The intuitive mind is a sacred gift and the rational mind is a faithful servant. We have created a society that honors the servant and has forgotten the gift. —Albert Einstein

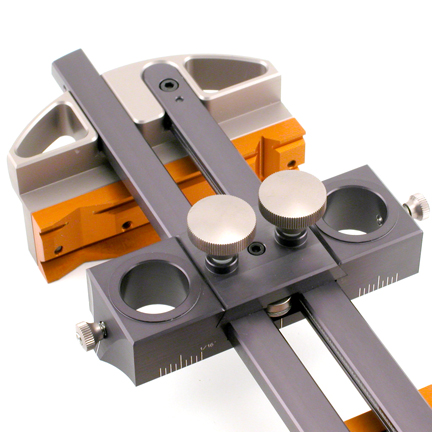

Over the past six months or so we have been developing the second version of the Jointmaker Pro. Most of the things we have addressed are transparent to current owners with the exception of our work on various linear motion options for the tables. Here’s a brief progress report;

We developed a recirculating linear bearing system for the sliding tables that fell flat on its face within 2 hours at the recent WIA conference. Although disappointing and embarrassing, this is the fuel that lights fires in the brains of engineers. I am pleased to announce this failure has been fixed. Here are the pros and cons of the new design;

PRO: The cost is identical to the current dovetailed rail design

PRO: No lubrication is required

PRO: Attaches to all existing JMP’s

PRO: Much more efficient

CON: Not as quiet as the original version (uses acetyl ball bearings)

From our perspective, there are more pros than cons but we are interested in your thoughts. Below is a video of a prototype retrofit version–the final production versions will be slightly different visually but it is easy to see the efficiency of this system. For those that are interested in converting to this system we are forecasting the cost for new rails, new tables and new fences to be around $395–delivered. Again, the video is of a prototype!

JOINTMAKER SW

We are building prototypes of a new version of the JMP that has only one sliding table opposing a fixed table—similar to all sliding table saws—and it’s working title is the Jointmaker SW (single wing). If this passes our tests, we believe this version will have a street price around $795. The cost savings emanate from the elimination of one linear motion table, and a reduction in metal/machining/anodizing expenses by allowing the blade to tilt 45 degrees in only one direction. It will tilt approx 18 degrees in the other direction for dovetail cuts.

If you have an opinion/suggestion/comment regarding this version, please chime in. We will post a video of a working prototype within the next couple of weeks.

KERFMAKER NEWS

All of the Kerfmakers will be out of our warehouse this week and we are reopening orders for the second run–our website will be updated in the next day or so to accept orders. I warned everybody that “The Tool You Want Real Bad” is aptly named. We have another batch in the oven so if you want one before the holidays, now is the time to order.

COMMEMORATIVE TOOL # 16

We will formally announce the CT-16 Palm Brace this week via email (and I will let you know here as well.) I have been playing with this tool for a couple of months now and I am completely stoked as to what it does in my quest for silent woodworking. It is not a panacea but what it does, it does very well and I am sticking to my guns that this is best screwdriver I have ever used.

The DJ-1 Drilling Jig, Round 2

We are completely sold out of the first production run and will announce pre-orders for round 2 this week as well. If you missed the first go, you may want to consider getting your name on the list for the next batch–this is one incredible tool.

That’s enough for now. We look forward to your comments.

—John

First let me say the motion on the new rail system looks incredible. That will be one impressive upgrade to an already incredible tool.

The single sliding table idea is great… Makes for a great “hand cut” dovetail making machine that will drive traditionalists nuts I’m sure.

Does this mean we will have 2 island paradises to come visit you on now that there is a 2nd run of both the DJ1 and the amazing Kerfmaker? Or have you decided on one larger purchase… maybe New Zealand?

We are pleased with the new ball bearing slide…so far. We are still testing but would not have let the cat out of the bag if we were not excited.

I have moved on from my island quest…thinking planets and galaxies now–working on the details for Pizza Hut delivery which is complex.

–John

While Pizza Hut is better than Domino’s, I would have hoped for something more along the lines of Wolfgang Puck for food delivery…

Or Peter’s San Diego Pesto company.

I’m glad that you’ve figured out the issues with the bearings on the JMP. The video is great. I love the idea of the single sliding table, and allowing the 18 degree tilt for dovetails. I think I need to go and play with Roger’s a bit more. Maybe with a project in mind…

Lots of folks excited about the Kerfmaker delivery. Me, I’m holding out for the black chroooome (gotta say it right) marking gauge. That’s one sweet tool.

