Drivel Starved Nation:

The following stories may, or may not, be true.

Back in the ’80’s a customer at a trade show went way out of his way to inform me that spending money on good tools is money wasted. He then went on to explain how he makes his own tools out of salvaged railroad rails. This is when I first realized that woodworkers are the cheapest people on the planet. Cheap-asses in the first degree!

How did I deduct this? Because I am one too. Back in the mid ’90’s I was aghast at the cost of vasectomies so I did my own.

Man, did that hurt.

If you are thinking about following my example, email me; john@DontEverDoThis.com for what I would do different…

This is the first of a three-part post that will give you some really cool gift ideas that any cheap-ass woodworker would be proud to make, and the recipients will be equally excited. I am talking win-win here! And, if you happen to own a Jointmaker Pro, you are going to have a blast.

Before I begin, I want to clarify that I have never claimed to be smart, and every teacher I have ever had will confirm my own belief that I am some kind of subspecies. But that has never stopped me from recognizing extraordinary work made by techniques I never new existed.

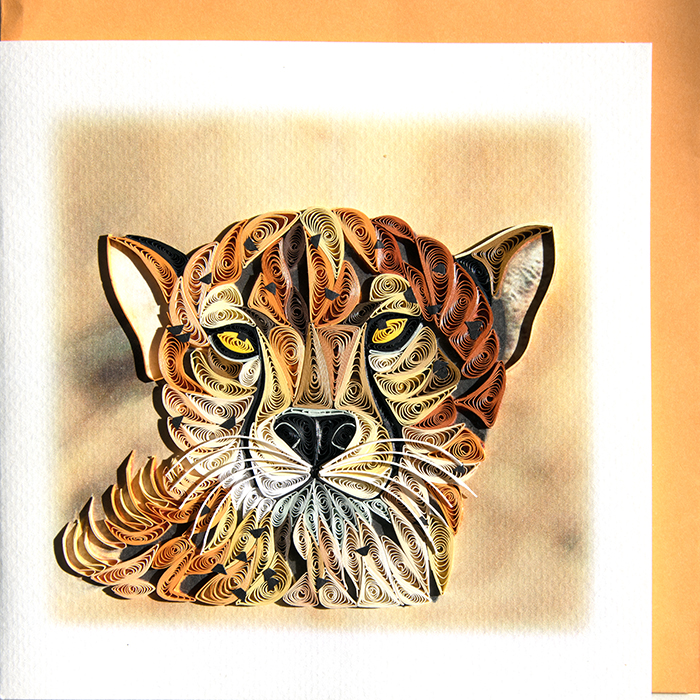

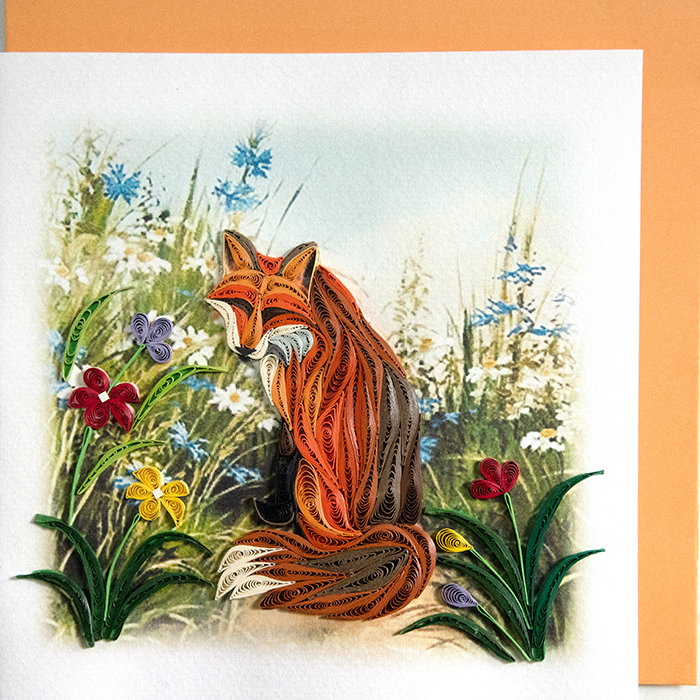

POP QUIZ: What is quilling?

Briefly, quilling is the act of making three dimensional shapes with paper strips. In the old days, a quill was slotted and used to twirl the paper strips. The image below is an example of quilling using 1/16″ strips of colored paper. Get this, the edges of the strips are glued to the paper to create this greeting card, the color around the border is the included envelope.

To give you a better idea of the scale, check out the following two images;

I discovered this line of hand-made greeting cards a week ago while on vacation and bought one of every design they had in stock;

CAVEAT: I have no affiliation with the company that makes these amazing works of inspiration. I am just so excited they exist! You can read about the Yoder-Do story here.

AND what you see here on this Totally Awesome and Worthless Blog is the tip of the iceberg of their creations. I may be really late to this discovery and if so, so what. This stuff is worth sharing.

In my next post, I am going to expose you to another cool creation that I discovered while sipping a foo-foo drink on the beach. Combined with a quilled image, I will show you how to make some really cool, choice quality stuff.

So, trust me and order some of their cards and let’s have some fun together.

Lastly, the railroad rail toolmaker is real, the rest is crap I made up in attempt to legitimize my existence.

-Still Your Favorite Tool Potentate!

PS: OH CRAP! I forgot the most important thing in the whole world! None of the cards pictured above were over $10.

How cool is that?

