Prologue

It seems everybody that pulls an intervention on me accuses me of not listening. Not true!

I remember some conversations with my Mom, here are a couple when I was five or six;

“You need to be home by midnight or I am going to tell your father!” Or;

“What ever possessed you to pull a stunt like that?” (I hated the word “stunt”–there was so much spittle at her volume–I preferred “spontaneous acts of irresponsibility” even though it caused a bit more spittle, it was face saving in a strange sort of way.)

There were a couple maternal threats about fire starting, hygiene, and fratricide (I was the oldest…) but the one line that looks like it may come true (and the theme of this post);

“If you continue to hang out with the wrong crowd, you are going to end up in prison, just like….”

“Like who?” I asked.

“Nevermind.” she replied.

…………………………………………………………………………………………………………………………………………………………………………………………………….

Last Monday (seven days ago) I hung out with one of the worst crowds known to undercooked poultry–ended up in the hospital and somebody is going to pay–I suggest you pay attention because I am serious. And I am not talking lawyers here…

Over the past week I have watched every Charles Bronson movie, every Steven Segal movie, and have a new life long idol: Buford Pusser–how could I not? As one skilled in the art of woodworking, his skills are obvious and enviable (I wish he would he would have left plans for his stick);

The crowd? Here’s a pic;

Salmonella–a bad crowd for sure–trust me. (Note: The fat bastard towards the upper right-hand corner is the leader.)

Before the hospital visit, the Emergency Response Team from my local fire department paid me a visit. They all looked like a bunch of 6’4″ flat-bellied actors in rubber gloves playing fire department guys. My wife was VERY impressed–offered to cook them a Thanksgiving dinner on the spot if they would stay.

They asked me a bunch of questions that were hard to comprehend while in the curly fry position. I passed on the ambulance ride and fifteen minutes later found myself in the hospital–man those lights were bright.

Never saw my doctor–eyes hurt from the light but I do remember her asking me;

“John, can you provide us a stool sample?”

“What? How am I supposed to that?” I painfully moaned.

“I am going to give you a cup and you need to hold it to catch the sample–I know it sounds gross–can you do that?”

“Gross? You got to be kidding me. Next time you are at home watching the NatGeo special on killer volcanoes on your HDTV, flip the screen upside down and imagine holding a cup under one of those volcanoes–ain’t gonna happen. Just treat me for everything that kills humans–I have insurance with a high deductible.” I remember thinking.

The next four days were not fun. Typically when I am sick, I turn on Jerry Springer and am cured instantly but not this time–this was bad–I had to man-up and assume the killer volcano curly fry position for four straight days. Did I mention that I was shaking like a paint mixer the whole time?

I knew I was getting better when revenge entered my consciousness and I discovered Buford.

These movies were all the training I needed or wanted, but I didn’t know if I had it in me to kill. I do–can’t wait actually. And I don’t care if this blog entry incriminates me, prison is a Cabos San Lucas timeshare compared to what I survived (turned out to be a killer version of Salmonella but luckily I owe so many people money that my will to live is off the charts–isn’t that awesome?)

When you decide to become a killer like me, you have to plan carefully–unlike woodworking. You have to carefully decide who the victim will be and PLAN for their demise. You can’t just blast 400-500 people off the planet in hopes of being successful. PLAN. And I do have a plan. And I definitely have a victim (“assignment” to those of us in the know…).

Thanks to Bufford Pusser, I will not rest–maybe not blog again–until I find the guy that invented single ply toilet paper–you have my word he will be fatally harmed in the messiest possible way.

–John

Behind the Scenes

Behind the scenes at Bridge City Tool Works!

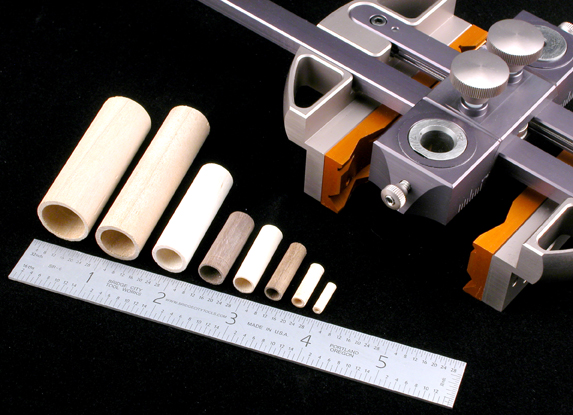

Look What the DJ-1 Can Do…

September, 2nd, 2009

John here, your favorite Tool Potentate with yet another overdose of piffle…

So, after what seemed like an interminable amount of waiting, I received my DJ-1 Drilling Jig this past Monday. Today I thought of a cool little test to see how accurately I could drill holes in the end of a dowel but discovered no dowel rod hanging around the office. Went down to my favorite woodworking emporium to see Carl, (I haven’t seen him since he sold me the plane iron eating volcano wood) but again, he was hiding from me. Bought a dowel assortment and in less than 30 minutes my test was complete.

