2015 Production Run Updates

09/25/15 – Though still in the early stages, production on this run of JMPv2s, Precision Fences, and Accessories has been underway for a while now. This is mainly do to the JMPv2’s linear rails, which take 4-5 months alone to produce. The extruded parts are currently being pulled, and machining on many of the other parts has begun as well. We expect the JMPv2, Precision Fence, and Accessories to be complete by the end of the year.

11/30/15 – The production on the JMPv2, Precision Fence, and Accessories is in full swing. Many parts are still being machined, though some, such as the tables and front and rear plates, have made it to the anodizers. The linear rails are almost complete, as are their bearing blocks.

Unfortunately, we were notified that the die which was used to produce extrusions for the JMPv2’s side stretchers broke. The new die took 3 weeks to make before they could begin pulling extrusions. They just finished and shipped the extrusions last week, which are currently being machined before going to anodizing. We are hustling to minimize the effects of this delay, though it will push assembly into January.

12/14/15 – Machining continues on the JMPv2, Precision Fence, and Accessories, and more parts are making it to the anodizers everyday. The orange tables are currently being lasered, and the front and rear plates are expected to join them this week. Finished parts have begun trickling in, including the saw blades which arrived from Japan on Thursday.

12/24/15 – More JMPv2, Precision Fence, and accessory parts are arriving, while a constant stream of parts continues to come from/go to the anodizers. Most of the parts look great, though the front and rear plates had to be sent back for re-anodizing due to some very unsightly racking marks. After being reworked, they will be sent off to be lasered. In the meantime, JMPv2 hardware pack assembly will begin next week.

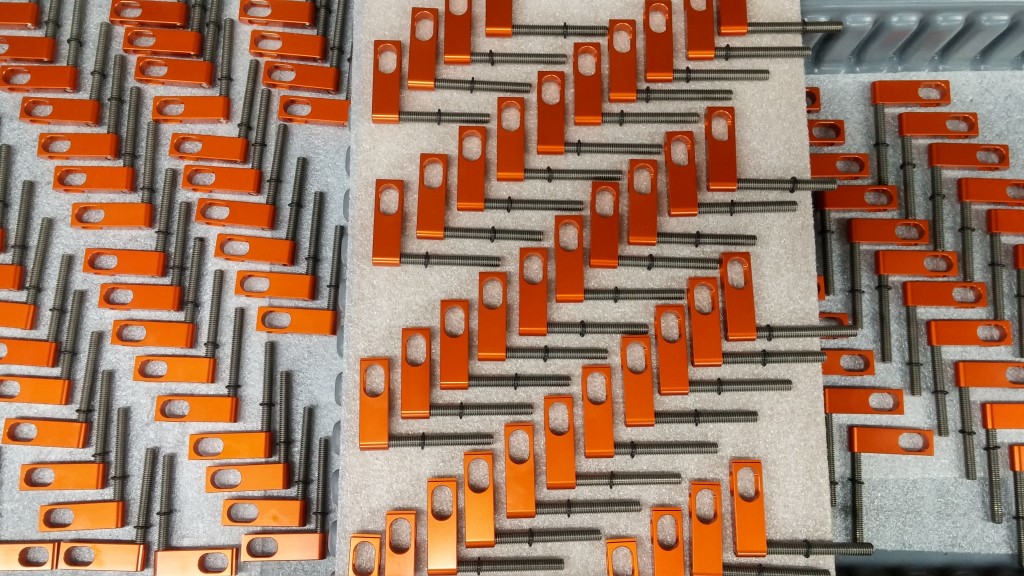

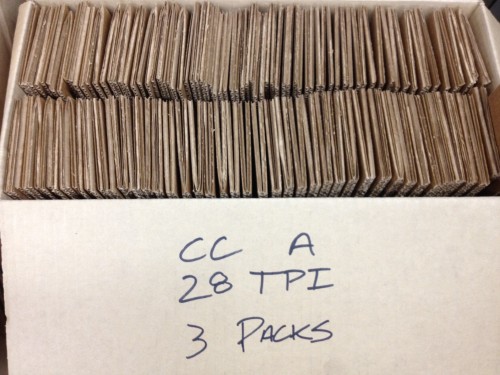

01/11/16 – The last of the front and rear plates that needed correcting were re-anodized and sent to the laser etchers last week. JMPv2 hardware packs are still being assembled:

The last parts will be arriving from the anodizers throughout this week/early next week. Subassembly will begin this week; we still expect final assembly to be complete by the end of January.

