7/19/12 – The heads are being machined already. The 24″ rules are done. We wanted to make the rules first so that we could ensure the heads fit properly for a good press fit. Cursors are starting up shortly.

8/9/12 – All parts are underway. First articles of the two part head are back. Man these look good. It looks like these should be ready to go by mid September.

8/16/12 – All is going well here. I suspect we’ll be able to get these out by the first or second week of September. Packaging is coming along now. This version of the AS-24 has a rule that is actually 24″ in length. Previous versions of this tool was 1.5″ shy since that was the amount pressed in to the head of the square. So, we could not re-use our box die from 7 years ago. Bummer. New die is being made for the longer tool. This box is a flip top corrugated and not the paper wrapped chip board that our smaller tools are in. The size of this box is not conducive to the chip board material.

8/30/12 – All of the heads are at the anodizer. The remaining parts will be complete next week. This is coming along well. The lever is pretty sweet too. John’s arthritic finger will like it. Boxes are being made, foam liners start up next week.

9/6/12 – The heads will be picked up on Monday. We will then press the straight edges in. In order to ensure the best accuracy, we will laser the graduations on the rulers after they are pressed together.

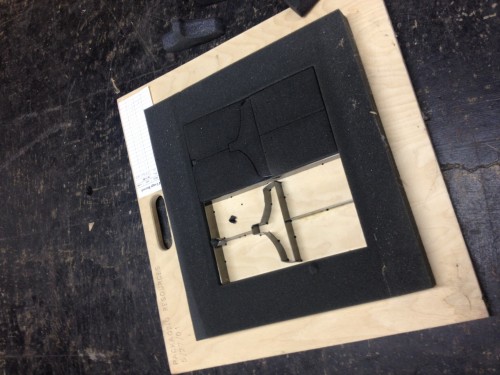

I like seeing the big piles of parts that we get in for these tools. The lever creates some interesting negative spaces.

9/13/12 – Dropped the cursors off at the anodizer today. It is always a treat to pick up parts for the first time. Sometimes we do a 3d print out of the parts, other times not. I had not done one of the cursor yet. I stare at these parts on my 27″ monitor all day, and they look huge. The cursor today just seemed small when I finally saw it. They look great, its just sometimes it catches you off guard. I think a lot of people have the same reaction when they finally receive the Kerfmaker.

9/13/12 – Dropped the cursors off at the anodizer today. It is always a treat to pick up parts for the first time. Sometimes we do a 3d print out of the parts, other times not. I had not done one of the cursor yet. I stare at these parts on my 27″ monitor all day, and they look huge. The cursor today just seemed small when I finally saw it. They look great, its just sometimes it catches you off guard. I think a lot of people have the same reaction when they finally receive the Kerfmaker.

The die here is an old die to make the foam for our Depth Gauge. Plywood with an embedded blade to make the shape. Very simple.

9/20/12 – The center pivot and the rules are getting pressed together now. Tuesday they will be delivered to me. Then they get the laser treatment. The cursors will be anodized complete in the end of next week too. Lots of parts being anodized right now. We are preparing for the final assembly though. Here are the boxes already made up.

9/27/12 – Everything is at the laser outfit today. I hope to have them returned for next week so that final assembly and packaging can happen then. After they head off to the distribution center, they should be ready to ship on October 10th.

10/4/12 – Well, the laser outfit is still going at it. The rulers alone have 30 hours of run time on the laser so they needed to clear out some other jobs to fit these in. All should be complete by Tuesday. I will bring a freshly made demo to the WIA Pasadena show while the remaining get assembled and boxed. The cursors are a fantastic little piece of machining. The machine that the cursors were made on is a 5 axis Makino, pretty sweet machine. Some thrilling videos of it: (not of the Cursor itself, sorry)

10/10/12 – We dropped some AS-24v3 and Cursors off at the distribution center today, so they will most likely be shipping out on Monday.

10/18/12 – More went out this week with more to come next week. This is the first product on our new Pre-Order system. There were a few minor glitches, but overall, things are working well.

11/8/12 – These are about wrapped up. A few more blems than anticipated unfortunately.

Michael,

How about a picture of the die that cuts the foam?

Thanks,

Rutager

That’s a lot of cursors. Glad that you’ve sold so many!

— Peter