Drivel Starved Nation;

I am pleased to share that the pre-order window for our new HP-9v2 Dual Angle Block Plane, and the NEW HP-12 Dual Angle Smoother will open next week. You will receive an email announcement with all the details if you have signed up to receive them. Pricing will be announced at that time (duh).

Both of these incredible bevel-up planes with stainless steel soles will come complete. This means there are no accessories to purchase, with the exception of spare irons (I do recommend having a spare iron, I always found it annoying to be forced to sharpen an iron in the middle of a job…). Speaking of the irons;

The best plane in the universe is as useless as a football bat without a razor sharp iron. The cutting edge, which is defined by the intersection of the bottom of the iron and the bevel or micro bevel, is the heart of the plane. For an optimal edge, both of these surfaces need to be reflective. Honing a micro-bevel on an 8000 or 16,000 grit stone is straight forward if not easy. Creating a mirror surface on the back of the iron takes work. Often times, hours of work.

Thankfully, all of the irons for these planes are factory lapped to an optical surface that is RMS .5 or better. RMS is calculated as the Root Mean Square of a surfaces measured microscopic peaks and valleys. An RMS value of .5 indicates an optical surface, and in metal, that means a mirrored surface.

I bring this up because, if you lap the back of these irons, and it doesn’t matter how good you are, or what stones you own, you will have an extremely difficult time (read “impossible”) matching the factory lap. This means that any effort to hand lap the back of the iron is going to DEGRADE the factory lap. So don’t! The microscopic burr on the back of the iron should be removed only with a leather strop. Lastly, DO NOT back bevel these irons, that is just stupid. To sum it up, these irons are best in class.

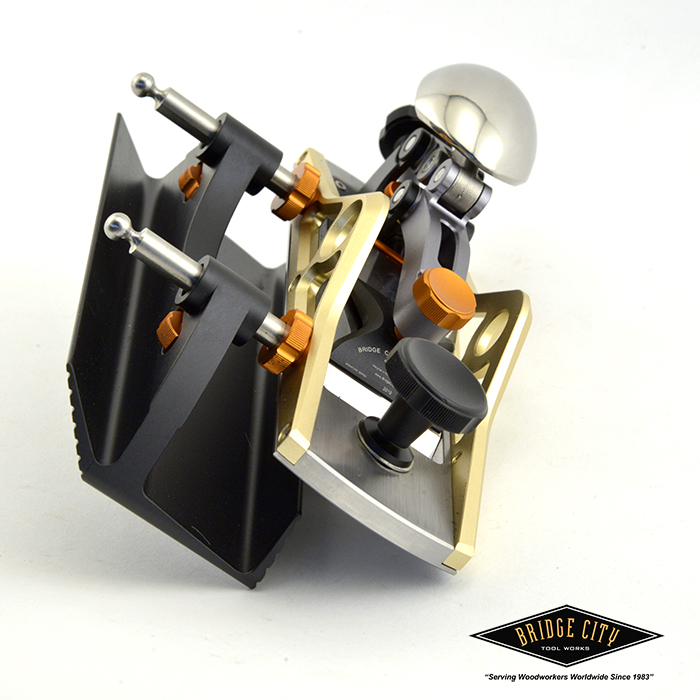

The HP-9v2 Dual Angle Block Plane has three new features. 1) The blade clamping pressure is now adjustable without tools. 2) The anti-backlash split-nut is now adjustable without tools. 3) The thumb nut on the lead screw is now retained with a frozen screw.

Here is what is included in the HP-9v2 Dual Angle Block Plane;

1) Plane body with all integrated components (there is nothing to take apart) including an adjustable mouth.

2) Fully lapped A2 tool steel, dual ground iron (you do not have to spend hours lapping the back of the iron) hardened to Rc 60-62. One edge is 30 degrees (25 degree bevel plus a 5 degree micro-bevel) and the other is 35 degrees (30 degree bevel with a 5 degree micro-bevel). Bedded, this creates a 42 degree low angle block plane, and a 47 degree general purpose block plane respectively. It is literally two planes in one. My desire to house a dual grind iron led to the shape and clamping mechanism of this unique tool.

3) Magnetic blade guard

4) Precision Anti-Backlash Lead Screw The iron is engaged to the depth adjuster via a pin nut attached to a 0.5mm thread pitch lead screw. One full revolution of the lead screw increases the depth of cut by .1mm (0.004”).

5) Two Depth Skids and components. This allows you to convert the block plane into a mini-thickness planer. The accuracy is crazy, the components will all be withing 0.05mm (0.002″) of each other.

5) Guide Fence and components. For those who desire added security or need a little help because of a disability, this fence will allow you to make perfect 45 degree chamfers and assist you in making dead square edges.

7) Micro-fiber plane sock.

8) Instruction Manual

9) Beautiful BCTW storage box with foam liner.

10) More detailed information regarding the HP-9v2 can be found here.

The HP-9v2 fits hands of all sizes and is simply one of the most fun planes I have ever used. It is my personal favorite and I think it stands a good chance of being your favorite as well.

The HP-12 Dual Angle Smoother comes with two irons. The bed angle of 12 degrees is identical to the HP-9v2. Available attack angles include;

1) 42 degrees for end grain or straight grained wood.

2) 47 degrees for general purpose work

3) 60 degrees for woods you like to swear at

4) Gap toothed scrub iron for rapid stock removal in flattening warped or cupped wood. This iron is almost never used with the grain unless you are creating “julienned” wood for decorative packing material (which is actually a lot of fun).