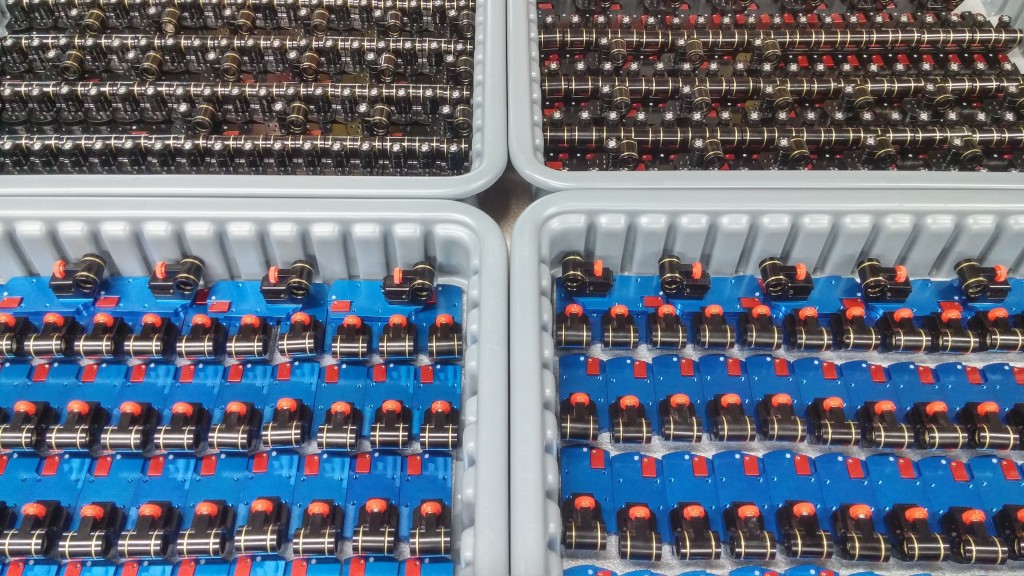

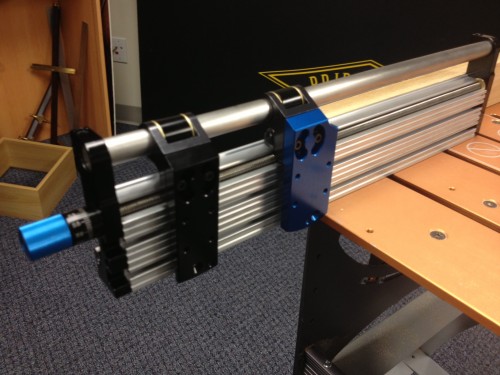

01/16/16 – The front and rear plates arrived from lasering, along with the Precision Fence end caps and graduated tubes. JMPv2 subassembly continues, including rear height screw assemblies:

and keel assemblies:

Most parts have arrived from the anodizers, and those that have not arrived are due to arrive early next week. Boxes and foam is arriving Monday, and we expect to begin packing up Jointmakers, Precision Fences, and Table Saw Sled Kits by the end of the week.

01/24/16 – All hands have been on deck this week/weekend for Jointmaker and Precision Fence assembly:

It may not look like it, but the Precision Fence actually has more parts than the Jointmaker:

All of the Jointmaker Precision fences have been assembled and are being packed up along with the accessories. The Precision Fences for the Table Saw Sled Kits will be assembled early this week, and all assembly and packaging is still expected to be complete by the end of the week.

