Wow.

I am tired.

But it could be worse…prepare yourself for a shameless plug; I love Skechers shoes–look them up and do your own research. It took me a couple of weeks to get use to them, but now, oh my. Can’t wear regular shoes without looking like…a penguin with frostbite. Do yourself a favor and try a pair on. You won’t go back.

WIA was, just like all the other WIA’s, phenomenal. As you might imagine, the staff at Pop Wood was pooped but not without reason, they did a great job. I did not hear a single complaint all weekend, and when I did, it was from my own mind because it was too busy to retrieve food…

If only every trade show was done with such passion. That said, I think I am (perhaps BCTW too) cooked for future trade shows…

Although I love talking to friends and customers, especially the Drive Starved Nation (who turned out in force), I now have strong reservations about shorting my family for what really amounts to…money. Shame on me. Now I realize that the reason I attend these things is to see my fellow tool makers–kindred spirits for sure–but I could just call them all and chit chat every once in awhile, which I now intend to do! We at BCTW love our customers, but they talk to us regularly wondering where their orders are and we don’t need to go to trade shows to update them… (did I just write that?) Yes you did.

Anyway, I would like to mention all the names that showed up but I would likely leave several out, maybe all, so I won’t. Thank you all.

To the staff at PW; thank you–what an effort. Hope you made a buck or two.

To all the toolmakers–keep up the great work and let’s get more people in this business–the more the merrier.

Yes, I am getting old.

–John

PS: For those of you wondering, the KM-1 Kerfmaker was a hit.

Behind the Scenes

Behind the scenes at Bridge City Tool Works!

Off to “Woodworking in America” and other News…

September, 28th, 2010

It is going to be a long two weeks for your favorite Tool Potentate.

This weekend I will be demonstrating a couple of new things, showing a couple of new prototypes, and meeting customers–one of which I am certain Fred West is going to nominate for next year’s Sh!t Bunny Award. This should be fun even though I am sure to develop a whopping case of writer’s cramp…you know, from orders…

Then I am off to Indianapolis for a Tool Making class at Marc Adams School of Woodworking. That should be fun. There are still a couple of openings for those who live in the area. Speaking of which, I am thinking of teaching a week-long class on tool design next year at MASW–we need more people making cool tools. Really–rising tides raise all boats.

We were going to close the order window for the DJ-1 Universal Jaws this week but have decided to wait until after WIA to include those orders as well. As you may know, we were recently able to reduce the retail price well over $100.

Speaking of which, sometime today we will update our website with the prices for the extension jaws that several of you think you need. Actually, I have a couple of really cool ideas for pin wheel gears with these jaws.

We really scrambled the past couple of weeks to get a Jointmaker Pro SW ready for this show. If you have manufacturing experience, I invite you stop by and figure out how we are able to sell this for $795–consider that good handsaws are now 3-400 smackers. Here is a pic of the unit we shipped off yesterday;

I will also have a JMP with the new ball bearing rails. We are getting real close to filling all our orders and yes we are late–so I expect an assassination attempt (or eight) in Cincinnati. If you find me prone in my booth go ahead and loot–money clip is in front left pocket.

For those of you who have a table saw and do not own a KM-1 Kerfmaker, please see a doctor… or me, I will trade you cash for one. Live. In real time. No waiting.

If you are going to WIA, please stop by and say hello!

–John

Why Hourly Rate Motels are Good for Toolmaking…

September, 22nd, 2010

Last week I actually made something.

Sounds weird I know, but I get almost zero shop time—Hollywood starlets are cat fighting over my availability (those old black and white films I starred in just won’t go away), my dogs eat golf balls when I am not looking, and I have a such a terrible way with words (domestically speaking) that I find myself in cheap motels…

For example, NEVER say this to your wife when she serves you dinner;

“What is this, a placebo?”

So, last week after I got kicked out of the house, I was kicked out of the motel (I only paid for an hour). It’s not as bad as it sounds as I have a thing for shag carpets.

I ambled down to our prototype shop and made the parallelogram sled and tenon attachment posted earlier. The tenon attachment was made almost exclusively using the table saw and the KM-1 Kerfmaker. It was my first REAL project with the KM-1 and it was shockingly easy. Fun. Amazing. Did I mention I love this tool! (Yes, this is an unabashed plug, but an honest one.)

We needed the sled and tenon attachment to film the TM-1 Tenonmaker video which is coincidentally, or miraculously (considering Michael worked on it) posted below.

As you can see in the pic below the mortise and tenon joints are flawless . These are through mortise and tenons and they are the hardest because… they are the hardest. And I know you know this.

Here’s the video;

Yes, I used to make furniture. Some of it actually sold. But I can honestly say, in all these years, going way back to the mid-1960’s, I have never made more perfect fitting joints in such a short period of time.

Actually, forget the time, these are dead perfect in every respect and I can’t remember doing this in such an easy fashion. Ever.

Furthermore, I have not made a mortise and tenon joint since 1982!

Easy perfection? That is no oxymoron.

The TM-1 will prove it.

–John

PS: Last night I came up with a new line;

“I don’t know how you did it, but this is the best canned soup I have ever eaten! Besides the Spam, did you add some salt?”

Didn’t work–But I was close!

