Drivel Starved Nation-

Before I begin a rage filled diatribe, I must first share a Grandpa report…

Last week, 4-year old grandson “Speedy” (aka William) and family came over for dinner. Behind the house are several kiddie gardening tools including a little kiddie hoe, and the popular bird feeders.

“Grandpa, I think the birds are hungry.”

“Do you want to help me fill the bird feeders Speedy?”

“No” he says. “I need to pound dirt with this hoe, but I will watch you do it.”

I don’t know why I think this is so cool. But it is a reminder that we all need to live in the moment — if possible. And possible is always doable, especially pounding dirt.

THE END

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________

DIATRIBE TIME…

There are few subjects in woodworking that are more polarizing than the use of a honing guide.

There are those that think they are completely unnecessary. There are those that like them (like me). And there are those that shill them (like me).

According to my math, I win 2 out of 3. In other words, if you like them, I like you… or you are like me… or I am like you… you get the idea. But I digress…

If I am not mistaken, there are only two woodworkers who are both business owners in our community and degree holding educators. Marc Adams, and yours truly. Actually it is Dr. Marc Adams to be specific. My degree is a B.S. degree which some will agree, suits me just fine, especially the BS part. I bring this up for the purpose of sharing THE…ONE…THING I remember from my teacher training;

“Teachers should open minds, not close them.”

I get a little more than agitated when those with an influential voice speak in absolutes. That is not teaching, that is brain-washing. And it pisses me off.

Chisels and plane irons need a surgical edge for optimal performance — and for safety reasons. If you have the ability to do this without a honing guide, I salute you.

When I first started out in woodworking, I found it hard to believe that the difference in attack angles between a low angle block plane and a regular block plane was the difference between 42 degrees and 47 degrees.

Five measly degrees.

I remember thinking about this during one of my insomnia sessions. I realized that a measly 5 degrees is a 10 degree slope. A 10 degree slope is several degrees more than the federal regulations for the maximum slope of interstate highways (6-7% = 3-3.5 degrees). And, as a bicyclist, a 10 degree slope is what we call a “grinder”. So, degrees in little numbers do matter.

Don’t you find it interesting what I learned when I should have been sleeping?

I like to play around with the edge geometry of my plane irons. In order to do this and eliminate inaccuracy, I prefer to use a honing guide. I am also anal about how my edges look — I LIKE the look of a factory edge. But that is just me. If you disagree, that is just you. Neither one of us is wrong — nor right.

You go ahead and do whatever it is that makes woodworking enjoyable for you.

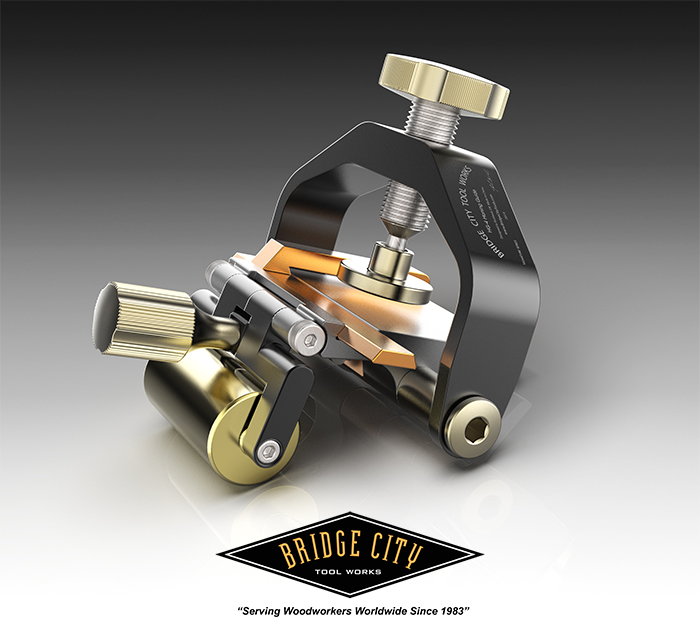

If you are still reading this Totally Awesome and Worthless blog when you should be in your shop making something, or sharpening something, I am sharing that I recently completed the redesign of the original HG-1 Honing Guide, hence the new HG-4 moniker. Here are the changes;

In this new version, the unit has been widened to accept irons up to 70mm (2.75″) in width. That just about covers everything available today.

I also added hard stops to the lead screw so it is no longer possible to crash the brass roller into the lead screw. The axle is now anodized aluminum which will not react with wet brass. I moved the clamping bridge forward to more readily accept spokeshave irons. And I eliminated the rubber pad which was a pain for really narrow chisels. Cosmetically, I changed the knob designs to what I call “nicked knurl” to be consistent with similar type knobs on our other new tools.

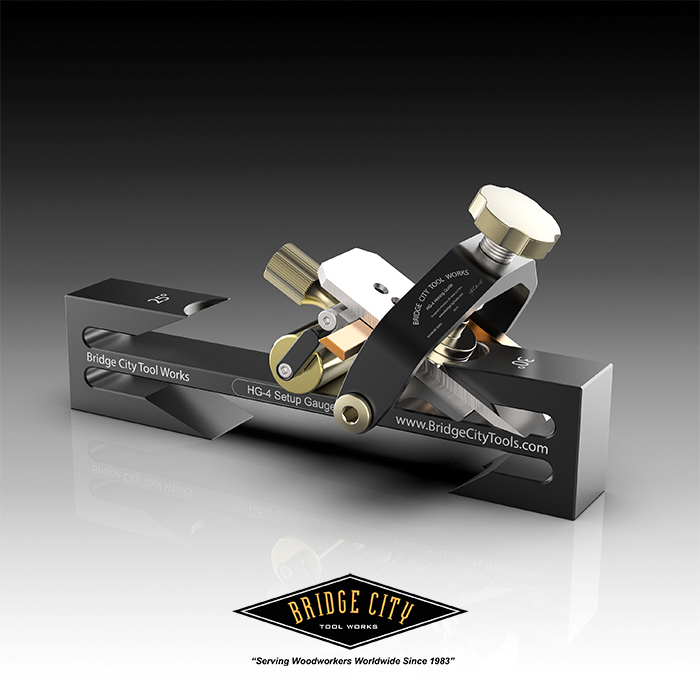

In the image below, you can see the changes I made to the setup guide;

Three of the fixed references have cutouts to eliminate interference with the clamping pad.

