Drivel Starved Nation; A couple of months ago, I broke the news about a new dust collector technology that we are employing in our prototype shop – the Gyro Air. Before I get into the details of this collection system, it is important to understand why I want to ditch my standard cyclone collector — which likely looks just like yours. I am allergic to wood dust, and in 1983 I gave up a promising furniture making career on the orders from my doctor. (Bridge City came to be, so don’t feel sorry for me.) Today, I can work in our prototype shop for maybe 4 hours when I start to feel pressure in my sinus cavities. It takes me about half a day to get back to normal. The cause: our current collector leaks. In addition to the leaks, changing the bag is a major pain, so it gets changed when half-full. The noise is awful and the thing is just ugly. So, when I discovered the Gyro Air on one of my trips to China I was more than curious. Caveat: I am not a dust and fume control expert, nor do I know much about sound control. But I will do my best to display my ignorance in such a compelling way that you will think I am an unqualified genius! Furthermore, I will do so without confusing you with engineering jargon or big words like static pressure, velocity pressure and other such data that hurts your ability to comprehend. Ready? In a traditional cyclone dust collector with a bag filter, the dirty air is pulled into the system by a paddle wheel fan. Once inside, the air is spun, and the centrifugal force created by this mini-cyclone slams all the fine dust against the filter bag, the big chunks find their way into the center of the cyclone which gravity helps move to the poly collection bag. The really fine dust creates a dust cake, and it helps plug all the holes in the fabric filter contributing to the efficiency of the system to remove particulate. So yes, you need dust to remove dust. Moving air in a dust collector is a zero-sum game, what goes in must come out. As the filter becomes clogged with fine dust (by design) the motor must work harder to get the air out. This restriction of the air flow escaping, reduces the flow of air at the intake. And you can tell the air had to fight like hell to get out of the filter bag by the heat that is created. Cyclone dust collectors are good at creating heat. (Great in the winter, bad in the summer.) At some point, you need to remove some of the cake so the system becomes a bit more efficient. This is typically accomplished by rotating a scraper against the filter shaking some of this cake dust into the poly bag. When is the last time you did this to your collector? Shame on you! (FYI, it should be done weekly or maybe more depending on your activity.) Because of this resistance to moving air, a larger horse power motor is required. And you need more HP for the “instant on” of AC motors. It is here where the BIG LIE appears. In America, we tend to look at simple benchmark numbers like cubic feet per minute (CFM) to compare one dust collector against another, and of course, more is better. Manufacturers are happy to provide you with this benchmark number and you have every right to confront their BIG LIE, but you don’t, you believe them because you have no way of proving them wrong. For CFM to be a meaningful number, you need compare one collector to another with the exact same “under load” criteria. Of course, this is inconvenient for the manufacturer and, as mentioned earlier, it doesn’t matter — you believe the brochure. It is here where I will depart and describe how the Gyro filters air with a new and much more efficient approach. The Gyro Air also moves air via a paddle wheel fan, and it too has a filter. What happens before the moving air hits the filter is the news here. The Gyro Air intakes dirty air and splits it into two cylindrical compartments. Within each compartment is a sheet metal separator that would make Archimedes proud. These giant tapered “screws” have one function and that is to quickly spin the dirty air. Now for an analogy… Remember the amusement park ride where you stand in a giant round metal cage and it starts to spin “sticking” you against the wall — then the floor drops out from beneath you? Imagine what would happen to you if you did not have the metal cage behind you? Bye Bye! Located beneath the two sheet metal screws are holes where the dust is literally flung into two collection bins. In short, the Gyro Air is insanely efficient at separating the dust from your shop air by using simple physics. Now here is what is interesting. There is a filter on the Gyro Air, but per recent certified tests by government labs (in China), the air leaving the two chambers is so clean, a filter would not be required at all! (0.01 percent of the dust hits the filters) Selling a dust collector without a filter is simply not believable, hence the filter. The Gyro Air runs on 220-volt AC (20 amps) and this is converted to DC by a Siemens phase converter. By using a DC motor, variable speed (and CFM) is possible. Why is this important? You may not need the full capacity of the Gyro for every machine you are collecting. Reduced air flow dramatically reduces the noise output of the unit. Now that you understand the basic difference as to how the Gyro Air works, here is my unvarnished review. WHAT I DISLIKE ABOUT THE GYRO AIR • The cord on my unit was ridiculously too short. I spoke to the factory and this has been addressed. • The variable speed indicator is in hertz (which is a linear relation with fan speed, the more hertz, the more air you are moving). The readout currently makes no sense to me even though I understand it. That said, in use, you tend to dial down the airflow by sound. Pressure indicator on the left, bin full indicator in the center, control panel on the right  • This thing is heavy. I am not sure this should be a complaint, the weight is the byproduct of making an incredibly robust machine. I mention this because getting this unit down a flight of basement stairs may be a major chore. • The front intake port is in the lower left corner of the unit. This means that the ducting (which tends to run on walls), needs to make a couple of turns to get to the front port. I think the unit could be improved if they reversed the intake port to the rear. The front of the machine would be unfettered and you could save some space by backing it up to existing ducting. That said, there are a couple of advantages of having it on the front. The included step down reducer that allows you to use your shop vac hose on the Gyro is a cool feature for cleaning out the bottom of my table saw cabinet. The other positive front feature is you can see if the Gyro has attempted to digest a shop rag, or rodent…

