________________________________________________________________________________________________

“Don’t expect anything original from an echo.” — Author Unknown

________________________________________________________________________________________________

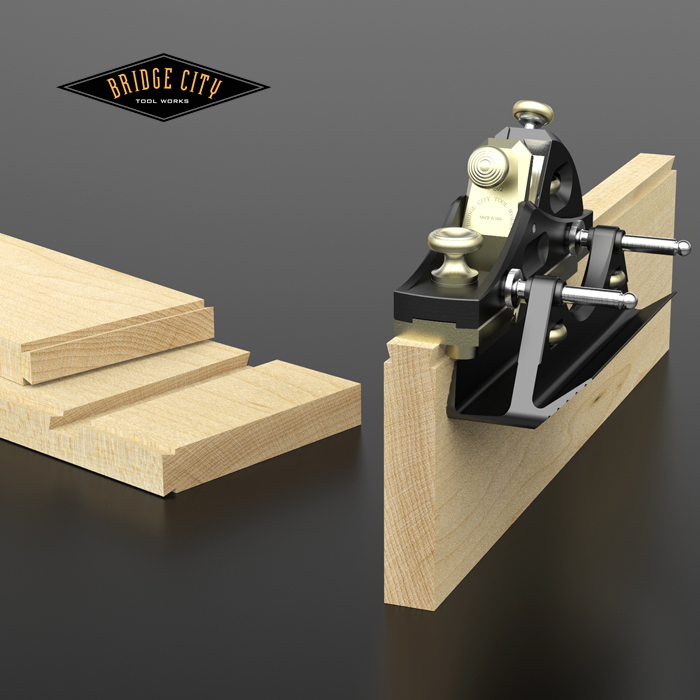

Geez-I alluded to our upcoming dovetail plane, how it depends on our new dado soles to function, and what happens? The Drivel Starved Nation wants to know more–no rest for the weary around here..

I have made maybe 60 or 70 sliding dovetail joints during my furniture making career. I can say that this joint, at least for me, is one of the most difficult to master–there are so many variables that can leave you more than frustrated. The challenge makes it fun. But that was yesterday…

DAMN! Cooter Ditchman just walked in the office… I am going to hide under my d

“Hi John! Long time no see–did you drop sumpun’ under your desk?”

“Oh hi Cooter-what brings you to Portland?”

“In town for a pitchfork convention and have time to spare…what dat on your monitor?”

“I am working on our new sliding dovetail kits for the HP6v2 and..”

“Looks like the bottom has holes-never seen that before–what dat for?”

“Well Cooter, the system we have developed requires very little thinking-you make the male portion of the joint first, it’s easy, set the fence and cut the right then the left. For those joints longer than 6-8 inches, we will provide a system for tapering the joint. Then you use one of the new HP6v2 dado kits to plow a groove or dado in your stock along a center line. Because the dado sole will cut deeper than the dovetail sole, there is a very precise “shim sole” that fastens to the dado soles when used for sliding dovetails. Using the exact same blade depth setting used to make the male, the dovetail sole will bottom out in the dado or groove.

The only other variable to deal with is the width of the female. We have a new gizmo that will adjust the guides for an exact fit to the male–even if it is tapered.”

“That looks dandy. What is the CT-18 going to be?”

“Cooter, I am not going to tell–it is bad luck–I think your cell phone is ringing.”

“I don’t have no cell phone.”

“Well, I can hear it ringing.”

“OK, gotta go. Member, if you ever get to Floyds Knobs, look me up!”

Hey, his phone really was ringing.

Anyway, as I was saying, if making sliding dovetails is not as easy as making a rabbet, well my name ain’t Cooter Ditchman!

Couple of bullet points:

- When making the male, the plane sole rides on the surface of your stock, and the shoulders are cut with a circular scoring cutter.

- The exact same iron setting is used to make the female.

- We will do all the math for you. You will need to keep your iron sharp, and do the pushing.

