____________________________________________________________________________________________________

“It ain’t ignorance that causes all the trouble in this world. It’s the things people know that ain’t so.” — Edwin Armstrong

____________________________________________________________________________________________________

I have been fairly inactive on this blog for the past month and when that happens you can bet one thing: I am not getting any sleep. Do you think I am a perfect candidate for Propofol–or at the very least a prescription strength stool softener?

THE NEXT NEW TOOL FROM BCTW IS…

I can’t remember in our 28 year history of ever designing a tool specifically for me. And yet, over the past 6 months, that is precisely what I have been working on. I am calling this project my “one man war against inertia”.

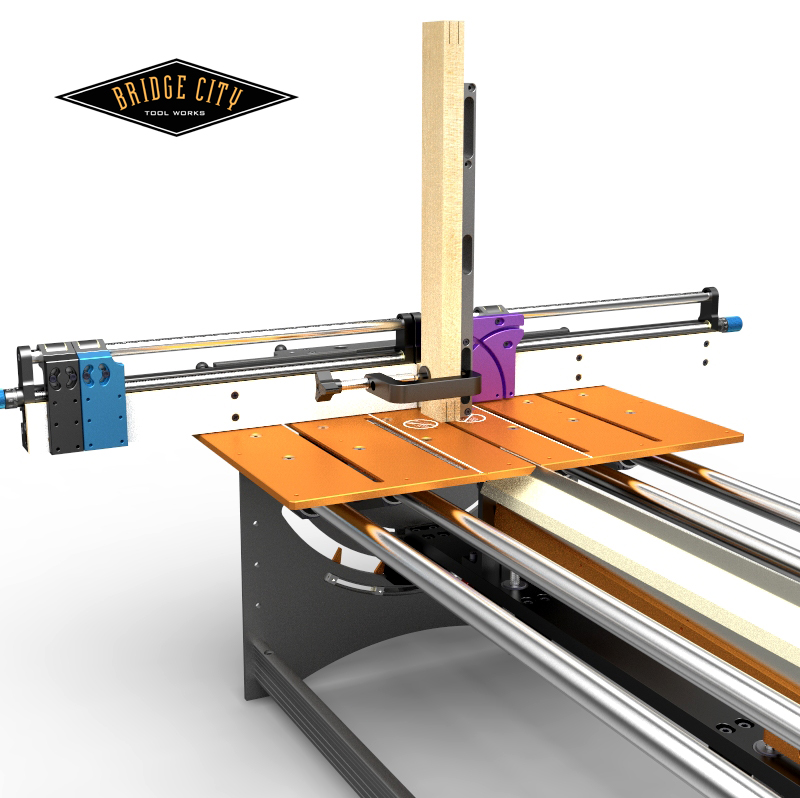

For all the wonderfully precise things you can accomplish with the JMP v2, it is woefully inept all by itself if you want to do more than crosscut. To take advantage of the finest cut in the land I dare say, one needs a bit of help. Admittedly, I have obscure desires for this tool–as mentioned prior, making wooden gears is one such odd notion. The inertia that needs to be overcome are the plethora of jigs, clamps and fixtures that I need to make in order to make what I have designed. I just would rather have a system.

About six months ago I set out to solve my odd needs. I didn’t spend much time pondering looks–I refer to the JMP as my “early 1950’s Soviet submarine” aesthetic. I want the ability to do what I want fast, and as pragmatically as possible.

What I am about to share is the first tool that I can remember designing for my needs. And in so doing we hope you will agree, our new fence system takes the Jointmaker Pro v2 to a whole new level of capabilites.