Well smart or not – you’re a great mentor

Thanks for the insight

Woodworkers aren’t the cheapest in the world – luthiers are. I remember a when Chris Laarman first showed his incredible luthier planes. While many of the luthiers in attendance admired his tools (and some didn’t) they balked at the $125 price. Any many were guys who sold 5k – 10k guitars. I got to know Chris a bit and suggested that the old collector types might be more willing to purchase his planes than the luthiers.

Today if you can find one on the used tool market, expect a Laarman plane to go for $500 and up (way up).

Great cards John! I’ve been buying a line from a company called niquea.d distributed by papyrus who just went of business. They also do quilling and I’ve been giving them to my wife the last few years… more artistic than realistic like these. Love them both, must take a lot of patience to create. I’ll have to check them out, thanks!

Kurt, that is why I felt a sense of urgency with this company. It looks like they have been around for a couple of years, but I have absolutely no idea how these can retail for $7-8 bucks. They are stunningly beautiful and equally well crafted.

-John

Quilling was a fairly popular craft in the 70’s.

I made quite a few Christmas ornaments out of white paper.

I still have my quilling tool made from a sewing needle.

I definitely will be ordering a few of the cards.

Thanks for the info.

Greg

Those cards are stunning! I can’t believe they are so inexpensive. The labor that must go into those is incredible – not to mention the artistry. My guess is that it looks easy to do – until you try doing it. There’s some serious skill involved there. As I scrolled through the images I was trying to guess what one of those would cost. I started adding up the number of little rolls of paper, the time spent shaping the rolls, gluing them down, and even designing the piece in the first place. I would charge $50 for each one of those – and that’s probably still underpricing them. They must make about $1 and hour!

Thanks for sharing, John. I’m looking forward to the next post. And please don’t share pictures of your vasectomy scar…

Peter

Keeping my scar private is a good idea Peter and I will seriously consider it!

John

Did you do a “double knot” just in case?

Can never be to sure . . . .

Ah… the voice of experience.

I must say that with everything going on in the world right now we could all use a new tool release!! Give us something to get excited about and something to look forward to!!

Indeed the work of quilling is intensive and the price of the object made is hideously inadequate in comparison to the number of hours involved. My wife has taken up quilling and has produced some incredible pieces. When she sold her work and was happy to receive the payment, I questioned ( in my mind ) how she could be so happy to receive so little for all the time and effort she put into each beautiful piece she created. But she made people happy, and I suppose if it makes her happy to do so, then that is what counts.

I am a woodworker, and while I try not to spend a lot of money on my tools, I must admit that I am a proud owner of several of your fine tools, and wish I had the money to buy more. I have an AS-3, CS-6, an SE-24 an Awl and a BP-18 and I use them all. one of these days I would love to get a HP-9v2 or the HP-12. We shall see.

I am working on it!

-John

Well, since nobody at Bridge City will answer my emails, I’ll try a comment here.

Bought a JointMaker Pro. It got delivered about a month ago. I used it to cut some lumber. About 3000 push-pull passes in the course of a week or two. Had some problems because I started using it without making sure the saw blade that looked like it was installed was actually tightened down, so that bound and buckled and cost me a saw blade. My own damned fault.

But the little blue plastic gears that raise and lower the saw blade are stripped. I didn’t man-handled the mechanism for raising and lowering the blade, just raised it while cutting, then lowered it. A couple hundred times.

https://s3.amazonaws.com/vs-lumberjocks.com/qc12g4u.jpg

I emailed asking for replacements, and no reply at all. Hell, I’d even be willing to pay for them, rather than having to owe my buddy with a Bridgeport for having him make up a set of steel ones for me. And nobody answers the phone at BCT, either.

Really sorry you sold the business, John. They need someone who cares about the customer in-house.

Dave,

This is just not how Bridge City should be operating, I apologize for your experience.

Please email me direct; John@bridgecitytools.com and I will get you back up and running as fast as I can.

Regarding the gears stripping, that is supposed to happen if there is too much resistance in the gear train. So the real issue with your saw may not be those gears. Regardless, we will get it fixed.

-John

Not even close on woodworkers. I have been at this over 50 years, and have seen a lot of stages. Woodworkers have cheapness limits that are set in a number of ways. Blacksmiths, knife makers, those guys are insane. They will make just about anything and they will pull it off. The fact that most woodworkers are skill adverse and don’t have metal working skills severely limits their ability to really do it yourself. There was a time around 1980, when FWW was publishing plans for your own bandsaw, and bowl lathe, and sliding table table saw, when it looked as though the radical self-creation might take off, but if nothing else, the cheap tools, then from Taiwan, killed that.

Skill adverse? Look at Rob’s brilliant work around on hand cut dovetails. He really figured out a brilliant process. But you are not likely to elevate you native skills by going down that route. Lutherie is interesting because the production is amazing, the standard so high, but you can pretty much make a guitar with less skill than it takes to draw a stick figure. And I am not criticizing that. But if you don’t have a lot of skill, and you are stuck in wood, you are not going to be able to invent your woodworking everything.

So not all the squares are marked down. I am going to order the 1/5 square, as that is my favorite visual angle for dove tails but it is not even as low cost as the discounted one. The discounted one is larger and originally quite a bit more expensive more expensive. Poor customer relations on your part.

My opinion.

Jerry

Woodworkers have cheapness limits that are set in a number of ways. Blacksmiths, knife makers, those guys are insane. They will make just about anything and they will pull it off. The fact that most woodworkers are skill adverse and don’t have metal working skills severely limits their ability to really do it yourself. There was a time around 1980, when FWW was publishing plans for your own bandsaw, and bowl lathe, and sliding table table saw, when it looked as though the radical self-creation might take off, but if nothing else, the cheap tools, then from Taiwan, killed that.