Oh, one last thing. Please tell all your friends about the TM-1 Tenonmaker. Just once I would like to stay in a Holiday Inn after dinner.

Hair Shirt and Moleskin Pants…

September, 16th, 2010

Two weeks ago we introduced the Universal Jaws for our DJ-1 Drilling Jig. After the announcement, I spent four days in Atlanta that could best be described as “unproductive” financially. Little did I know what would transpire a couple of weeks later…

While in Atlanta I met with one of our suppliers who really wants to do more work for us. So on a whim, I asked them to quote the Universal Jaw project since we are still in the pre-order phase.

Over the past three decades this has NEVER happened but we are able to dramatically lower the price on this amazing kit based on a new cost structure. It’s a big deal. This is approximately a 30% savings totaling over $120! (For those of you who have ordered, your second installment will be reduced accordingly). FYI, the pre-order phase closes on Oct 1. We are thrilled and think you will be too!

As mentioned, this has never happened before and we don’t anticipate it happening again. As insurance, sometime tonight (after happy hour I presume) I will stuff a big spud in a knee sock and flagellate myself for an hour while wearing a hair shirt tucked into my moleskin pants. (For those that don’t know what flagellate means, it sounds like something it is not.)

Now for Something Completely Different…

By Monday we will have shipped all of the Special Edition (limited to 50) shoulder planes. They really came out nice and sexy and work awesome. As in, holy moleskin, did I just make that shaving?

We have less than 10 remaining, so if immediate gratification is your game, your lucky number is 800-253-3332.

Again, something different…

For those of you waiting for your JMP, we are entering the anodizing phase. This means we are getting close to delivery. I will have the new Single Wing JMP at Woodworking in America and don’t plan on bringing it home. This means come early and find out what the deal is…

The CT-17 is also a couple of weeks away.

And Lastly…

Before my flagellation begins, I must share that next week we will begin taking orders for the tool that will make you a tenon guru. Wait until you see the video… square pegs in square holes has never been perfect for the uninitiated until now.

–John

Table Saw Sled with a Twist…

September, 13th, 2010

Sometime in the late 1970’s I was commissioned by a San Diego couple to build a 21 drawer silver chest. They opted for hand dovetailed drawers. It was a cool commission because they traveled a lot and requested that the back of the chest look like the front of a cabinet.

Prior to one of their jaunts, they had some overripe teenagers turn the drawers to the wall. Presumably this would foil the “smash and grab” crooks that had them pegged as rich folks.

Because it is next to impossible to build one of anything profitably, I knew I was going to make two, one for them and one for the house–forget the fact that we did not own any silver silverware–had plenty of other less expensive stuff instead.

Combined, I had about 750 dovetails to cut. The parallelogram sled in the video below was my solution. As you will soon see, it was not difficult to knock out the pins in a day. Yes, I made the pins first, and then cut the sockets by hand. Pins/tails first–nobody cares–they just need to be spot on.

The sled in the video was made from stuff lying around our prototype shop. We had a couple of miter gage bars which was convenient, otherwise I would have purchased some 3/8″ x 3/4″ cold rolled steel bar. For the working surface we attached white plastic laminate to MDF with contact cement.

The four pivot studs (made from readily available 3/8″-16 threaded rod) are permanently attached (thread lock) to each end of the guide bars. The guide bars are attached to the top with 10-32 screws. Make the shank diameter of the 10-32 screws a bit over-sized and you will have no problem creating a smooth sliding table. You will need to know how to drill and tap.

The other two legs of the parallelogram are maple, with one hole and one slot. Once everything is assembled it is safe to cut the sled table in half.

The fences tilt about 30 degrees–any more and you risk the sled becoming unwieldy as the sled approaches the fulcrum point (the rear edge of your table saw top.)

The simple tenon jig attaches to the top via a “t” nut buried in the sled top. I was shocked how easy and fast this was to make using the KM-1 Kerfmaker.

This is a basic and really useful table saw accessory. You should see what you need to know to design your own version. There are plenty of opportunities to improve upon this basic design.

Drawbacks? You do lose a bit of cutting depth (thickness of the sliding table), and cross cutting width (you can remove the rear fence if need be) which negates this issue.

You will see this sled in future videos and the first coming up is the Tenonmaker!

If you have any questions, feel free to ask.

–John

This video is short but informative.

Here’s a front view of the chest. The pulls were made from steel bar, brass and rosewood.

This was from the ’70’s…the decade of exposed joinery. (I apologize for the quality of the images, all of my slides are being eaten by mold.)

The drawers were lined with Pacific Silver Cloth, a fabric embedded with silver particles that really helped the silver pieces stay nice and tarnish free. The October Company (also still in business after all these years) made the Pacific Silver Cloth drawer liners–they have a complete array of liners and holders for custom builders–they can also screen print your sig or logo as I had done.

The advantage of side hung drawers is twofold, you get more drawer space in a given vertical space and aligning the fronts is easily accomplished by adjusting the rails from the rear (prior to attaching the back). Even though these are side hung, they pass the “one finger test”–drawers close with one finger from any corner.

Off Topic: Star-Spangled Banner

September, 9th, 2010

Been out of town for two weeks and several members of the Drivel Starved Nation are in panic mode because of my lack of interest in my blog while I am on VACATION!

