Drivel Starved Nation-

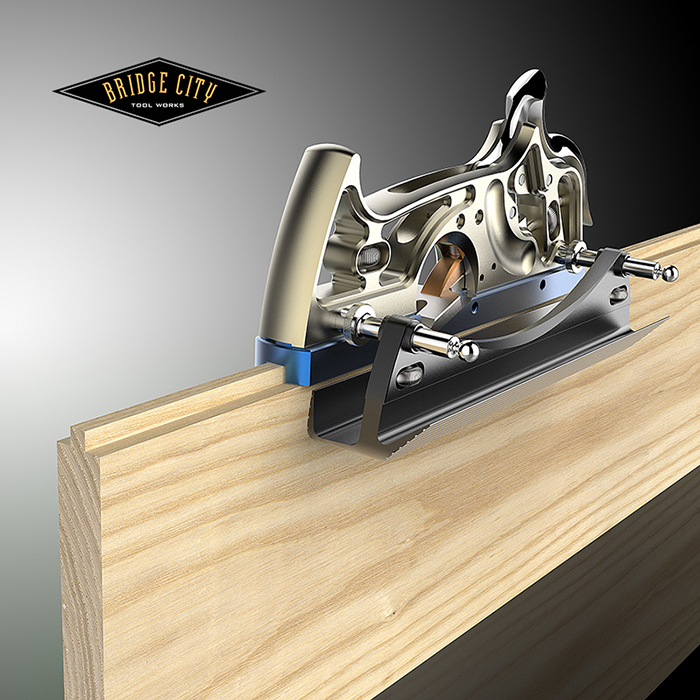

Next week we will open up the pre-order window for the HP-10 Tongue kits that will mate with the Dado kits currently being manufactured. (We are waiting on scoring cutters which are little works of art and this job should ship the third week of August.) Here’s a pic of the 1/4″ tongue kit in action;

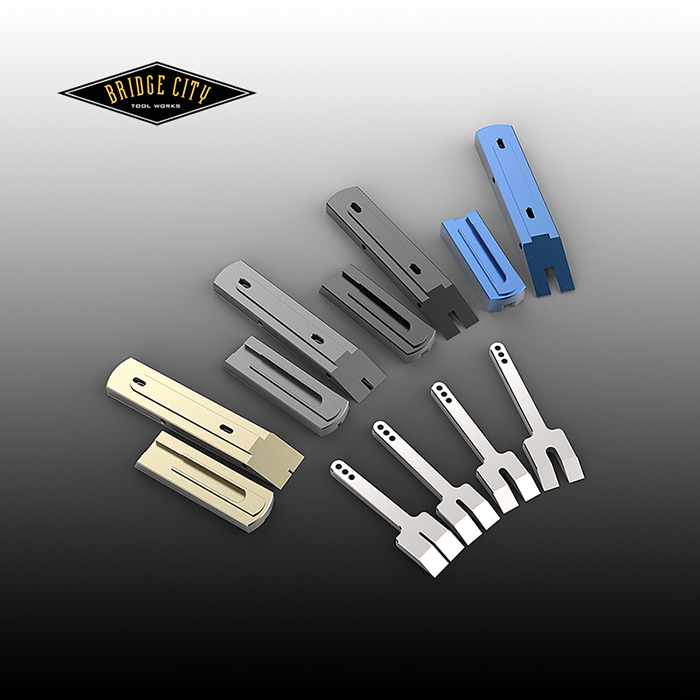

Here is the complete kit, and as you can see, they too are color coded to their groove making counterparts;

Lastly, I have been running tests on my new Gyro Air, and just today learned that the Gyro Air air separation technology certifiably removes 99.9% of the particulate BEFORE the recirculating air hits the filter. In traditional cyclone collectors found in small shops approximately 35% of the particulate hits the filter. This of course requires a motor and fan speed sufficient to force air through the cake and the bag. This creates noise, heat and is no where near as efficient.

More to come!

-John

What would be an application that calls for a .0625″ tongue? 😛

David,

Here are a couple;

One of the tenants of my design classes is using material that is scaled for the piece. In one of the class critiques, a student shared a picture of a spice rack with shelves that were 3/4″ thick. I asked, “What kind of spices are you planning on storing?” He replied “the normal grocery store spice bottles.” I asked why his shelves were 3/4″ thick and he replied that his wood was that thick. Ugh. This was the foundation of “John’s Rule #63″; Consider cutting your stock thickness in half, you project could end up twice as good!

So, for small boxes, particularly made with rare wood, one might find it intriguing to book match a flame pattern of resawn stock for the top. I have done this with material thickness that was as small as 1/8″ to 3/16″ thick. In this example a tongue and groove seam makes clamping the stock SO MUCH easier.

If the box has floating panels, which is almost always a good idea with solid wood, stock this thin can take advantage of an offset tongue to float in the grooves of all four box sides.

And here is another example of a 1/16″ tongue that can be really useful. Say you have a thin piece of exotic wood, or a white wood where you want to make inlay strips. This can be done entirely by hand with the tongue kit. Your groove will be 1/16″ deep and you would cut the tongue to full depth of .125″ This will allow you to cut the parent stock at say 1/4” width and use the base for clamping. The inlay strip can then be liberated flush to the surface with a flush cut saw.

Of course there are other ways to do all of this, but the suggestions above are all powerless, and extremely accurate.

Make sense?

-John

John…Makes sense. I might propose a spline of 1/16″ for some of the joints mentioned. 🙂 Dave

Agree, that is an option as well.