Here are a couple pics of my experiment;

I know what you are thinking–do they nest? Let’s see…

It’s hard to believe this kind of accuracy is achievable without any layout using only the lowly hand drill…pretty cool. FYI, twist drills work better than brad points in end grain.

Is it as accurate as center drilling on a lathe? Probably not, but it is damn close, and without the lathe. As I babble I suspect you are thinking of project ideas that range from magician illusions to illegal substance abuse– yes/no?

Win a Hundred Bucks!

The DJ-1 has its own forum here. And we will give $100 BCTW gift certificate to any DJ-1 owner who posts a pic of the custom jaws they created to solve a drilling problem. Now that is what I call free money.

Win ONE MILLION DOLLARS!

Yes, it’s true–I am swimming in undeclared income and I am tired of it. Hence this new idea that shall be known as the Economaki Prize. Here are the rules;

The Economaki Prize will be awarded to the first person who discovers a new oil field (1 million barrels of oil, minimum yield) using only the DJ-1 and a hand drill. I know I could win it but I am not interested in winning my own money.

By the way, I used the DJ-1 and a hand drill to install a pacemaker in my golfing buddy yesterday–worked great! Don’t recommend brad points here either… Going to try a lobotomy on Louie dog later.

Now for something completely different;

I’m Not a Woodworker but I Play One on the Internet Dept:

Did you know that we have a forum dedicated to the discussion of design? You can check it out here. And, if you are so inclined, we would love to have you share your work. What is refreshing about this moderated forum is the lack of moronic posts (present company excluded) and the deemphasis (isn’t that a weird looking word?) of technique discussions. We hope you participate.

Well, I have thousands of unrelated thoughts I want to share but I have to return a call to the IRS–if this is what I think it is, you better find that oil field fast.

–John

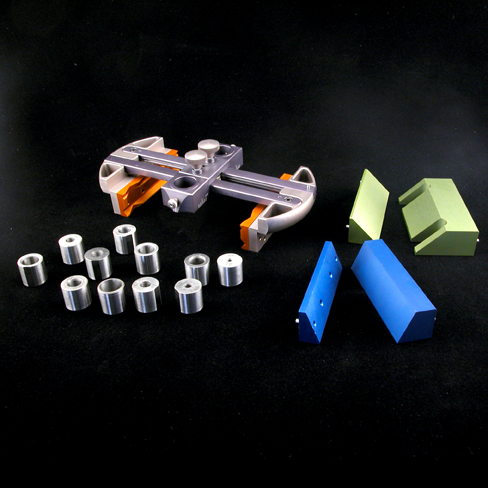

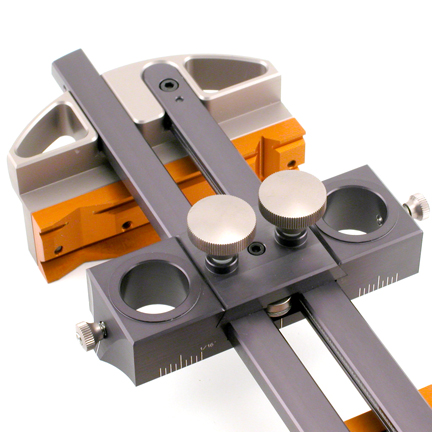

Look What’s Shipping This Week from Bridge City…

August, 24th, 2009

It is always exciting around here when a big job hits the warehouse and today is one of those days–

The DJ-1 Drilling Jig, one of the coolest things ever to happen here will begin shipping on Wed or Thursday of this week. And if you have been waiting for one, we, and other owners are anxious to hear from you–please consider becoming a regular contributor to the DJ-1 forum.

