Drivel Starved Nation,

For those of you do not own a JMP (shame on you) it is known for precision and an unbelievable quality of cut. The harder the wood, the smoother the finish.

Last week I received an email from fellow DSN member Nicholas Phillips who graciously shared his amazing work, and equally graciously allowed me to share it with you and all of the DSN. He has had his JMP for only a month, but WOW! I think you will enjoy this photo essay (these are all copyrighted images folks, so please ask for permission if you plan to share outside of this space. Please again.)

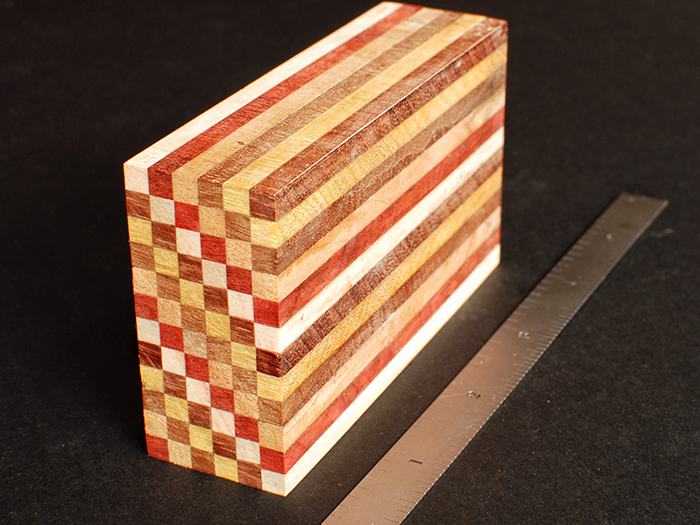

Nicholas, as you will soon learn, is an incredible craftsman and shared with me that the accuracy of the JMP has made his life easier, which is cool. Check out how he makes all the geometric patterns in this compilation image;

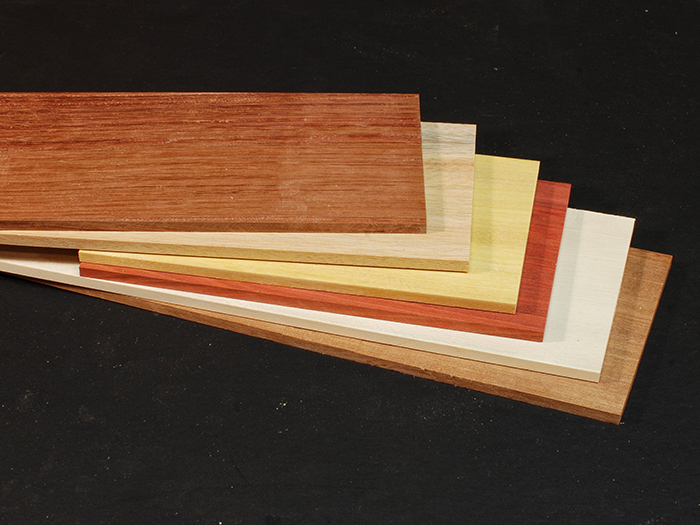

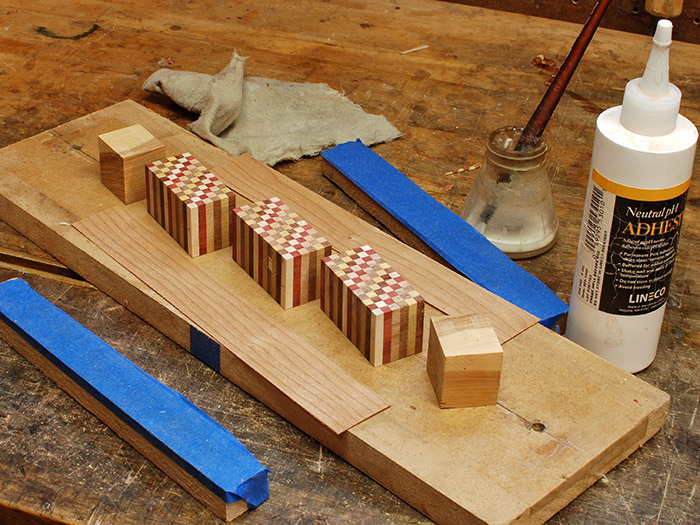

Nicholas starts with carefully prepped stock, all 3/16″ thick…

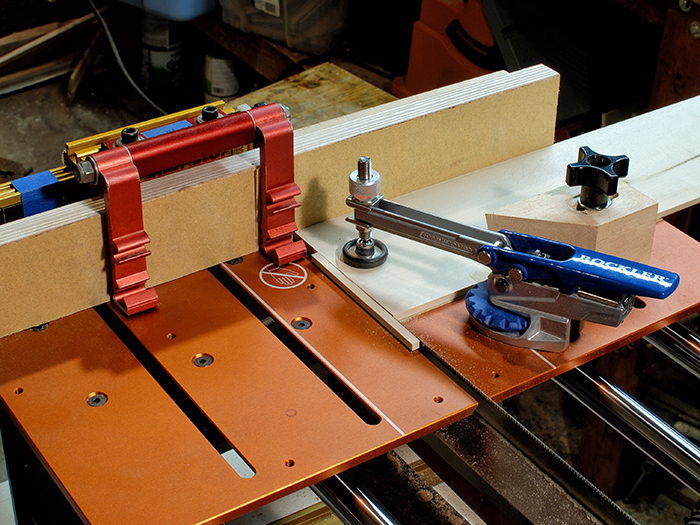

He notes, “Made this fence for the JMP, including some of INCRA’s hardware for the stop. You can’t see it, but there is 200 grit sandpaper under the board. Clamped down and sidewise. I’ve set the stop to cut 3/16” so I end up with square sticks.”