Are those HP6’s in the background of the JMP video? Talk about tool porn!

– Peter

John,

Since the CT-16 and the DJ-1 are coming out at the same time and the fact that these tools are not something i can just pay in full with my weekly allowance my wife gives me, will you consider leaving the tools open to purchase longer than normal?

ForumMFG: Anytime we do a limited run, which is every time in this economy, all you have to do is give us a call–we can almost always work something out.

I can share that the CT-16 will have a 3-4 week ordering window. The DJ-1 will be longer.

Peter; You should start a pesto business!

–John

John,

Great work on the new slides. This is the new “Tool I’ll Want Real Bad!” The tables look to be almost effortless, and a little extra noise wouldn’t bother me at all, might even drown out the “voices!”

I gave my KM-1 a test run last night and it worked perfectly. I can’t help but to think about how much time I’ve wasted creeping up on a good fit. The Kerfmaker is just simply a huge time saver and accuracy booster.

The last bunch of tool offerings are really getting my creative juices flowing, I’m finding all kinds of cool applications for the DJ-1 and will be posting some photos on the Forum soon.

-Rutager

John,

One more thought, I was just using my JMP for some small stock, and of course I don’t need to pull the table all the way back, but it seems easier to work to a stop at the end of the pull stroke, so maybe the new rails could incorporate an adjustable bumper that could be set for stock width. Another benefit would be that you could set it so you wouldn’t fall off the blade when cutting.

-Rutager

Rutager;

The Kerfmaker is an awesome time saver–thanks for the second party validation! We should have sold it as the Anti-Creep tool–bet sales would have been in the billions. I am sure glad they are all on their way–people were getting a little cranky with us…but one thing I will add, in 25 years, we have never been early and always late–consistent yes/no?

The new JMP table system is almost effortless and the biggest advantage in my opinion is the feedback you feel in cutting. Now it is EASY to know when to adjust pitch based upon the resistance.

Without this ease, we would not have addressed the single wing idea–so far it looks like it will work great–will know more in a couple of weeks.

Regarding your specific need, clamp a piece of soft wood to one of the dovetailed ways to interfere with a complete table retraction–put a bumper on if you like–this should be a good field fix for you. I want users to make a complete retraction when possible to avoid crashing the blade into the stock on a blade raise move.

–John

John,

I am one of those who was getting “a little cranky” as you put it in your response to Rutager, and unfortunately I am only getting crankier. You have had the benefit of my money for the last 3 months and not once has there been any communication to me initiated by BCT with an update on my order.

I have had to send emails seeking information. I have been told in emails that the orders are being sent out in the next few weeks, to next few days to hope to have them all out by middle of next week to have them all shipped by Friday to yours should be sent out by the end of the day. Here it is a day and a half after that supposed deadline and still nothing sent to advise that my order has been processed nor has a debit been made on my account. In two emails I have been offered a long story about being busy, no-one else to help process orders, answer phones, emails, process orders etc. For a company that has been around for 25 years and takes pride in that, I would have thought dispatching orders would be better organised by now.

It seems as though you have an almost perverse pride in never having been on time with meeting deadlines and running late with shipping for the last 25 years. I understand this is a consequence of the business model you have and this is not my quibble.

What is most disappointing to me is that there has been a pathetic lack of communication initiated by BCT about progress, all the information I have been given has only been forthcoming in response to emails I have sent.

Surely this could be improved and improved past just sending emails with spurious promises such as “I hope to get yours out by the end of the day” type responses that do not get honoured.

I am disappointed to have to post such a negative entry on the blog. I believe that sending yet another email to one of your staff is just a waste of my time and electrons as none of my previous emails seem to have achieved much.

Ray

Ray-

We announced that we would ship at the end of Sept. and we were 3 weeks late. There is no perverse pride, it was our best guess based upon the order volume which we increased in the middle of the run. That said, we do have a history of missing our dates and I am largely to blame–often times I will stop production if I don’t like what I see. That was not the case here, volume was the issue, a pleasant problem but nevertheless a problem.