I am in panic mode because I am back….

So, time to be COMPLETELY HONEST…how many of you know what “spangled” means?

Remember, there might be a cherry tree nearby….I had to find a way to make this a woodworking related thread.

That said, please share the one time you heard our National Anthem and you were shaken to your core…maybe a tear or two…

Several years ago my buddy and I attended a USC/Oregon State football game at the Colliseum in LA. While he was out looking for beer (I think) I stayed behind to watch the largest marching band I have ever seen.

So you can imagine my surprise when everybody stood up to listen to a single trumpet for the first stanza. Each subsequent stanza employed a couple more instruments and at the end, the entire band was involved.

As I felt myself unable to sing, I noticed EVERYBODY around me was in tears. At that moment I knew, warts and all, that I was born into the greatest nation (no offense to Canada…played hockey for 20 years) and feel compelled to share that experience. There have been others, but this one sticks out.

So, did you really know the meaning of “spangled”?

Now share.

-John

Greetings from IWF in Atlanta…Sorta.

August, 29th, 2010

Just wrapped up exhibiting at the 2010 IWF show at the World Congress Center in Atlanta. (We shared booth space with the Idaho company that makes our JMP and several other tools.)

I have been coming to this show since 1984 (it occurs in even years only) and it has always been the biggest show we have attended. IWF caters to all aspects of the wood industry–everything from kiln fire solutions to the worlds’ first powerless tablesaw…HEY! That is from Bridge City!

This show could never be completely walked in two days, and there was always something to learn.

This years show however is a different story.

First, the square footage of exhibition space was down over 60% from 2008. YIKES!

Second, attendance was dismal. That said, the people I spent time with were fantastic. But the fact remains, it is painfully obvious the woodworking world has changed dramatically.

Certainly the issues surround the housing market are central to this decline but I have never seen anything like this. For example…

In 2008 there was a company (which shall remain unnamed) that did $78.8 million in annual revenues. This year they will not break 8 million.

I spoke with a small business that sold power equipment–in 2008 they did $8.2 million. The first six months of 2010 their sales were $420K.

A REALLY BIG company that I will not name, and I know you know their products, is down 92% from 2008. Ouch. And from what I can triangulate, a significant percentage of the attendees were at the show looking for….jobs.

But this is not a story seeking sympathy. Quite the contrary, I am unbelievably grateful for the support we have received from the Bridge City family, in particular, YOU ALL (couldn’t resist…) from the Drivel Starved Nation. Why?

Because, as of this writing, we are thrilled with our market position in this economy and you are the reason. So, thank you for your continued support during these unsettled times.

Now for the details…

Several members of the DSN stopped by and I just about dismembered fellow member Dmarkowi during a JMP demo. But I didn’t and that is a good thing.

Talked to several members of “Lumberjocks” who were proud to show me cell phone pics of their homemade Kerfmakers. (When you get a chance, help me understand this please…)

And lastly, Atlanta is, and always has been, a fun city with great restaurants and an upbeat vibe (my discovery this year was “il Localino”, a great Italian eatery on a sleepy street).

And as I fondly remember the incredible basil gnocchi from Saturday night, I am sadly uncertain if I will return in 2012 and this thought is really bugging me.

–John

CS-12/18 v2 Combination Square Set-BLEM SALE!

August, 17th, 2010

I hate blems.

That said, we have less than 24 CS12v2 Blems (almost everyone of them have a slight blemish in the black chrome). This solid stainless steel square includes one 12″ blade and one 18″ blade. Read more details here.

Kit includes ONE head, one 18″ blade and one 12″ blade.

Retail: $369,

Blem price: $299

Founder’s Circle Price $289 (you save approx. $50)

Because we have so few of these, it is probably best to call;

1-800-253-3332

or email;

sales@bridgecitytools.com

While supplies last.

–John

PS: For those that ordered metric blades, your squares will ship in the next 10 days, the metric blades have yet to arrive.