• This thing is heavy. I am not sure this should be a complaint, the weight is the byproduct of making an incredibly robust machine. I mention this because getting this unit down a flight of basement stairs may be a major chore. • The front intake port is in the lower left corner of the unit. This means that the ducting (which tends to run on walls), needs to make a couple of turns to get to the front port. I think the unit could be improved if they reversed the intake port to the rear. The front of the machine would be unfettered and you could save some space by backing it up to existing ducting. That said, there are a couple of advantages of having it on the front. The included step down reducer that allows you to use your shop vac hose on the Gyro is a cool feature for cleaning out the bottom of my table saw cabinet. The other positive front feature is you can see if the Gyro has attempted to digest a shop rag, or rodent…  • I had to purchase a 220v 20 amp to 220v 30 amp adapter plug as all our circuits are 30 amp here.

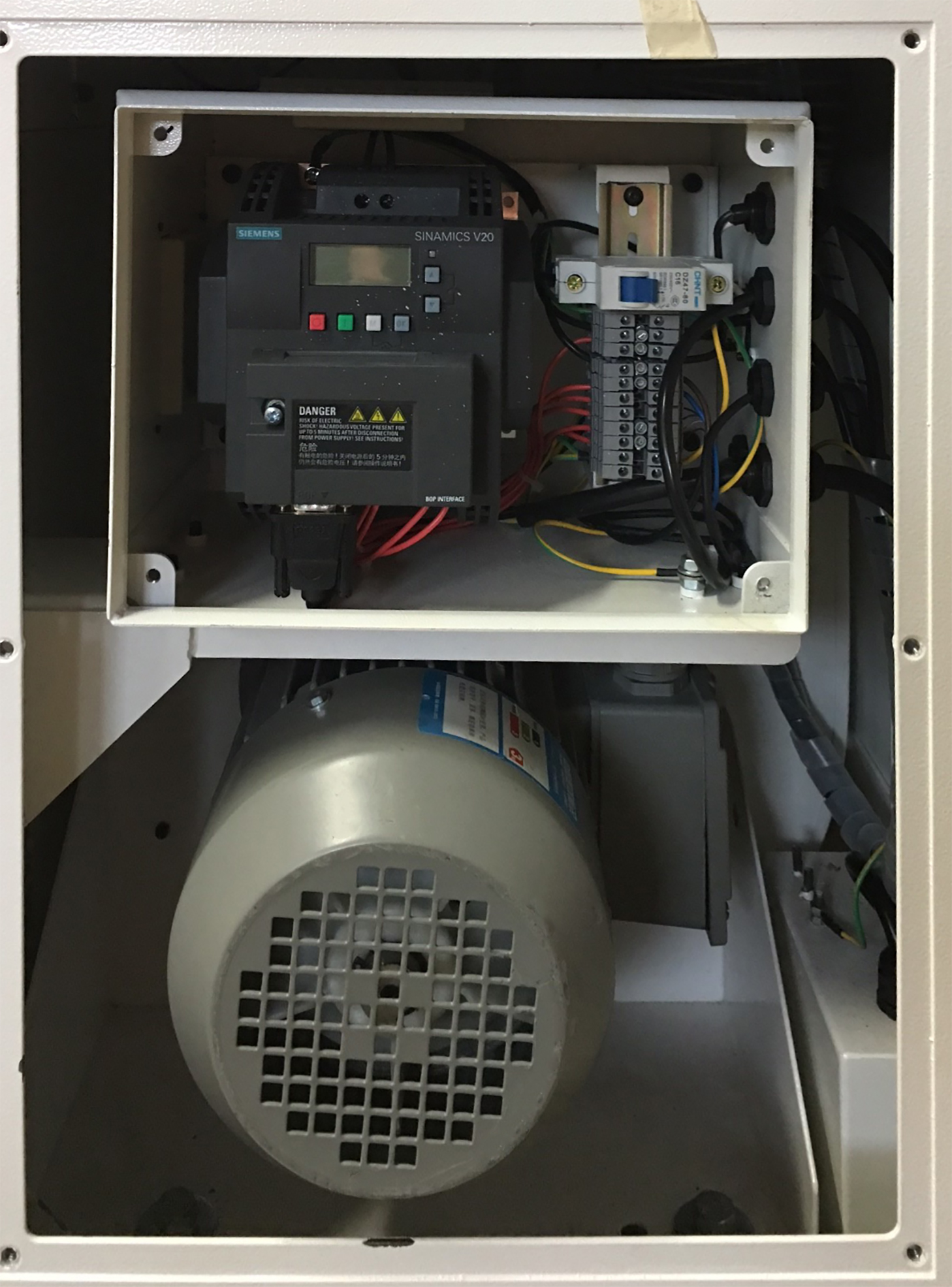

• I had to purchase a 220v 20 amp to 220v 30 amp adapter plug as all our circuits are 30 amp here.  WHAT I LIKE ABOUT THE GYRO AIR • At full throttle, the Gyro breaks into the high 70’s decibel (dBa) range. My existing cyclone hovers between 84-86 dBa. OSHA recommends hearing protection for prolonged exposer of 85 decibels or higher. (Decibels are a ratio and the difference between two decibel readings is not linear.) In