Drivel Starved Nation-

Here’s the latest news regarding your favorite Tool Potentate…

JOHN OUT OF THE OFFICE DEPT.

This Thursday I depart for China, first stop is Guangzhou. A week later, I will meet up with the BCTW field trip participants in Shanghai for a couple of days of food and tourist attractions–this should be really fun. We then will all board the bullet train (over 300 km/hr and smoother than flying!) for Nanjing. More great food and a visit to the museum of China’s greatest living woodworker. This will be an incredible experience, and I will be sure to take lots of pics and videos for you.

On November 3, I will be taking the bullet train to Beijing and that evening we are meeting the American ambassador to China (Mr. Terry Brandstad) and his wife, Chris, for dinner and chopstick-making! (Did you know that they extrude the bodies of the bullet train out of aluminium? It’s the largest extrusion in the history of the planet!)

NEW PRODUCT DEPT.

This week we will open the pre-order window for Pencil Precision™. I think you will thoroughly enjoy making pencils–I’m an old guy and not easily amused (except at my own mistakes) and this thing is just a blast to use.

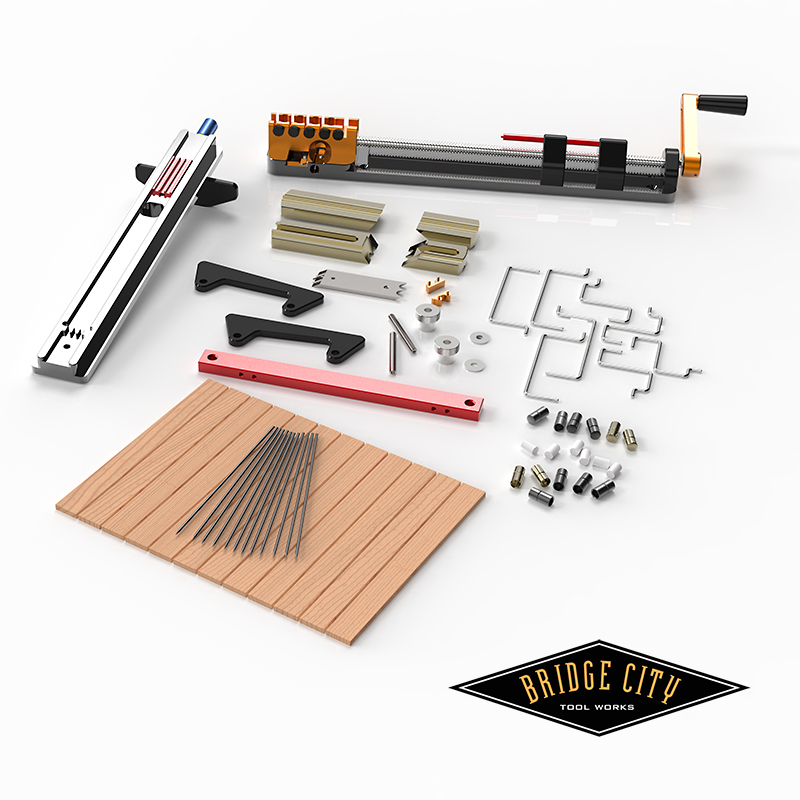

Many of you own an HP6v2 plane so we are offering two kits, one without the plane and the other with an HP-6v2. This is a globally sourced project with components made in the USA, China, Germany, to name a few. Without question, this is the best value tool making kit we have ever produced – Here’s a pic of the kit without the HP-6v2…

This kit includes two sole kits for the HP-6, the planing fixture, the extrusion fixture, and enough blanks and ferrules to make 12 pencils. It will allow you to make round pencils. The extrusion die kits for beaded and hex pencils will be sold ala carte and are $89 per set. This way you can buy just what you want. This kit is under $450!

The kit with the plane is only about $100 more.

Yes, the orange crank is removeable to reveal a 1/4″ hex… do the math on that one you power freaks!

Yes, the orange crank is removeable to reveal a 1/4″ hex… do the math on that one you power freaks!

In both kits you will receive a sample of six ferrules with erasers and six without. This will allow you to explore both pencil making options. The ferrules come in eight colors and you will understand why when you make your first pencil with child or grandchild assistant. Watching the look on their faces when it is their turn to pick which color is priceless.

We will announce the spectrum of colored pencil options at a later date as we are in negotiations with potential suppliers. The kit comes with 12 2H leads and we will offer black lead options in the following hardness: 4H, 2H, H, HB, B, 2B and 4B and Red and Blue. We recommend H and HB for little kids.

AND, all pencil component options, whether it is 12 leads, 6 plain ferrules, 6 ferrule/erasers or 12 cedar blanks are all under $9.00. The material costs for making beautiful custom pencils will be right around $2.50 each. Combine that with the fun of involving your entire family is simply unbeatable.

