Drivel Starved Nation-

Today we have some cool things to share.

A while back, I shared how the grids for my sculpture “Fog of War” were made and you can see the pics here.

It is much harder to do accurate work in small scale but it can be made easier with an approach that yields consistent results. In the case of the grids mentioned above, the components all had to be the exact same thickness. This was surprisingly easy because all of our small planes accept depth skids which makes thickness planing thin stock a breeze. Without depth skids, there would be no Chopstick Master.

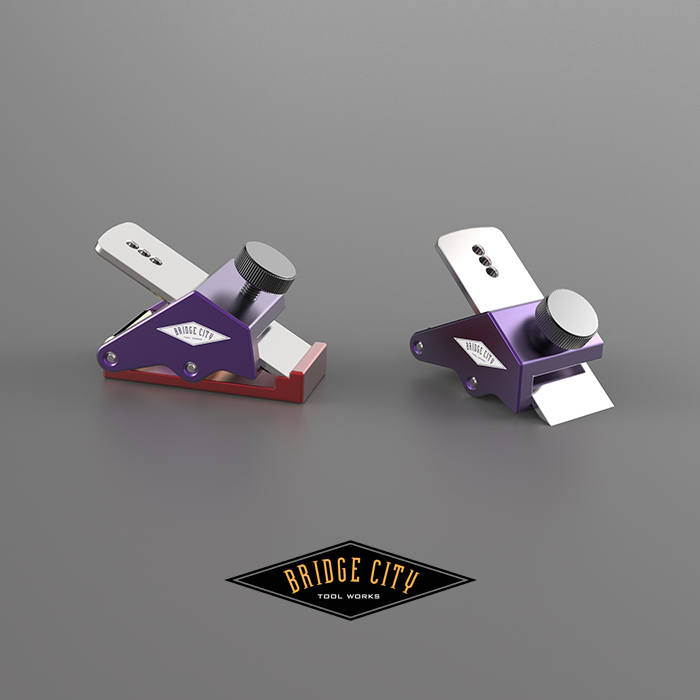

A month or so ago an intrepid DSN member asked us to consider making an arm for the CSM that would NOT taper stock. It was a good idea and today we are pleased to share the Flat Stock Arm for the CSM. Here’s a pic;

This new arm will allow you to thickness plane banding, inlay strips, and other thin stock requirements down to .06″ thick and of course you can use it to make thicker material simply by adjusting the depth skids on the plane. The little wooden stop is shop made by the user, not supplied and the reason is easy to digest, we have no idea how tall to make it for YOUR needs. 1/8″ material, end grain up will do. The reason we do not have a metal stop is to eliminate the possibility of the iron hitting the metal stop. That would be a big ‘ouch”. In most cases, you can use Masonite®. Lastly, those of you who own the CSM will get an email in the next day or so, the price is $29.00