addition, noise is a perceived annoyance — the same decibel reading of noise at one frequency compared to another may create different perceived levels of annoyance. In practice, the noise of the Gyro air at full throttle is less annoying than my existing cyclone as the numbers indicate. At less than full throttle… OH MY, what a difference! I really like this feature. For example, I do not need full throttle to collect my 12” planer. I need full throttle to collect both sanders simultaneously. Here’s a pic of the Siemens converter…

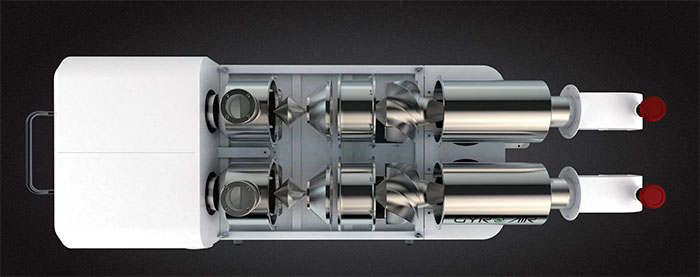

WHAT I LIKE ABOUT THE GYRO AIR • At full throttle, the Gyro breaks into the high 70’s decibel (dBa) range. My existing cyclone hovers between 84-86 dBa. OSHA recommends hearing protection for prolonged exposer of 85 decibels or higher. (Decibels are a ratio and the difference between two decibel readings is not linear.) In addition, noise is a perceived annoyance — the same decibel reading of noise at one frequency compared to another may create different perceived levels of annoyance. In practice, the noise of the Gyro air at full throttle is less annoying than my existing cyclone as the numbers indicate. At less than full throttle… OH MY, what a difference! I really like this feature. For example, I do not need full throttle to collect my 12” planer. I need full throttle to collect both sanders simultaneously. Here’s a pic of the Siemens converter…  • The Gyro Air is incredibly well made. Here’s a pic of the machine guts…

