________________________________________________________________________________________________

“All great deeds and all great thoughts have a ridiculous beginning.” — Albert Camus

________________________________________________________________________________________________

Pleased to share that the DJ-1 Universal Jaws are at our warehouse and are being shipped this week. They came out great and we are excited to hear your feedback. We have a couple of extras so if you missed the order window, give us a call: 1-800-253-3332.

ALL of the CT-17’s are back from the grinders and are going through fit & finish in our prototype shop. Here are a couple of pics of the grinding machines;

The surface grinder is a big one…

There are two set-ups in this image, planes are getting their soles ground on the right, and one side square to the sole on the left…

Here is a closer view of the sides after grinding…

From here, each body is hand de-burred, the mouths are filed by hand, and the mechanism assembled. All told, there are approximately 2 hours of work per plane left at this point. So close!

Next week I will be traveling down to L.A. to visit Roger Savatteri’s new shop and meet with a gaggle of folks interested in the Jointmaker Pro. I am really excited to present the new accessory fence (still in CAD form) for feedback and comments. We will be gathering on Saturday and if you would like to attend, RSVP Roger: savatteridesigns@earthlink.net.

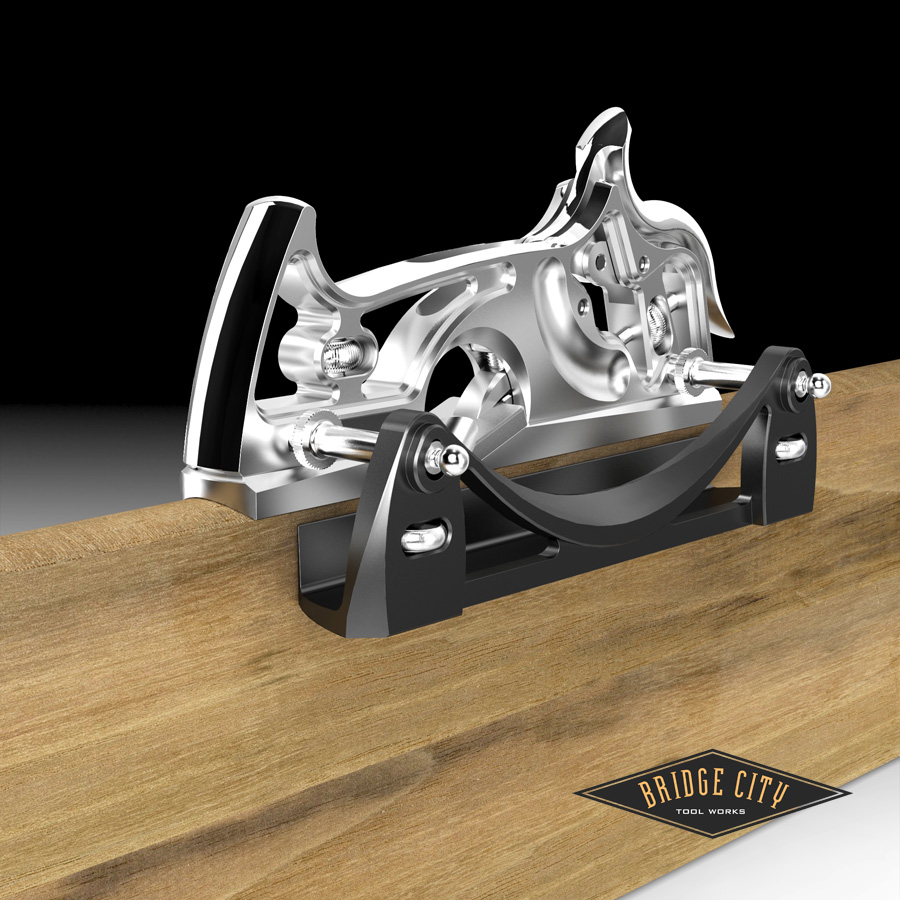

Last week I announced our 2011 Special Edition tool, the Fox Tail Crowning Plane. As mentioned we are only making 50 and as of about 10 minutes ago, half are spoken for. Here’s another peek:

Lastly, we should be seeing first article of the new HP6v2 profiles we introduced earlier in the year…

Lot’s of stuff going on here–all thanks to folks like you!

