Drivel Starved Nation!

Last Friday I received a package containing the new HP-9v2 Dual Angle Block Plane and the new HP-12 Dual Angle Bench Plane. These are first article versions for my inspection. The changes I recommend will be implemented before I arrive in Nanjing next week.

This is the first time I have seen the new packaging and obviously the tools. But before I begin, do you remember all the internet crap slung my way when we first introduced this tool? I do, and I wish I could forget it, but I cannot.

There, I feel better already.

The new packaging is really remarkable. (I’m really not into packaging, but because these will be sold through dealers, packaging is important.)

Here is the subtle box with a sleeve that keeps the lid on;

With the sleeve off the new box design becomes apparent;

What I find incredible about this box is the craftsmanship. The corners are sharp, they look like they were CNC milled out of a billet of cardboard. I also like the brown reveal.

With the lid removed you can see all of the components;

So much for the box, here are the goodies inside (sans the depth skid hardware which I forgot to take out of the box);

So far, my first impression was a solid positive.

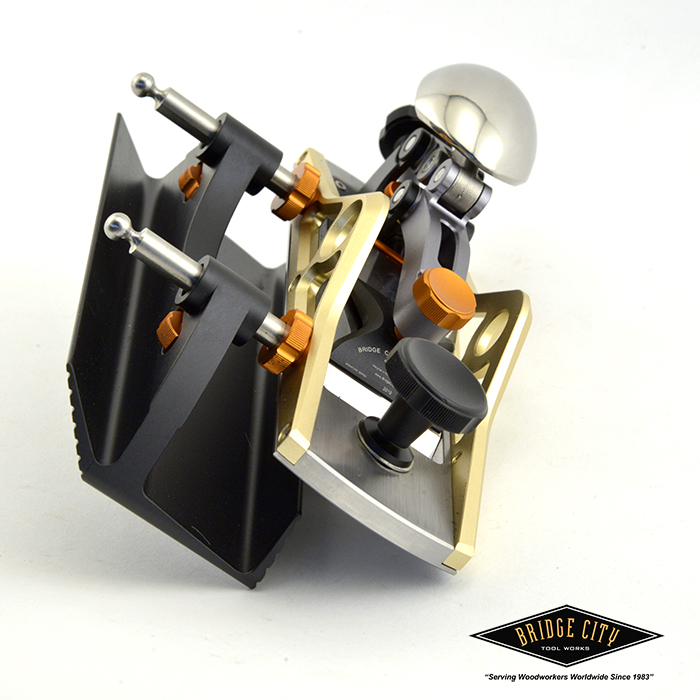

Here is the improved HP-9v2 straight out of the box, it houses a dual grind iron making it both a low angle and regular block plane;

There are two areas that are critical for this plane to function flawlessly. One is the 12 degree iron seat and the other is the flatness of the sole. Checking both involves the use of feeler gauges. We guarantee that the bottom of all of our planes will be within .002″/0.05mm. I first make sure the top of the granite surface plate is wiped clean, as is the bottom of the plane. The iron is retracted and then locked in place. Here you can see the plane on a granite surface plate trapping a .0015″ feeler gauge.

If I can pull this out without friction, the plane is rejected. For block planes, I take four readings: heel, toe, left side, right side. (For longer planes I check six places, heel, toe, and two checks on each side.) I was thrilled that this unit passed, as did the flatness of the iron seat. The finish of the stainless steel sole, and the adjustable mouth was beautifully done;

Next, I put on the guide fence. I am pleased to report the new fence posts that now jam to the body work perfectly with finger tightening.

Next test was the depth skids;

Not much to report here, they worked and looked great.

The overall fit and finish was outstanding. I have an issue with the micro-bevel on the iron (it is too damn big) and I have an issue with the iron lapping. All easily solved.

I am happy to share this little insight into tool making. If you thought this was cool, just wait until you see my next post showing the new HP-12!

-Still Your Tool Potentate

Mr. Potentate,

Am looking forward to perching this fine piece of American design. Perhaps two.

Will there be a preorder, meaning full payment up front, or all of that has not been worked out as yet ?

If I recall it was stated that it will not be released until much later in the year, correct?

i have been buying your tool for only 5-6 years, wish it could have been from the start.

thank you ralph

Ralph,

I cannot answer your question definitively, but I do believe they will need to do some kind of order commitment to quantify their manufacturing numbers. Right now, Harvey is having difficulty keeping up (this makes me laugh, it is all I ever knew!) so we will see. I have spoken with Mark Strahler, the new BCTW president and they are exploring how to do this with the new website if need be.

So, after all that… I don’t know.

-John

Wow, John – that’s one sweet piece of machinery! It looks gorgeous. And I’m sure it works beautifully. I love the anodizing color on the sides. Nice work!

And I do appreciate your offering to us, the Drivel-Starved Nation. I was, indeed, feeling drivel starved. Keep up the great work!

Thank Peter.