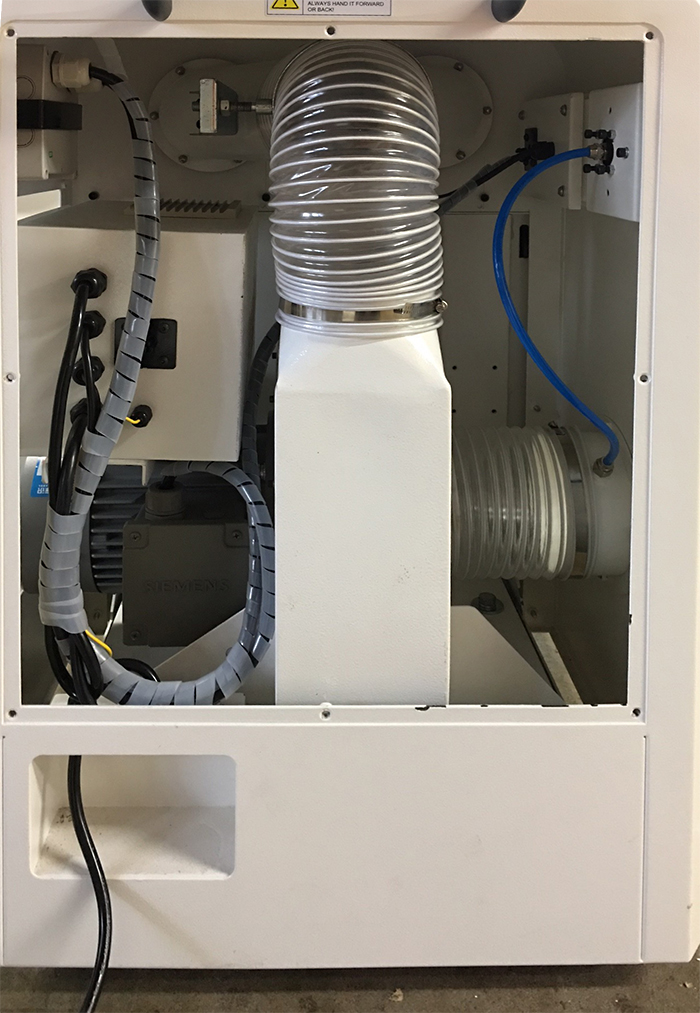

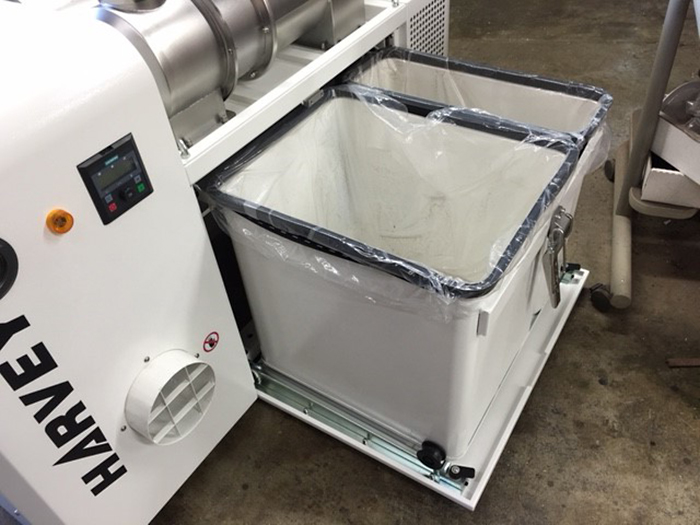

• The Gyro Air is incredibly well made. Here’s a pic of the machine guts…  • I love the dust collection bins. As in LOVE! You open a door, release a latch, and both bins, one with large chips, the other with fine, roll forward and are easily emptied. And get this, because I currently empty my leaky cyclone collector when the bag is half-full, the capacity of the Gyro Air (120 liters) is greater than my current practice. Dust Collection Bins in the Unit

