Brain Food;

“We like the opinions to which we have become accustomed from youth; this prevents us from finding the truth, for we cling to opinions of habit.”

Moses Miamonides

1135-1204

Egyptian Physician

Jointmaker Pro Update: At the end of today we will have shipped approximately 2/3rds of all the Jointmaker Pro orders. My chest pains are subsiding…

The Jointmaker Pro forum (the link to all of the BCTW forums is at the bottom of our splash page titled “Community Forums”) has a section on project ideas and one idea was a contest that took advantage of the capabilities of the Jointmaker Pro.

Please chime in here–anybody interested in a project contest?

Here are my thoughts as expressed on the JMP forum-

We will ask the Jointmaker Pro Supreme Emperor (that would be me) to conceive of a project idea (and the rules) that will put you and your Jointmaker Pro to the task–maybe 2-3 times per year. You would then set about designing and making your solution.

As the Jointmaker Pro Supreme Emperor, I would judge all entries for a yet to be disclosed prize. All entrants would receive five free JMP saw blades after your project is submitted (photo posted on forum).

We would then post the winning plans for others less inspired–all for free.

That is all I want to share at the moment–other than this could be really fun.

Your thoughts?

–John

Behind the Scenes

Behind the scenes at Bridge City Tool Works!

The Prices of Progress

March, 17th, 2009

And now for today’s lead-in quote;

“Karate is a form of martial arts in which people who have had years and years of training can, using only their hands and feet, make some of the worst movies in the history of the world.” –Dave Barry

OK, I am not going anywhere with that, but it brightened my day–yours too I hope.

Amid all the controversy that surrounds the Jointmaker Pro, the opinion most befuddling to me is the one proffered by “purists” who claim that cuts made with the JMP are “cheating”–whatever that means.

Today I was reminded (thanks to one of our forum members) of a different day in a different discipline not that long ago…

Do you remember the first hand held calculators–the ones introduced in the early 1970’s that only did arithmetic functions? They sold for $395 (that’s a whopping $2087.59 in today’s dollars!) Here’s a tool that purists vigorously defended just a couple of presidents ago;

Remember these?

Ironically, this site is rather fun. It works on screen, instructions are included. Imagine using one of these in a 400 level physics class with the bull horns of war protesters outside…

“WHAT DO WE WANT?”

“PEACE!!!”

“WHEN DO WE WANT IT?”

“NOW!!!”

A bit oxymoronic don’t you think? Now, don’t the bullhorns echoing around the internet regarding “how” a cut is made in wood seem rather silly?

Oh, and imagine how abacus owners must feel.

–John

PS: The Jointmaker Pro would have retailed in 1970 for $226.00. If you want to have fun with price comparisons, click here.

JMP Feedback and 1 Idea;

March, 11th, 2009

We are about half-way done shipping the Jointmaker Pro’s as of this writing and the feedback (so far) has been positive. You never know with something so new and controversial–today is a good day.

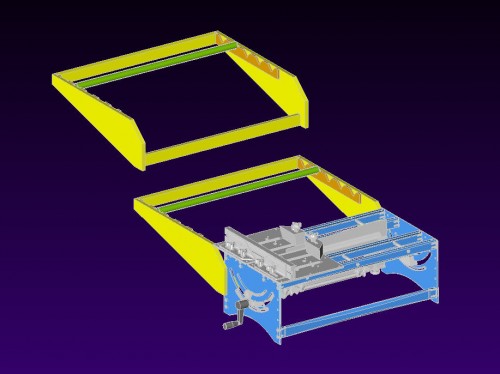

One of the changes we made to the production version of Jointmaker Pro is the ability to add user designed jigs and fixtures. Below is a quick concept of a dead man to keep from loading the linear tables when cutting longer stock. This idea would fasten directly to the front and rear plates and offers minimal resistance to stock traversing.

I would likely make this from 1/2″ baltic birch ply and design around any stiff round stock (pvc, conduit, dowel, closet rod, aluminum tube, etc). Perhaps include another brace with a lip on the down legs of the wings for blade storage. This is a seed idea for our customers–more ideas and feedback can be found on the Jointmaker Pro forum on our website.

Now here is some good news for us, we have 7 JMP’s left. (Actually we have 17, but 10 are reserved for my Silent Woodworking class at Marc Adams School of Woodworking in May). We anticipate beginning the wait-list for round two in about two weeks or less.

Monday we begin the video shoot on my secret new controversial tool that will challenge how you think about another aspect of woodworking. Silence is golden! (Stolen from that 60’s song by The Tremolos or Tremeloes…which in turn was originally recorded by the Four Seasons I believe.) Damn I am getting old.

Stay positive, engaged and enthused!

–John

FYI: My 2009 Teaching Assignments

March, 5th, 2009

As a trained educator with two dogs that won’t follow a single command, it is time to announce my teaching engagements for the year:

What: CAD for the Woodworker

Where: Marc Adams School of Woodworking (Indiana)

When: May 4-8

Who: No more than 20

What Else: Laptop or computer required.