This run is sold out, so if you would like to be notified when the next run is happening drop us an email at;

sales@bridgecitytools.com

(our website is getting fixed at the moment.)

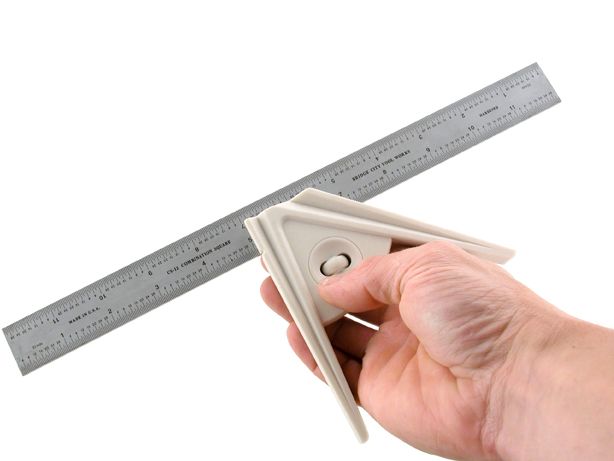

Meanwhile, here are a couple of pics of the final version–as you can see we made a couple of changes…

We are going to make some unbelievable movies with the production version–they will be posted on the forum.

–John

Polymeric Sand and Arnie

August, 19th, 2009

Fact: Portland, Oregon resides smack in the middle of the world’s largest temperate rain forest.

Fact: John Economaki, your favorite Tool Potentate lives in the Portland area.

Fact: John Economaki’s deck was eaten by carpenter ants.

The winter of 2008 dumped a freak 21″ snowfall on my back deck (everywhere else too)–and when it all melted, I noticed the deck not only dropped 6″ (not good considering parts of it are seventeen feet above the ground), but it also liberated itself from the house and this is where the story begins…

The lot of Casa Economaki is part of the Tryon Creek watershed, one of five in the Portland area that annually funnels five months of rain back to the Pacific Ocean. What this really means is we have no yard–our house is just enough to the side of a ravine that it stays put–except for the aforementioned rear deck which now too was on its way to the Pacific Ocean. Basically this is a residential lot where one can pee in the yard anytime–something I have been meaning to try.

There was no laborious, gut wrenching decision to make, the deck had to go. Fortunately, while at the Portland Home and Garden Show, I saw a deck guy who was wearing the hat of my favorite college football team, you know, the only team in 2008 to beat USC. I knew right there this was an omen, and Patrick at Northwest Deckscapes made me an offer I couldn’t refuse–yank, and dispose of 750 sq. ft of rotten deck for $1K. Isn’t college football great?

Patrick, who has built hundreds of decks informed me this deck made his top five MOST ROTTEN DECKS. Why? All of the structural beams were HOLLOW because of carpenter ants. And if this sounds bad, IT IS only because carpenter ants have their own freakin’ website!

Determined to foil the ants, I perused the internet for options. It seems Ipe, a hardwood from Brazil is the wood de jour for a somewhat maintainable deck. However, the more I learned, the more it became apparent this is a terrible choice–it IS NOT a sustainable yield product, and it is, like many tropical hardwoods brought into this country under less than credible circumstances. What to do…

I researched fake wood (not me), concrete, concrete pavers and slate as I was convinced that a wood deck in the world’s largest temperate rain forest was a poor choice. The problem is that the deck is elevated. Alot. So, what does this have to do with Arnold Palmer you ask?

Years ago I attended a golf tournament and while relieving myself in the woods, a golf ball trickled by–struck by none only than Arnie himself. He had two options, punch out to the fairway or hit the ball between two trees about twenty yards away–through a twenty inch gap…

He took a club out of the bag and lined up for the shot between the trees. At the last minute he put the club back in his bag, grabbed another and turned to punch his ball back into the fairway.

“That’s the way Arnie! That’s what I would do!” screamed a fan.

Arnie slammed the club back in his bag, reached for his first choice and without hesitation, dialed an incredible shot between the two trees that landed on the green and as you might expect, the crowd went wild–which was awesome because nobody saw me pulling up my zipper.

When you consider stone or anything heavy for an elevated deck, the internet is rich with definitive suggestions–all free of course.

“Don’t do it.” Or, my favorite, “Only an idiot would put stone on an elevated deck.” And thanks to Arnie I knew what to do.

