Sure seems like I find myself in Cincinnati at least once or twice a year…

The fine folks of Popular Woodworking are graciously hosting a Lie-Nielson Hand Tool Event this coming Friday and Saturday. Personally, I am hoping to see some sunshine… what a wet spring in PDX. (Horrible model helicopter weather, which has saved me some repair money for sure…)

The hours are 4-9 on Friday with some kind of after show event where attendees get to hurl insults and food at the tool makers. (I am going to try and hit Chris Schwarz in the forehead with a ripe avocado for suggesting that I needed a blog). Should be fun. Saturday is noon to five (FYI, I will be gone around 3PM on Saturday–I have a ride to Knoxville that I can’t pass up).

I will be demonstrating the new Jointmaker Pro v2 (upgrade kit), and it is fantastic if I do say so myself. Oh, I will also have a prototype CT-17 Dual Angle Block Plane to show too.

Will there be discounts available for those that show up and buy stuff? I am afraid so.

I would love to chat with you if you can find the time!

Best-

John

Behind the Scenes

Behind the scenes at Bridge City Tool Works!

A Really Cool New Contest From Bridge City…

May, 27th, 2010

Yesterday the Dow dipped below 10,000 and I know why.

Michael Berg (who claims to work here and is 100% responsible for all of our manufacturing delays) became a first-time father. Clearly the Dow saw this in negative light.

Apparently he finds time to make babies but ignores your needs for our latest and greatest new tools. Go ahead and be mad–personally I am hotter than a sphincter after a bad Mexican meal…

Well, we (that includes you) can fix this (not the delays) by laying the foundation to make Michael a super dad. Here’s how;

Let’s create the world’s greatest check-off list for newbie parents. I have started it below, you can add yours in your post.

Furthermore, please share your greatest parental scam–mine is below. Why? Well parenting is 100% fun 100% of the time.

THINGS TO LOOK FORWARD TO AS A PARENT of a NEW BABY BOY

- Drool. Lots of it.

- Toxic Diapers

- Bed Wetting

- Projectile Vomiting

- Mysteriously Broken Windows and Major Appliances

- Barefoot Lego Hell at 2:10 AM (All we need to do is carpet bomb the Middle East with Legos. Game over.)

- Soccer Games at least 120 miles away (or so it seems)

- Emergency School Counselor calls … AT WORK.

- Clothes and Shoes that NEVER FIT… for TWO FREAKIN’ DECADES!

- Missed Curfews

- Sleepovers so carefully coordinated to confuse parents that Jack Bauer comes out of retirement to help solve.

- Never hope to finish higher than third in the pine box derby.

- Stitches. Lots of them.

- A crusty sock or 10….(this should come as no surprise).

- The smell of the family aquarium after returning from the family vacation is rather special.

- From age 9 to 19 you will be the dumbest bastard that ever lived. However, intelligence can be purchased through massive allowance raises.

- Never forget this parent formula: L=CS x 4W (Lice equals clean sheets four weeks in a row).

…now it is your turn! Add your contribution to the list.

MICHAEL, WATCH OUT FOR THESE SCAMS;

Back in the 60’s the World Series was played during the weekday. This meant I needed a week long disease to watch Mickey Mantle and Roger Maris during school hours. So I perfected the art of holding the thermometer up to my bedside light, and shaking the temperature down to 101-102. This works fantastic!

On day three, my mom came in earlier than expected and yanked the glass tube out of my mouth (by the way, oral thermometers were relatively new thankfully).

“You have a temperature of 113.”

“Is that bad?”

“It won’t keep you out of school. Get dressed.”

Busted, I had to have a better plan. So the next morning I brought my “A” game.

“I don’t feel very well.”

I received the cursory hand to forehead and was asked, “Do you feel sick to your stomach?”

I offered a barely audible. “Yes.”

“THEN GET INTO THE BATHROOM NOW!”

My plan was working–all moms hate vomit–can’t say I like it myself either. While in the bathroom I clandestinely opened the vanity door and removed the bucket of cleaning supplies–these were temporarily dispatched to the ugliest shag throw rug you have ever seen. I then dipped the bucket into the toilet and filled it with about a quart of sparkling fresh toilet water. And then I waited.

About 5 minutes passed when I heard my mom walking towards the locked bathroom door…

“John, are you OK?”

