________________________________________________________________________________________________

“When we engage in what we are naturally suited to do, our work takes on the quality of play and it is play that stimulates creativity.” — Linda Naiman

________________________________________________________________________________________________

The next two weeks I will be in Indianapolis teaching two classes; Creative Thinking/Design and Toolmaking 101. I am really excited about both of these classes and always enjoy my time at the Marc Adams School of Woodworking. I am also bringing a couple of my helicopters because there are plenty of places to crash on the school property.

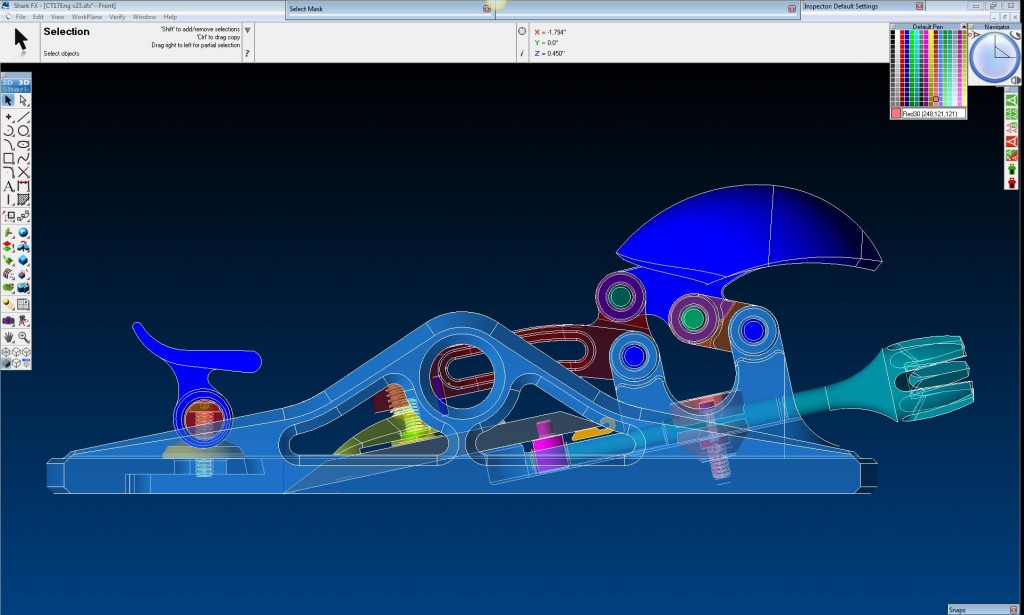

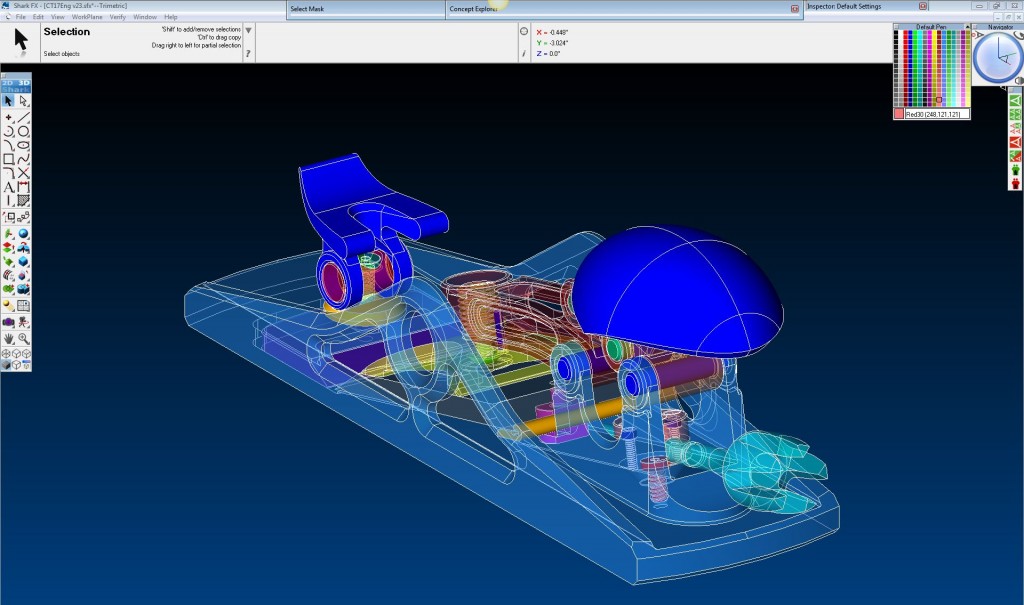

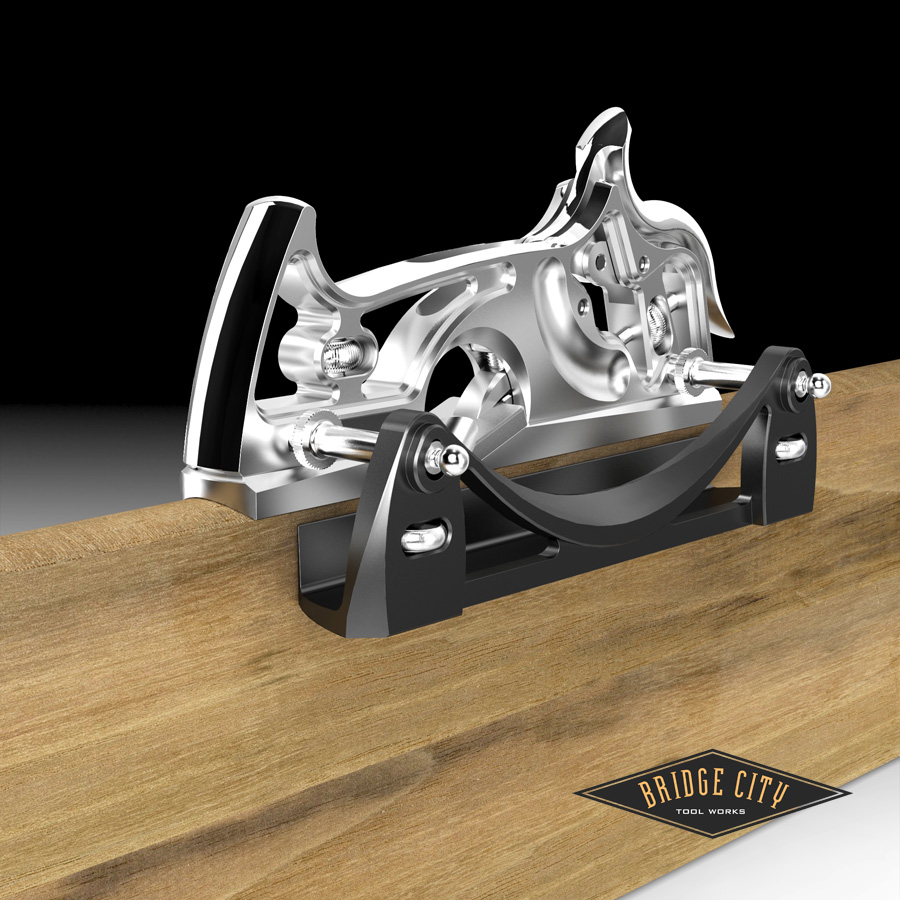

I really like the quote above–most days I can’t believe I have earned my living for almost 30 years by playing here at Bridge City. Speaking of which, I have three major R&D projects going, all of which I am really excited about. One however is keeping me up at night: an accessory fence system for the Jointmaker Pro family of saws.

I want to do so many things with this tool that set-ups need to be easy, fast and off the charts accurate. The new fence system will allow you to move a stop in 0.001″ increments and get the heck out of the way in a hurry if need be. More important, I want to be able to cut gears, and this system will be the foundation for that attachment next year. We have also found away to add the clamping system to the fence (way cool) and I should be able to share images when I get back at the end of the month. We are also anticipating doing something really rare–and that is for those who purchase this system, we want to buy back your original fence (The metal components, knobs and lock bolts). We will strip and re-anodize the aluminum for the base fence system of future JMPs. I hope to have a working prototype to demonstrate at Woodworking in America at the end of September.

My personal shop is now in a back bedroom of my house. Space is limited, and these three new saws are going to be very welcomed in my cramped working space. (I would have more room if I did not have to share this space with a female shoe collection that would make Imelda Marcos proud…fortunately, Louie dog has, and will continue to whittle the collection–he just needs more help with his stealth techniques). Here’s the skinny…

The most popular of all the Japanese saws are the Dozuki, Kataba and Ryoba. Because of their traditional length, they have always been tough to store. No longer, as these fold and the handle becomes a blade guard.