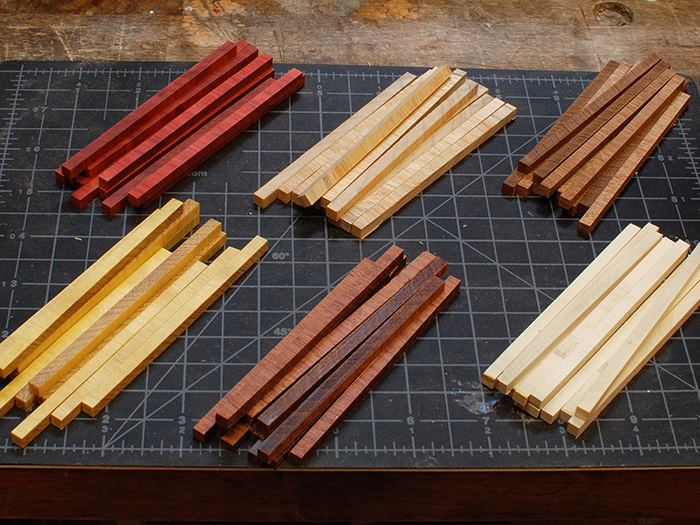

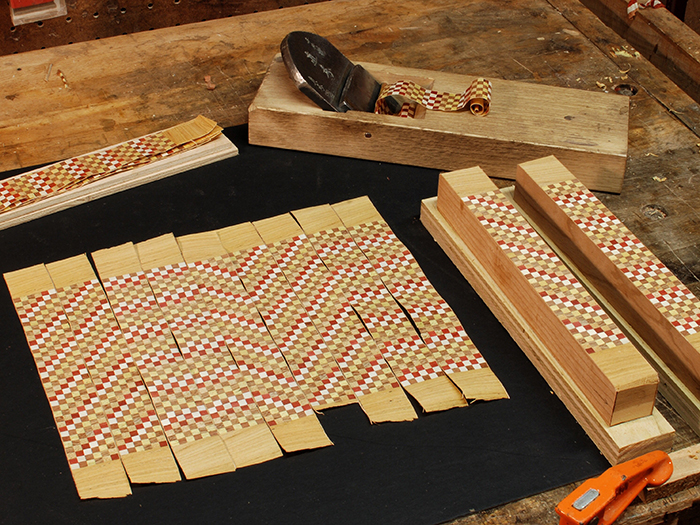

These results speak for themselves…

The next step is to glue the the sticks into 3 x 3 blocks with string…

Close-up of the accuracy required…

He cuts three blocks from one, and the JMP creates very little waste….

This glue-up creates the final length…

Lastly, using a handplane, 0.12mm shavings are made creating the veneer!

Since I know you are all like me, curious to a fault, check out his website. You can also follow Nicholas on Instagram

Lastly, this story from his blog is worth the time to read – Congratulations Nicholas Phillips! The Japanese TV show which is fascinating even if you don’t understand a single word of Japanese.

On behalf of all of the DSN, THANK YOU for sharing your work with us!

Now, I have never done similar work, so listen up! Do NOT ask me technical questions I can’t possibly answer. BUT, if you would like to leave your thoughts to Nicholas as a comment or two, PLEASE DO!

-John

PS: All photos were shared on this Totally Awesome and Worthless Blog courtesy of Nicholas Phillips, Affine Creations, AffineCreations.com

Just WOW, such cool use of the JMP. Thanks for showing us Nicholas’s great designs.

That’s really stunning work – and so incredibly precise. Thanks for sharing, and thanks to Nicholas for letting us see his amazing work! It must make you happy to see your tools being used for such creative work, John.

– Peter

Peter,

The best part of this job is living vicariously through the work of our customers. Tools are no different than musical instruments–in the hands of a dedicated user, magic can happen!

Congratulations to everyone, on the new baby, on the retirement, and on the moving on. I got my KM2 today and I’m going to use it for joints on a pergola for the Wisteria. Best of luck to everyone at BCTW. John, you mentioned an indexing jig for the JMPv2. I hope that as the Grandbabies are napping you will think about this and come up with a design for the new team to produce. I WANNA CUT GEARS!!! Thank you for your efforts, quality, and support from everyone there. Bill F

Thanks Bill!

Yup, the index device for the JMP is on my radar.

Thanks for thinking of us, but more important, thank YOU for supporting us all these years!

Best-

John

What a cool way to make veneer! So many unique uses for the JMP with a little imagination. Texture. Patterns. Precision. Perfect.

Thanks for sharing and thanks to Nicholas for thinking beyond the box.

Neil