___________________________________________________________________________________________________

“The best part of one’s life is the working part, the creative part. Believe me, I love to succeed… However, the real spiritual and emotional excitement is in the doing.” –Garson Kanin

___________________________________________________________________________________________________

The folks at Popular Woodworking magazine have announced two 2012 dates for Woodworking in America (WIA);

October 12-14 at the Pasadena (CA) Convention Center

November 2-4 at the Northern Kentucky Convention Center (Cincinnati)

As of this writing, we are certain to be at the Pasadena venue. Our attendance at the Cincinnati event depends upon, well…you!

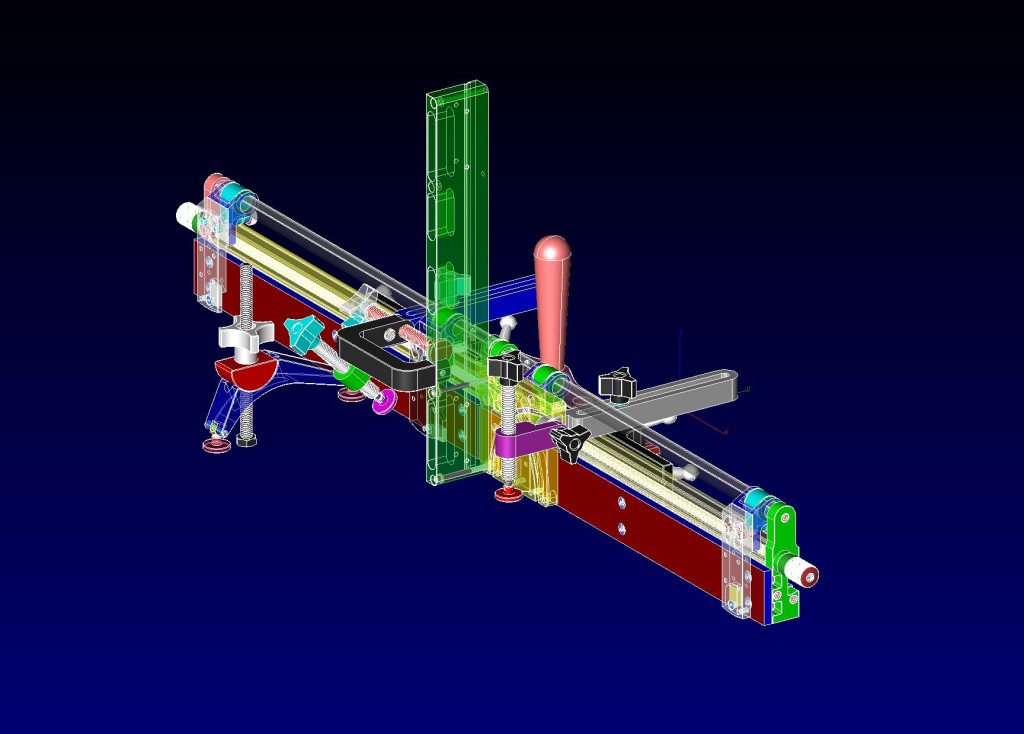

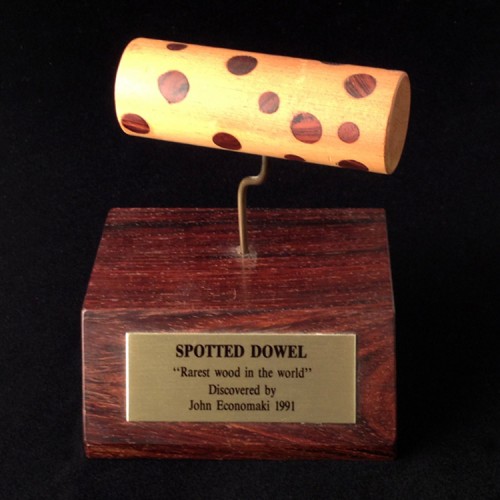

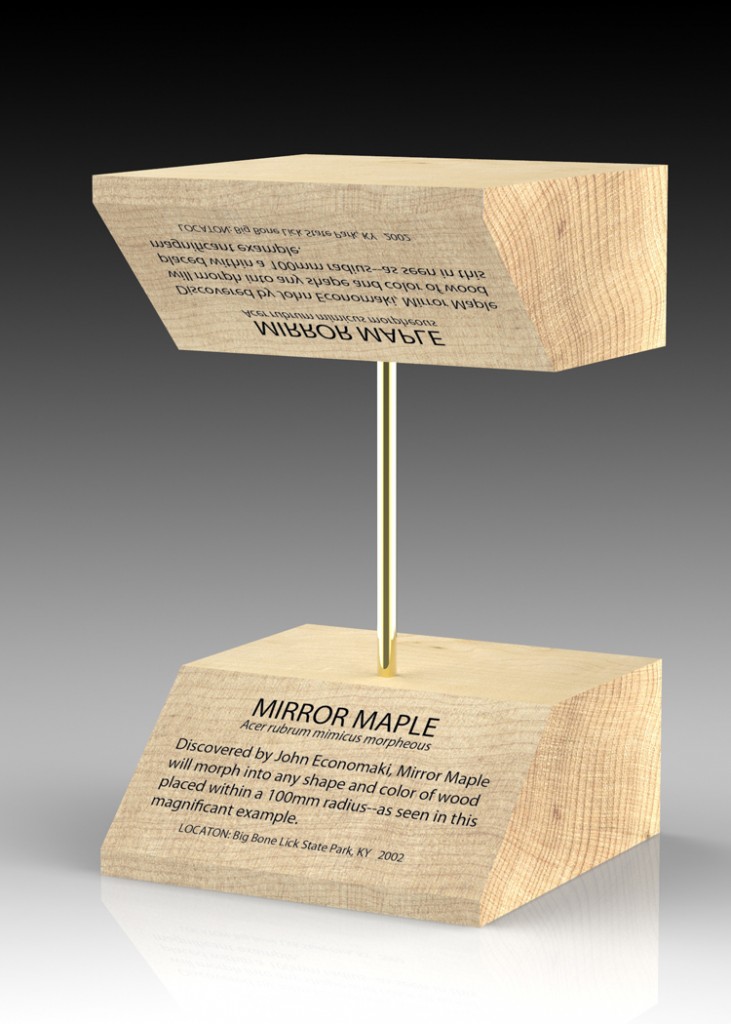

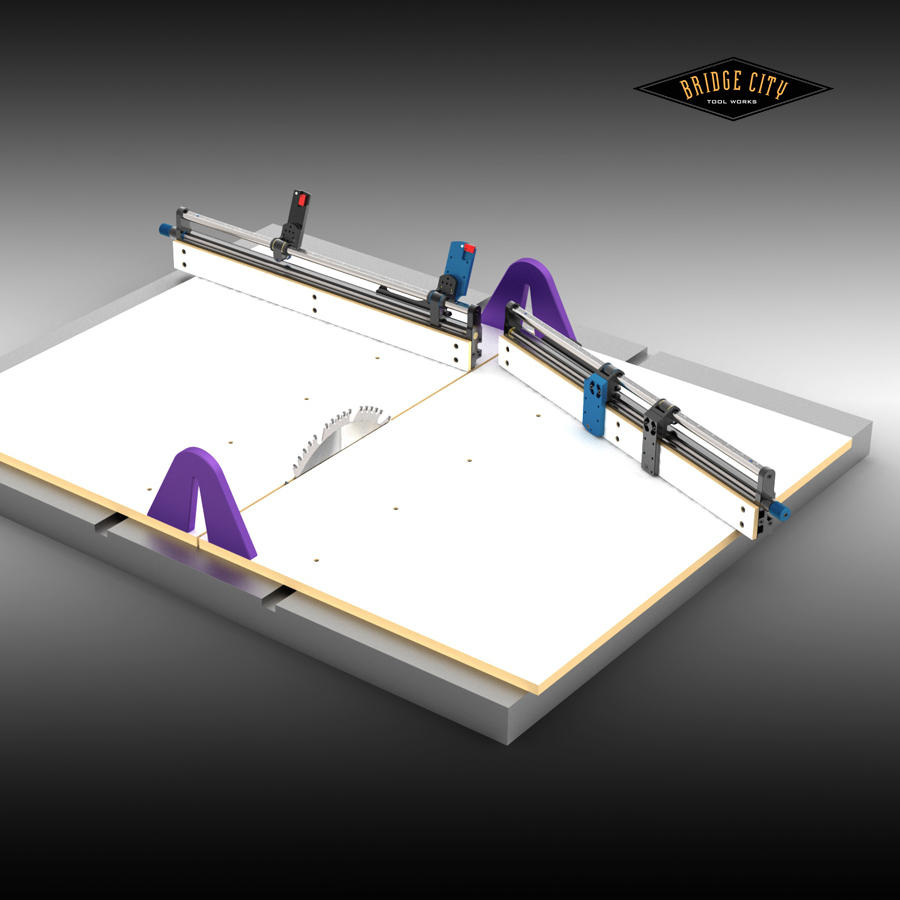

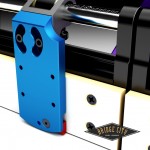

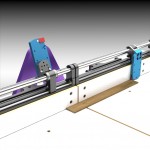

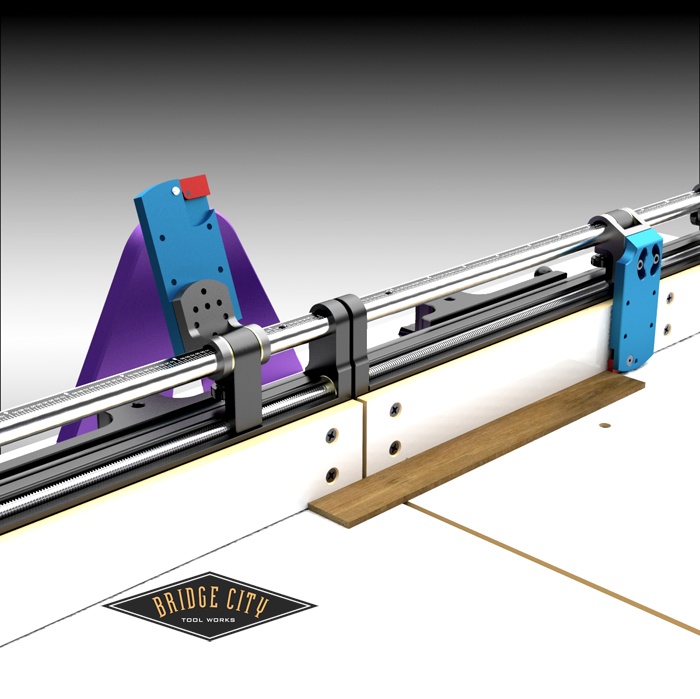

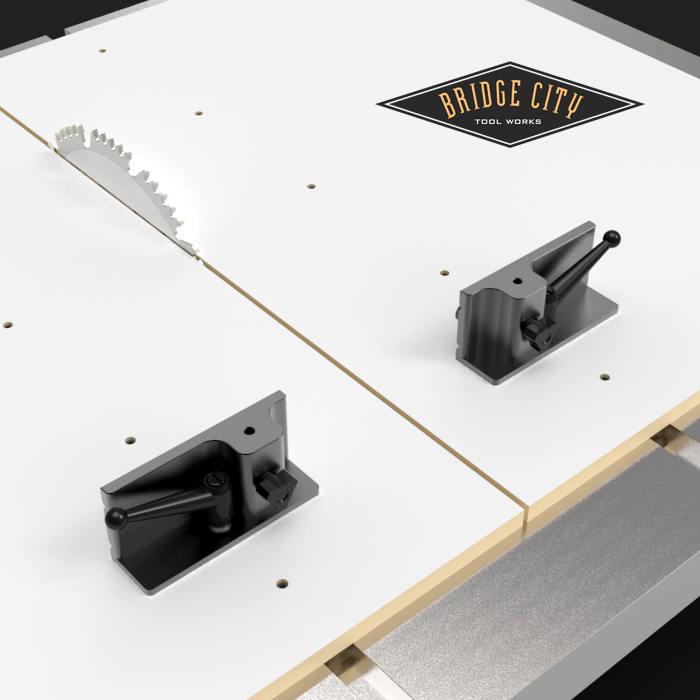

