Drivel Starved Nation;

I spent the month of February working on some new concepts and I finally finished the 2015 Fab 50 tool. Why the name “Fab 50”? Because each year we pick a design and fabricate 50 units and move on to something else the following year. This year’s version is something else…

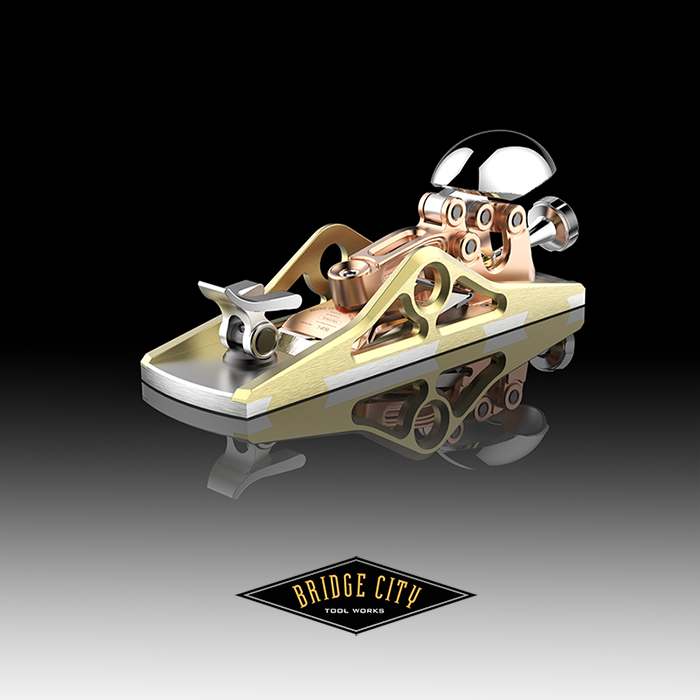

2015 Fab 50 tool – Think Copper!

One of our manufacturing partners has been nudging me towards using copper in something, so this dual angle block plane (it is both a low angle and regular block plane) has 4 CNC milled, solid copper components. The sole is stainless steel and the sides are 360 brass which are double dovetailed to the sole. All of the copper will be lacquered so it will keep its sexy look. The sole is 1.8″/46 mm wide and 6.25″/159 mm long. It is a variation on the the CT-17 theme from 2012. You can see how the mechanism works by clicking on the video tab at the bottom of this link.

I am excited to share the initial image with you;

Thanks for taking the time to peek at what should be one of the finest tools we have ever built.

-John

What an amazing marriage of old-school materials and contemporary styling! I love the fact that the sole is double-dovetailed to the sides – such an interesting combination of traditional joinery and CNC shaping. Just shows that there’s never just one way to do things. Beautiful tool. I hope I get to see one some day.

Was the strength of copper ever considered to be an issue?

Steve

John,

That copper is just sexy and like many sexy things, I hear it can be difficult work with. How does it mill?

Very cool looking tool, that’s for sure, I’m glad I have a “place” at the table,” any prediction on completion dates?

While I’m burdening you with questions, how’s the chopstick making fixture coming along?

Best,

Rutager

way cool, dude. and, the photography is not a bad second. welcome back, consuelo kept the ship afloat while you were away.

2 observations:

1) It’s beautiful.

2) I’d be fascinated in what a rendering of a patinized unlaquered version would look like. The contrast between the matte green and the stainless would be interesting.

Dave,

I am going to do just that live with one of the two or three showroom versions.

Thanks for the kind words… are you on meds? LOL!

Best-

John

FYI, Consuelo is the ship. Pleased to learn upon my return that it is still floating…where it is headed is a mystery to me.

Best-

John

Rutgers,

I have someone holding my hand through the copper milling, and I am repeatable being told not to worry.

The chopstick jig? I have two words after returning from China…

HOLY CRAP!

More later. And, thanks for the business!

Best-

John

Steve,

Yes, of course. The bigger issue was milling expertise. Some of our shops won’t touch the stuff.

Let’s put it this way, it is going to be a very good memory for our customers and possibly a very bad memory for me. I like the odds.

Best-

John

Thanks Peter.

If it wasn’t morally illegal, I would buy all 50 of these as an inheritance for my two kids. That said, they know that they need to keep their day jobs…forever.

Best-

John

Sexy! I want!

Have you thought about galvanic corrosion with the copper and the carbon steel blade? The stainless lever cap parts would be alright but what are the pins in the linkage assembly made out of?

The pins are stainless and black oxide coated. They are also greased so all should be well.

Sides are brass, sole is stainless as is the polished cap. The iron will be optically lapped and coated with oil so it should store well. All of the copper is lacquered.

This is going to be an exciting project.

Best-

John