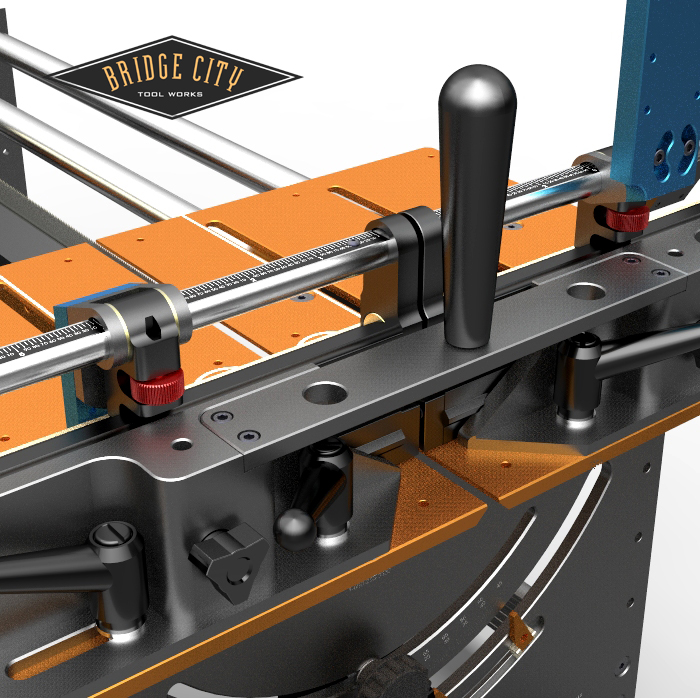

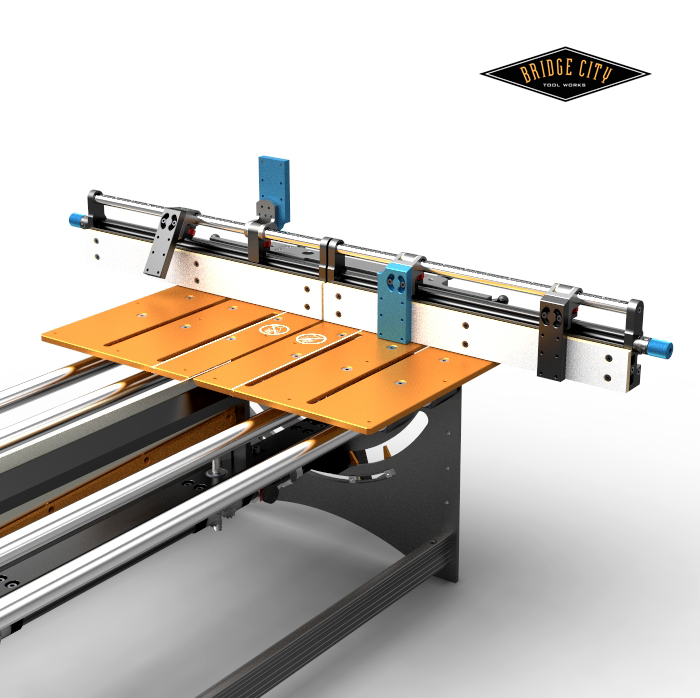

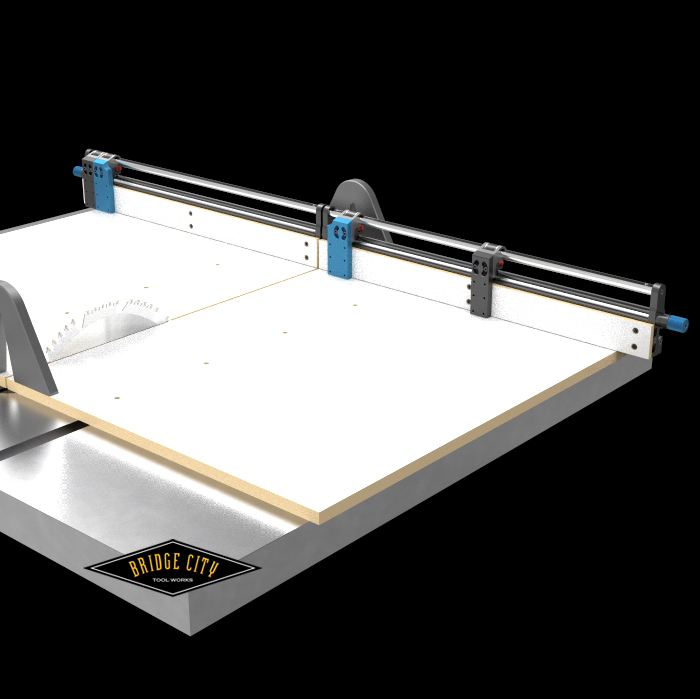

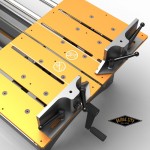

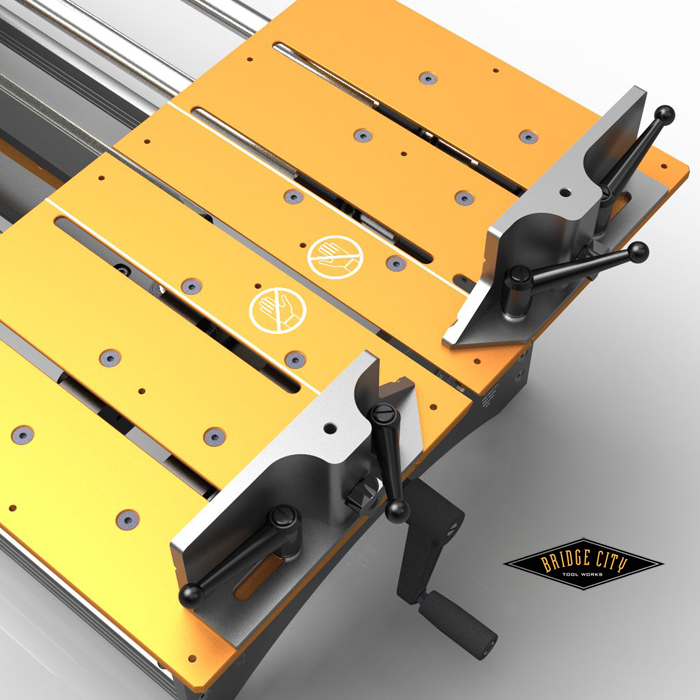

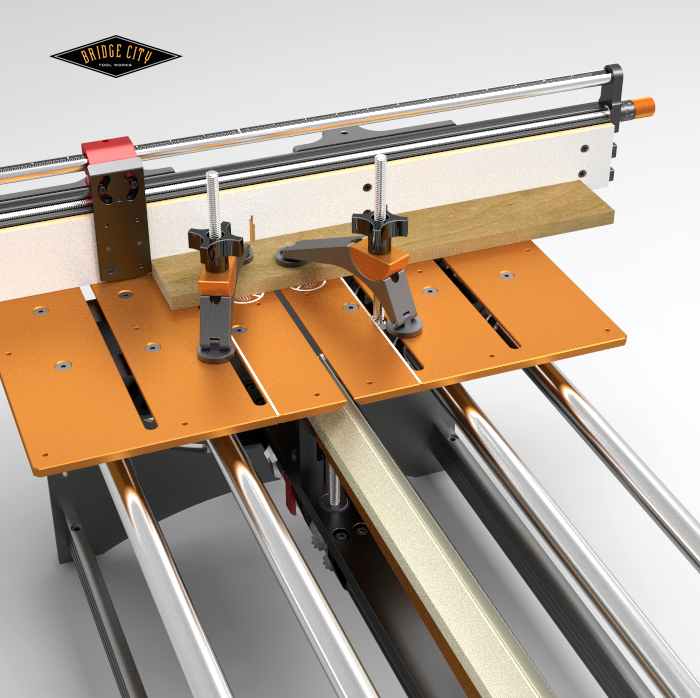

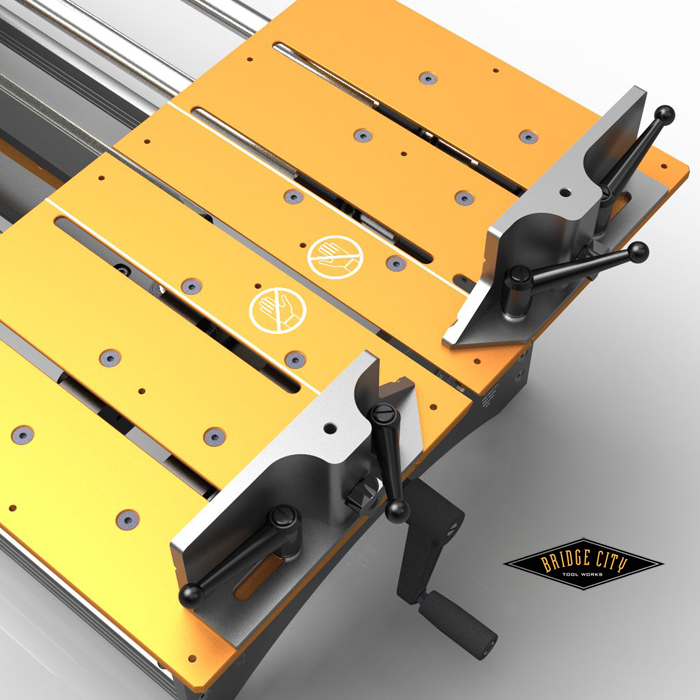

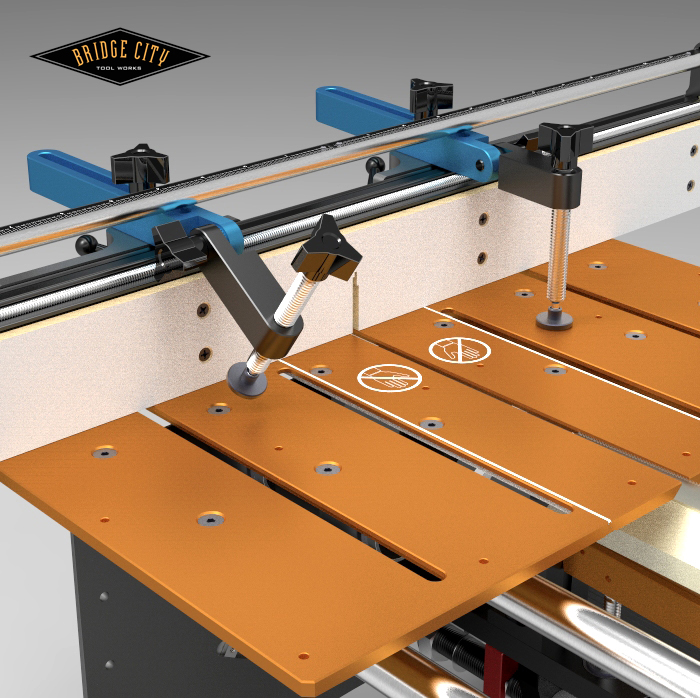

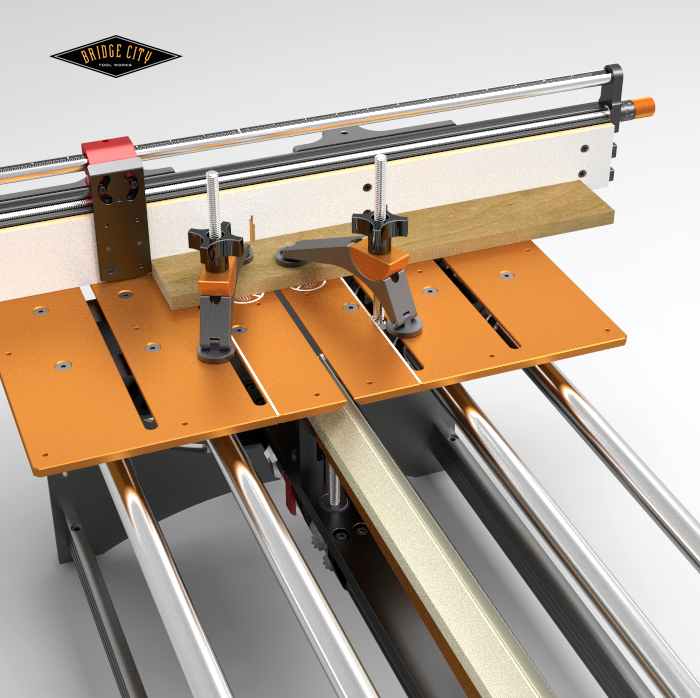

The fence system begins with a new foundation. Don’t fret, your old fences are still going to be useful, just not in the same spot. As you can see, we have incorporated lever locks–we needed to conserve table top real estate. As shown, your existing wooden trap fence and the square wood fence can still be attached. I suspect most will appreciate that this set-up is now adjustable without tools.