01/29/16 – All of the Jointmakers, Precision Fences, and Accessories have been assembled, and pre-orders began shipping out this week. The only tools not completed are the Metric Table Saw Sled Kits. The graduated tubes, which were already delayed, arrived and are extremely oversized. We are correcting the issue, but these unfortunately will not ship until the first week of March. This issue does not affect the Imperial Table Saw Sled Kits. Pre-orders will continue to be processed throughout next week, after which we will begin going through the wait list.

04/07/16 – We are slowly contacting those in the waitlist for the JMPv2 Jointmaker Pro and its accesories–so keep your eyes out for an email from us!We hope to start going through the waitlist for the Table Saw Sled Kits by the end of the month, too!

04/25/16 – Extra units have been all sold out. Until the next pre-order window–which is sometime towards the end of this year!

09/10/14 – We are still processing those who have pre-ordered the JMPv2 and its Accessories. We are hoping to start going down the waitlist by the end of this month!

10/9/14 – We are waiting for a few more parts for the Precision fences, sled kits and accessories to complete those who have preordered these tools. We are hoping to fulfill everything soon, but are just on the waiting line for production completion. Also, we have exhausted all the extra units for Jointmakers and Precision Fences at this time. There are a few Stands left up for grabs on our website in the next couple of days. We have yet to go down the waitlist for the Table Saw Sled Kits and will give an update if we are able to go down the waitlist for those as soon as preorders have been fulfilled.

12/18/14 – All parts have been machined and most have arrived. We are just waiting for the last few Precision Fence parts to arrive from the anodizer.

12/29/14 – The final Precision Fence parts just arrived from the anodizer. We now have all the parts we need to finish the remaining Fences and will add them to our current flurry of assembly.

2012-2013 Production Run Updates:

2/9/12 – Now that John has finished quadruple checking out all possible kinks with the design, it is my turn to take a stab it now. I go through each and every part; dimensioning, applying tolerances, and final aesthetic details. I then pass it on to the machinists who program it all in to their machines.

The extrusion die is already made, and we have a sample batch of metal all finished up. I went to film the actual extrusion this week for you all, but they pushed the metal through 2 hours before they said they would so I was not able to witness the process for the fence. I only saw the stack of metal on the pallet. Next time it should work.

2/23/12 – We are shooting to ship the Jointmakers by the end of June. For those that ordered one of the Fence systems only, we should be able to get those out earlier, most likely beginning of June. The assembly time on these will be the slow part. There are more parts to the Fence Systems than there are on the whole Jointmaker, and we are shipping them mostly assembled. We will ship both the JMP and Fences together if you ordered them together.

3/15/12 – Finalizing some of the tolerances and dimensions of everything, triple checking everything before production goes full steam.

4/12/12 – Parts are being made and working out fit issues. So many parts on this thing!

5/10/12 – Sorry about the long delay in updating this! Extrusion metal is just about done. The hard chrome plated steel rods are being made right now too. The end of June is looking slim right now though. Especially with the many unknowns dealing with assembly of the fence units in a production environment.

5/17/12 – This project has been the first one for us to use some new CAD software, Solidworks. It is the industry standard for solid modeling. It does work differently from our previous CAD systems that we used to re-sell. Solidworks has come a long way in recent years and it is nice to be on board with it. But man, the learning curve is steep. It is definitely an improvement when it comes to prints, specifications and detailing though. All said and done it will be great.

The state of manufacturing is amazing though. All of the shops are busy busy and lead times for new work is getting longer. I have 6 machine shops making parts for me right now. I need more too!

5/31/12 – We are fortunate that we are making the JMP from aluminum because the price of brass is through the roof at this point! I am happy to not be using brass too much anyway, I personally don’t like shiny brass, only the tarnished brass color. Aluminum is quick and relatively easy to machine at least.

I am trying to see if I can do some tracking to determine the origin of our aluminum. I think it would be interesting for some customers to know the history. Ideally I would like to know if the aluminum is a recycled Coke cans or beer can, or an old engine block from a Mazda (I believe I heard somewhere that they are one of the few who make aluminum engine blocks..)

