Rarely do I keep track of my hours on a tool but the CT-17 has been easy–I haven’t worked on much else since my work retreat in January. This adds up to about 300 hours of fun for me. Some of the components of the CT-17 were designed, and redesigned, almost 30 times. Why? Because of Dunhill’s Maxim:

“It must be useful, it must work dependably, it must be beautiful, it must last, it must be the best of it’s kind.”

This is, I believe is the best set of guiding principles one could ever adopt.

As many of you know, for the past couple of years I have spent much of what little free time I have learning how to perfect the art of crashing model helicopters. What makes this fun is the solitude of sitting at my little repair table and fixing what broke on my latest three second flight.

During this process I became a fan of helicopter parts–all have been reduced to their essence–no excess weight, materials appropriate for the function, aerodynamics when applicable and engineering that is just plain sexy– a Hiller rotorhead (amongst others) is a kinetic work of art.

Starting with the CT-14, where we skeletonized the body of a shoulder plane, we have embraced “helicopter ethics” in our work (when possible). For me, I am continually asking myself, “Is this the least amount of material to work and remain functional both physically, emotionally and aesthetically?” The CT-15 was also designed with minimalism in mind as was the DSS-6 Double Square and the DJ-1 Drilling Jig. After all these years (27 and counting…barely most of the time), I think these pieces are amongst our best work.

There are two reasons for sharing this information; one, prior to making a single chip in metal, a great deal of resources (time and prototypes) were dedicated to the form and function of the CT-17–this is a lesson easily and frequently skipped by hobbyists (and some pros). I have always asked students in my design classes; “How many of you figure out what you are making while you are making it?’ The show of hands is almost always unanimous–not good. Interestingly, if I were to only make one of these, the total time from idea to finished product would be ratio of about 10:1 in favor of the design time.

Second, by sharing that I have an undeniable influence in this case (model helicopters) I am suggesting that influences are everywhere. I almost got killed one day walking across the street because I stopped to marvel at the design cast into a manhole cover (cell phone cameras have given me a new lease on life). One of my furniture pieces in our “Original Design” forum was inspired by the landing lights of the Portland International Airport. There is such a huge difference between “looking” and “seeing” that you never know what direction your work will take as you progress in the world of design.