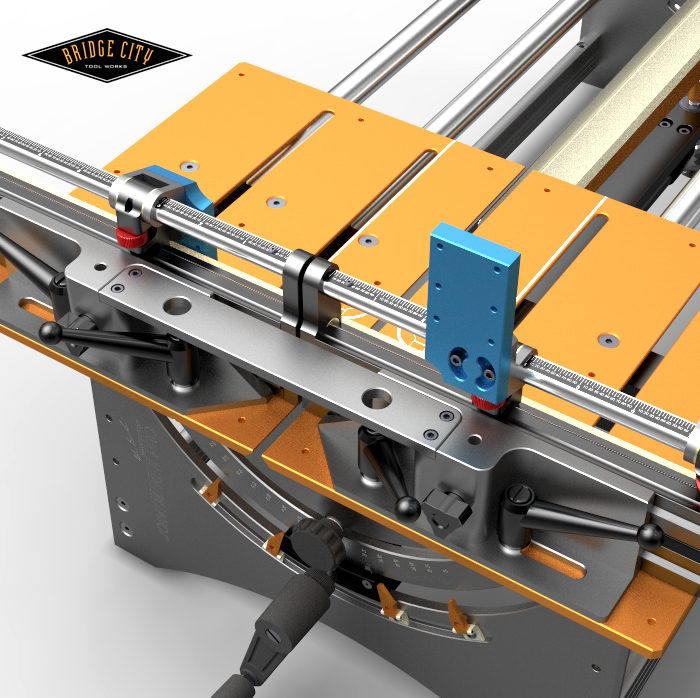

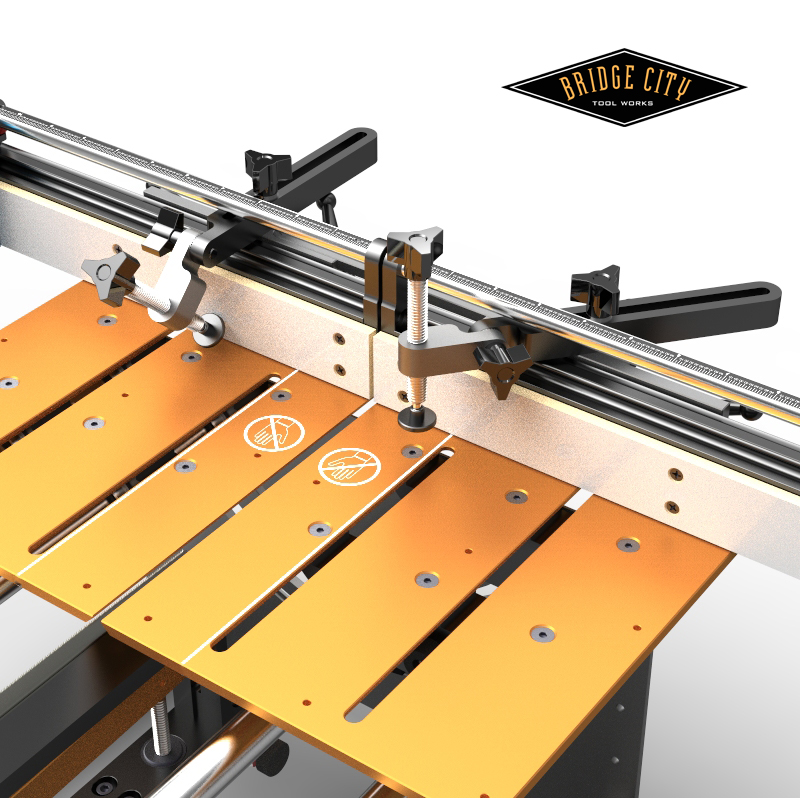

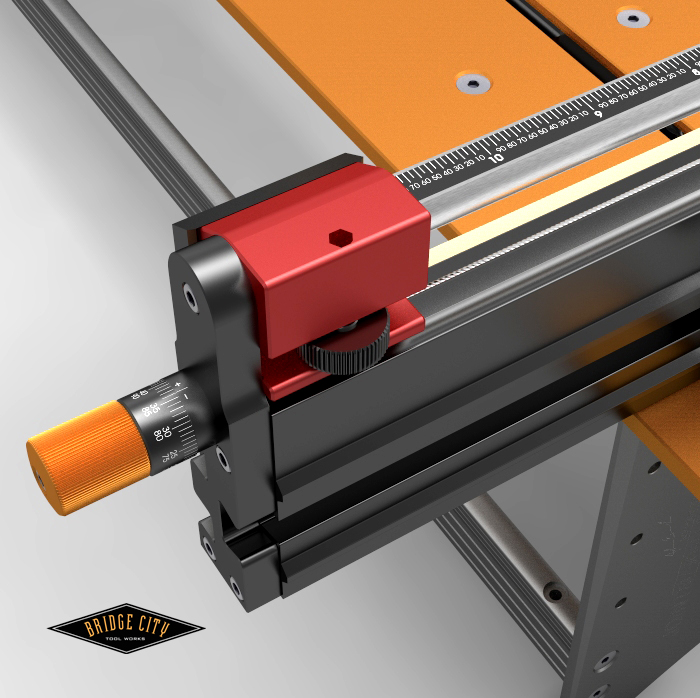

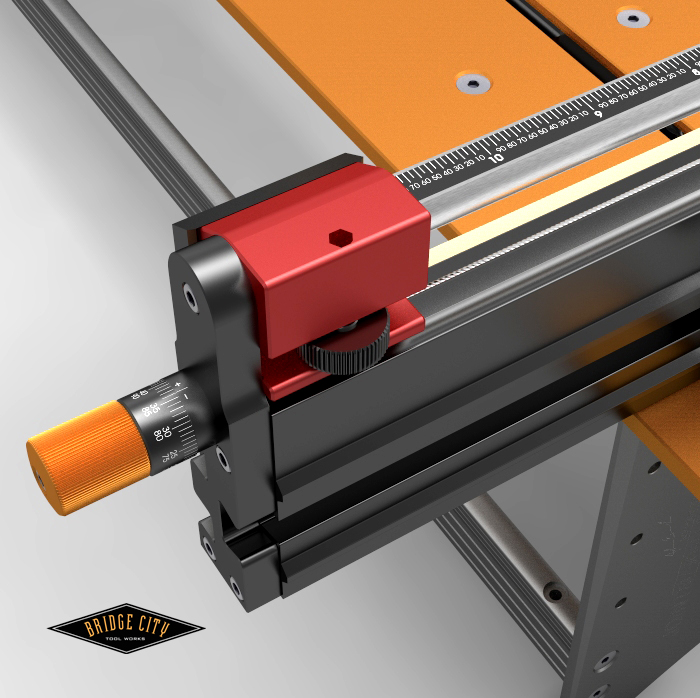

The extruded aluminum fence body slides on and off with ease. Notice the two stops–they engage a lead screw that allows them to be adjusted in 0.001″ increments and yet can quickly disengage for rapid traverses or flip completely backward for a squaring cut prior to a length cut constrained by the stop. They are the shape they are for several reasons, they can pivot, be removed and are drilled and tapped for our accessories or yours. It is our version of an open source stop system. Lastly, there is zero backlash in the lead screw or in the heads when engaged. This is really important and awesome to boot.

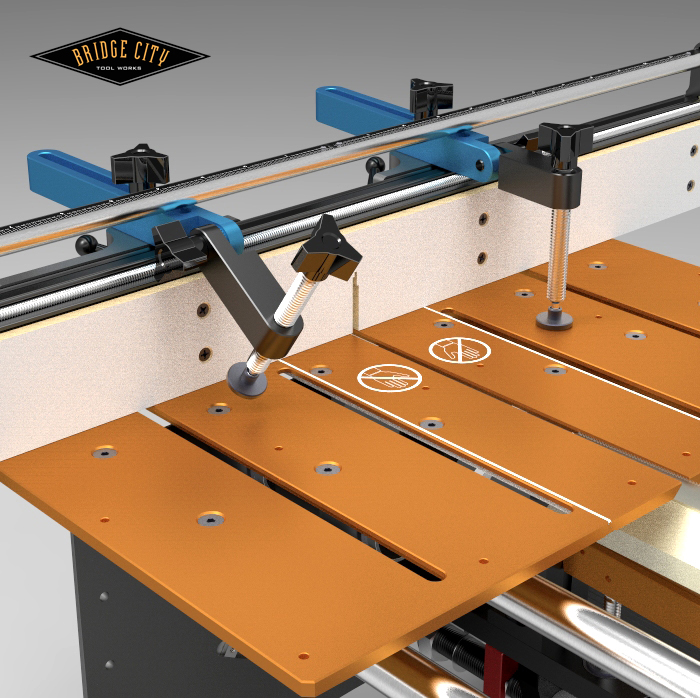

The system comes with one pre-drilled melamine/MDF skin that slides onto the fence. This bridges the cavity in the extrusion which is required when the fence is tilted. The fingers also contain a nylon adjusting screw that allows you to square the surface of the finger to the tables. This is imperative for a couple of the attachments to avoid compound cuts. The finger thickness is ideal for the KM-1 Kerfmaker and the TM-1 Tenonmaker.