6/14/12 – With the testing and revisions that are happening, the schedule is being pushed out. I’ll have more details next week.

6/21/12 – Looking like end of August these days. Revising Revising..

7/14/12 – Whoops, the 4th threw me for a loop last week. All schedules lead to the end of August. I have 5 separate machine shops making these parts for me. At least these guys are in the 21st century and prefer email. I hesitate to use anyone who still prefers faxes!

7/19/12 – Rods are just about finished up for the Jointmakers. Time to go get them straightened. Cranking along here for the JMPv2. I did a design revision this week to make the laser grads easier to do on the Fence system. The grads will be lasered directly on to the stainless rod, and not on to an adhered piece of aluminum.

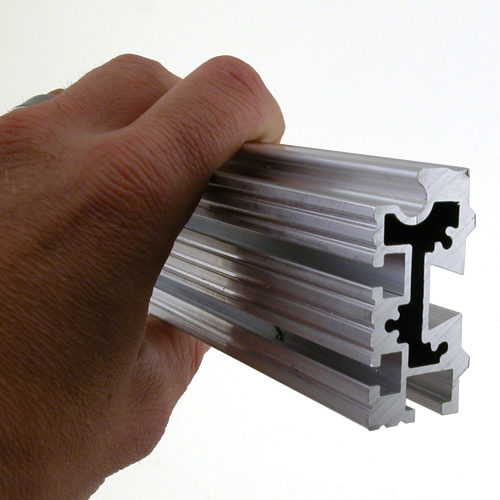

8/9/12 – Here is the fence extrusion part sample. You can see a couple of 3/4 round holes in the middle. We will tap those holes with threads. There is enough purchase from the threads so we do not need to have a complete circle floating in the dies. The die cost increases dramatically if you have multiple cut outs. Things are moving along well now with all of the parts. Anodizing will commence in a few weeks. I need to anodize similar colored parts together in order to get the best color match. Even then, that is not a guarantee though.

8/16/12 – The Precision Fence system is moving along well. The Jointmaker Pro parts are going just as well. Anodizing is always a moving target, but I venture to guess that the second or third week of September, we should be able to start shipping this all out. September will be crazy around here!

8/30/12 – Parts are coming in. Next week will be crazy. Jointmaker parts are wrapping up now. Most of those are all at the anodizer. The Fence parts are all coming in too. Those all need to be anodized still, but they are looking good. Here are few pics of random parts. The wood desk they sit on was built by John… like in 1934.

9/6/12 – It has been a good week for parts deliveries. All of the Jointmaker table tops and front and rear plates are at the laser engraver. I am making room in our humble little workshop to accommodate all of the Jointmaker materials.

The packaging takes up a LOT of space and it gets pretty hectic when trying to package it all up.

Parts for the fence are coming out really well. Still waiting on a few critical pieces though. I am confident that we will be shipping this stuff out by the end of the month.

9/13/12 – Its been a busy week with parts flowing through here like a river after a spring rain. The hardware kits are just about all built up for the JMPv2. The Fence parts are following suit. Anodizer is moving in to overdrive now. They seemed to lose 2 days this week with tank issues. Just placed an order for 7000 6-32 screws. The hardware adds up fast on the Fence.

9/20/12 – The Jointmakers are coming along well. Packaging has started and going smoothly. Hardware kits are all made up.

The Fence Systems are mostly all at anodizers now. We have a couple of thousand parts at the anodizer now, so we are in the “hurry up and wait” period. Here are just a couple of shots of random components, packaging and parts.

A pallet of Front and Rear Plates with Table Tops. This pallet is bit heavy.

Stacks of Jointmaker boxes, packed up partially.

Knobs and bearings.

A box of Jointmaker blades. These are sent here from Japan in bulk. We then divide them up and package them in cardboard sleeves.