This is my fourth or fifth year teaching this class and it is a blast. The software we use is the same package I use to design BCTW tools (Cobalt)–a mid-range solid modeling package at $4,000. Students receive a fully functional STU license for $395. If you are looking to learn a new skill, or perhaps more important, become more efficient, this is a great week. 90% of the students struggle with the computer and by Friday they are up and running creating projects in the virtual world of CAD.

What: Silent Woodworking

Where: Marc Adams School of Woodworking (Indiana)

When: May 11-15

Who: No more than 18

We are going to turn conventional woodworking wisdom upside down in this class. The focus is how to produce gallery quality work in a soulful environment.

We are providing several Jointmaker Pro’s (and other yet to be released new tools) for this class and I am confident most students will have their life vector bumped way off course. Believe it or not, the shop of the future is going to be in a spare bedroom for many. No dust collector, no screaming machines, no hearing protection–just you, the right tools, and a desire to produce flawless work. Personally, I can’t wait for this one.

I don’t know about space availability or any other details other than when I need to be there (similar to how my dogs know the location of their food bowls). You can learn more here.

If you have never been to MASW, it is an expansive educational complex plopped in the middle of an Indiana corn field. Marc confessed recently that he used a Bridge City try square to layout the lake on the property, hence; Try Square Lake. It is not quite visible from space but it is dead square–a true marvel of the limitations of a back-hoe–no fish swimming in circles here.

–John

Henry Ford would be proud….

March, 2nd, 2009

As promised last week, we began shipping the Jointmaker Pro kits today. Concurrently, we are preparing the assembled versions and thought you might enjoy this picture. (It will take us about 10 days to fill all of our orders so check your email for shipment confirmation and tracking number).

As a reminder, the manual is posted here.

–John

Jointmaker Pros Begin Shipping on Monday

February, 26th, 2009

We’ve taken much heat about our slow delivery of the Jointmaker Pro, but we made all the right decisions in making it as close to perfect as we are able.

Next Monday, March 2 we will ship the first wave of saws and continue shipping over the next 10 days on a first in, first out basis. For those who want to peruse the Users Guide, it has been posted on our website here;

Jointmaker Pro Users Guide

We have approximately 25 unsold Jointmaker Pro units remaining from the initial production run. When those are gone we will begin the wait list for the second manufacturing run.

Stay tuned, we are going to be introducing another disruptive new product in the coming weeks.

–John

Jointmaker Pro Updates, Misc. News

February, 6th, 2009

Each year I leave Portland’s rainy winter for a solo, two week work retreat. Despite what you may be thinking, the emphasis is on work. This year I parked my rear in St. George, Utah.

The sequence of each day is as follows; shower, coffee shop/New York Times, banana, CAD work, lose track of time, (including when to eat) and around 10-12 hours later I heat up a bowl of soup and watch (when it is on) “How It’s Made” on the boob tube and then retire. I repeated this routine 14 straight days on this trip. With the exception of the banter at the coffee shop, I am isolated from people and all of their annoying habits.

Or maybe it is the other way around…

I have a list of objectives that I barely dent–which is always disappointing to me. I routinely overestimate my capabilities and although this is difficult for me to admit, I also have a life-long habit of underestimating–the delivery dates for the Jointmaker Pro are a fine example. I think I am caught in some kind of weird dimension trapped between under and overestimating because in this strange world things are done before they start yet they are never finished.

Good thing I have dogs–they appear to understand me. However, they are English Setters…

Good news regarding the Jointmaker Pro, the saw blades will arrive towards the end of this month and that is all we are waiting on! What a great journey this project has become and I can’t wait to see it unfold in other ways.

Years ago, I used to be a studio furniture designer/maker and from this experience I have frequently used the term, “gallery quality work” when describing the capabilities of the Jointmaker Pro. But what does this really mean?

There are four basic elements to working wood (which is different than woodworking), dimensioning stock, sawing, drilling, and shaping. All of the other ancillary process of shaping wood fall into these base categories–including joinery. Gallery quality work implies that as you progress through any of these four basic zones, your efforts are as intended and yield predictable results. Cuts are clean, holes are true, faces are parallel (if that is your intent) and you have no need for putty, filler, or other back peddling activities that hammer at your productivity or the quality of your efforts.

Of course, this is easier said than done, but I am committed to finding ways to pursue this philosophy without the need for an ear-busting, headache-inducing dust collection system. The Jointmaker Pro was the first leg on my quest.

In a few weeks we will unleash the second leg of this quest with another revolutionary idea that will equally broaden your understanding of what it means to to do gallery quality work without power… actually you will need some source of power to play music.

Stay tuned (pun intended).