And at that epochal moment I inhaled, and while letting out a guttural scream, I dumped the water back into the toilet from a height of about four feet (even back then, my attention to detail was astonishing don’t you think?”). I then added a couple of gag coughs and some spitting for added realism.

“I am calling school–you are staying home–brush your teeth and get into bed.”

And on that Thursday in October, 1960, I watched (on our 12″ b&w TV with Sputnik legs) Mickey Mantle smack two homers–and the Yankees cruised over the Pittsburgh Pirates 16-3.

From that day forward, “the bucket trick” never failed me.

Now it is your turn. Share you greatest scam and Michael will pick a winner. This winner will receive one of the hundreds of disemboweled tools that has turned Micheal’s office into a Superfund site. Trust me, somebody is going to win something.

Surprisingly, I feel pretty good after sharing that story.

–John

PS: Actually Calder Cary Berg, this post is for you, all seven pounds of you. Welcome to the world.

Bridge City-2 Unbelievable Blems, The New DJ-1 Universal Jaw

April, 30th, 2010

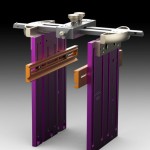

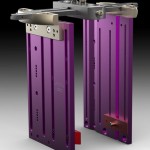

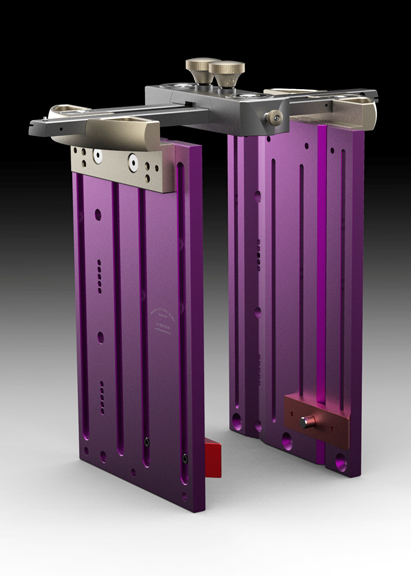

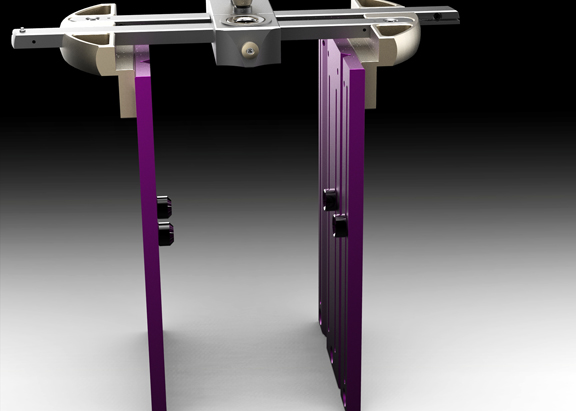

As far as blems go, Michael has set a new kind of record here… below are the first two CT-16’s he assembled. What do you think Donald Trump would say at this point?

After spending most of last night in the bowels of the internet (thanks to all who have shared their views) I finally decided to finish the Universal Jaws for the DJ-1 Drilling Jig. As of this writing, prices and availability are yet to be determined.

I am excited about this tool, and it has a growing and enthusiastic user base which is cool. These jaws take it to a new level.

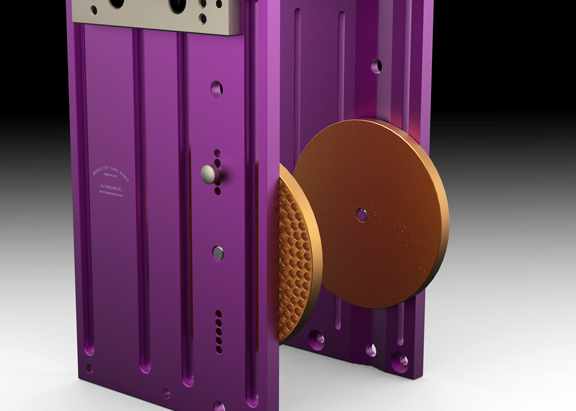

The picture below will allow angled drilling on flat, square and round stock up to 45 degrees. It is fairly straight forward, align ONE jaw (flat stock rides on top of the jaws) with a reference tool. Place anything reasonably round (a short piece of dowel or conduit works great) in the “v” groove, close the jaws together and tighten the second jaw and now both are planar. It would be fun to offer a drilling challenge pitting this device against a drill press…

The two little jaws below index to the plates and provide a pivot/axle for drilling radially. They slide up and down the plates and will allow you to make “Tinker Toys” if you will up to 12″ in diameter. Your stock spins on the 1/4 diameter axle and if you need a larger diameter pivot, make your own by center drilling dowel on the DJ-1 and cut to length to bush the 1/4″ metal shaft.