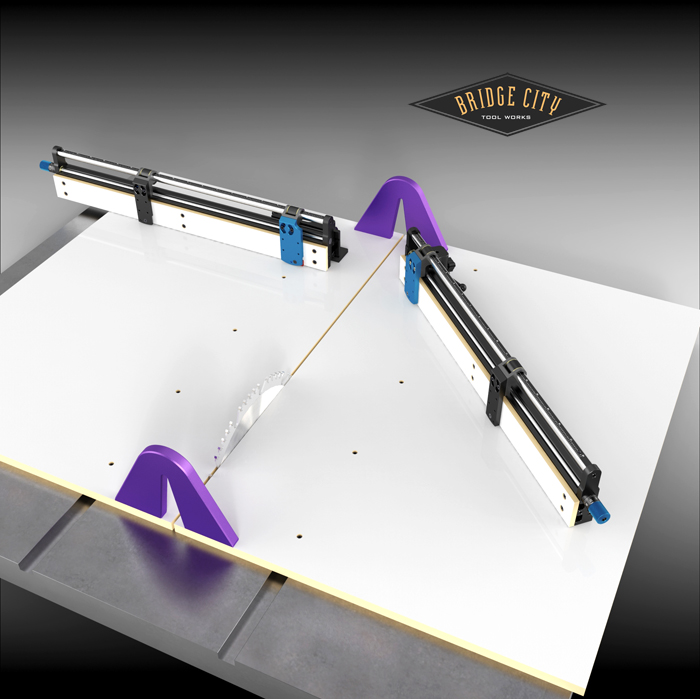

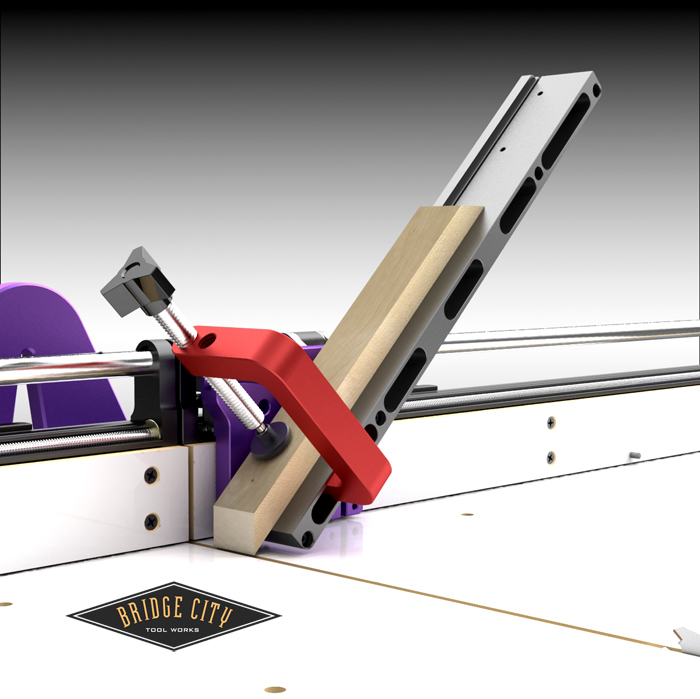

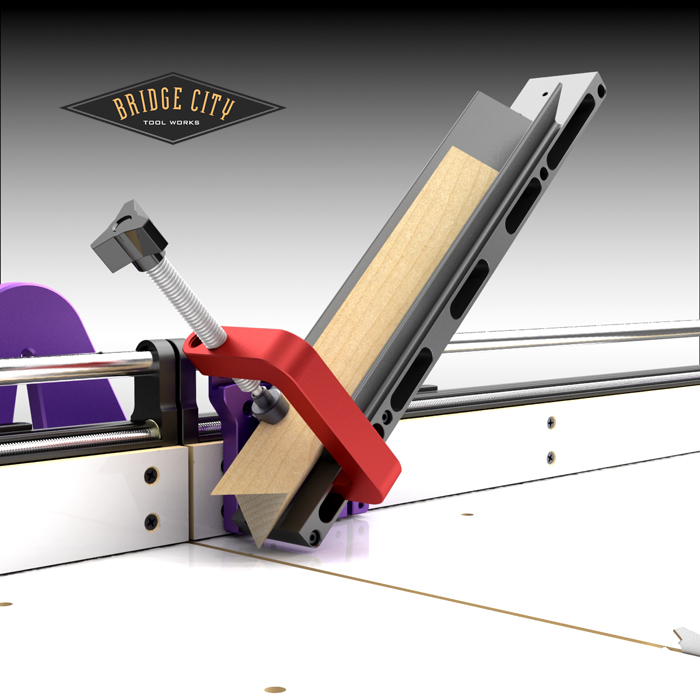

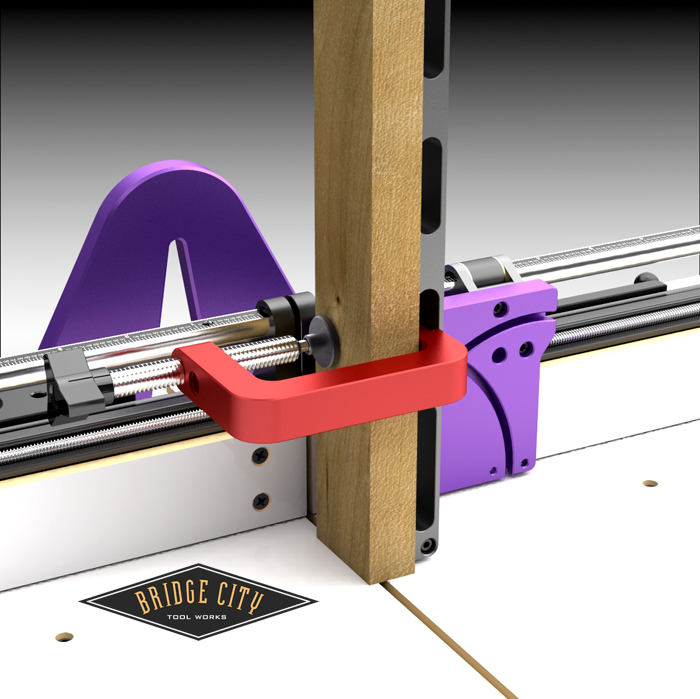

We are expanding the “Silent Woodworking Academy” this year to include not only the Jointmaker Pro line of saws (and our new fence system) but the DJ-1 Drilling Jig and the HP-6 Planes. And we will be making a new project to help raise scholarship funds—last year’s Earthquake After Detector was a blast.

Our “little experiment” last year of staffing our booths with customers was just plain fun for all and we hope to repeat the experience.

If you happen to enjoy being part of the Drivel Starved Nation and are either a Jointmaker Pro owner (including those waiting for the 2012 production run), or a DJ-1 owner, or an HP-6 user, we are offering airfare, lodging and some great evening meals for your enthusiasm, willingness to “talk shop” and help make our little fund raising project a reality. You will also have ample time to visit the Marketplace. We need at minimum, 5 volunteers per venue, but will fill the Pasadena slots first.

Typically you will fly in on Thursday and be home on Sunday. It really is much fun.

If this sounds like something that you want to be part of, we would like to hear from you;

john@bridgecitytools.com.

Please include a brief, one or two sentence statement as to why you would want to slave away in the Bridge City Silent Woodworking Academy, and your city preferences. We will do the rest. Lastly, please enter “WIA” in the subject line of your email to help me sort the thousands of applicants…

–John