-John

PS: I will be demonstrating a PRODUCTION VERSION of the Jointmaker Pro on Feb 13th and 14th at the Crucible in Oakland, CA. It is free (sponsored by the fine folks at Lie-Nielson Toolworks) and just maybe, I may have a surprise with me…

Jointmaker Pro Update

January, 27th, 2009

Two weeks ago we received all of the components for the Jointmaker Pro–holy cow, I have never seen a BCTW project with so many parts! Prior to anodizing the aluminum parts, we assembled one unit and the results are…

Spectacular—in every sense! For those that have seen the prototype in action, the production version features over 80 changes and all I can say is I thought the prototypes were cool, but now, like everyone else waiting for delivery, I CAN’T WAIT to get mine!

Parts come back from the anodizer this week and they are off to the laser house next week. Packaging for both versions (unassembled and assembled) are finalized, and we have decided to forgo a written assembly manual for a DVD or web-based assembly tutorial which we will finish next week. Lastly, the saw blades should arrive from Japan any day now (it took 4 months to make all of these blades).

We also decided to do a little bit of sub-assembly work for the unassembled versions for those who have limited assembly experience. Now, all one needs is to be able to do is insert and tighten screws.

While the components were being manufactured I took the JMP on the road to a couple of the Lie-Nielson Hand Tool Events (if you can go to one of these, they are intimate, fun and educational). One thing became apparent to me after demonstrating this tool for eight hours straight—my back ached.

As a result, we redesigned the stand so the back of the Jointmaker Pro is now 3” higher than the front. This accomplishes two important things, it shortens the sawing stroke and it makes it easier to see your cuts. It is one of those counter-intuitive decisions that really makes using the tool fun. I demonstrated this change to show attendees and everyone agrees this is an awesome improvement. Whether you use our stand, or make your own, we recommend inclining the Jointmaker Pro without hesitation.

As those patiently waiting know, we have taken our time to make sure the user experience is going to be as flawless as possible. We can’t wait to learn how our owners use this transformative tool—it truly changes your perspective on project ideas.

Lastly, I am on the second week of my annual two-week work retreat. I would have posted this update last week but I am in Utah and forgot the password into my blog…

This whole password thing is really getting to be an issue for my aging brain.

–John

The New and Improved CS-2 Centerscribe is Now Available!

January, 12th, 2009

Of all the tools we have produced over the past 25 years, the Centerscribe has never left the top ten for good reason–the Imperial measurement system makes it easy to make time-consuming and frustrating mistakes (example; divide 7-13/16″ in half, or thirds…).

We have made significant improvements to this popular tool and I am pleased to share this brief overview;

- Eliminated backlash by replacing the rack and pinion drive with a closed-loop cable. It is smoother and a joy to use.

- Eliminated binding issues in humid environments by replacing the wooden arms with aluminum arms

- Added the ability to insert a mechanical pencil (number one request)

- Added the ability to find center on cylindrical stock without using guide pins

- Added the ability to find center on square/rectangular stock without using guide pins

- The CS-2 has the ability to accept accessories

- First accessory is the mortise/tenon attachment

The little movie below illustrates how easy it is to use the CS-2 for all of your centering requirements. In addition, pay particular attention to the new mortise/tenon attachment – it is incredibly useful. For example, say you have a table leg that is 1-3/4″ square and you are going to attach stretchers that are 3/4″ thick using a 1/2″ tenon. This means you need to layout the 1/2″ tenon on the 3/4″ stock and the 1/2″ mortise on the 1-3/4″ square leg.

With the new mortise and tenon attachment this is a math-free breeze. Simply set the attachment to 1/2″ using the built-in scale, secure in place and make your scribe lines. At this point the thickness of your material does not matter because the 1/2″ setting will be perfectly centered on your stock each and every time without any math.

You have really never seen anything like it.

“>

For this week ONLY, we are offering free shipping when you purchase both the CS-2 Centerscribe and the new CS-2 Accessory. If you already own the CS-2 Centerscribe, you’ll get free shipping on the purchase of the Accessory. (The free shipping applies to any other in-stock items you add to your shopping cart as well!) Just use promotion code CS-2FREESHIP during order checkout. Much more information and regular web ordering details can be found here, or feel free to order by calling one of our friendly marketing associates at 800-253-3332.

And lastly, a belated Happy New Year!

John

Snow Day(s) at Bridge City

December, 22nd, 2008

I have lived in Portland since 1973 and have never seen this much snow–just heard on the radio that we may be setting an all time record.

I ventured outside to capture a couple of pics–and for those of you who routinely see 16-18 inches of snow, it paralizes Portland, as we have no infrastructure to deal with it.

Needless to say, we are all working at home until the roads are cleared which may be a couple of days.

And as stressed out as I get knowing that we are not at the office helping our customers, I must admit this is (so far) rather fun.

Although nobody is home to answer the phones, we are all working at home and can be reached via email; sales@bridgecitytools.com.

And from all of us at Bridge City, we wish you a safe, warm and joyous holiday with your family and friends.

Warm regards–

John