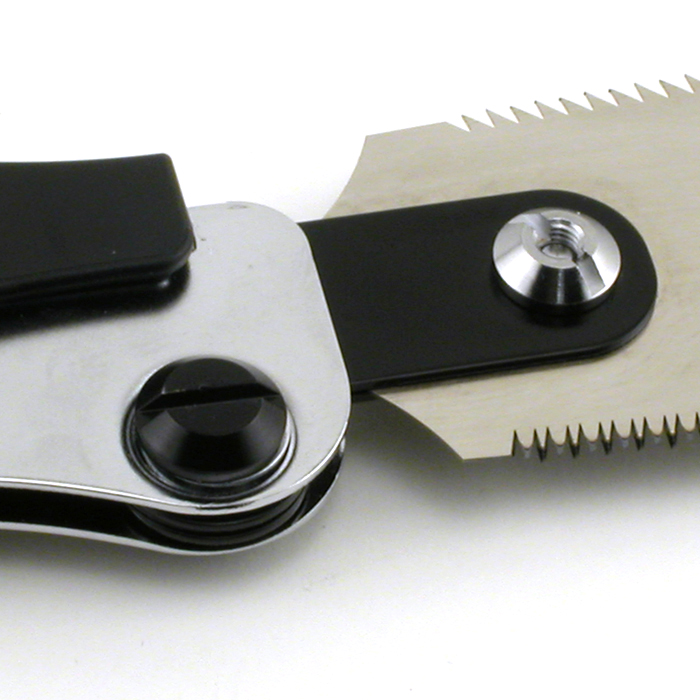

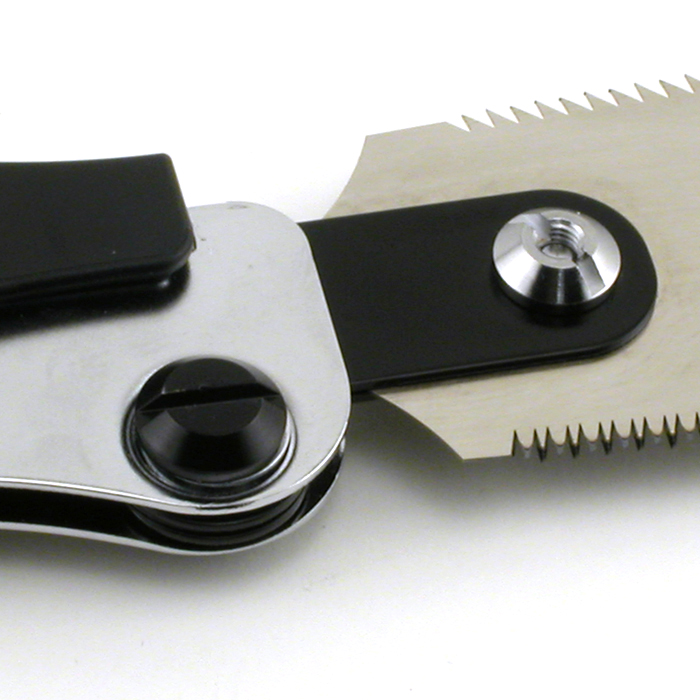

The locking mechanism is fast, rigid and intuitive. Why even a caveman…

The 28 TPI Dozuki blade is .012″ thick, (.33mm) and leaves a kerf of approx. .020″. It is faster than our JS-1 and I really like that I can fold it and put it in my back pocket. OAL is approximately 24″.

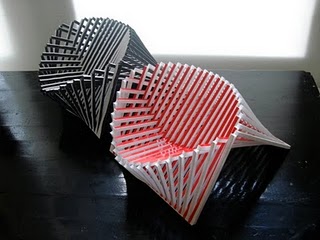

The 20 TPI Kataba (below) is a deep cheek cutting saw–and is perfectly suited for tenons and furniture making. The added mass of the handles makes controlling these saws a breeze–they fall under their own weight during cutting. (It is easy to spot the induction hardened teeth.)

Below is an image of the Ryoba–the utility saw for crosscutting and ripping. The fast cutting crosscut (16 TPI) is the saw of choice when you need to cut a large board in half across its width. The 12 TPI rip is used for…you know…ripping! (There is an included guard for the exposed teeth of this saw when folded.)

Here they are together;

The handle is common, and the blades are replaceable so one option is to purchase the kit version of the saws…

We are still working on pricing (and the value of the dollar is not helping) but check this out; Handle plus three blades will be around $140. Add one set of spare blades and the total will be under $200.00.

It will take three months to make them, and we will stock spare blades but not complete saws or handles. Offer coming to your inbox next week!

–John

![]()