After more research, I discovered a brand new product called Silca Grate from SilcaSystems. Made from ABS, this stuff is fantastic–the contractors price was $2.50/sq.ft. Leg one done.

Next, I was exploring concrete pavers at the local Home Depot and discovered a pallet of 6″x12″ slate (petrified mud if you need to know) pavers from Turkey. I was able to order five pallets and the cost was $2/sq.ft.

Tallied up the dead sq. ft. weight (13,000 pounds of slate) and Patrick did all the load calculations and frame design work. (this deck will hold 300 people which is about how many people I owe money…) We agreed upon a price for the pressure treated deck framing and all new footings. Leg two done.

I don’t know squat about pavers, mortar or masonry but in my internet travels I discovered polymeric sand and it seemed too good to be true. It is not sold in box stores (yet) but I did find some organic polymeric sand in town–about $12/55lb bag and I needed 12 bags. Leg three done.

I really liked the stainless steel cable railings however at $90 per lineal foot and with eighty feet of railing, I had to explore other options. The cheapest metal railing I could find, which was so ugly I couldn’t imagine living with it, ran about $40/ft. So I decided to design my own railing out of extruded aluminum and 1/2″ conduit. Leg four done.

It’s been a fun summer project and perhaps the following pics will inspire others. (The links provided are for educational purposes only and represent my experiences and my solution–in other words I am sharing without payola.) It is my hope that I will croak long before the deck succumbs to slate worms.

Louie Dog before his favorite napping place was ripped out–

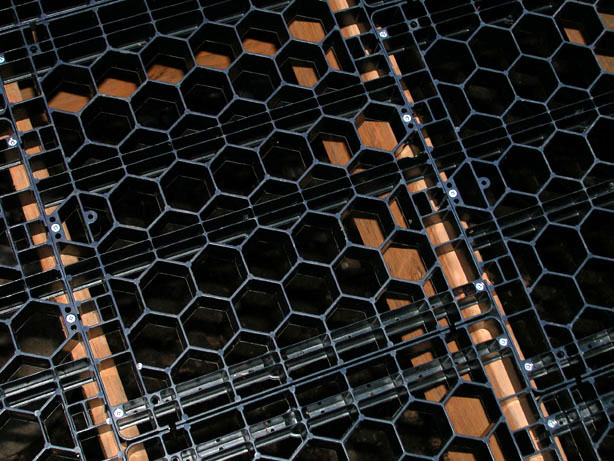

The new deck frame and the beginning the Silca Grate installation–

Silca Grate is made from ABS–just about indestructible. It was easily cut on my table saw using a triple chip blade. It took me two days to put in the 2700 stainless steel square drive screws purchased from McFeely’s—

After three days (could of finished in two without beer), the Silca Grate is fully installed–the bucket was my installation seat and knee saver…

Here’s the view the coyotes see–

Although I tried to minimize cutting the slate, I found it to be remarkably easy with the masonry saw (diamond blade) I rented for the week. The cutting was all done in my driveway–did I mention this is really easy?

Prior to laying down the slate, I rolled out a strip of landscaping cloth to prevent the polymeric sand from leaking to the ground below–

The tile spacers available at the box stores were too little to be of use so I cut up three sheets of 1/8″ Masonite into 1″ square spacers visible below. This was laborious but tolerable once the stereo was loud enough to bother my neighbors–

The shortest distance from my driveway to the back deck deck was through the house. All 13,000 pounds of slate were hand trucked through the kitchen. It’s no wonder I am such a popular guy around the house…

Almost done, sorta–

Once all the slate pavers were in place, I broomed a layer of polymeric sand over the top surface of the pavers. Then, in what was the most boring part of the entire job, I sat in the sand and pulled out the spacers with a pair of pliers/vice grips. A second layer of polymeric sand was broomed in to fill all the seams.

This deck is in the woods and I decided that any kind of “pattern” would be incongruous with the surroundings. I opted for random placement of the pavers without ever exceeding five in row or column. And now when I think about it, this is indeed a pattern but it fits in better with surrounding trees.