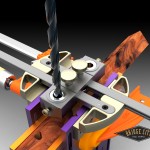

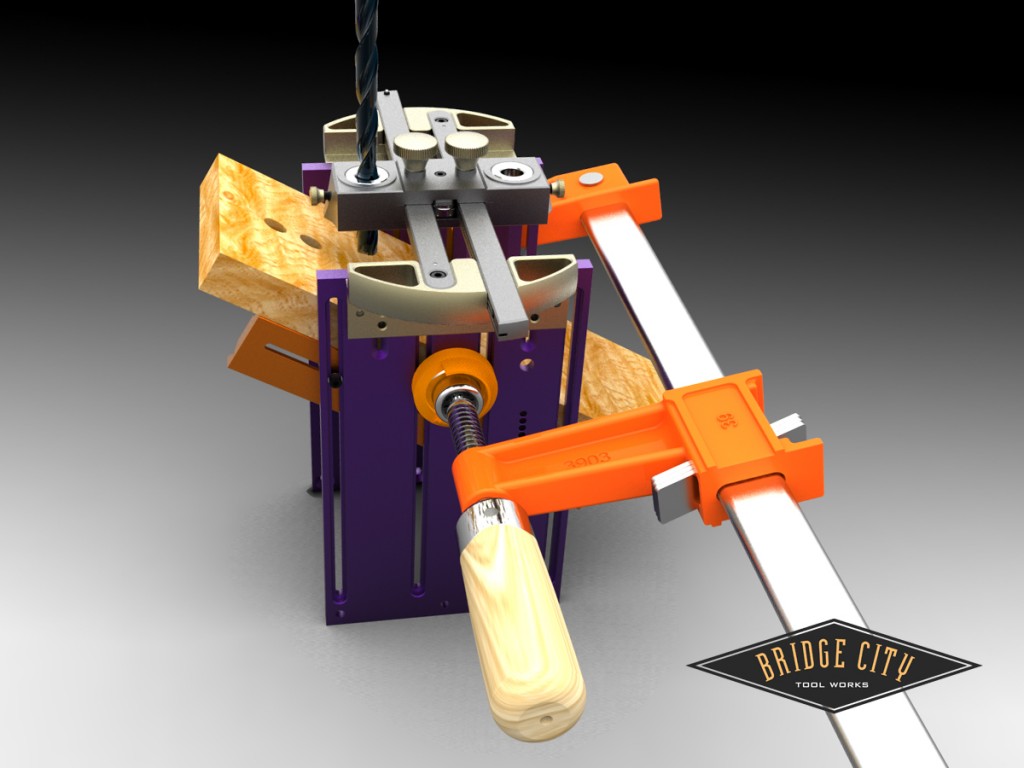

DJ-1 Universal Jaws Helps Make Your Work Full of Holes…

August, 12th, 2010

As much as I love drivel, and I know you crave it, today’s post is full of holes…