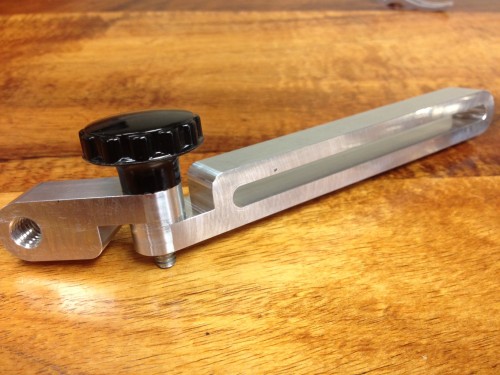

One of the Fence pivots.

Screws for the hold down clamp, waiting for knobs to be glued on.

09/27/12 – The JMPv2 Instruction books are printed, just a couple of last Finger Stops and Bearing blocks to load in. The Jointmakers should start shipping on Wednesday. The Fences parts are either all at the anodizer or already back. Assembly has started on the the parts. Here is a sample fence with an un-anodized extrusion. It is working great, super smooth and tight!

10/4/12 – We shipped out a bunch of Jointmakers this week. After assembling a few Jointmakers today for the WIA show in Pasadena, I realized there are a couple of issues. Nothing serious and all can be resolved. But we’ll be contacting the people shortly on steps that can be taken. It turns out a few parts were out of spec, and I did not see it until final assembly. Luckily, most have not shipped, so we can rectify in house before they ship out.

The Fence Parts are trickling in from the anodizer and sub-assembly is ongoing.

We received the threaded rod in, all cut to length. We were not impressed with the quality of the threading, so we ordered new rods made of 18-8 Stainless Steel. It is fast to cut, so it won’t delay us. Anyone have a need for a gazillion pieces of 14.4″ long 1/4-20 threaded rod?

10/10/12 – We worked on sub assemblies for the Precision Fence all week. I assembled 5 units for the WIA show in Pasadena and they are working out really well. We ended up having to go back and make some part adjustments on the Jointmaker parts so none of those were sent out this week. Time to go to California!

10/18/12 – The first trial of the productions fences went very well last week in WIA West show in Pasadena. John and I arevery psyched for this to be in the marketplace. It will be a game changer on the the Table Saw for sure.

More Jointmakers went out this week. More will go next week with probably only a few to go the following week. I need to finish assembling 5 more for the WIA Midwest show too. I have the frames built up, I still need to do the Keel Assemblies.

At this point, the Fences should probably really start shipping in the first week or 2 of November. There will be 5 Jointmakers and Fences to purchase at the WIA Midwest show next week. We sold all five at the Pasadena show, and now there are a lucky few out there who have them in hand.

10/25/12 – Lots more parts assembled. We made a Table Saw sled today to bring to the WIA Midwest show next week. Sub-Assemblies are piling up. I think I’ll have you all assemble this on your own next time around! The WIA show materials bogged me down this week, even though my team was able to keep assembling.

11/8/12 – Jointmakers are down to the last few on the wait list. They should be all wrapped up and out next week. The Fences will quickly follow suit. The timing of the WIA shows threw a wrench in to my time, but things are cranking along now. Packaging and shipping should start during Thanksgiving week. Sub-assemblies and packing going strong all next week.

11/15/12 – We shipping will commence on November 28th. We are up to our ears in parts. I actually have John doing some of the final assembly on the fences. We both concur that they are actually all pretty fun to assemble. Everything just fits together so well, that it is a joy to do. Sorry to say that you all won’t get to try it for yourselves since we will ship them assembled! (Except for the basic attachment of course.)

11/21/12 – Still on track for next week. Gobble Gobble!

11/29/12 – The bulk of the Jointmaker Pro Fences went out this week. The rest will go next week. Table Saw Sled kits start leaving next week. The metric versions of everything go after that. All of the Jointmaker Pro saws are shipped. Phew.