• I love the dust collection bins. As in LOVE! You open a door, release a latch, and both bins, one with large chips, the other with fine, roll forward and are easily emptied. And get this, because I currently empty my leaky cyclone collector when the bag is half-full, the capacity of the Gyro Air (120 liters) is greater than my current practice. Dust Collection Bins in the Unit  Here they are ready to be easily emptied…

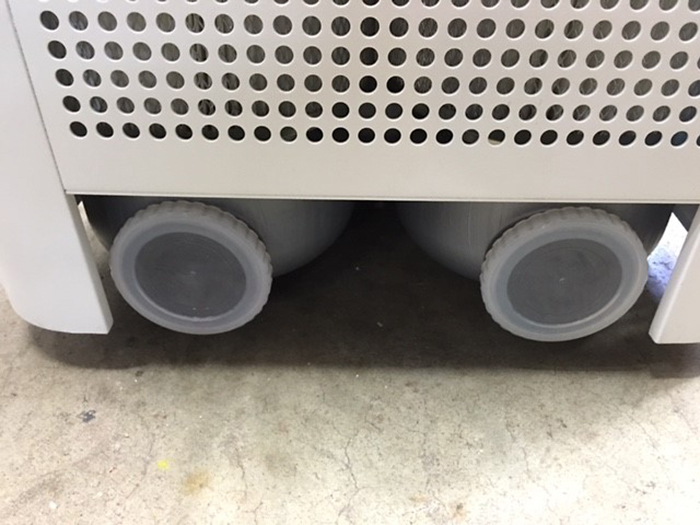

Here they are ready to be easily emptied…  • Since the collection bins are hidden, I like the indicator light that reminds me they are full. • You do not HAVE to use poly bags in the Gyro. If you were to fab a plastic liner out of sheet stock, you could simple pull the liner, empty it, replace and get back to work. • The CFM comparison… without a way to measure under load, I can say that comparatively, they are the same. I have the system connected to a dual, 4” splitter, one line collects my 12” planer and a 12” disc sander. The other line collects 2, 6” industrial horizontal belt sanders. All machines have blast gates. I tested them all and as mentioned, I cannot tell a difference. • WAY LESS HEAT • The air moves more efficient through the Gyro Air which I believe will save me some money on my electrical bill. • Only 0.01% of the dust will go into the filters. This means that if you forget to clean the filters for 3 months, the Gyro Air will still work without a noticeable change in air flow. By the way, cleaning filters on the Gyro is easy; turn the two aluminum knobs for 5 seconds. The filter cleaning knobs…

• Since the collection bins are hidden, I like the indicator light that reminds me they are full. • You do not HAVE to use poly bags in the Gyro. If you were to fab a plastic liner out of sheet stock, you could simple pull the liner, empty it, replace and get back to work. • The CFM comparison… without a way to measure under load, I can say that comparatively, they are the same. I have the system connected to a dual, 4” splitter, one line collects my 12” planer and a 12” disc sander. The other line collects 2, 6” industrial horizontal belt sanders. All machines have blast gates. I tested them all and as mentioned, I cannot tell a difference. • WAY LESS HEAT • The air moves more efficient through the Gyro Air which I believe will save me some money on my electrical bill. • Only 0.01% of the dust will go into the filters. This means that if you forget to clean the filters for 3 months, the Gyro Air will still work without a noticeable change in air flow. By the way, cleaning filters on the Gyro is easy; turn the two aluminum knobs for 5 seconds. The filter cleaning knobs…  These two little containers trap the dust from cleaning the filter. I think it will take a decade for these to fill…

These two little containers trap the dust from cleaning the filter. I think it will take a decade for these to fill…  This is an inside view of the Gyro Air system…

This is an inside view of the Gyro Air system…

• I really like the professional looks of the Gyro Air, and I think the technology is fantastic. There you go Drivel Starved Nation. In short, I am thrilled with the Gyro Air for our shop. As mentioned in my previous post