I just spoke with our staff and they assured me that each and every email gets answered. Regarding the comments you have received from our staff, you were told the truth–we were snowballed with volume and were not as fast as anyone would have liked on the processing end. (our website is under repair so the KM-1’s were a manual nightmare–which is now over). Once our site is finished, we will have the ability to contact specific customers regarding order status, whereas right now we have to blast the message to everybody on our list which we will not do.

Ray, there are no excuses, we could have done a better job and we apologize for your experience with this order–it is on its way and you should have received email notification today–if you have not, please contact me direct (or if you wish to discuss this further);

john@bridgecitytools.com

Regards,

John

Hey John,

I received my three tools you can’t live without today and they are beautiful. Unfortunately, now you have me considering the JMP Next Generation. Without even thinking about it I will be waiting with bated breath for my MG-5 and the CT-16. As Jean Luc said “Make it so” 😮

Fred

Fred; Now you need to make some sawdust using the KM-1 and report back… Your Tool Potentate needs a hug.

-John

Hey, Tool Potentate (or should we just call you “TP”? Or maybe “Single Ply” for short?). Here’s a hug: [_]

Now, I think you need to check your spam filter, as I sent you several emails, and you haven’t responded. I can’t imagine any other excuse (oh, I know – you’ve got lame ones like nasty people were trying to make you deliver tools to them on time, and too many people ordered “The Tool You’ll Want Real Bad” and you can’t count your money fast enough…) for not having responded to my brilliant, evocative, inspirational and sometimes irrational prose.

And on another (somewhat ADD) note, I’m guessing that Michael did the music for the palm-brace video? He sure was snarky about the violin concerto in the last one. Ingrate. And you can tell him I said so. See if he gets pesto next time…

– Peter

Peter;

No emails in my spam box–please re-send–after you find a cure for Akashiwo sanguinea, aka Killer Foam.

TP works.

John

john@bridgecitytools.com

.

After having just cut veneers of Spalted Maple into pieces 6″ by 1 1/4″ lengthwise on my JMP I’m really looking forward to the new sliders. One thing that has helped a lot is to keep the blade waxed on a regular basis. When I went from not waxing to waxing there was a big difference in resistance, especially when you have the blade sandwiched between that amount of wood. (ok, for those not familiar with the JMP, one is almost at capacity – thickness wise when re-sawing on the JMP.)

The big question(s),,,,

Once the JMP-2 gets going will the “Upgrade” be available before, during or after the rollout?

and would the new JMP’s be a black chroommme combination?

Also,

When the “JMP-1” table package will be jettisoned, it would be interesting to see the uses they could be put to use for in an “afterlife”.

-Roger

.

Roger;

It is likely the upgrades will be done long before the v2 saws are ready.

Next week we will begin testing on the single wing version.

As you know, rip cutting is not the JMP’s strong suit but I agree, the new system will help–a lot! I have never tried the waxing idea–perhaps when you get time you can share how you do this in the JMP forum?

I agree, I am already thinking of ideas for the dovetailed linear tables…

–John

Roger – does the waxing leave any residue that makes finishing difficult?

– Peter

P.S. Excellent use of “black chroooome”!

P.P.S. TP – excellent use of Akashiwo sanguinea (back when I was young (a couple of years ago) it was Gymnodinium sanguineaum. How things have changed!) I’ll get right on it. Are you having an outbreak up there?

Peter;

(Disclaimer; PFranks is a world class oceanographer and I am not) Yes, thousands of critters washing up dead from Oregon to Canada–one of the worst on record. It is being called “Killer Foam”–basically the phytoplankton from hell.

–John

Peter,

Short answer – no.

Long answer – When I apply the wax to the blade, I let it sit a little – and then buff it off…. so there is no wax residue on the work surface. (Note – On my Inca planer there is a stainless elevator plate that holds the board as it is being passed through – I and every other Inca owner waxes/buffs that surface in order to facilitate an easy pass through.) Hopefully tonight I will be talking about this and other tidbit JMP points on the BCTW forum.

-roger

John – yes, this is one nasty critter. I’m amazed I hadn’t heard about the bloom – usually the press is hounding me for pithy quotes about red tides like, “it doesn’t have to be red – it can be green or brown or yellow, depending on the organism.”

Global climate change for ya…

Looking forward to the black chroooome palm brace outbreak tomorrow!

– Peter

Peter;

In a strange sort of way, this discussion is more interesting to me than woodworking at the moment…

I think we need to open a “Back Porch” forum in our Community section to appreciate the diverse and talented people who frequent here… I will do this next week.