–John

Now THAT’S a surface grinder! Wow!

Thanks for the update, John. It’s pretty impressive that you can line all the planes up like that, and have everything co-planar. I’d be scared that one of them would tilt and screw everything up.

I think I saw mine in there. Can hardly wait to try it out!

– Peter

P.S. Where’s the HP6-v2 article coming out?

Peter: “first article” is a mfg. step whereby the very first part is scrutinized for errors. Think of it this way…imagine you wanted to create a PHD from Canada and the “first article” was nothing more than an aoemba…lots of tweaking to get to the goal.

Make sense?

🙂

-John

Ah. So it’s something beyond a prototype, but not yet the finished product?

Speaking of unfinished products, when’s that book with Joe Felzman coming out? I’ve seen a few of his recent pictures, and they’re even more stunning than usual. I’m thinking that Fred needs a framed set of Joe’s images of the BCTW tools to hang in his workshop of shame.

– Peter

“I am really excited to present the new accessory fence (still in CAD form) for feedback and comments.”

Will you be posting that info here after the meeting? I know that I would like to see the proposed design.

-D

I do plan on posting this (similar to the feedback loop we all participated in regarding the Universal Jaws for the DJ-1) as soon as I get back from this meet and greet.

Something to ponder: I am getting cuts in eastern hard rock maple that are glass smooth–so I want/need to make gears on my JMP–I have a class 5 fetish for clock mechanisms–John Harrison is at the top of my hero list. Megan Fox is a class 4 fetish (at the moment).

In order to do this, I need the ability to move an index system in 0.001″ increments for the proper cuts needed for gear teeth. That is one criteria that I am building into this system–all the rest of the applications that I can think of pale in comparison to this need. So whether one wants to cut gears or not, the ability to move stops/contraptions/etc in really small increments will be built in. AND, I want the system to be user modifiable–that is, if you have a really weird need, I want this assembly to be able to adapt.

Furthermore, I want this ability to disappear really fast when I don’t want this capability so I can do more traditional types of cuts. That part is done. I don’t plan on putting the original fences (the two metal component) back on my saws. And, both the straight and trap fences are backwards compatible.

What I am really excited to get feedback about is the new clamp system that is built in to the fence system (or not–it is an option) plus the ability to cut odd shaped pieces. (not rectilinear).

So in this case, I am driving the design for needs that I have, and the feedback from fellow users is paramount in making sure that we get this right the first time so it will accommodate future needs for all.

Make sense?

–John

PS: I don’t know how this totally awesome and worthless blog picks these goofy avatars (I like them) but mine actually looks like me–weird.

Of course it makes sense. But that’s because you’re mature enough to know that you don’t have all of the answers within yourself. Looking for input from others requires a level of self-knowledge sorely lacking in design today.

You know what I would like to see? I would like for someone to come up with a really cool design for some jig or tool that I can make with the parts left over from converting the JMP to v2. Can’t wait (but must wait) for the conversion kit to arrive.

John,

Do you have any pictures of the jig holding the plane bodies sole up?

It would be interesting to know how they referenced the plane bodies parallel to the bed of the grinder.

Unrelated point. Have you ever seen what happens when a blanchard grinder loses power to it’s magnetic chuck? It is quite spectacular. Thank goodness nobody was hurt.

“Do you have any pictures of the jig holding the plane bodies sole up?

It would be interesting to know how they referenced the plane bodies parallel to the bed of the grinder.”

No pics but I can tell you how it was done. The bottom surface of the sole is parallel to the top surface (in theory anyway). Consequently, a fixture was made that uses the two standoffs for the clamping mechanism as the rear support and a large standoff was sunk into a fixture plate to support the nose, and ground to the correct height so the bottom of the plane was parallel. The bodies were all nested and the soles were “dusted” which is a grinders term for removing very little material.

Like any mfg. process it was not fool proof–the operator still needs to pay attention. That said we are thrilled with the results.

–John

John,

Sounds like you need to make a dividing head for your JMP, then you can cut any number of teeth you want, and any weird index/spacing you feel like! The only problem with dividing heads, is they take some thinking/math to get them set up, and you really have to pay attention when adjusting them between cuts so you don’t miss a step.

John