The real advantage of this honing guide is the ability to adjust the angle on the fly with the rear knob. It is fast, precise, and it suits me just fine. And if it suits you just fine, they will be available later this year.

Lastly, I would never unleash a new tool into the world without some feedback from a trustworthy source. So, I had the following conversation with dog tormentor “Mr. Squirrel” on Saturday afternoon;

“Mr. Squirrel, I value your opinion and have something to discuss with you — do you have a minute before Jitter dog, and Bella dog, find out you are here?”

“Mr. Squirrel, as someone who values sharpness, both in claws and teeth, what do you think about honing guides?”

There. The debate is settled.

-Still Your Tool Potentate

Why is it “4”? Normally the numeral means *something*.

They do. #’s 2 and 3 are assigned to the two versions of honing guides I designed for the Chopstick Master.

John,

Years ago there was a squirrel that would drop twigs from up in the tree on the head of the neighbors dog-can’t think of any other reason it would do that except to mess with the dog.

I’ve really liked the HG-1… except for very thin chisels, they would pivot on the clamp, have you tested those on this version?

Muscle memory is a great thing, be it sawing or sharpening, but like many folks, I sometimes am away from the shop for months, so a guide is a must for me.

Wasn’t there a honing guide included with the HP-6 dovetail kit too?

Yes

Maybe it’s time for me to change my thinking. I owned one guide once, which I did not love and got rid of. Since then it’s been freehand for me. The exception is finger planes (and I have a bunch) which I found cumbersome to do freehand (particularly if they have a radius) and years ago bought a couple of simple small guides for those plane irons. More recently I got the 2 guides for my HP-8 and I do like those guides. Plus as I’ve gotten older my ability and fondness for holding irons down on my stones has waned. So I’m interested in seeing what John and BCTW has in store for us.

Yes—change your thinking! 😄

You didn’t answer Rutager’s question about narrow blades…

Blades less than 3/16” in width can be clamped but the pad needs to be centered, since it pivots to accommodate tapered irons.

I know this may not be the right forum, but is there an update on the pencil precision?

Will do!

John,

I’m glad to see you remember some things from your Industrial Technology Education days at Iowa State. I just retired from teaching woodworking at Ames High School two years ago. I remember our metals classes. Glad to see you are still designing some tools. I might have to add a few more to my collection. Craig Boylan

Craig,

Congrats on your retirement!

I loved my time at ISU, and if not for Al Sherlock, Webber and crew I cannot imagine where I might be right now other than a federal prison…

John

UPDATE: I have created a new clamp pad that will address centering and clamping narrow irons. See new image.

John

UPDATE: I have created a new clamp pad that will address centering and clamping narrow irons. See new image.

John

Do you know when these will be available exactly? I would like to order 2 right now! I have wanted one of the older versions forever. Is it just me but you seem to be the only company capable of making this tool, simple capable, user friendly. You would think someone else would have figured it out by now.

How do you suggest setting up for the 48 degree angle on the HP-12 high angle blade edge?

The iron of the HP-12 is bedded at 12 degrees with the bevel up. One end of the iron is ground to 25 degrees with a 5 degree micro bevel equaling 30 degrees. This will give the user a 42 degree attack angle.

The other end of the iron is ground to 30 degrees plus a 5 degree attack angle which equals 35 degrees. Bedded, this creates a 47 degree attack angle.

If you want 48 degrees precisely, you will need to modify the micro bevel to 6 degrees.

-John

Are these released into the wild? I really like the design/features, but have not been able to find a single review anywhere.

Brian,

With an unconditional money back policy, why not just find out for yourself? Your real world experience trumps reviews.

Just sayin’…

John

Ahh, I had forgotten about the unconditional guarantee – ordered.

Well I waited a year but with today’s flash sale I ordered one. Time to stop free handing my sharpening!

Hi John,

I recently purchased this honing guide even though I already have a few because it’s just so elegant. However I’m having some difficulty using it. Specifically, the initial placement of the blade in the guide. The manual says “Place the HG-4 on a flat smooth surface. Looking at the HG-4 from the side, clamp your iron or chisel so that the bevel is approximately flat on your work surface.” This isn’t working very well for me. A more precise method would be helpful. Something like lines etched into the set-up gauge for each of the 4 angles. Alternatively, the overhangs for each angle could be milled to the distances needed. I intend to scratch these dimensions somewhere on the set-up gauge, though that isn’t a very elegant solution. Thanks and keep the great products coming. Jeff

Jeff;

Do you have our setup gage? This makes it really easy. Let me know and I will follow-up. John

Yes, I have the set-up gauge.

I thought I had replied to this, but do not see it, so this may be a duplicate reply, Yes, I have your setup gauge.

Hi John,

This is my third attempt to reply to you. The two previous attempts seem to have dropped off.

Yes, I have the setup gauge.

Hope this one gets to you.

Jeff

Hi John.

Will the newer hg4 work with the hp6 irons and guides?

Regards

Jason

Jason,

Yes.

John