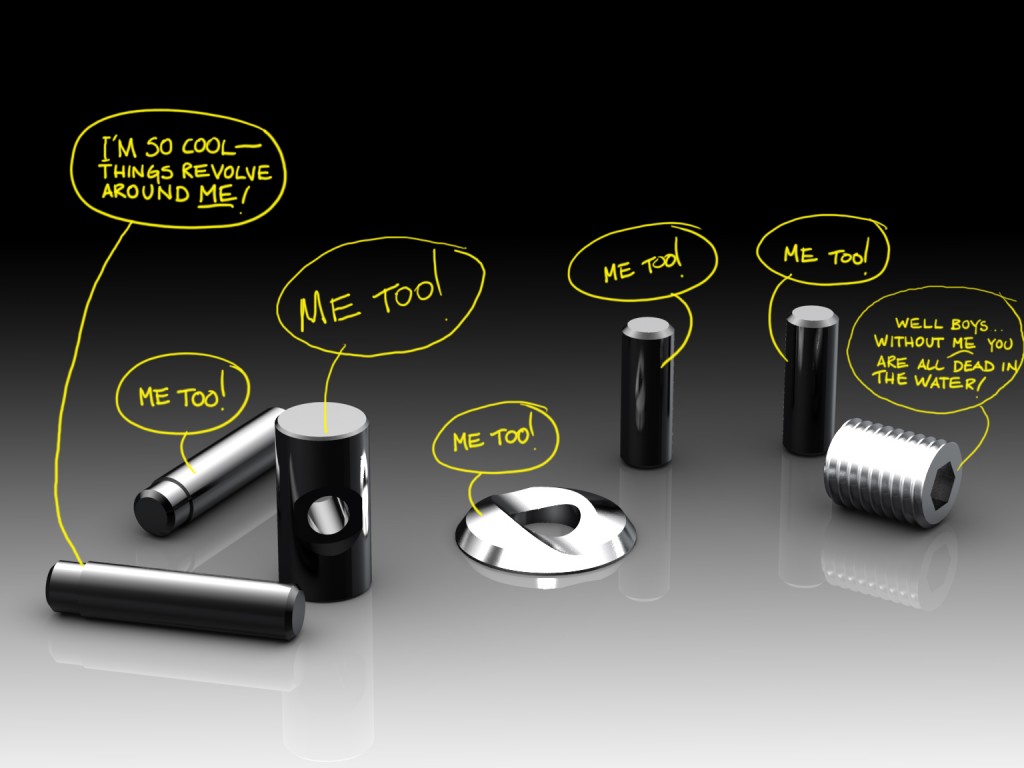

Personally, my work is seriously fun and I can’t wait to share the CT-17 with you. And speaking of fun, Clue #8 is pictured below.

–John

Dude, this is going to be such a awesome tool! I can’t wait!! And I don’t even know what it is or have the slightest idea! One thing is for sure, it’s a new invention and I love new inventions!

.

Obviously, the element on the far right (with the hex recess) is for the stem end of the stainless “Tulip” from clue #6.

Now, the ribbed surface on the outside of the far right piece would appear to be a cutting/scoring element of some sort.

At the same time the ribs appears to be continual spiraling motion.

So,

Ok,

I’m gonna throw out another guess……..

The CT-17 is a tool that when all the parts are working in unison becomes a “Wood-threading Devise”, that would have adjustments for thread pitch for both the female and male counterparts. (and various diameter sets will be made available)

We’re obviously coming full circle now, since this concept has been percolating since John made his Nutcracker years ago.

It took a few helicopter crashes/repairs for the link to manifest itself.

-Roger

I wonder is that plug cutter looking thingy fits into the largest black clyinder pictured above?

“Well boys, without me you are all dead in the water”.. Does that have something to do with flying a helicopter over a pond of water and trying to flip it over?! Then all of a sudden you find yourself in the water?

John,

Those are some seriously gorgeous parts! My guess now is that there is something similar to a batten(helicopter blade for inspiration!) That is adjusted with the many cylinders to layout an arc, curve or even a wave(rotor wash!) on your workpiece which is then traced with a scribing point or maybe a pencil.

-Rutager

Really nice post, John. I love learning about the thoughts that go into design, and the philosophy behind the design, almost as much as I love the product.

And I LOVE the products!

– Peter

Okay I think we’ve been shown about half the parts and I still don’t have any good guesses. I do think that the cylinder with the hole through it fits into the groove of the washer shaped part and possibly the tulip shaped part goes through the cylinder alowing the tulip part to swivel, why? I don’t know!

One thing I do know though, is the big prize is slipping through all of our fingers!

-Rutager

We’ve been shown 13 of the 23 parts. I’m guessing that John could show them all to us, and it still might be difficult. Do you suppose that he designed this just to flummox us?

Mike

Clue 9: It will schedule to ship in March 2011, be officially delayed until April 2011, and unofficially delayed until well after CT-18 has been announced. }->

And I’ll still order one assuming I can imagine some possible use and can afford it….

“Clue 9: It will schedule to ship in March 2011, be officially delayed until April 2011, and unofficially delayed until well after CT-18 has been announced. }->

Well, at least we are consistent.

🙂

-John

A tenon cutter?

.

The 2 items barrel objects on the left are obviously meant to be inserted into a fitting – probably on some form of flat stock.

so what?

this may lead to…….

I don’t know exactly how, but what we may be looking at is some type of hand held (with the help of a tabletop) vertical lathe.

Think a curvilinear plane that’s operated in an eggbeater fashion.

The difference here would be the ability to form something that is divergent from the 360 degree action restriction that you have on a lathe.

Another way of interpreting the concept would be John’s “silent woodworking” version of hand held router, that goes beyond the HP6 series.

-roger