Using an electric leaf blower with the nozzle almost parallel to the surface and only a few inches away, the sand was blown off the deck creating a 1/8″ reveal between the pavers. To make the polymeric sand turn to concrete, I lightly misted the entire deck surface–this is crucial because too much water will wash the polymers away. This is the deck prior to misting;

After the polymeric sand dried the surface was sealed with a low luster masonry sealer. I tried several brands on test pieces and liked the product from Behr the best–here’s the finished deck;

The deck rail which came in at half the price of the cheapest metal railing I could find was made from aluminum “I” beam, 1/2″ electrical conduit (EMT) and 1″ x 4″ extruded aluminum. The aluminum was delivered in 22 foot lengths and all cuts were done on my table saw using a triple chip blade (for non-ferrous metals and composites). I also became quite adept a drilling holes.

The top cap miters were much easier than I thought. I clamped each long rail section to the top of the table saw at 45 degrees with strap clamps and raised the blade up and through the extrusion to complete the cut–this worked perfect for a one-man operation on long, heavy stock–it was a reverse chop saw move.

What saved my bacon, and what always saves my bacon is McMaster Carr. I love this company. Through them I discovered tube connector nuts (they are at the bottom of the page). These nuts allowed me to fasten the ends of the EMT to each other with threaded studs and to the rail posts. This is so cool you have to try it!

All of the parts were powder coated (including the heads of the lag bolts) and were installed to the fascia boards with the lag bolts and an impact wrench. Too keep the threads of the lag bolts from showing, I cut small sections of conduit to fit between the flanges of the “I” beam. It was a lot of cutting (used a De Walt 18v reciprocating saw, which is also one of the best garden trimming tools ever invented) but the results are professional–unlike this blog.

I made plenty of mistakes along the way. One of the pavers was put in upside down and I thought I could chisel away the polymeric sand…dumb me. I think I will leave it.

The lesson here is that Ipe was about $6 a square foot and it is now possible to entertain much more durable options for around that same range.

I hope I have the last deck I will ever need. It was a long project (I have a full time job you know…) and I really haven’t had as much time to enjoy the space as much as Louie and Jitter.

–John

The KerfMaker–the Really Expensive Version…

July, 28th, 2009

Came into work this morning with the bright idea that somehow my daily agenda would be realized. Since this never happens and I continue to think otherwise, I award myself the “Bozo of the Day” award.

My plan was derailed when I was forwarded this thread on Lumberjocks.

So, we have opened up orders for this group and you too if interested.

And then there is the expensive “home brew” version as mentioned in the thread that may be of interest to you as well.

Looks like my day will start after lunch–this internet thing is starting to creep into my productivity which at the moment is supposed to be focused on Commemorative Tool #16.

John

PS: Speaking of the internet, for those of you who Tweet, you can follow Michael’s Tweets on Twitter (never thought I would string those words together);

http://twitter.com/BridgeCityTools

Why one would do this I do not understand when you can be in the shop making things…

An Open Letter to the Tattoed Woodworker

July, 27th, 2009

Today Michael sent me a link that is not only disturbing, but needs to be shared.

Here it is;

http://thetattooedwoodworker.com/

Dear Tattoed Woodworker;

I confess that this is the first time I have seen your site. Your “final” post is heartfelt, sincere and it has not fallen on deaf ears. I am going to do my best to change your mind.

I first joked about the “Woodworking Taliban” about a year ago. Now I learn they have found a way to discourage you from sharing your woodworking experiences through their quotidian diatribes, mean spirited intent and stupidity.

As we approach our 26th year, we have been dealing with similar sentiment since year one…

Our first catalog that contained a prepaid business reply envelop arrived on doorsteps in 1984. When the first responses arrived, we received the following notes;

“Who the (insert f-bomb here) do you people think you are? We don’t need yuppie tools.”

And this little gem; “Thanks for the catalog, my friend has a pet shop and the pages from you (sic) catalog fit his bird cages perfectly.”

And then there were BRE’s that contained our entire catalog–this in hopes that we would be buried by insurmountable postage bills.

You are not alone.

Chris Schwarz reviewed a BCTW tool awhile back and had to filter the blog responses; “they were hateful and slanderous”. So what do we do? We don’t send advance review copies of our products to Chris any longer–neither one of us needs the aggravation. The next paragraph is more telling…

First, the Woodworking Taliban is more real than you think. Have you ever noticed threads where somebody has a tool that is so bad he must share it with the masses, instigating a chorus of boos, and as the thread wears on, a better solution (always for less money), a better product, a glowing review from a non-offending tool purveyor is posted by a woodorker? We in the industry call this the “payola posse”. These rabble grousers are PAID to sit around and plug away on forums. They exist here, Australia, England… Nice, tidy, informative and slimy.

