this, but I’m more interested in reading what the rest of you have to say than in hearing myself type.

Gary

Very interesting thoughts, Gary. I like your distinction between the artist and the “realizer” (the person who actually makes it). Dale Chihuly would be another example of that – he doesn’t do any glass blowing, yet it’s considered his sculpture when it’s done. On the other hand, you have the craftsman actually doing his craft. But in between the artist and the craftsman you have people like architects and designers who most people would not expect to ever actually make something. They just think it up. (“Just!” Ha!)

I have no problems with people using whatever tools are available to achieve their vision. Personally I love the process of design AND realization. In everything I do. It’s a constant cycle of learning and creating.

A question: If we accept sculpture designed by someone, but realized by someone else, why would we not accept a painting designed by someone, but painted by somebody else? I can’t think of any Picassos not done by Picasso…

– Peter

Hello,

This is a very timely conversation for me, since I just recently had several conversations about handwork vs machine vs CNC with a couple of woodworkers last weekend.

I spent last weekend at the mall for our guild’s annual show; I’m also on the show committee and was teamed with a begining woodworker who had built his own CNC router. Our task was to build the trophies, and we used his CNC to make a stepped cup and ring to hold a clear medallion in place; we also used many regular shop tools and handtools including: HP-6 1/16″ roundover and a smoothing plane. The CNC parts were very nice and quickly made, doing them by router would have involved several templates and multiple cuts, doing them by hand would have been very tricky and would have required great carving skills!

The best insite into not using the CNC was that from a civilization standpoint, eventually the skills needed to do fine work would get lost after several generations.

Because of my new friendship with my trophy making partner, I now have access to a CNC machine, but have drawn MY “line in the sand” at using the machine to make templates, fixtures or forms for the vacuum press. In other words, only things that help make the piece, but not parts of the piece itself. YOU may “draw your own line” without judgement from me!

As for your comment on making dovetails by machine that match those by hand, I would imagine that if a process/robotics guy decided to make a machine that worked more like a JMP with a blade rather than a bit, and then have a chisel like blade(s) take out the waste, it could be done. Of course, a large segment of the population seems happy with staples holding their drawers together and many more who don’t know what a good dovetail looks like, we’re left with just a few people, and I would have to believe that the “romance” of a craftsperson cutting them might be just as important to them as the joint itself.

Just one man’ rambling on the subject, thanks for reading,

Rutager

Nice, thoughtful rambling, Rutager. That’s a very interesting line in the sand. I’m not sure mine’s so clear. At what point does a tool become so powerful (in what it can do) that it takes away from the craftperson’s craft? Presumably there’s still some art in programming a CNC machine, and making it work properly. And making beautiful things with it.

If I had a business, I might worry more about these things. But since I just do woodworking for fun, then anything that takes the fun out of it (and the chance to learn and grow) would be across my line in the sand. I think that as I improve as a woodworker, my line in the sand gets both more blurry, and closer to the hand-tool side than the power-tool side. But it’s silly to judge anyone for the tools they use. One would hope that the work they produce would be the more important thing.

That being said, I think your “romance” comment is quite accurate. And it goes for both the craftsman and the recipient.

– Peter

Hi Peter, you’re just hanging with the wrong billionaires. The right billionaires agree that investment-grade paintings untouched by the putative artist are Triple-A. I’ve done sculpture for Jeff Koons, maybe best known for polished-stainless balloon dogs (that we made) and his “Made In Heaven” series (NSFW, really!) with which I had nothing to do. In his studio in Chelsea he has 100 assistants who, for his paintings, drive Photoshop to his direction, generate paint-by-number charts (really) stand at big glass tables day after day mixing paint to match pantone chips while the elite studio-monkeys fill-in the numbered lines as fund managers and drug king-pins bid ever more millions for every ejaculation. Jeff can’t weld or carve or paint or draw; I don’t mean Frank Gehry expressive but not descriptive drawing, I mean just plain bad. I believe he eschews the very notion of an artist engaging a medium unless his medium is the straight-faced fabrication of didactic pseudo meaning splattered over every tchotchke. Wow, I spelled tchotchke correctly first-try. Koons openly and explicitly channels Warhol’s concept of an art factory. Takashi Murakami has extended it to his Superflat concept which I think (I hope) takes deliberate shots at the established contemporary art industry, but fosters real, young artists who find their feet and get a boost. Some of Murakami’s stuff is rather brilliant while (maybe) transcending craft. Claes Oldenburg is unable to draw badly. His every note and throw-away sketch (which I never throw-away) is infused with meticulous, instinctive expression and subtlety. His maquettes, of string and cardboard and canvas and paint are beautiful. I think that, from the artist’s own hands, they are more beautiful and meaningful than their descendant large public art sculptures yet they display little of the kind of virtuoso craftsmanship that we often discuss.

Gary