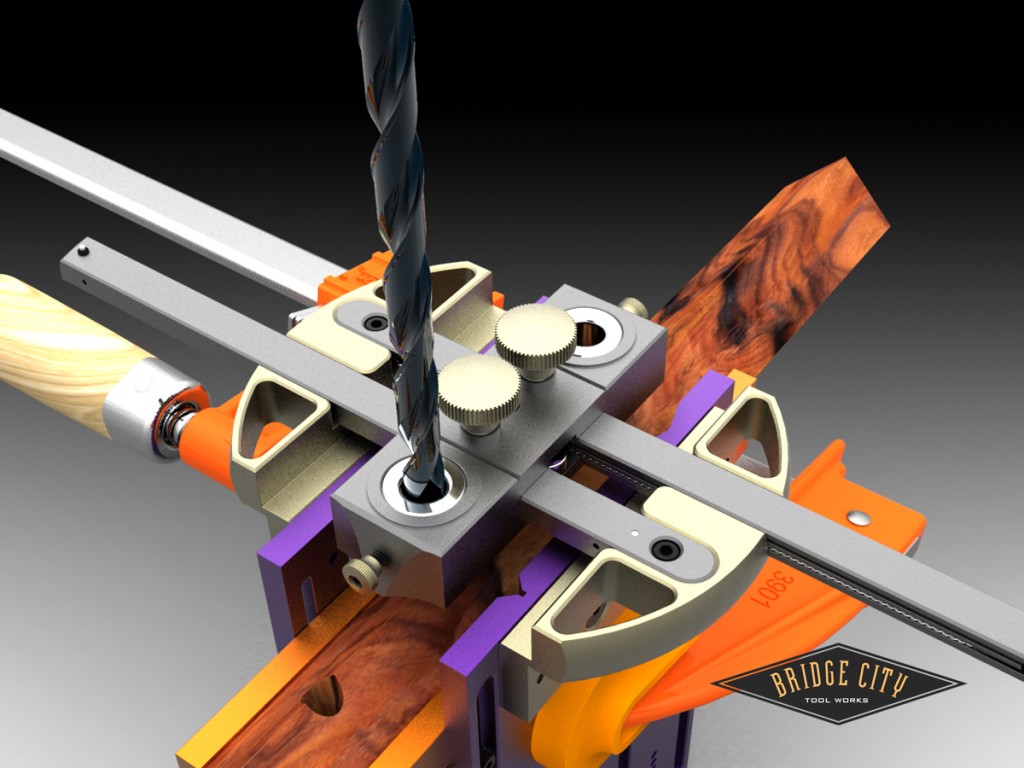

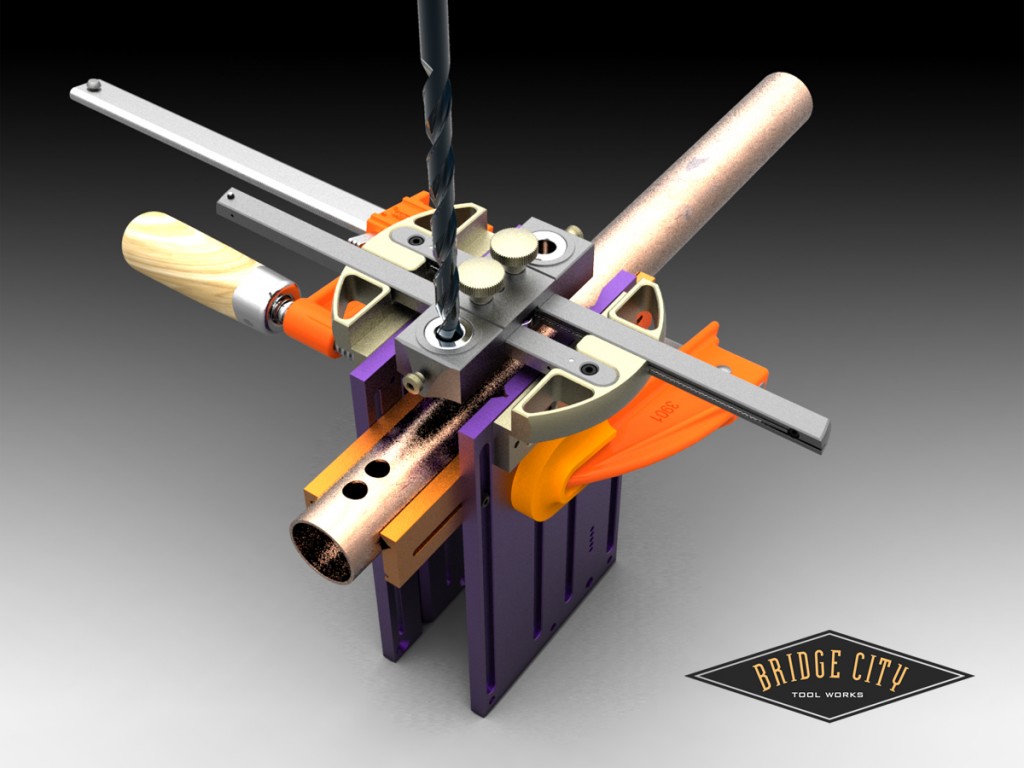

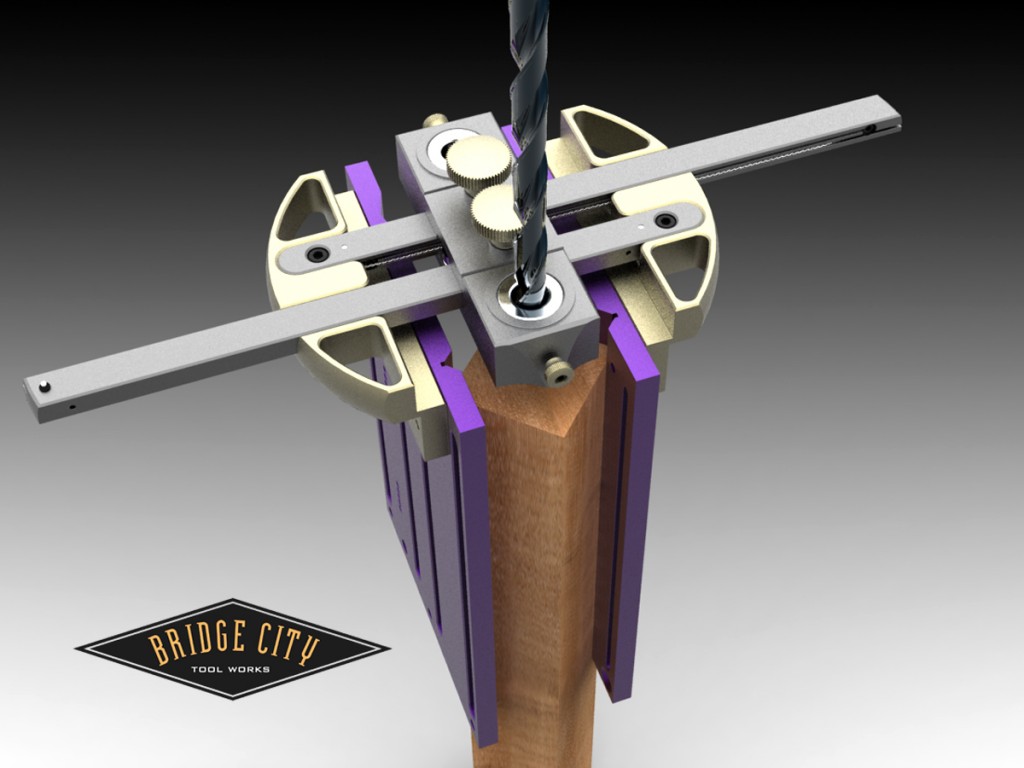

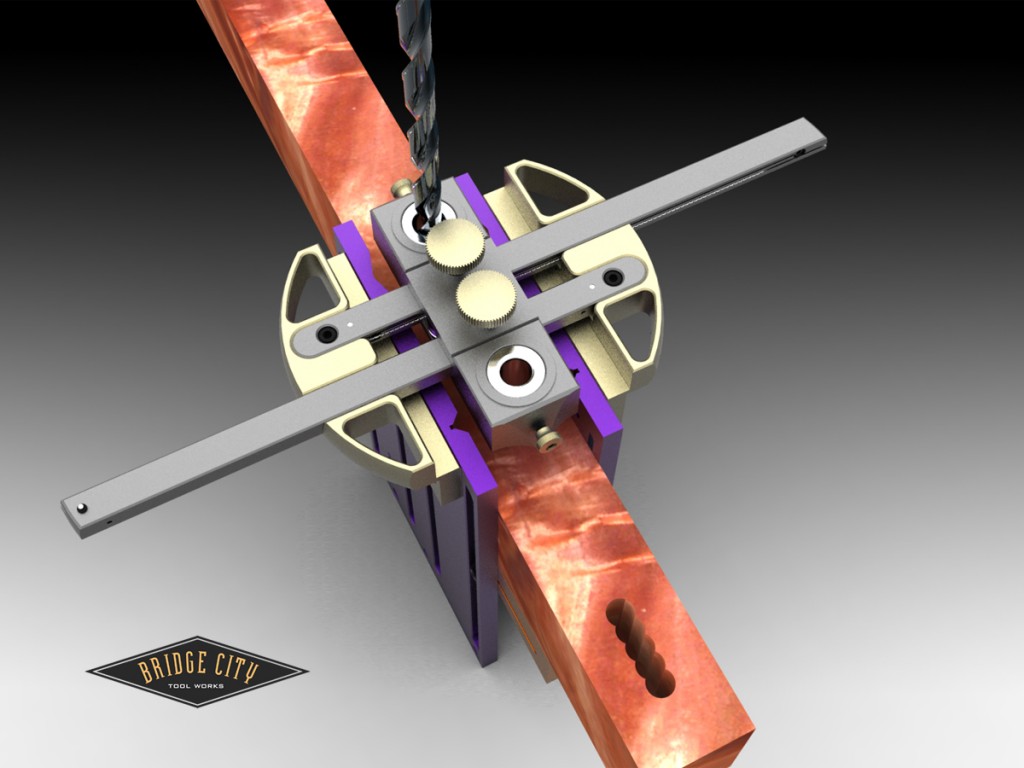

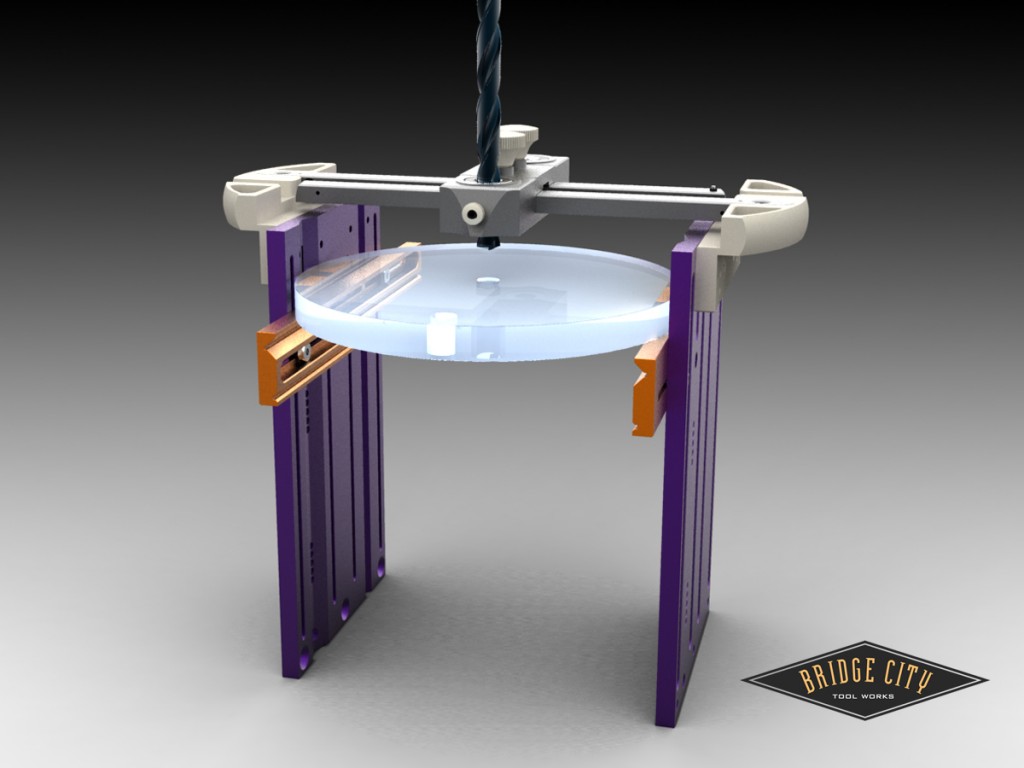

Next week we will introduce the DJ-1 Universal Jaws and the capabilities are amazing, pics below.

I would also like to extend a big thank you to all who helped perfect this accessory with a special thanks to Roger Savateri and Rutager West.

Pricing and availability will be announced next week.

If you currently do not own a DJ-1, we are taking names for the next batch.