- The iron cuts from the side. It will shrink after repeated sharpening and lose the relationship with the sole. How do you think we fixed that?

- Blind dovetails are accomplished by banding.

- You will be able to obtain two different shim soles for the dado kits to vary the height of your dovetails.

- Questions?

So, if you want to add an almost foolproof way to make sliding or tapered dovetails, it begins with our two new dado kits. Make sense?

THE MOST AMAZING OPTICAL ILLUSION I HAVE EVER SEEN DEPT:

Look at this image. Believe it or not, the blue and green stripes are the same color. Read about it here.

–John

John,

I was wondering how it was going to work. Looks great.

1- Would a dial-able fence system be desirable with this setup?

2- Would the dovetail setup be available on the other new plane you are doing?

The fence looks great in black.

Masood

John,

Awesome, as usual. I absolutely love the HP-6; it is without question my favorite tool to use. I can’t wait to make a small wall hung cabinet using this to fasten the shelves to the sides. And oh yea, the black fence is real sexy!

On a mostly unrelated note, I was talking to Fred West (no relation) about the HP-6 hones and how it would be nice to have a hone for the CT-9 and the new fifty version crowning plane irons. Any chance of this?

Thanks, Rutager

Quick comment on the optical illusion: if you use two scraps of paper to isolate just one band of the blue, you can clearly see that it is green- pretty cool mind messing trick!

Awesome optical illusion, John. I sat down with Gillian and blew it up on Adobe Illustrator to prove to ourselves that the blue and green were the same. We were shocked that they were!!! Amazing!

This whole sliding dovetail system sounds seriously cool. I’m very much looking forward to seeing how it works. Will there be a prototype to see at the WIA?

Love the black fence (not that I get a vote).

– Peter

P.S. In case I hadn’t asked: what’s the CT-18 🙂

John,

Love the new profiles!

hmmm, While we are on the subject of the HP-6 family of planes, is there a whiff of progress regarding a particular cabinet design that was on the drawing board to house the myriad of irons that are available?

cheers,

roger

@Roger: good to hear from you! I want to address Hp6 storage in 2012.

@Masood: A micro adjustable fence is a possibility but that is the easy way! I am working on something better.

@Rutager: What did you do to rally the groups around black? OK, black it is.

@Peter: Will not have this at WIA.

– John

John,

I am happy to here about the dial-able fence. Should have expected the answer.

Now I have more questions,

1- The height of the dovetail in the pictures looks like about 3/8″ . since the cuter slices from the side and the shoulders are cut using a disc that means if we had, let say 5/8″ height capacity one could shim the bottom of the sole to get unlimited heights under 5/8″. It may require a different blade angle or it may mess up the Math. Am I smoking?

Maybe the question should be, can we have adjustable height.

2- Would it be better to have 2 HP6s during this process? One set up for dovetail and one for the Dado/Groove since the blade height has to be spot on Like what we do now with the routers. (Not that I am trying to talk you in to talk us in to more HP6s.)

The answer to your shrinkage question. I will take a shot. Is the blade embedded in the sole vertically and is adjustable for shrinkage.

Thanks

Masood

John,

No rally was needed (but I did have one scheduled, just in case;) we’ve been paying attention to your rants about good design and determined that a fourth unrelated color “stole” the focus from the whole. Of course you already knew that and were either testing us or have been spending way too much time at the anodizer looking at the pretty colors and/or inhaling the fumes.

Best,

Rutager

John,

This is a great addition to the HP-6 arsenal. If sliding dovetails weren’t so tricky we all would use them a lot more than we do. So….What is the minimum and maximum width, shallowest and deepest dovetail for this little gem?

Also, I like the colors on the new HP, but I have to agree that when I read the comments on “keep it black” for the HP-6 I’m in total agreement. The black “fits my eyes” a lot better on this plane for some reason. I still like the rosewood – classy look, but I will probably get one of these also.

I have a question for you on the tool collecting forum.

Dennis

Hello, ist this plane available?

Currently, no.