___________________________________________________________________________________________________

” I woke, she fled, and day brought back my night. “ –Edgar Allen Poe

___________________________________________________________________________________________________

Dear Drivel Starved Nation;

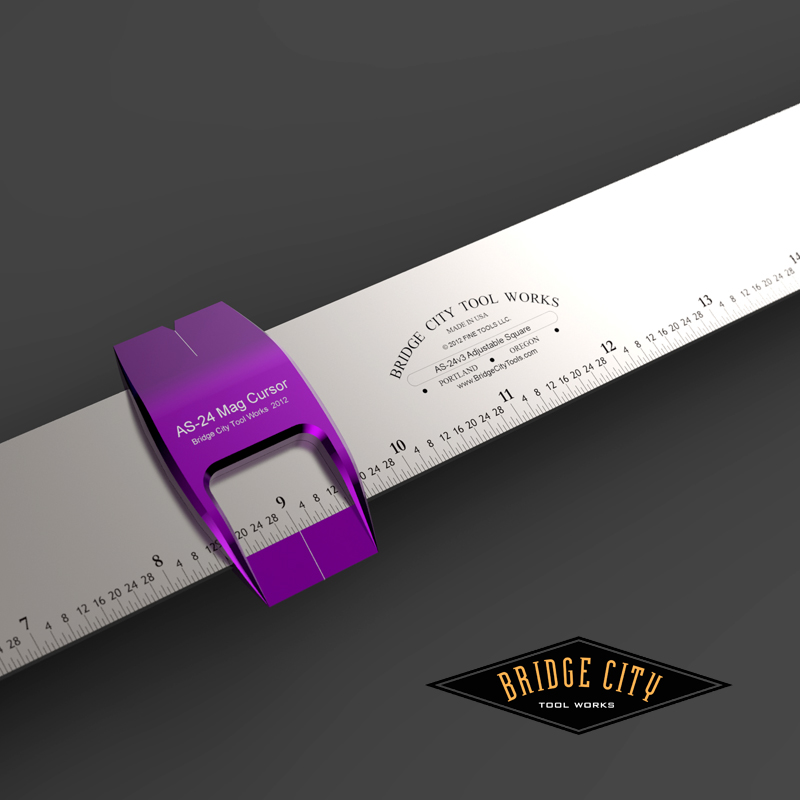

I returned last week from my annual two-week teaching assignment at the Marc Adams School of Woodworking. Tool Making and Creative Thinking were the classes.

Before I share with you my Indiana automobile accident, a shameless plug is in order; the CT-18 Dual/Low Angle Smoother offer expires on Monday, June 4th. This is likely the coolest plane we have made yet, and unlike any plane design that we are aware, as in ever.

Also, sitting in our front office are the last remaining HP-8 kits. There are 2 in brass and 4 in stainless steel. These are not going to our warehouse so you will need to call (800-253-3332) to order.

CREATIVE THINKING 101

All creative ideas are either based upon existing ideas or are the innovative combination of existing ideas–this is the fundamental truth behind creative thinking. In addition, to have a great idea, you generally need to reject a lot of ideas.