12/6/12 – The Table Saw Sled kits starting shipping today. Most of the Jointmaker Pro fences are shipped, minus a few stragglers who are reluctant to update their credit card numbers….and also, sorry to say, the Metric versions. We ran short of extrusions, well actually, we were shorted extrusions, so more need to be made.

We loaded pallets of Fences in to the UPS truck every day this week and last. Tis the Season!

I spent most of today straightening the miter gauge rails that are included with the Sled Kits. My blacksmithing experience came in handy!

12/13/12 – It looks like the Metric versions of the Jointmaker Fence will be complete in January. It is such a bummer since we have have a few stacks of parts complete and ready to go. I want to see some pictures of people Table Saw Sleds so send them on in!

01/03/13 – The remaining extrusions will be finished with machining on Monday. Then off to the anodizer. Hopefully we can get them all out the door by the 17th.

01/17/13 – The extrusions were delivered today! Agh. I dropped them off at the anodizer today. The metric units should be assembled and shipped out in the first week of Feb. span>

02/07/13 – The bulk of the metric precision fences shipped out today. A few remaining go out next week.

I’m curious how much the anodizing changes the dimensions of the pieces. Do you have to take that into account during the milling?

— Peter

We get very little growth or loss with the anodizing process. I believe they have refined the process enough so that we don’t even consider it now. This was not the case years ago.

I was reading earlier in this blog and noticed you are now using SolidWorks — I’ve been hooked on it since around the 2005 version. It’s the only way to fly. My only problem with it is that it isn’t forward compatible and one has to upgrade each year to be in sync.

A gazillion pieces, not so many. I could use a few – use pieces of 1/4-20 in clamping, etc on my smaller machines. Could you tuck a few into the box when you ship my fence?

🙂

John

Looking forward to getting this awesome update to the JMP!

I am happy that the fences were well received. I am a little hurt that those of us who have been on a waiting list for nearly a year were not sold the fence before the “lucky” people at the shows.

It may appear that those at the show were lucky, but the parts for the show models were rushed to us-and we barely made it–we are still waiting on a couple of parts for the rest of our customers (outside of the WIA units).

–John

I understand how important the WIA shows are. Providing woodworkers across America the ability to view and purchase the JMP Pro with the new fence system will increase possibilities for all of us who are planning on owning one of these wonderful systems.

I too was a little disappointed by the fact that after waiting nearly a year, those of us in the “backlog” would have to wait a little longer….but I certainly can understand the importance of the WIA.

However, after purchasing a JMPv2 Pro and also the JMP fence “the works”, I received an email indicating that those that purchase the same combination at WIA will also receive a JMPv2 Stand for free.

I participate in the pre-ordering process, because when the tools are that good, it’s worth the wait. But I must admit to feeling a little slighted after reading that email today.

I understand your frustration about the timing. It was not our goal or plan to attend the shows with the fences before we shipped the product. Trust me, we would have much rather have had them in your hands already!

As far as the show special with the free stand; the units are used thoroughly through the weekend, often enduring hard use by beginners. While they are new prior to the show, they are not new by the end! There is no way we could offer them as new units at that point. This is the fourth time we have done this special for shows.

I appreciate your note, and I understand. I am busting butt to get the fences into your hands as soon as possible!

Michael

I await my fences with baited breath. (It’s been baited so long I think it’s stink bait.) LOL! No, maybe it’s the Sushi. Or the Bourbon. Oh hell. I can wait.

Oh man, that’s a bummer about the metric fences. With the week between christmas and new year’s off I was was looking forward to some serious JMP quality time.

Alas. Appreciate the head’s up though.

Dear John,

I was on the waiting list to get the precision table saw sled kit. I have never heard back from Consuela whether you made enough to get to the waiting list customers. Is there enough?

Thanks,

Tom

Folks;

I am the wrong person for customer service questions.

The answer to specific tool productions questions are most often found on the production schedule tab om the top of our site. Wait-list questions can be found by emailing sales@bridgecitytools.com

I am trying to do absolutely nothing and these questions are forcing me to work. Now I am exhausted. 🙂

-John