Drivel Starved Nation,

First, I really do hope all of you are well and that everybody in your orbit is well. I don’t think anybody is better prepared for a pandemic shutdown than those of us with a shop. So far, all is well here and I hope to keep it that way.

Before I fill the space between your ears with some Drivel, I do want to get serious for a moment.

There was a comment posted on this blog from a customer with a JMP that needs warranty work. This person claimed that he has received no response from customer service. I understand this pandemic has really created a mess of things, so I want to state unequivocally that this is not something I will tolerate. Pandemic excuses only work for a short while before they become a crutch for incompetence. If anybody has any issues at all, and you are head-butting the wall of unbearable frustration, here is what you do; complain to me.

john@bridgecitytools.com

I will make sure that the chicken salad you ordered is in fact, what you will receive, not the odoriferous alternative.

Whew. I feel better now.

When I last posted on this Totally Awesome and Worthless Blog, I was hoping to get you back in your shop making some cool frames for the twilled cards in my last post. Unfortunately, this project stalled on the spot because Amazon announced they were only shipping stuff they deemed important. This is no longer the case, as I just received a pair of ostrich feather covered handcuffs, so I will revive this project ASAP after my shop stuff arrives. Did I just say that?

PENCIL PRECISION UPDATE: The first pre-production components will be in hand in July. To refresh, I completely redesigned this last fall, but production has been impacted by you-know-what. So I am really excited that this is getting back on track.

Over the past three months I have been working on the HP-6 for the international market, which meant I had to re-create all the profiles in metric units. Truthfully, I should have done this in the very beginning. So, those items are now in the production planning stages.

A couple of weeks ago I received these two boxes in the mail;

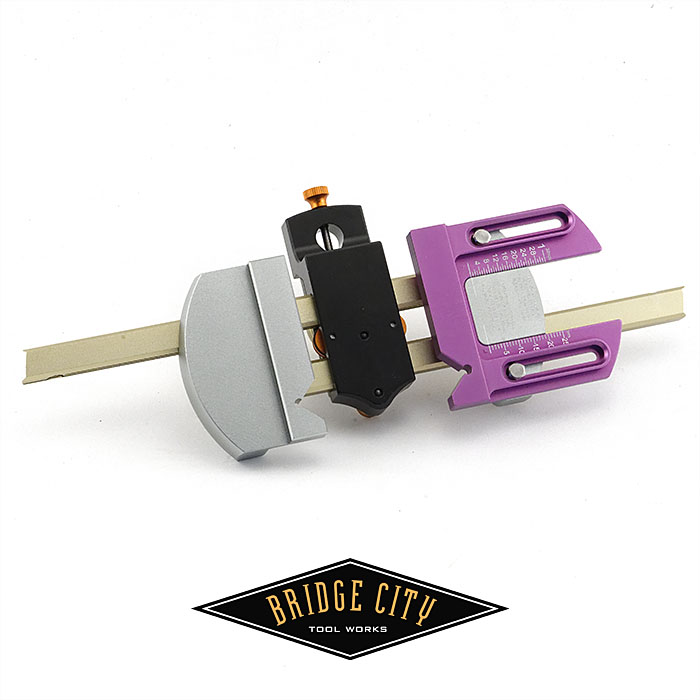

And inside were the production prototypes of the redesigned CS-3 CenterScribe and the new titanium Palm Brace awaiting my approval.

The CS-3 CenterScribe now comes with the mortise/tenon attachment built into the tool. Also different is the lock knob, which is only used when you are using the CenterScribe with one outrigger engaged so it works like a marking gage. The new lock knob thread is now metal which presses against a skid plate to keep from scoring the arms.

This is an exciting redesign and I cannot wait for this to hit the marketplace this summer. Interestingly, this prototype required no revisions which is always a good thing.

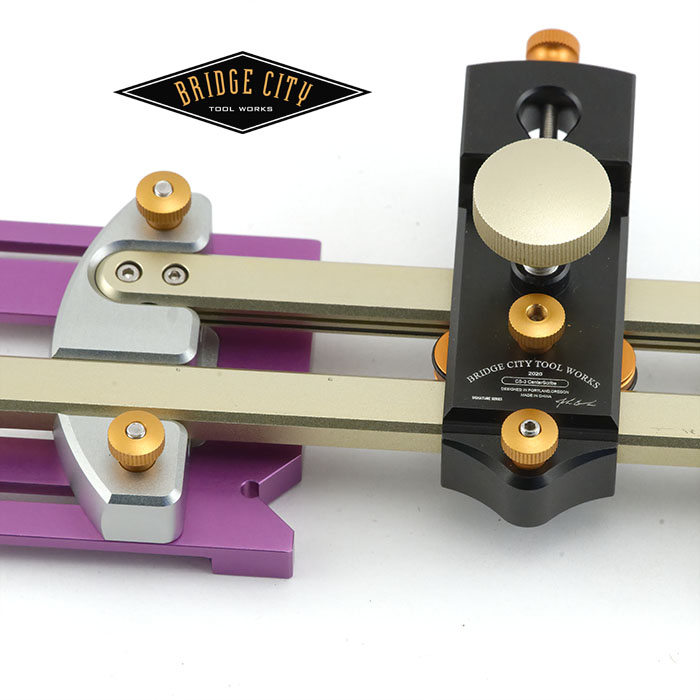

The titanium armed Palm Brace looks like it just came from Q’s lab (Q is the dude that made all of James Bonds gadgets….). This is one of the coolest tools I have ever held and the reason is this jet-black PVD finish. If you are unfamiliar with PVD coatings, click here.