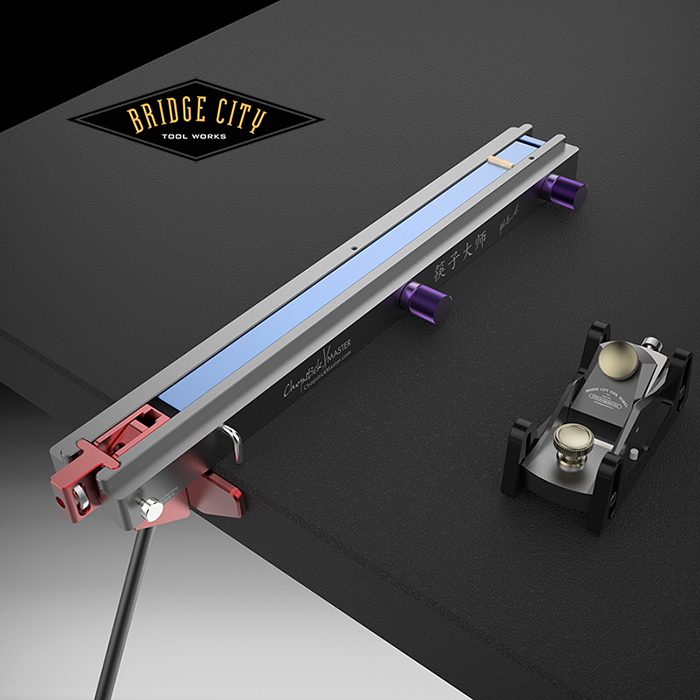

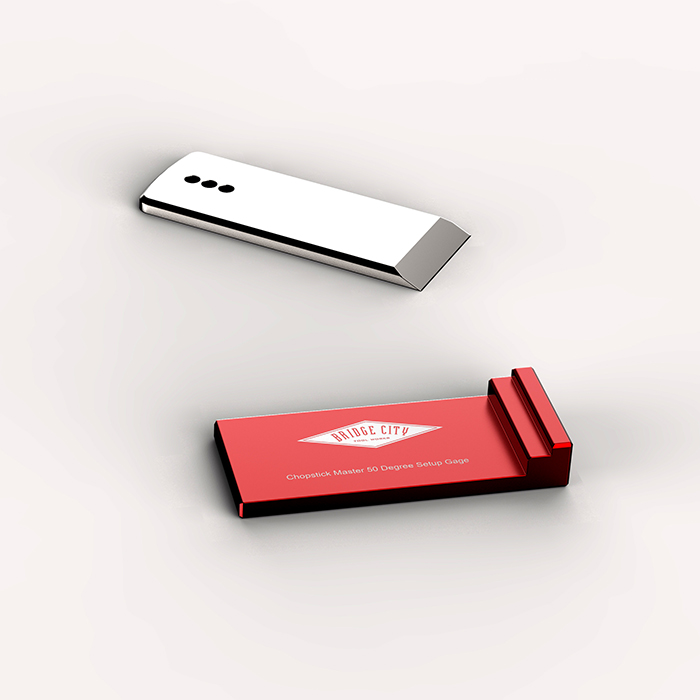

For those of you who are making your own blanks out of your scrap bin, you likely have some stock with switchback grain. This can be a real problem with a low angle plane as provided in the CSM. Help is on the way with this new accessory kit;

The micro bevel on this iron is 50 degrees. The plate allows you to set the iron the correct distance to repeat this hone. When set, it looks like the setup on the right, you will be running on one roller…

A 50 degree attack angle and a very narrow mouth opening will really help in many difficult grain encounters. Price for the kit is $41.95.

For those of you who do not own the CSM, here are a couple of non-eating ideas you can ponder;

How about a sofa made from 8000 chopsticks?

Or how about some really cool home decor items made from chopsticks?

Ever thought of making a canoe out of chopsticks? This guy did!

Hey, this sea urchin lamp made out of chopsticks is cool.

Chopstick place mats anyone?

How about a table, dress, flip flops, and other cool chopstick projects? It’s all here.

Here’s a rubber band gun video. Yes, all chopsticks.

Lastly, here is a lesson on how to eat with chopsticks.

Lastly again, don’t forget to have some fun today!

-John

This will be a great addition. These are my first Bridge City tools in a long time, I got away from hand tools quite awhile ago. I bought the first of the scratch awls, the depth guage, mortice guage and the center finder. I’m very happy to still have them and put them to use. You guys have been very busy in my absence, Your blog is very enjoyable and helpful. I can’t wait to see what’s next! Keep making the most beautiful and innovative tools in the industry, it’s very much appreciated.

Welcome back – we missed you!

Team BCTW

A question that I suspect you will be answering frequently: will the flat-stock profile work with the CSM-v1?

Yes.

Yay!

John,

Could you, if you put a tapped hole near the front with a set screw, be able to set a custom taper on the stock you were planing?

Thinking if I wanted to make small tapered lamination this might work great?

Rutager

Rutager,

I had contemplated doing this but decided against it. Here’s why,

The manufacturing tolerance for the depth of the groove this arm resides in is really loose. And because this needs to fit both v1 and v2, I dealt with this issue by adding 0.01″ to the diameter of the hole the pull pin secures.

Because the hole is now a bit sloppy, adding an adjustable set screw would create a scenario where the arm could rock. I would hate that so I rejected the idea.

All that said, you can accomplish the same thing with wood shims that span the width of the arm, and yes, it would work just dandy!

-John

I cannot find the blue arm on the website to order it. Is it available now?

roger crooks

https://www.bridgecitytools.com/default/chopstick-master-flat-stock-arm.html