Anyway, for those interested in what is turning into an amazing mystery, click here.

–John

PS: Have I mentioned lately that I LOVE BLACK CHROME?

Great link, John. The scientists quoted in that article are all my old buddies. Wonderful people – you’d enjoy them. Give Michelle Wood a call (she’s in Eugene) and tell her I sent you. You’d enjoy her. She has good taste in ceramics, and a very cool house in the woods (kind of appropriate I guess).

I did my thesis work on Alexandrium fundyense (though it wasn’t called that at the time) on the east coast. Pretty similar to Alexandrium catanella in lots of ways. It’s pretty impressive that after a century of studying these blooms, we still don’t have a clue as to why they occur. Young scientists will usually tell you why. But by the time they get to my age (not so old!) they realize that they don’t really have a clue. The question would be: what kind of data do we need to gather to find out what starts the bloom? Frankly, I don’t think we even know that. It’s a wonderfully rich problem. My take is that if we can understand why we get red tides (or harmful algal blooms – HABs), we would learn a lot about how the planktonic ecosystem works. It’s like studying someone who’s sick to learn how healthy people work. You study the ecosystem when it’s in a “sick” state so you can figure out what keeps it healthy most of the time. But it’s easier said than done.

Don’t eat the shellfish. We have a superb shellfish monitoring program in the US, so it would be very unusual for toxic shellfish to reach the market. But stick to east coast shellfish for a month or two…

But remind me again: do you like Black Chroooome?

– Peter

John,

Here are three major hugs as I used my Tool I Wanted Real bad on my table saw and my band saw and it was SWEEET!!!!:o) Oh and did I mention that I Love black chrome even more than you do so I say get cracking cause, cause I want my MG-5 and my CT-16. Now I am willing to wait for a whole day? :o) How much they gunna be hittin my wallet fer? :O

Fred

I was on the website yesterday around 4:00 and on the main page it was showcasing the ct-16. Picture and all! I got interrupted and wasn’t able to click on it for more information and then it disappeared!!! So disappointed! Must of been just working on the website or something??

Is the ct-16 gonna show today?!

The CT-16 will go live before noon PDT 10/30. Yes, we were testing. FYI: Order cutoff date is Dec. 3

–John

I just clicked on the CT-16, and loved the price!!! Unfortunately I’m guessing it was a mistake (only $10 more than the drill/driver set). Bummer…

– Peter

Hex bits are spendy. No mistakes here.

John

TP – it was my misunderstanding. I had thought that the CT-16 was to come bundled with the hex bits (and at the time I clicked the picture on the web page, it had the hex bits in the picture). So it looked like the Palm Brace was only $10, once you’d paid for the hex bits. Now I see that they’re two separate sets. And given your description of how hard it was to find decent hex bits, the price for that set is probably quite reasonable. Together the price is about what I had guessed for the set (actually a bit lower!)

Now a $10 black chroooome palm brace… 🙂

– Peter

John,

Have I mentioned how much I dislike you and Michael and everyone else that works at Bridge City? I was FORCED to pre-order both the CT-16 AND DJ1. My hands were tied and fingers bent to the position that only allowed me to press the pre-order buttons. This was all done at gun point and I think that I should be compensated by having the very first one of each of these. Yes, I know it is the second go round with the DJ1 but I will accept the first of this run. 😮

I think now you can all see the horrid situation I was placed in by this oh so despicable company.:o:o:o

Fred

This black chrome material, how scratch resistant is it? Will you ever pair it up with your burnt orange? That would be an awesome look. Last question, any of these tools come with a case to protect them when not in use? What about the bits?

DJ1-2 Question. . .

So in doing another run on the DJ1-1, will the DJ1-2 have any changes made to it before it goes into production again.

If there are changes, will those upgrades be available for the DJI-1-1?

Had to ask!

ps. Where does one grab the smilie faces I see in Fred’s posts above?

-Roger

Got an email this morning telling me that my Kerfmaker is on its way, really looking forward to having it in my hands, getting so envious of all those who have gotten theirs and already used it.

John thank you for the email and, never fear, I was not offended by your comment about which Customs agency I have to watch out for.

John,

Just curious but what happened to that black Chroooome combination square? I hope I didn’t miss it…I got my hats yesterday and my extra drill bushings today.. this is getting habit forming. I’m thinking I could actually wear the hat and provide you with some midwestern advertising for a discount on tools….maybe we can work a deal on that one? I ordered my CT-16 tonight – looks like the bits come with a case and the drill doesn’t….Will it fit in the bit case??