Here is what is included in the HP-12 Dual Angle Smoother;

1) Plane body with all integrated components (there is nothing to take apart) including an adjustable mouth.

2) Fully lapped A2 tool steel, dual ground irons (you do not have to spend hours lapping the back of the iron) hardened to Rc 60-62. One edge is 30 degrees (25 degree bevel plus a 5 degree micro-bevel) and the other is 35 degrees (30 degree bevel with a 5 degree micro-bevel). Bedded, this creates a 42 degree low angle smoothing plane, and a 47 degree general purpose smoothing plane respectively. The additional iron is ground to 43 degrees plus a 5 degree micro bevel for a 60 degree attack angle. This is used for squirrely grained wood. The scrub iron attack angle is 47 degrees.

3) Magnetic blade guard

4) Precision Anti-Backlash Lead Screw The iron is engaged to the depth adjuster via a pin nut attached to a 0.5mm thread pitch lead screw. One full revolution of the lead screw increases the depth of cut by .1mm (0.004”).

5) Two Depth Skids and components. This allows you to convert the plane into a mini-thickness planer. The accuracy is crazy, the components will all be withing 0.002″ of each other. This is a great tool for making thin stock that is repeatable. There are holes drilled in each skid if you ever need to add a piece of wood to create a guide fence.

6) Micro-fiber plane sock.

7) Instruction Manual

8) Beautiful BCTW storage box with foam liner.

9) More detailed information regarding the HP-12 can be found here.

I realize that the vast majority of people who purchase these planes are doing so sight unseen. So, what does it feel like to use them? Here are my thoughts;

Although the irons have a factory micro-bevel, I like to do this myself. As mentioned in a previous post, I am a fan of using a honing guide in conjunction with my 8000 and 16,000 Shapton waterstones. However, they will cut fine out of the box.

I also wax the soles. I have paraffin, but I really like using carnauba car wax better. That stuff is “lightning in a can” for a hand plane. I don’t have a favorite brand, I think they would all work just peachy. I rub the wax on with a rag and cover the entire sole surface (don’t forget to retract the iron unless you want square finger tips…) and let it sit for 15-20 minutes and I buff the wax off with a clean rag. Oh my, what a difference. These planes waxed are slipperier than a bad Mexican meal…

The HP-9v2 Dual Angle Block Plane fits my hand like a glove — the rear tote tucks neatly into the palm of hands large or small. Bear paw hands too. From here, you can choose to place your index finger on the orange knob that controls the clamping pressure (for smaller hands), or the indent in the front tote (for larger hands). Your middle finger and thumb fall into the circular cutouts in the center of the plane sides. For two handed work, you can use your non-pushing hand on the front tote. Whatever feels most comfortable for you is the correct holding position.

With the iron properly adjusted, begin your cut with the iron behind the stock, not on top of it. When properly set, this plane will make silky shavings that will bring a smile to your face. The combination of a sharp iron and a dead flat sole never fails to impress. As mentioned earlier, this is my absolute favorite plane, it is just a joy to use.

If you are using the guide fence for a perfect 90 degree edge, you control the angularity of the cut by canting the iron to achieve perfect 90 degrees. This is a big deal for creating joints for edge gluing thin stock — guitar backs, and boxes are examples that come to mind.

There is no getting around that the HP-12 Dual Angle Smoother is a a heavy plane. However, the inertia with a waxed sole leaves me with the feeling the plane has a motor. The cuts, whether fast or slow (I like slow) are awesome. I would not say these things if I truly did not believe you will share similar sentiment after using either of these planes — I am not the least bit worried that I will have to eat these words.

These two planes will handle the bulk of your flat making needs. We will add our shoulder plane and the scraping plane soon and together, these four planes will address the needs of the majority of avocational woodworkers.

Lastly, you will be gobsmacked by the quality, workmanship, and performance of these two planes. We believe this dedication to quality and performance will rub off in your work… it is what we mean with our motto;

Quality is Contagious!

-John

John, The instruction manual, will it contain your info for the care, sharpening, that you put into your blog of June 14, 2019. That info seems important to me.

Ralph

Ralph,

Yes!

Good question, and thanks for asking.

John

Will this new fence and guide work on the original HP-9 .If yes ,will it be available for purchase ?

No, the fence components are not compatible with the USA made versions as the v2 versions are made using the metric measuring system. Sorry.

I completely switched to the metric system about 2 years ago and I wish I would have done it 40 years ago.

Thanks for asking.

That said, I may some original HP-9 fence kits in our skunk lab inventory, email me direct at john@bridgecitytools.com and I will get back to you.

-John

So glad to hear you’ve chosen to go with metric and thank you for your hard work! I’ve recently been working with Japanese plane blades and I wonder why manufacturers don’t use their method of a thin layer of hard steel and a heavier main body of softer wrought iron or steel? I finally purchased a slow speed sharpener so for me, the harder the steel the better at this point but I’ve consistently felt like the yellow paper steel produced the most satisfying results. Given that the Japanese pull saws have become so popular I just figured their steel would follow but that doesn’t seem to be the case?

Adam,

The knowledge to make “Japanese style” plane iron blades is concentrated in Japan and I know of no one in this country who knows how to do this at scale. I could be wrong on this, and if so let me know!

John

Thank you to get sharing this information. But it will be truly great to get some more details!

Just noticed the Chinese connection when I received a tracking notice with a Chinese origin.

Maybe that is why the brass does not corrode any more, but not a development I welcome.

My last purchase from Bridge City.