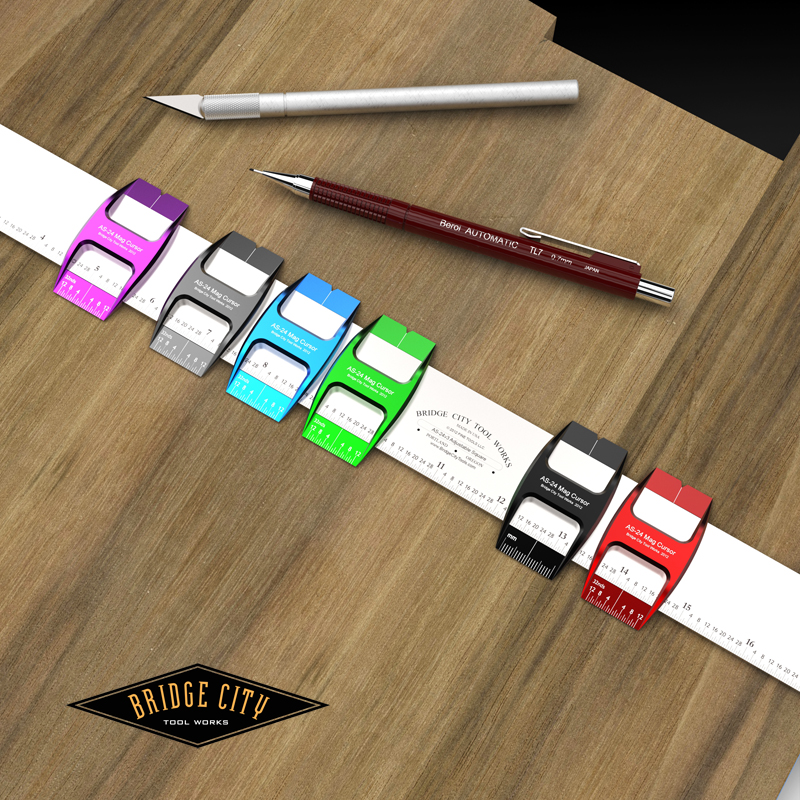

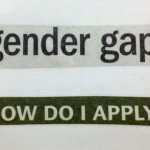

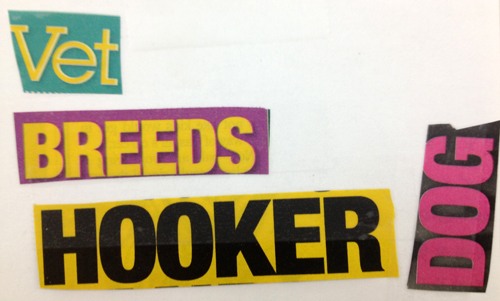

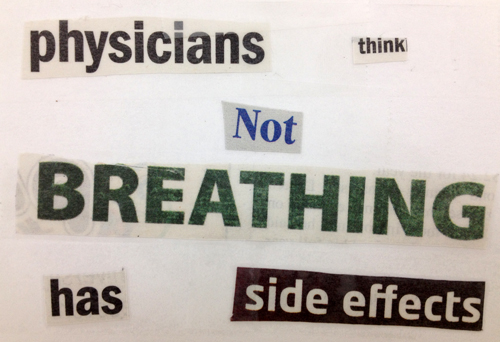

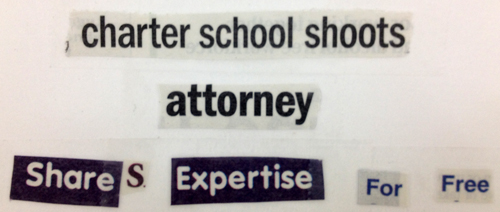

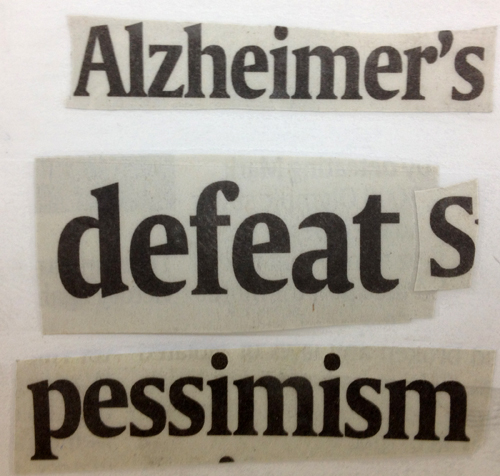

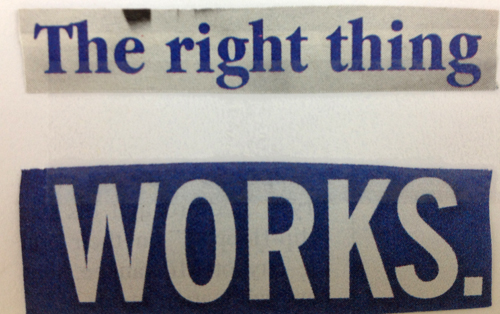

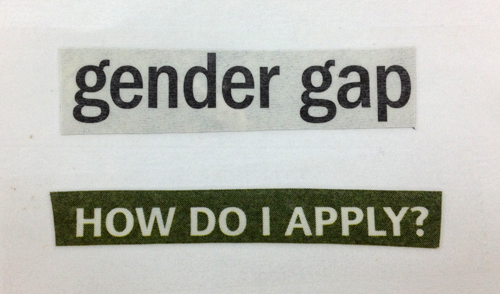

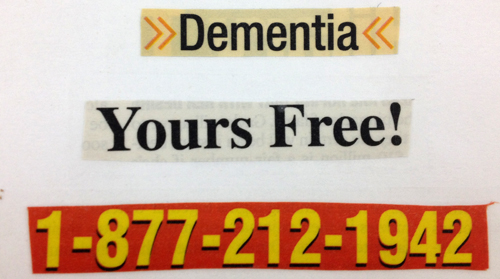

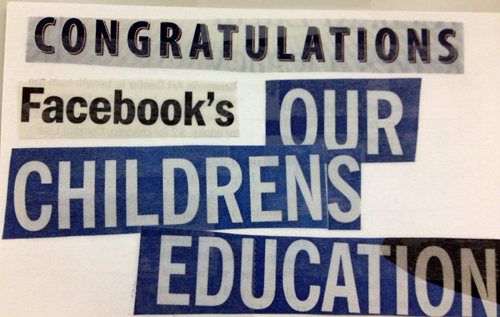

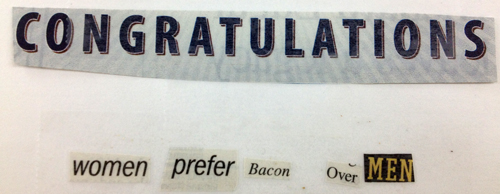

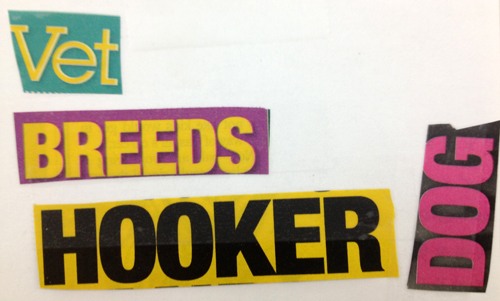

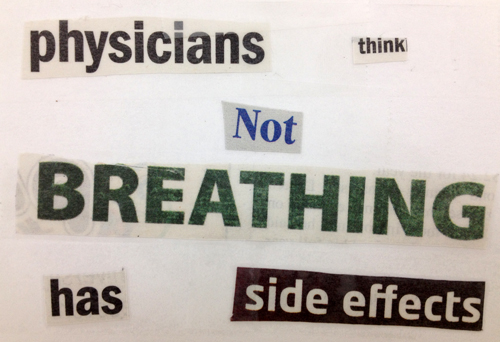

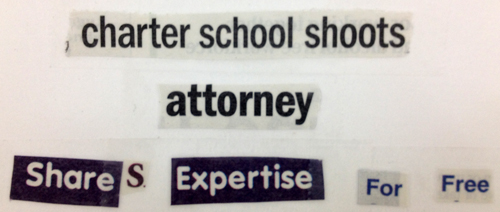

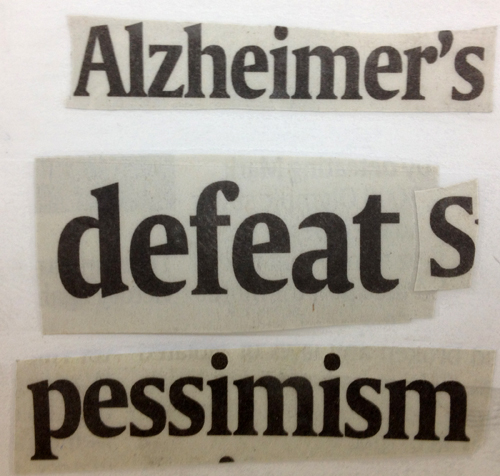

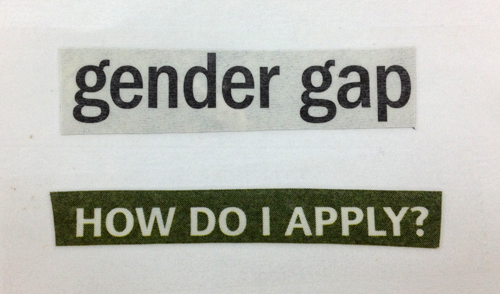

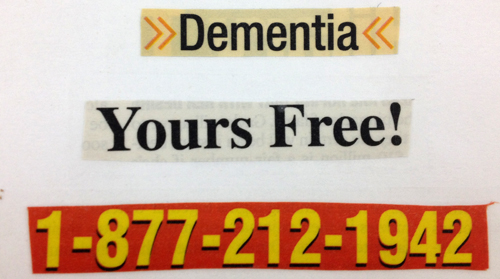

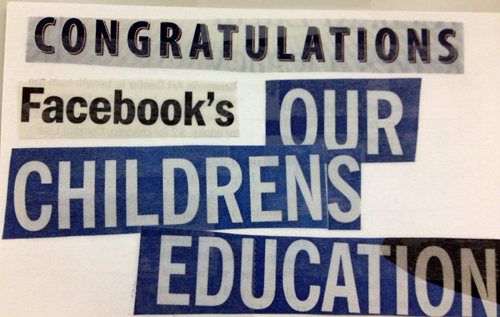

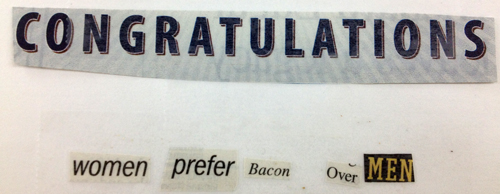

The “warm-up” exercise we do in the Creative Thinking class each morning is the re-construction of headlines. Mainly done for laughs, we selected approximately 10 candidates out of 100 or so entries over the week. As with last year’s class, I now share a couple of my favorites;

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

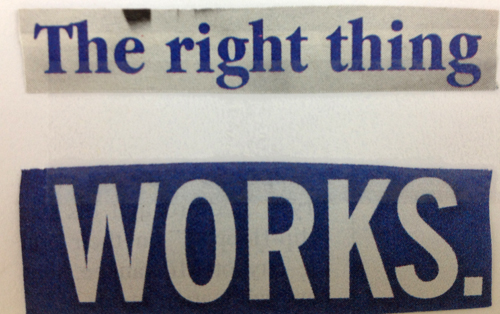

My FAVORITE…