• I really like the professional looks of the Gyro Air, and I think the technology is fantastic. There you go Drivel Starved Nation. In short, I am thrilled with the Gyro Air for our shop. As mentioned in my previous post , the Gyro Air 2016 introductory price is $3995 with free, drop gate delivery in the lower 48 states through December 31st, 2016. The first shipment will arrive in the states the last week of November. So, if you are looking to buy your shop an awesome holiday gift, give us a call; 1-800-253-3332. Lastly, we will not ship any unit until we have a verbal agreement that you can maneuver the crate to its final resting place. If you have questions, ask, I will do my best to answer. All pertinent specs are listed below. (Regarding the factory dBa data vs my measurements, factory numbers are the result of lab measured noise in a sound proof room.) -John GYRO AIR TECHNICAL SPECS Electrical Power Requirement: 230V, 1PH, 60 HZ Breaker Size: 20A Internal Inverter Type: Siemens V20 Motor Type: TEFC Induction Power: 2 HP Speed: 2,280-4,275 RPM Performance Max. Air Flow: 1,110 CFM Max. Static Pressure: 18-1/2 inch/water Impeller Size: 12″ Main Inlet Size: 6″ Adapter Inlet Size: 4″ x 2″ Filter Emission Rating: 0.05mg/m³ Filter Surface Area: 75 SF Noise Rating: 61-72 dBA Max. Dust Bin Capacity: 32 Gallon Manual Filter Cleaning: Yes Intelligent Dust-Full Monitoring System: Yes Pressure Gauge: Yes Product Dimensions Overall Dimensions: 56-1/4″ x 23-1/2″ x 33-7/8″ Packing Size: 59″ x 28-1/2″ x 42-1/4″ Product Weight Net/Gross: 445 lbs./510 lbs. Shipping / Billing Info: This product ships direct from the manufacturer: • Your order will ship in approximately 2 – 4 business days. • Express or overnight shipping is not available for this product. • Ships via ground to the 48 contiguous states. Cannot ship to Alaska, Hawaii, PO Boxes, APOs, US Territories, Canada or other foreign countries. Return Information All returns must have prior authorization. Freight is customer’s responsibility. Warranty Information Harvey Supply offers a two-year warranty. If you have warranty questions, please contact Harvey customer service @ 1-888-211-0397.

, the Gyro Air 2016 introductory price is $3995 with free, drop gate delivery in the lower 48 states through December 31st, 2016. The first shipment will arrive in the states the last week of November. So, if you are looking to buy your shop an awesome holiday gift, give us a call; 1-800-253-3332. Lastly, we will not ship any unit until we have a verbal agreement that you can maneuver the crate to its final resting place. If you have questions, ask, I will do my best to answer. All pertinent specs are listed below. (Regarding the factory dBa data vs my measurements, factory numbers are the result of lab measured noise in a sound proof room.) -John GYRO AIR TECHNICAL SPECS Electrical Power Requirement: 230V, 1PH, 60 HZ Breaker Size: 20A Internal Inverter Type: Siemens V20 Motor Type: TEFC Induction Power: 2 HP Speed: 2,280-4,275 RPM Performance Max. Air Flow: 1,110 CFM Max. Static Pressure: 18-1/2 inch/water Impeller Size: 12″ Main Inlet Size: 6″ Adapter Inlet Size: 4″ x 2″ Filter Emission Rating: 0.05mg/m³ Filter Surface Area: 75 SF Noise Rating: 61-72 dBA Max. Dust Bin Capacity: 32 Gallon Manual Filter Cleaning: Yes Intelligent Dust-Full Monitoring System: Yes Pressure Gauge: Yes Product Dimensions Overall Dimensions: 56-1/4″ x 23-1/2″ x 33-7/8″ Packing Size: 59″ x 28-1/2″ x 42-1/4″ Product Weight Net/Gross: 445 lbs./510 lbs. Shipping / Billing Info: This product ships direct from the manufacturer: • Your order will ship in approximately 2 – 4 business days. • Express or overnight shipping is not available for this product. • Ships via ground to the 48 contiguous states. Cannot ship to Alaska, Hawaii, PO Boxes, APOs, US Territories, Canada or other foreign countries. Return Information All returns must have prior authorization. Freight is customer’s responsibility. Warranty Information Harvey Supply offers a two-year warranty. If you have warranty questions, please contact Harvey customer service @ 1-888-211-0397.