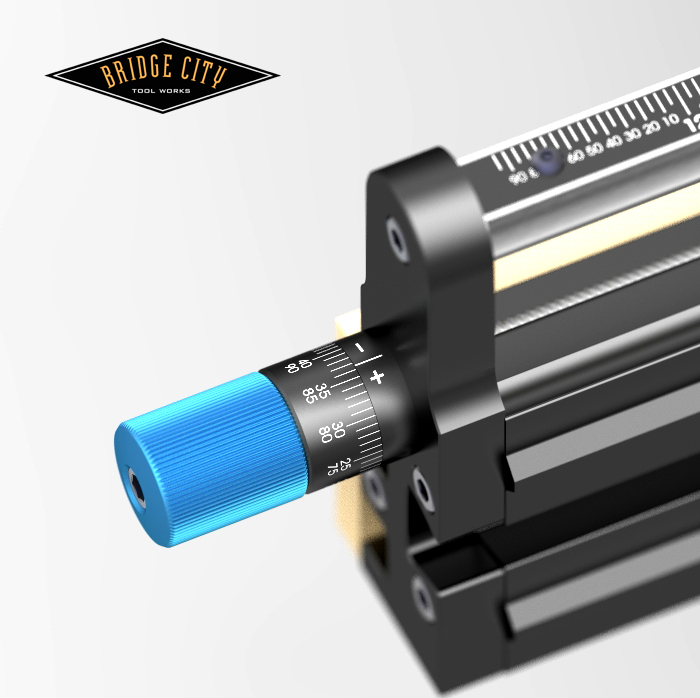

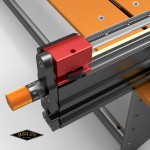

The stops are fast and positive. The thumb wheel raises and lowers the acetyl head lock (won’t scar the extrusion) which removes the backlash in the head. Stops can be used on the either side of the saw blade. There are left and right reading rules in the traverse bar. If you know your cut length, you can get a stop in place that will not require more than one revolution of the micrometer adjustor. Both the rules in the traverse bar and the graduated rings on the micrometer adjustors float–meaning that you can cut a short section of stock with a stop, measure the piece with a caliper and calibrate the fence to the correct distance. This takes only a couple of minutes and need only be done when the fence has been moved. The plus and minus signs indicate which direction to turn the adjustor to lengthen or shorten your cut length.

The system reads in .001″ increments and is repeatable (it is affected by temperature). Here’s how it works; if the red stop is between the 4 and 5″ mark, the first number is 4. Next, notice the location of the red head on the rule–in this hypothetical example it is between 2 and 3 tenths of an inch (marked 20 and 30), so the second number is 2. If the head has not crossed the .050″ hash mark, then using the image above we would read the inner ring of numbers which is 36. The stop is set to cut lengths of 4.236″. What is amazing is how quickly this can be achieved. No clamps, no wood scraps, just set and go. The finger thickness is ideal for both the KM-1 Kerfmaker and our TM-1 Tenonmaker. We are working on a metric version. AND we are working on a similar version for a table saw sled system–I want one of those too!