–John

……………………………………………………………………………………………………………………………………………………………

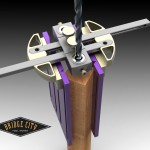

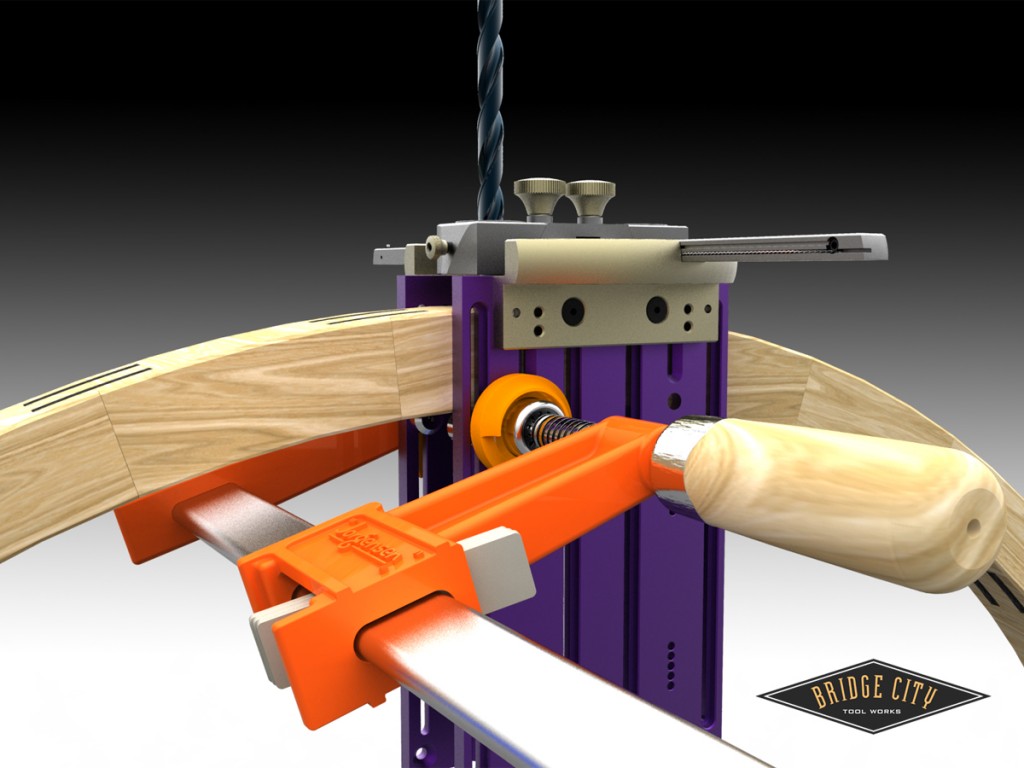

To drill angled holes at any angle, set one of the orange jaws to your angle of choice with a t-bevel. The second jaw is aligned to the first by clamping them together with a piece of dowel in the “V” grooves and tightening the second jaw–the dowel will automatically align the loose jaw to the fixed jaw. You will want to position your stock as close to the bottom of the DJ-1 body for both maximizing drill depth and accuracy.

…………………………………………………………………………………………………………………………………………………………..

Drilling dowel holes in miters are easy, set your jaw angle and you are ready to go. The DJ-1 Universal Jaws now feature viewing ports so you can see your center-line if it extends down either face.

………………………………………………………………………………………………………………………………………………………….

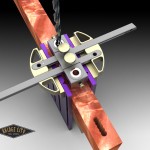

Drilling on the “bias” is ridiculously easy and really only doable through a drill bushing. If your stock is square, the hole will enter straight down the corner.

.

…………………………………………………………………………………………………………………………………………………………..

Center drilling round stock/pipe/tubing has never been easier or faster. The difference between the Universal Jaws and the standard jaws is in this case, the orange jaws can be angled or lowered, either increasing capacity or adding the ability to drill angled holes.

………………………………………………………………………………………………………………………………………………………….

Center drilling square stock, or round is fast and accurate. No layout required as DJ-1 self-centers. The advantage here over the standard jaws is increase stability.

…………………………………………………………………………………………………………………………………………………………..

Because the drill is bushed, there is no bit drift if your stock is close to the bottom of the bushing. This means drilling mortises is really accurate and they clean-up much faster. This is not possible on the standard jaws without making custom jaws.

………………………………………………………………………………………………………………………………………………………….

Center drilling axle holes without layout is fast. If your stock will not support itself during drilling, cut a base slightly narrower than the diameter out of plywood and bridge across the orange jaws. This is not easily replicable on the standard jaw set–actually not possible.

………………………………………………………………………………………………………………………………………………………….

Simple radial drilling can be done with the small radial drill accessory (included with the Universal Jaw kit). You can control depth with easy to make drill stops out of dowel–they take a couple of minutes with the DJ-1.

…………………………………………………………………………………………………………………………………………………………..