When I return from China we will begin filming the HOW-TO video tutorial but to wet your whistle, here is a short video peak at one of our prototypes in the skunk lab. I removed the crank and I am using a Dewalt power screwdriver (I love this tool) with an almost dead battery. Each die is really a circular plane iron and serves as not only the cutting edge, but the chip breaker as well. It doesn’t get any easier than this!

Pencil Precision is a complete hobby/factory in a box and this is what it isn’t: a toy. This is a professionally made tool that will last generations–which is a whole lot longer than a smart phone.

Just sayin’.

-John

Can’t wait to start cranking out pencils!

So, inquiring minds want to know why making pencils out of different woods isn’t a good idea?

Have a great trip, looking forward to seeing the videos.

Let’s say you make a pencil out of ebony (stupid by the way, what a waste of a precious resource) and gave it away.

How would the user sharpen it? It won’t sharpen with a razor sharpener and not likely on opposing helix sharpeners.

Always remember, if you are going to use an exotic wood, the responsible use is for an item that stands a better than 50% chance of existing as long as the lifespan of the source tree – this is typically a couple hundred years.

John

Good “points”- little pencil humor- very little pencil humor.

So discounting exotics, any hardwood would probably not sharpen or move through the cutting dies nicely, correct?

I’ve done walnut – it’s OK.

That’s so seriously cool John. I’m really excited to try it.

With a longer bed and screw, your apparatus could double as an arrow maker. Or at least a dowel maker.

I usually use mechanical pencils – mainly because I can never find a pencil sharpener when I need one. Time to do some research…

Thanks.

Working on the dowel thing next year….

Arrows are not my thing.

Safe trips. In another world I’d be going.

Sorry you couldn’t make it… we might do this again next year—we’ll see.

John

Responding to John’s

All that one would want in an aphorism, but I’d like to add three points:

. All projects produce waste. Re-sourcing that waste to new projects is worthy. Making lead-holders from wood that has lost its preciousness because it is too small to be of much use is philosophically piquant.

. Some objects are precious because of how they are made, or of what they are made. Their preciousness over-valors their utility, and they endure in our human world by being willfully unused.

. Even wooden lead holders — pencils — are only partly useful. (If the “lead” were precious, it wouldn’t be put in the

1½”4 cm at the ferrule-end of the holder.) I have saved pencil stubs for re-use (I have both stub-extenders and a Japanese device that mortices one end and tenons the other for gluing into usable lengths), and saved stubs I never intend to re-use — they are like retired driving gloves — attesting to peregrinations mapped elsewhere. Saving the final stub of a pencil I used to sketch ideas, itself crafted from scraps of fine wood left over from some realized project, is to me an honorable extension of the amusement you anticipate. Some pencils should be made from some fine wood.Additionally ???? — how ’bout a jig that spirals a hexagon-cross-section (or grooves/ribs) on the cylindrical blank?

Those four “?” were a smiley icon.

That’s a facisnating problem to solve…

Especially since it is solvable ;-).

The rotation should not be difficult (just a hunch). I have no idea whether the cutters would need to be modified (it is clear the positioning of the second and third cutters would have to be different {unless the angle of rotation is in phase with the modulus of the cutter and the distance between them}). My hunch here (having hunches is one of the pleasures of not being in the business of solving these problems) is that the existing cutters will work, but that better cutters would have each cutting face offset by the entry/exit angle of the wood.

Fwiw, I’d buy the extra hardware with a smile. “This is a pencil I just made, and I’ll show you how to make one. And _this_ is a pencil that you won’t see anywhere else.“

Kirby-

It is solvable, and the more expensive the solution the better… ????

In order to make a helical extrusion using a fixed die set, the dies themselves would need to be progressive smaller, helical and “timed” to pick up where the previous helix die left off. This insures the stock is rotating while being cut. At least this is what I think at the moment…

Right now, in my jet lagged mind (I’m sitting in my hotel room in Guangzhou), that is where my hunch is parked. This could be broached I suppose, but emerging technology in 3D printing seems more attractive to me price wise. Broaches can become very expensive real fast. Actually the truth is I have no clue!

There’s another way to do this but not as simple as what we are doing with Pencil Precision, and that is using a similar technique as making helical gears using a hob.

All food for thought, meanwhile keep enjoying your cost free hunches!

John

Just popping in with another thought; what if the beading was small enough to accomplish with just one die, then it would just be a matter of driving the pencil forward while slightly turning?

Could two different threads be used to move and drive the pencil through the die, one very course that held the pencil and the second fine enough to smoothly drive the pencil through the die?

While you’re in China, have a cheeseburger for me!

One of the mockups in the previous post showed a pencil with a sort of rounded triangle profile. Will there be a die set for that one as well? Or is that profile achieved in a different way? I only saw hexagonal and beaded dies listed under the pre-order.

Yes, the Reuleaux profile will be available before we ship the base units, I am still working on the matching ferrule options ( the round ferrules look like crap on that profile).

John

any thoughts on the eta for the pencil precision?

April, 2108. Oops… 2018!