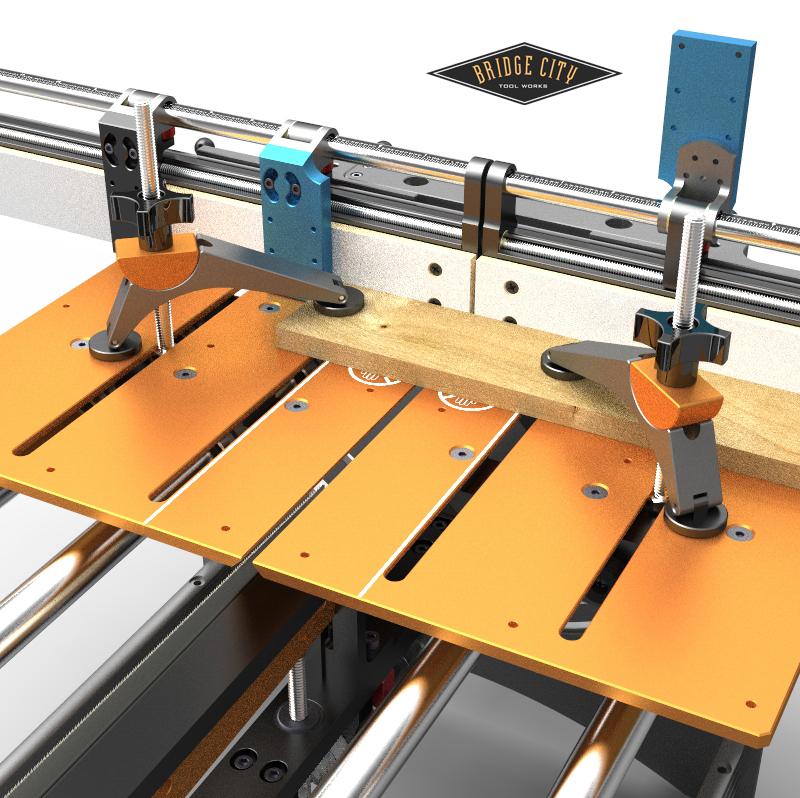

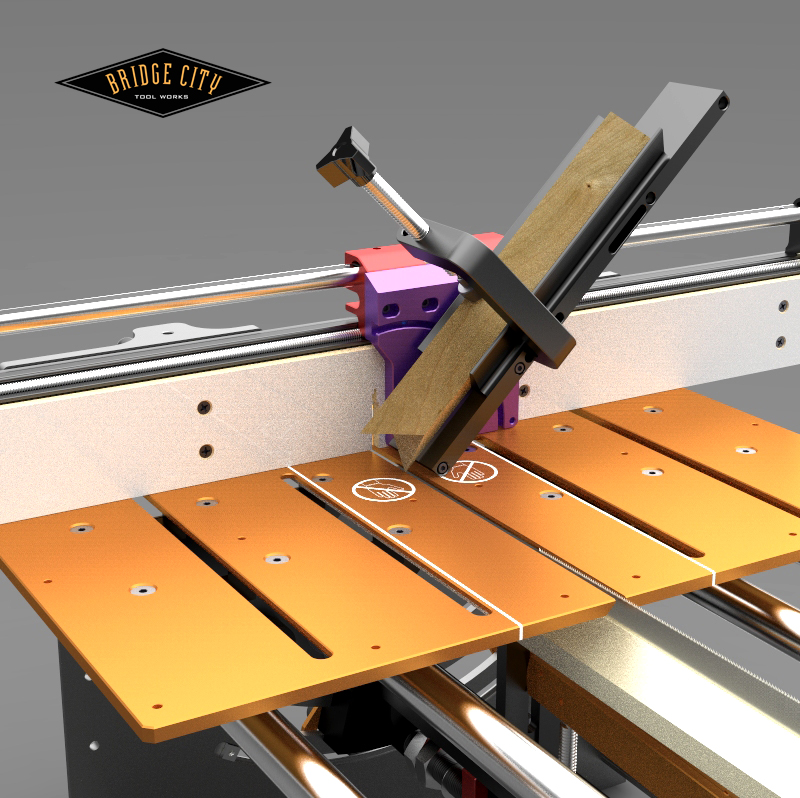

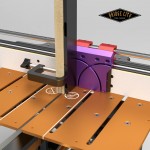

The space beneath the traverse rod allows for our new articulated clamps. They pivot on the fence and can be angled in 5 degree increments. For many crosscut applications this is all the clamping needed to keep the stock from riding up on the blade.