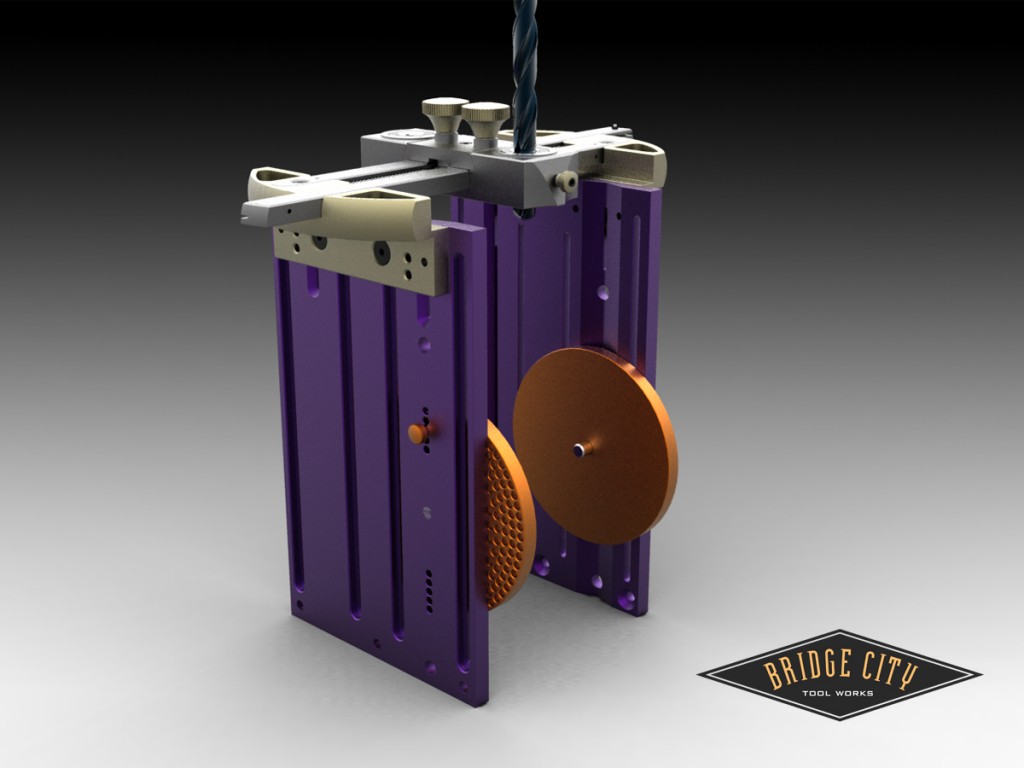

Many cool projects in wood involve hubs and it is now easy to drill spoke holes. It is even easier with the optional index wheel kit.

………………………………………………………………………………………………………………………………………………………….

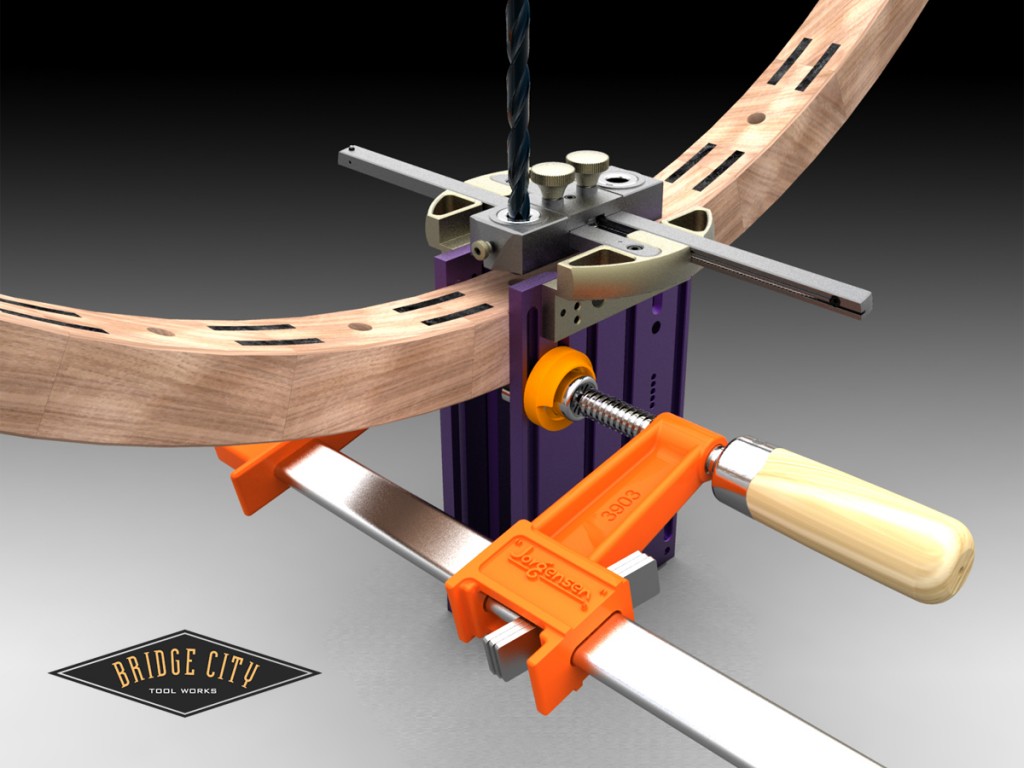

Just about any concave surface can be configured beneath the DJ-1 bushings. Here we are demonstrating how to concave drill spoke holes on a 48″ diameter rim.

………………………………………………………………………………………………………………………………………………………….

Convex is easy too. There is no limit to the diameter.

…………………………………………………………………………………………………………………………………………………………….

The optional index wheel kit will allow you to make pin gears, and other precisely spaced radial holes. The stock is held to the wheels with double stick tape for positioning during drilling.

The Incredible Work of Dalton Ghetti…

August, 7th, 2010

To All Members of the Drivel Starved Nation;

Every once in a while an artist appears with a body of work beyond words…

how cool is this?

–John