Drivel Starved Nation-

My latest trip to China was my favorite to date. When you are on an informative trip, fun is easy to find. When the weather is perfect, trips like this become magical.

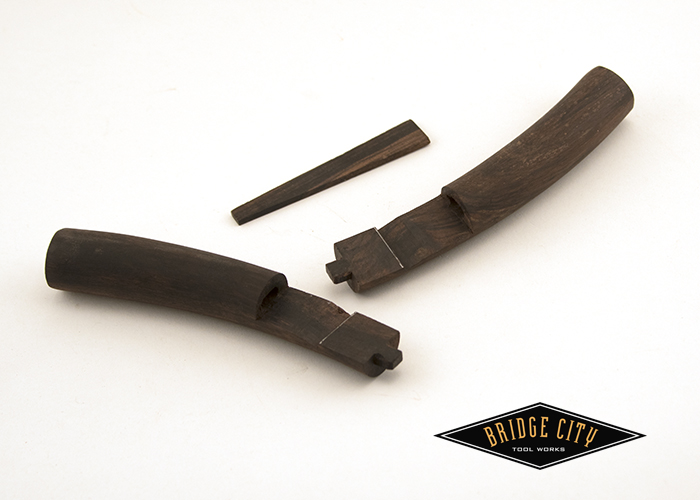

The highlight for me was the gift Mr. Yang, the Hong Mu Master presented to me. It is a sample of the joinery used in his masterpiece pictured below;

As explained by Mr. Yang, his students are not allowed to build a chair until this joint is mastered;

Incredibly, mastering this joint can take up to a year. The rosewood supply he has is finite, so there is no tolerance for waste when it comes time to make a chair. And because there is no finish, the joints need to be perfect to become invisible. It truly is an amazing display of craftsmanship. The joint itself (I wish I would have asked if it had a name) is a thousand years old I am told.

Here is a short video by Academy Award Winning Cinematographer Wanna Be Consuelo;

Each chair arm has 6-8 of these joints. They are incredibly strong and could be completely functional without adhesive… they are that strong.

Pretty cool yes/no?

-John

Cool indeed, how much of the joint could be cut on the JMP and would those cuts help to keep the rest of the chisel work lined up?

How about the DJ-1 or 2, could they help out too?

Yes! Very cool.

I don’t know the Chinese name for that joint, but Gustav Ecke, in his book about Chinese furniture, calls

it a Cogged Scarf Joint. Sounds logical, yes? And yes, it is a very strong joint due to close tolerances and fine wedging action.

See plate #109 in “Chinese Domestic Furniture in Photographs and Measured Drawings” by Gustav Ecke, Dover, 1986.

Compliments to Consuelo.

P.S. This kind of scarf joint was also in common use for shipbuilding timbers (Western world) several centuries ago. So, it’s hard to say where it originated.

Rutager,

Give it a go and report back!

Bob-

Thanks for filling in the blanks!

John

Thanks for all the great blogs – what a cool trip! Such an intriguing mixture of ancient and modern.

I do remember a California Woodworker named Yeung Chan building a Chinese Ming Dynasty Chair that included that joint. The whole chair could be assembled or disassembled in about 10 minutes with no glue – incredible. He wrote a book on classic joints, but I’m not sure if he covers that particular one.

Thanks, glad you enjoyed the report.

-John

John,

Could you post a few more pictures from a couple different angles?

I would guess the joint starts square and then the stock gets rounded afterwards, thoughts?

Rutager

It’s basically a lap joint with each end terminating with a small tenon, the mortise is hard to see because this wood is almost black.

Yes, you start with a square cross section. The mortises on this joint are rounded which appears that they were drilled and then cleaned up with a chisel.

I’ll shoot some pics on Monday.