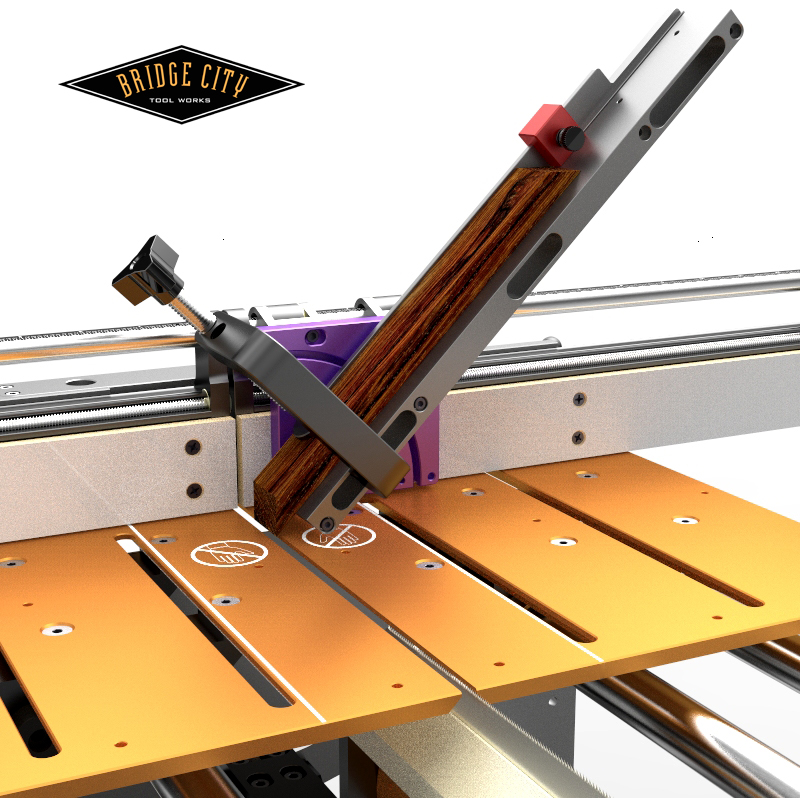

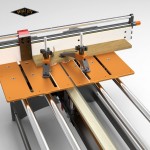

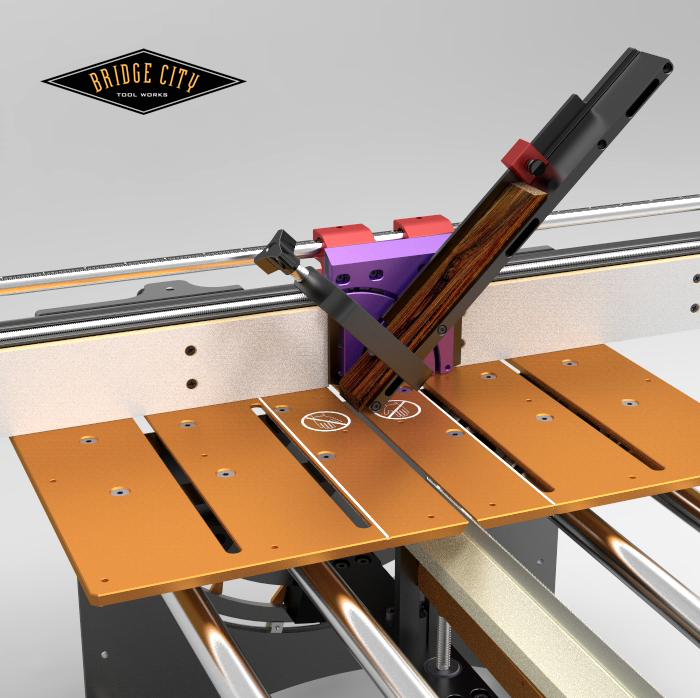

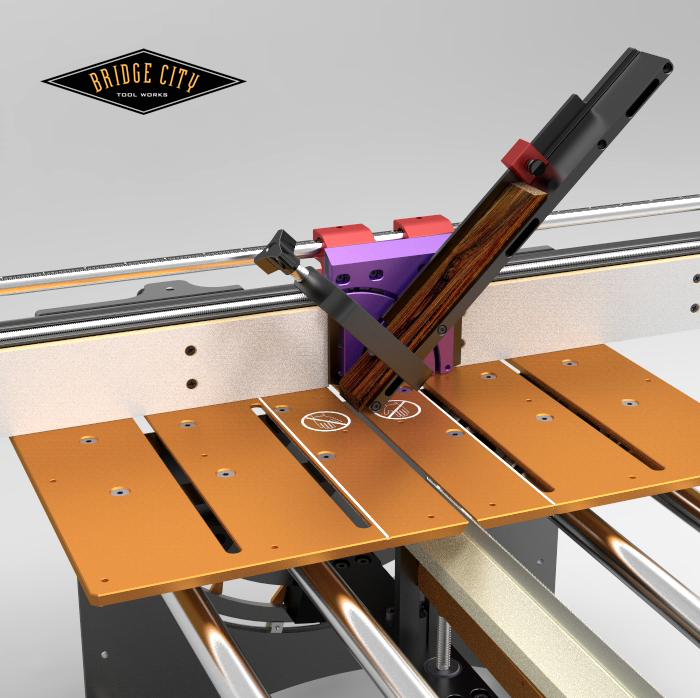

Miters are so much EASIER when you can tilt the stock. Our new miter/tenon attachment makes these cuts brain dead easy. Used in conjunction with our AngleMaster Pro v2, and you will be making perfect miter cuts without test fitting. That is no exaggeration. The aluminum C-clamp friction fits into the arm–this is crazy handy. And no, you can’t cut the C-clamp with the blade at it’s highest position.

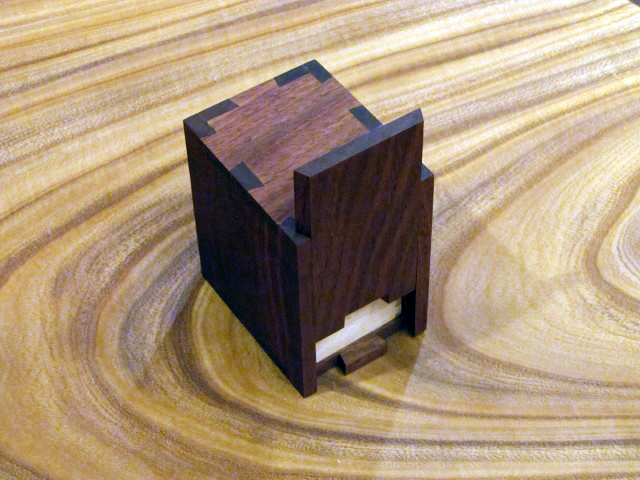

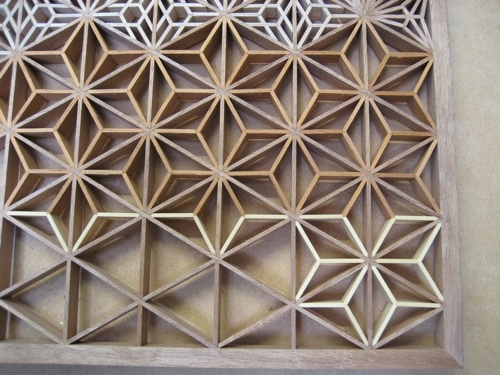

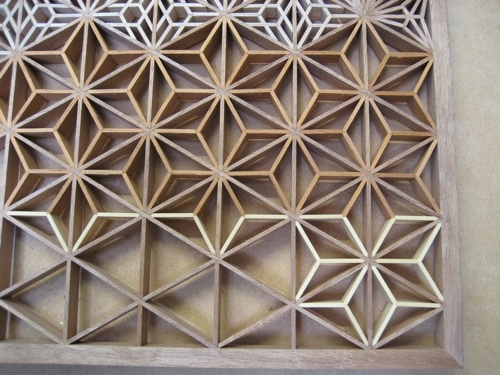

I overheard a conversation at WIA that the JMP would be lousy choice for the type of shoji pictured below;

It might have been an accurate assessment five weeks ago. But now I think the JMP may be the most accurate and fastest way to do this work. All thoughts are welcome.

Our new pivot clamps work fantastic. The swivel pads really help from damaging your stock. I actually positioned these in the wrong place, the part pressing against the tables should be inline with the screw line of the bearing blocks. Oops. These clamps can be used on a number of other jigs in your shop.

Mentioned earlier were the original fences–they are part of the system too. For example, they can be switched to the opposite table, reversed and used as trap clamps. In addition, depending on the width of your stock, you can move the old fences forward on the tables and orientated to 45 degrees and still be able to make 90 degree crosscuts without moving a thing. This will work on stock width just under 3″.

This fence is a huge boost to the capabilities of the JMP and eliminates the tedium of making one-off jigs and fixtures. I call them one-off because the next time you need it you can’t find it…

I am still working on my gear cutter–it will attach to dual fingers. And sometime next year we will offer an accessory that will allow you to cut tenons and half laps on mitered ends. Tomorrow I will post an image of the “V” Block accessory. That said, everything you see here is out for pricing and we hope to open pre-orders late next week.

We are really interested in your feedback and eager to learn if we have overlooked one of your burning needs as a JMP owner or FUTURE owner! Now is the time to speak up.

–John