Are woodworkers so stupid to believe this crap? Apparently so. But you don’t need to let them deter you.

I am asking that you reconsider your blog, and if I can help, I would be pleased to do so. I am going to begin with this post on my blog and few suggestions to help stem the tide of garbage on woodworking forums.

Don’t let the bastards win.

Regards,

John Economaki

President

Bridge City Tool Works

Here’s my wish list;

1. Regarding forum and blog posts, make your posts worthy of others time. If it doesn’t contribute, don’t hit “send”.

2. If all you have to say is that you can’t afford something, you don’t need to share. Everybody votes with their pocket book.

3. Don’t sit back and be a passive observer. Address moronic posts until they go away. Ignoring them really is not an option. If you are a moderator, don’t approve them at all–every decision has an unintended consequence, and that goes for non-decisions too. Silence them at the source and the copycats will learn to copy something positive.

4. Take the time to write those sites who you feel the most kindred and ask them to add rules to the posting areas. “Contribute, Learn, Share” seems to me to be much more useful than “Bitch, Moan, Too Much Money”.

This is a start.

And then;

Consider lending a voice of encouragement to the Tattooed Woodworker and ask him to change his mind–the world is a better place if you do.

Now I can get back to work designing tools that nobody wants and entertain the thought of going out of business for 26 straight years.

–John

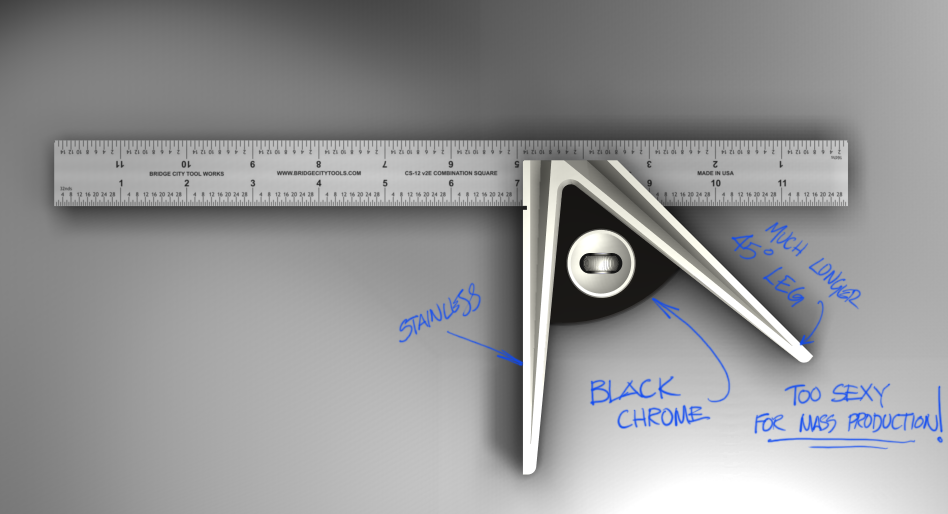

Bridge City Essentials; Combination Square Too Sexy for Mass Production!

July, 23rd, 2009

In playing around with material choices that compliment my new found fetish for stainless steel, I stumbled upon black chrome. Black chrome–these two words make no sense together and yet they represent an intriguing combination–kinda like mince meat…

Anyway, as mentioned several weeks back, we are celebrating our 25th anniversary with a limited edition series of essential tools primarily made from stainless steel. The combination square below will be available around Xmas. It shall be known as The Tool Too Sexy for Mass Production.

Although I liked our old CS-12 (it was the most successful new tool in our history) this version CS12 SE, is hot. How hot? So hot that it will have a 9:30 pm curfew–now that is hot! Can’t wait to get mine.

The body will be milled from a solid stainless steel billet and the center section will be black chrome–holy cow is this going to be a beauty.

Actually I am changing the curfew to 8:00 pm–you want a date with this baby there will be only time for dinner–no movie.

The image below is a stereolithography model we made to check out the ergonmic aspect of the tool. The 45 degree leg on this tool is long enough to be a useful reference for checking miter cuts–something we should have dealt with on our first CS-12.

This tool is going to be a beauty in both function and inspiration. We will begin taking pre-orders soon, delivery by the holidays. I love the black chrome aspect because in different lights, the color shifts from black to blue to green–cool stuff.

