Drivel Starved Nation;

It seems that whenever we introduce a tool that is not “traditional” factions of the woodworking community, using their internet bullhorn, feel compelled to condemn the effort as heresy, an egregious assault on our “woodworking heritage”. These anachronistic views to me, and to us as a company, are about as much fun as pre-chewed food. Ideas evolve and so do tools — at least I like to think so.

New ideas are almost always the result of a changing perspective. And this is what I believe we do best, we rattle the cage of conventional woodworking wisdom with tool ideas that either attack or improve functionality deficiencies, inconvenience and work-flow efficiency, all with an underlying passion for aesthetics. Ironically, nobody needs any of these tool ideas… except me.

When I started my furniture making career back in the mid-1970’s, my small basement shop evolved into a 2,000 sq.ft. woodworking studio located in an old defunct furniture factory which still resides in a huge Portland gully. My view was Interstate 84, which was about 75 yards away. That shop contained all the “traditional” purchased hand tools you can imagine, and I despised many of them.

Back then, I had no idea I would eventually become a tool maker, but I do remember cussing under my breath about squares that were not square, block planes that needed half of a day of work to be functional (maybe more), and particularly my Record shoulder plane — that plane could not be used for more than 10 minutes without causing hand pain.

I remember being acutely aware how my store bought tools shared a collective ugliness which I surmised was the result from pragmatic cost compromises. Little did I know I was littering my brain with seeds that would eventually become Bridge City Tool Works.

Fast forward some 40 years later and I now have two shops — and it is not as luxurious as it sounds. In the skunk lab at Bridge City I work primarily at a stand-up bench I built in 1977 (it is from my original basement shop). This shop is full of Bridge City stuff and working space is small and precious. There really is not much room except for one little tool prototype project at a time. We are so cramped here that the table saw has to be moved to utilize the entry door cavity for ripping long boards. I suspect you understand what I am talking about.

My home shop is a back bedroom of my house which houses my Jointmaker Pro. There is another stand-up bench in the garage, but it quickly attracks clutter with important items like dog food, light bulbs and currently, window washing paraphernalia. The garage is also home to our dogs “Hyatt Suite”. In other words, working in my garage is next to impossible.

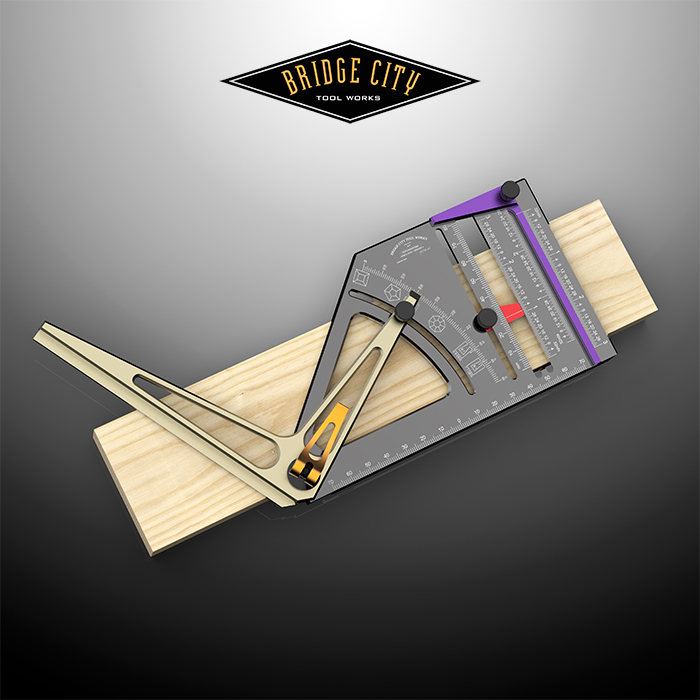

With this in mind, my tool design perspective has changed and you can see it in our latest design, the UG-1 Universal gage (which, by the way is a stupid name — I lost the vote here). Currently I am interested in working with as few tools as possible to accomplish my needs because I don’t have the space, nor the patience to find, then put away what I need for whatever project I am working on.

To be sure, I am rarely a fan of multi-tools and I own several, the most important of the bunch is the one I carry on my bicycle. That said, it seems multi-tools are full of compromises so when I set out to design one, it is not out of ignorance, I really want to solve my space constraints and simplify my work-flow in the most uncompromising way I can conjure.

In my next post I will explain all of the uses I have planned for this tool and will objectively (as much as possible anyway) grade each of the functions of this cool little tool! You will be able to agree or disagree, but I think the dialog might be enlightening.

-John

Very interested — would find this quite useful, afaict. A trio of questions which you might perhaps consider for your next post about the UG-1:

– Is there a way to set/transfer/mark angles between 0° and 45°?

– Are there any functions to be had from the non-right-angled side of the angled arm of either the purple depth/height stop or the red marking stop? (Do they read or reference anything?)

– Is there any function to be had from the angle made by the inside of the protractor arm and the angle of the body opposite the edge with the hook?

And two requests:

– Please consider adding measuring markings — similar or identical to those on your ever-useful SR-6 6″ Pocket Rule — to the outer edges. (This would entail moving the center-finding rule to another side, but, from my limited experience, the center-finding rule would be more functional on a flat surface than on the one above the hook.)

– Please consider including a slide-on nylon glide or other additional piece to replace the 4mm shop-made block of wood that you recommend using to compensate for (I’m assuming) the projection of the hook when the tool is used on a flat surface inside that surface’s edges, as it would be when setting the fence of the JMP?

—Kirby.

Kirby,

Thanks for the comments.

1) Regarding the standoff, it is now built in.

2) Regarding setting angles from 0-45, there is a way but it may not always be practical. You would need to place the hook of the tool on the end of your stock. As mentioned, that is not always practical.

3) Regarding other functions of the purple arm or the red marking gage stop, the red stop now houses the stand off, and the purple leg is tapered only as a design element mirroring the bevel arm.

4) There are no functions of the protractor arm and the body other than what is obvious.

5) The center rule works by setting the UG-1 on your stock, center and mark. We can certainly add a rule to the back side of the hook, and will do so!

Hope this helps! Thanks for speaking up, for the most part I listened!

-John