Thanks for this, John. I really love the idea of the Gyro Air – I have noticed that my sinuses are getting more and more sensitive to dust. I wear a respirator-type mask whenever I turn on my DC unit.

My problems with the machine as it now stands are:

1) The footprint is really big, and would take an inordinate amount of space in my garage shop.

2) The 220 V power supply would mean that I couldn’t run any other 220 V machine at the same time – I only have one 220 V outlet in my shop.

Do you have any sense that they might be working on a “hobbyist” model that runs on 110 V, and might be a bit smaller? I’d totally buy one of those!

Peter-

Agreed, this is likely not the machine for really small shops. However, it is low to the ground so there is an opportunity to put shelves above the unit.

The fine folks at Harvey read this Totally Awesome and Worthless Blog, so your comments will not go unnoticed.

-John

PS: I had a lot of fun writing a review about something that really sucks.

So it’s me, Rutager, Dave, and the guys at Harvey who read your totally awesome and worthless blog? Quite a Drivel-starved Nation you have there!

By the way, your review of something that really sucks did not suck. Indeed, it was quite thorough – thank you for that. Again, I’d love to see that technology in a smaller 110V package. It would potentially be a real game changer for hobbyists who are concerned about their lungs and sinuses.

I don’t read it for the articles…just the pics. 😉

BTW, does $4000 include the parrot? A parrot and sized to a 110v current might someday make a sale.

Dave-

Parrot not included. AND, you need to behave.

Good luck with that…

-John

No mention of a remote start John?

No RF remote start would be a real shortcoming for such a premium machine.

Joe

Hi. Thank you for the review. I’m glad you like it. I’m glad you are selling it. Can you point us to any independent reviews of the unit? A Google search turned up only videos supplied by the manufacturer. Certainly the manufacturer and you as a seller have much to gain from getting units in the hands of reviewers.

Fwiw, I volunteer. The electrical supply is not an issue for me. (The weight is, but I’ll see to that.)

Thank you.

Kirby.

Hey John, any way you could open up the sinamics , and take a picture?

(I’m curious if the analog input is already being used. if not, i could add a CFM sensor to mine, and then use it to drive the inverter speed automatically, so i only ever have to set CFM, not motor frequency )

Joe-

No, there is not a remote, but I agree with you, it’s a good idea. In my case it doesn’t matter, everything s clustered together, but i can see the benefit for others. I will pass it on.

-John

Kirby-

To my knowledge, our unit was the first or second in the States. So right now, my review is as an early adopter.

The Marc Adams School of Woodworking will be getting a unit in the next two weeks, so I am sure they will have comments. Most of the other sales that I am aware are in Europe and Asia.

-John

I will look into that when I get into the office today- I also want to ask the factory if such a mod might void the warrant which I suspect it might.

I received mine last week and got it setup this weekend. First impressions extremely well built machine. As with everything there is good and bad. The bad first, I have tried a number of things and there doesn’t appear to be a way to use remote controls with it. I have the standard 220 iVac control and it works with the machine but to start the flow it is a 2 step process. You have to turn the power on then press the start button. For a remote to work you would have to have a way to tell it to start when the power comes on. The remote will turn the power off. I spoke to a representative at Harvey today who is going to check and call me back within a day or two so I will let you know what they say.

Also they are the source for the replacement plastic bags and they are out of stock now but will be back in stock soon. When he calls me back he told me he will let me know when they will be in stock, what units they sell and how much they are.

Now the good and the question. I built my dream workshop for retirement about two years ago and when I did I had 8 station put in the 50 x 50 floor area. This is 6″ PVC pipe going out from a central equipment room. There are no 90 degree bends in it and essentially it is two rows of 4 stations each with the first row being about 20 feet from the equipment room and the 2nd run being about 50 foot from the equipment room. In each station I have a 6″ pvc connection with a metal gate, a 220 outlet and a 110 outlet all in a box like you would put a sprinkler system in.