Keep ’em coming – I’m enjoying it.

The black chrome combination square is coming soon!

Thrilled to learn you like your BCTW hat. We suggest it only be removed for the national anthem and funerals.

The bit set will come in a the same box as the brace, which is our standard BCTW box.

–John

Ray-Glad to learn your KM-1 is headed to a Custom’s office near you. Please check back in when you have a chance to use the tool.

–John

FYI; When we make either minor or major changes to a tool we append a v2, v3… The DJ-1 will remain unchanged with this mfg. run.

I don’t know how Fred embeds his emoticons–I am a tool guy who is never as happy as Fred. Fred?

–John

Black chrome is as durable as chrome. That said, the base material is equally important–the swing arm of the CT-16 is aluminum (to keep mass over the drill axis) so if you toss your tools around (an act which of course nobody on this forum condones) this may be an issue.

As mentioned, the bits will each nest in the same die cut foam liner as the brace.

We will investigate the option of a wooden case (which always surprises me since our customers are WOODWORKERS!)

–John

Fred;

Considering you have a Smithsonian caliber shop, you need to get others to start drinking the Tool Kool-Aid you so obviously enjoy.

I do agree with you–it is easy to dislike Michael and the rest of our staff–they never agree with me like I think they should.

–John

This may seem obvious, John, but: YOU’RE THEIR BOSS. FIRE THEM! That’ll fix that pesky lack of respect problem.

As for the smilies, I think that you can just use the usual things (colon dash parenthesis, semicolon dash parenthesis, etc.), and it’ll work. Let’s try it: 🙂 😉 🙁

Peter;

People fire themselves… I am just the facilitator. And for the record, this staff ROCKS–only if I ignore the insubordination, the arguing, that fact that I am “old fashioned” or “old” and that , “IT’S a NEW WORLD”, or “Why do you eat hot dogs from 7-Eleven?” and of course my favorite, “I am canceling your vote.”… and last, but not least, the constant reference to a speech impediment I have suffered with for over 30 years…can’t pronounce the word “raise”.

Isn’t life great?

And let’s propose a big toast to the physics of the opposable thumb (which of course only I think about…) because without which, we join the ranks of cloven beasts–multiple stomachs, methane maniacs, …

–John

John, your life sounds a lot like mine. I guess that’s the problem with hiring really smart, hard working, independent people. You can’t tell them what to do. I’m guessing you didn’t choose the music for the CT-16 video either. Your job has probably been reduced to ensuring that the final product is up to your standards. Other than that, stay out of the way, and let those youngsters have their way. They have more energy anyway. Sigh. I remember those days…

I took my Biological Oceanography class out for a “cruise” (research cruise – no deck chairs, and you have to work) today. Perfect weather, no harmful algal blooms, and none of the things we caught in our nets and sediment cores had thumbs, opposable or otherwise. Try being made of jelly and pooping out your mouth. Or worse yet, being a sea cucumber and breathing through your anus. Seriously. Talk about bad breath.

Do you think we should make Fred an honorary Tool Potentate? Or Tool Impotentate? He certainly has an enviable collection (though he needs to improve his BCTW assortment…)

– Peter

Does the dj-1 come in any type of case since there are so many pieces to keep track of?

John, My KM-1 arrived today safe and well, haven’t been out to the workshop yet to try it out, way too hot here today when I got home. Very impressed with the machining and tolerances at first glance though, I am sure it will be just as impressive when used in anger.

Ray;

Love your sense of humor–that was humor wasn’t it?

Thanks for the update–and I am sure your anger will be replaced with joy.

–John

“used in anger” means to use a tool for the purpose for which it is intended or designed, not just sitting in the lounge room, twisting the locking wheels over and over, setting the spacing to suit whatever parallel surfaces are within reach. For the record, the top of my coffee table is precisely 39.55mm thick at one end and 40.01mm thick at the other, according to the numerous measurements taken from my KM-1 after setting it off the wood.

I just have to wait for this heatwave to end so I can get out into the workshop. Longest, hottest start to November for a long time with consecutive days over 35 degrees celcius. For those readers who are in a different hemisphere, that is over 95 farenheit. Hasn’t been a maximum below 35 here for about a week, for us here that is a long time. And no end in sight.