This Palm Brace will only chuck 1/4″ hex tooling. Which means it will chuck everything from screwdriver bits, drills, to nut drivers. Those that have either of the two previous versions know this is just an incredible shop aid.

Here is an image to help you understand the scale;

The engraving on this prototype was all wrong, and has been corrected for the production run.

In my career as your Tool Potentate, the Palm Brace is in my top-five favorite gizmos. Availability is late summer.

I hope I made Q proud!

-John

PS: On weekends I have been working on my quarantine sanity by catering to my bird photography obsession. This bird, the Cedar Waxwing is one of my favorites and I was thrilled to add this image to my collection of bird images for my grand kids. I took this image around 8am at the Tualatin River National Wildlife Refuge, a 20 minute drive from my house.

Is this a cool looking bird or what? The orange wing tips, as well as the yellow tail are not feathers, this color is a wax that is secreted — the reason of which I have no idea. Like every other color scheme in wild birds that is not camouflage, the display is likely for attracting a mate. That’s my guess.

Is the Palm Brace the same as the original version other than the finish? Or does it have other differences?

Wings tipped with wax? What sort of witchcraft is this? Beautiful shot, John. Stay well!

John! Glad to read that your sense of humor is intact… I hope the rest of your extended family share good health, and a strong tolerance for your… wit!

The Centerscribe Mortise/Tenon addition is genius… If I can figure a way to add that to my type 1, I’ll let you know!

Stay well… thanks for the happy read! Mark in Camden

Great to have you back posting, John. The Palm brace looks great as does the new center scribe!

I’m not sure about the Ostrich feathered handcuffs, however! Could that be a new sideline business during the Pandemic?

Be safe!

Adrian,

The arms of this version are titanium, as opposed to stainless steel. It is lighter and stronger.

And damn sexy!

John

I know, but it sure makes for a beautiful bird.

Thanks Mark.

Cool looking tools! I will seriously look into breaking the swear jar to get these tools, that jar is overflowing because of you know what.

That is a good looking bird there. Don’t see many of those in Michigan. Imagine using those feathers pre-loaded with the color you want to paint a happy little cabin in a happy little forest by a happy little stream. Sorry, my inner Bob Ross is coming out.

Ostrich feather covered handcuffs? Never mind, I don’t want to know.

Paul,

BREAK THAT JAR!

🙂 John

Will the palm brace have less play in the bit holder? (The one I have wobbles a bit, which doesn’t really matter for driving screws but is a bit more annoying for drilling, and I’m wondering if the new one would wobble less. Like…should I upgrade?)

Adrian,

I don’t know the answer as I only have the one unit. I’ll make a cell video and send it to you this weekend.

John

Oh man. Just take my money. Bastard.

Gladly!

John: Have you considered making a full-size brace with 10″ (25.4 cm for the execs) sweep?

Also, I tend to think of weight as a “plus” in brace design . . . .

D

No I have not. The reason is the lack of bits. I really liked the the bits we used to sell from Japan that could be used in an electric drill as well as a brace…. don’t know if they are still available, but they were fantastic.

The old, two jaw brace chucks are a relic. I know others think they are great and that’s cool too. I am just not, at the moment, motivated to overcome the inertia, and biases from those days gone by. All the power to those who think otherwise, that is what makes the world a more interesting place.

-John

I’m curious whether the Center Scribe is self-zeroing? That is, if you loosen the screws holding the mortise arm and close the device all the way, can you then tighten the screws and get a perfect center line? Or do you have to use the scale on the mortise part?

It is self-centering, even if the screws are loose.

Nice!

Sorry, off topic, but who can I communicate with to get some support / guidance re my new JMP? Having some issues re setting it up that don’t appear to be correct.

Thanks

When will I be able to purchase the Palm brace?

I’m just here looking for giveaway codes! ^_^

I have both the original CS-1 and the PB-1 and use them both and will be tempted by the updated versions. One question though. My PB-1 is one of my all time faves. It’s only weakness (at least mine) is that it had a hard time locking the chuck tight enough to hold the hex bits. I find myself having to lock it again several times during use. Has this been addressed in the new version or is it just me?

Titanium?

Now I’m awake.

Tools made of Titanium?