I have been moving my Laguna 1.5 HP dust collection around for the past two years and it works most of the time. I recently added a CNC machine to my tool collection and it does a terrible job of collecting dust on that so I wanted to solve two problems with one purchase.

I got the machine and hooked it up to the two six inch runs, I have a 4″ splitter that I took off my Laguna and put the splitter that came with the Gyro on my Laguna and I connected those two short 4″ runs to my two 6″ pipes that stick out of the floor in the equipment room.

Now the rubber hits the road. I am not a data scientist but I at least wanted to know what I was getting at each station. I purchased an Extech AN 100 CFM/CMM Mini Thermo-Anemometer from Amazon, https://www.amazon.com/gp/product/B000X571KO/ref=oh_aui_search_detailpage?ie=UTF8&psc=1 turn the machine on. The Anemometer has a hand held fan type gadget that spins to get you the reading. There are multiple settings so I put it on the CFM setting. At the machine I expected it to read around 1100 CFM but instead it reads 5500 CFM, at each station I am getting anywhere from 3000 CFM to 5200 CFM depending on the station and the turns from the machine. I am not sure how to reconcile the 1100 CFM rating with the reading I am getting on the Anemometer?

Gene,

Thanks for the comments.

Regarding the remote, I agree, it would be nice, but I don’t believe it is possible, but maybe they will find an answer.

Regarding your CFM readings, I have no clue, and for me, all I care about is that it is collecting whatever I have it hooked up to it.

Let us know what Harvey has to say about the remote possibility.

-John

I’d bet that your anemometer is not designed for measuring the CFM through a restricted area (your 6″ diameter pipe). It’s probably assuming that you are measuring the air flow in open space. I’d guess that it’s taking the area of the propellor and scaling that up to 1 square foot, and then multiplying by how fast the air is passing through that opening. You’d have to scale your measurements by the cross-sectional area of the pipe (though first you’d have to know how it’s doing the calculation), relative to the area of the anemometer, and one square foot. Or something.

So this might be useful if I were standing outside in tornado and want to figure out the CFMs it was producing, nice!

At the end of the day it at least gives me some data points. I can measure at the machine and then at a station and see what the drop in CFM by that calculation is.

I agree with John’s comment, I think I could run 4 stations at a time with this machine in practice so I will test that out this is based on a feel comparison with my Laguna and how much it pulls using my hand as the gauge.

Gene,

Here’s what I did that was kind of fun; All four machines here have blast gates. My first experiment was running the planer, the other three blast gates were closed. I kept dialing down the RPM until I could see chips fall back onto the planar bed. I can run the planar only at about 65-70% of full power. WHAT A DIFFERENCE IN NOISE! The planar of course is its normal obnoxious self.

When we run both industrial belt sanders simultaneously, I use full power, works perfect. One sander and I can dial down the machine to about 80% which is also a dramatic improvement in noise.

I too have a request in for bags. We have a huge plastic bag factory here in PDX and I just may have them make them for us and our customers if Harvey doesn’t get them to LA soon.

-John

Can you please tell me some important things about the Gyro air like how it works and is there any speed control?

The Gyro Air is a revolutionary new way to control air born particulate in enclosed spaces.

In a typical cyclone style dust collector, an impeller draws air into the enclosure spins it, the heavier particles sink to the bottom, the finer particles form a “cake” on the filter, which actually helps further filtration at the expense of heat, and some leakage.

The impeller in the Gyro Air never comes in contact with dirty air, it pulls the air stream through the machine.

It is much more efficient.

Once the contaminated air enters the Gyro Air, it is channeled into two chambers. Inside each chamber is static, conical helix that spins the air. The resulting centrifugal force is so great that the particles are “spun” into the collection bins. As the air leaving these chambers is almost completely dust free. The last line of defense is a filter.

Yes, the Gyro Air uses a variable speed motor.

-John

Has bridge city figured out the ivac remote issue yet. I have the gyro air and would like to install the blast gates