Oh, almost forgot, The Tool Too Sexy for Mass Production will also be accurate to .002″ over the blade length.

And in case you missed the first Bridge City Essential, here’s a visual reminder–not many left.

–John

New Design Idea Bank on the BCTW Forum

July, 22nd, 2009

Hi All;

We are pleased to open a new forum on project design and to get the ball rolling I posted a couple of pics regarding a table I designed almost 30 years ago. More details here.

Now you have a place where the posts are moderated (no crap) and can share/learn/grow from others. I hope you take advantage!

–John

Asthetics is a Responsibility

July, 21st, 2009

Here’s a typical (although made up…sorta) thread that occurs like clockwork after we introduce a new tool;

–I just saw the new gadget from Bridge City and at $100 NO THANKS! –Woodboy

–two too many zero’s for me. —Frugal Farms Woodworking

–Yeah, I can buy a whole lot of tools on eBay for that price. –Cellulose guy

–You don’t need to spend any money on any tool. Just get old leaf springs from the dump and pound away! —Herc

–$100 bucks and NO MOTOR? You have got to be kidding me. –Angus

–I saw the BCTW 6″ rule for $14.95 and said, SCREW THAT! I had a six-inch ruler tattooed on my right index finger for 8 bucks! —Darryl

–Hey Darryl, is it still a 6″ ruler? 🙂 —Dante

–No, it’s now around 3-7/8″ long and still works–the rule from BCTW would have wrecked the blade and trashed the rule.–Darryl

…OK, you get my drift. These samples, and all their inbred cousins have their place in the free speech that nobody wants to read department but worse yet, they completely miss the point. And if this post makes you angry, then we are getting somewhere. (Progress is born from unsettled minds)

You are likely not a tool designer but I am. You likely make furniture or other wooden objects and if one is to believe the values that froth from the keyboards in today’s forums, you should never, EVER, entertain the thought of expressing yourself through your work–it just needs to work. Cinder block and 2 x 12 bookshelves anyone?

Think about it–the only thing that really matters (with function being a given) is your voice, your shapes, your forms, your decisions, and if done well, YOUR WORK has a chance of outliving you. This is an important responsibility and it is a big one if you believe that objects should be worthy of the space they occupy.

You are also likely to be a self-taught woodworker and have found yourself swimming in a sea of uncertainty regarding design, proportion, harmony, negative space and a host of other brain-eating words that prevent you from realizing your full potential.

The decisions required to create work with a meaningful voice involve a subject matter much deeper than woodworking techniques and it is tough to do this well on your own. Design is complex, deep, unbelievably rich and essential to serious woodworkers. So, what to do?

Read. Study the work of others. Attend JURIED gallery shows, and when possible, take classes.

And speaking of classes, there is still time to sign up for the Woodworking in America Conference on Furniture Design/Construction. The dates are August 14-16 and the location is right outside Chicago/O’Hare.

There is no way you can attend a function this intense and not get a major, vector changing bang for your buck. The folks at Popular Woodworking are a dedicated, hardworking bunch of woodworking freaks and they put on a great conference–I attended the first one and saw first hand how much fun everybody was having. If it were not coinciding with my class reunion I would be there. (If you are guessing which reunion I will disclose there is only one trailing zero…)

So, in closing, what do you think of this idea–if one is going to post negative things about the work of others on an internet forum, each poster must also include a picture of their work? And if the work being bantered around is from Bridge City it is compulsory to send a direct email to john@bridgecitytools.com?

If this were law, there would be design seminars weekly in this country.

Oh, one more thing–I never would say such inflammatory things if I did not care.

-John

Oh NO! Today is July 20th…

July, 20th, 2009

Today is the last day for pre-orders for the Tool You Will Want Real Bad, except for those who call tomorrow with some lame excuse (you know who you are).

FYI, it is true that we have sold under 500,000 units and can’t count all the money. However, we should have sold millions…

We think this completely awesome tool was not picked up by the search engines correctly. So please ignore the next paragraph, it is for search engine use only;

John Economaki Forbes 500, Bridge City to buy Hawaii?, John Economaki nude, Bridge City Kerfmaker creates Aluminum shortage, Tool Makers and mental instability, Bridge City Bails Out Feds, John Economaki NAKED

For those of you who need a refresher movie, click here

Otherwise, we are moving on–$59.

–John