The sexiest material of all, stronger and lighter than steel, impervious to moisture, with an extremely high Modulus of Flex? Understated and unpretentious industrial chic, well, if I must!

I have two Titanium mountain bikes, the rides of which are made conspicuously compliant due to that Modulus of Flex reducing the transmission of vibration.

What’s not to like?

Self-centering?

Does form follow function?

Of course it is, as it should be, as it was thoughtfully designed, not found under a rock.

Andy,

Hung@bridgecitytools.com

Hung@harveywoodworking.com

The Palm Brace will be available and in stock the first of August.

-John

Dave, this is news to me. The bits are locked by a spring loaded ball bearing, they should snap in place. Do all of your bits behave this way?

John

Hey, John, if you ever sent a video I didn’t see it. I forgot about this for a while and it just came back to mind so I took a look at my brace. The wobble is fairly small and it looks like it is due to the slop in the hex bit mechanism. I think it’s unavoidable with a mechanism like this, because there needs to be clearance so you can insert and remove bits, and probably to allow for variation in actual bit shaft dimensions.

The PB-1, on the other hand has a collet and screws down on the bit and holds the bit tightly with no movement at all. I have mixed feelings about the PB-1: I’ve never felt like I understood the design intent for how I’m supposed to hold the tool, because the little handle doesn’t seem to match any part of my anatomy.

Hi John – Regarding my PB-1 chuck. I am not the 1st owner and so either I may be doing something wrong or the tool was already imperfect. I see no spring loaded ball bearing. I turn the knurled collar to tighten the chuck and cannot get it quite tight enough with my old fingers to hold the hex bit. It loosens, I tighten again and continue to drill. It actually works for the small work I usually use it for – just not perfectly.

John – Regarding PB-1. What happens is that I cannot tighten the brass cover over the chuck tight enough to consistently hold the bit. It’s just small and my old fingers can’t tighten it well enough.

Not sure what you mean by spring loaded ball bearings. Could mine be missing?

So the tools became available to order this morning and I jumped. Question is however where to buy the kinds of bits for the brace that they had pictured. I’ve not seen that much variety before, but perhaps I’ve had my head in the sand. Any pointers?

I forgot to ask before placing my order for the PB-2… Is it ratcheting to allow screwing close to a cabinet’s side?

Thanks!

Ray

I’ve never seen some of the bits pictured. Anyone have sources for these things?

Hey, John, if you ever sent a video I didn’t see it. I forgot about this for a while and it just came back to mind so I took a look at my brace. The wobble is fairly small and it looks like it is due to the slop in the hex bit mechanism. I think it’s unavoidable with a mechanism like this, because there needs to be clearance so you can insert and remove bits, and probably to allow for variation in actual bit shaft dimensions.

The PB-1, on the other hand has a collet and screws down on the bit and holds the bit tightly with no movement at all. I have mixed feelings about the PB-1: I’ve never felt like I understood the design intent for how I’m supposed to hold the tool, because the little handle doesn’t seem to match any part of my anatomy.

So if I already have the CT-16 is there any reason to get the PB-2?

What about for people who placed their order on 3 August (such as myself) — I suppose some will get their tool in the first batch, while others won’t?

“What about for people who placed their order on 3 August (such as myself) — I suppose some will get their tool in the first batch, while others won’t?”

We were always FIFO (First In, First Out) and I am assuming that has not changed. -John

Adrian, no need to get the PB-2 if you have the CT-16. Save the money and buy me a gift card instead! -John

“I’ve never seen some of the bits pictured. Anyone have sources for these things?”

Michael, I really like this company: https://www.montanabrandtools.com/ -John

“I forgot to ask before placing my order for the PB-2… Is it ratcheting to allow screwing close to a cabinet’s side?”

Thanks!

Ray

Ray,, the PB-2 does NOT ratchet, it is a fixed chuck. -John

My PB-2 arrived yesterday, thanks!

The following is from a post I made on reddit: https://old.reddit.com/r/handtools/comments/igrwi9/bought_a_bridge_city_tool_works_palm_brace_pb2/

Couldn’t resist trying it out and it of course worked wonderfully (but still fiddling with the bit locking) — I wanted it for the small bits which were bundled w/ the Kurikuri minidrill brace back when it was available:

https://www.highlandwoodworking.com/drillbitforkuri-kuriminidrill.aspx

(and I wonder now if I should get a second set)

as well as some stubby drill bits and matching countersinks Lee Valley had available ages ago — the split point set in the left at: https://www.lumberjocks.com/reviews/1714 except I didn’t get a plastic holder? Oh, here we are:

– https://www.leevalley.com/en-us/shop/tools/power-tool-accessories/drill-bits/75248-set-of-five-82-hss-countersinks?item=14J0325

– https://www.leevalley.com/en-us/shop/tools/power-tool-accessories/drill-bits/75240-set-of-six-hss-stubby-twist-bits?item=14J0240 — actually can’t imagine using the larger sizes, the set in the Lumberjocks link makes more sense