____________________________________________________________________________________________________________________

YES I WAS IN AN INDIANA CAR WRECK DEPARTMENT…

As I headed back to the hotel at the conclusion of the Creative Thinking class three Fridays ago, I realized that I left my iPad at the school. Anything other than my iPad and I would have picked it up the following Monday. I turned around and headed back to the school–the time was 4:30 PM.

The Marc Adam School of Woodworking is pinched between two very large corn fields accessed by a two-lane, 45 mph rural highway. As I was approaching the school, which sits alone on the left side of the highway, I remember noticing the beautiful day, and observed there was not a car in sight on the ribbon of asphalt ahead of me.

I slowed down to make the left turn into the driveway and was half-way in the opposing lane (my speed was 7-10 mph) when out of nowhere I see this blue bolt of metal shoot past my driver door–both left tires were in the grass–it was surreal and unbelievable.

I felt a “bump” and stopped dead in the middle of the opposing lane. The blue car passing me is now 100-150 feet ahead of me in a full spin–it crossed the highway and entered the cornfield (on the right) rear end first before it rolled 2-1/2 times.

Here is a pic of the car, and some of the debris thrown from the car:

Once the car came to a stop, I pulled ahead, jumped out and ran into the cornfield to see if the driver was OK. I have never seen a roll-over accident, now I was involved in one.

The young lady driver was trying to stand up and I told her to be still, asked if she was OK, she nodded and I told her that I was going to run over to the school and get help. Fortunately Marc’s wife Susie saw the accident and already summoned help. The police and medical help were on their way.

Here is a pic of the damage to Marc Adam’s SUV (he provides a car for the week for instructors):

The police were great and I believe the young woman was sited for excessive speed. She was wearing her seat belt and I can only wonder about the results had she been unbuckled. Physically I was fine, but it took me another five or six days to calm all my “what if” concerns.

So, this is my reminder to all–seat belts WORK!

WHY A PUPPY DEPARTMENT…

I was excited to get home (understatement) and this is what greeted me;

Shelby is GUILTY!

I am glad May is over.

–John