The image below illustrates the set-up for radially drilling either concave or convex shapes. The hole will always be radial and there is no limit to the diameter–you could literally drill spoke holes in a Conestoga wagon wheel if needed. You can drill hoops from outside in or inside out. It is simple, fool proof and more accurate than any method we can think of.

The attachment below should be of interest to toymakers, clock makers, sculptors, and any wood worker with the need for indexed holes. There are five index rings (64, 60, 48, 36 & 28) and just about every possible combination can be generated with these five choices.

There are three main pivots for the wheels, and if one needs to index larger diameters (this will accommodate up to 14″ as shown) it is possible to gang plates together doubling the capacity or more. More on this later.

Stock can be held to the index wheel either with screws or, with a small strip of double stick tape which would be my preference in most cases. Again, arbor diameters are easily bushed by making your own bushings.

Couple of other timely pieces of news.

Our early bird offer regarding the CT-17 Dual Angle Block Plane which includes a free O1 iron in addition to the A2 stock iron, expires this coming Monday, May 3. FYI.

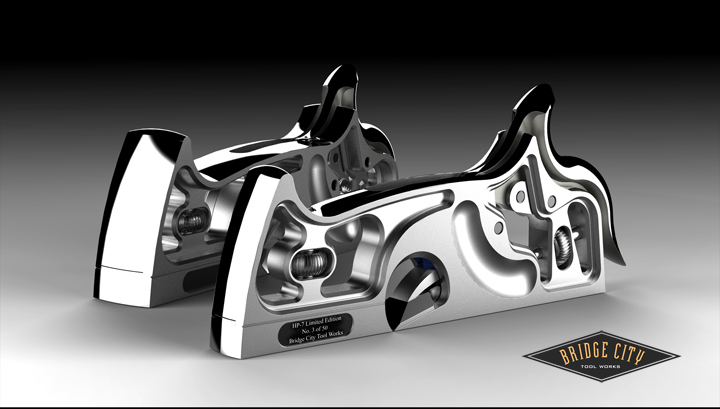

Also, we are producing a limited run of the skeletonized HP-7 Shoulder Planes (50 to be exact) and we have 10-11 that are still available. They are not for everybody but both of these tools are something else.

These are not available on our web store but further details are a phone call away by calling 1-800-253-3332.

Lastly, next week is the start of summer hours here at Bridge City. We work 4-10’s Mon-Thurs (phone staff works 8-5) until Oct. 1. Five months of 3 day weekends in Oregon is about as good as it gets.

I know I am looking forward to the change.

–John

PS: We made the blems pictured above to make ourselves laugh. Hopefully you too got a chuckle.

Geez…

April, 29th, 2010

Apparently, if one were to believe what one reads, we here at Bridge City have somehow offended most of the woodworking planet… sure seems like we should expect a visitor with an explosive vest packed with ball bearings soaked in rat poison… (I am exaggerating, but apparently not by much…)

Caveat; it’s late, I’m tired, and I don’t get it.

Australia:

UK

USA

USA:

and if this doesn’t satisfy your voyeur instincts, Google CT-17 yourself to fully integrate yourself in the sewer of the internet…

What the hell? I really don’t get it.

It’s been going on awhile.

I always believed that the ultimate vote was with the pocketbook. Does anybody who reads the crap on this blog get all the antipathy? Because I sure don’t and it is really wearing on our staff, and me. And before you think this is some lame-ass appeal for sympathy, forget it…not a single response to this blog post will be approved to be read by others.

From my perspective, our work either resonates or it doesn’t–we respect that. But all of the cheap-ass shots that our staff has to wade through, and the emails from customers who are wondering why WE don’t respond is really getting old.

Damn, I feel better–not really.

That said, there is a about a 99% chance I am going to die broke because of my art addiction–here is my most recent discovery…

If you are prone to self-reflection, love the out-of-doors, and are looking to support somebody who is talented, check out this artist. I just received one of his pieces, which at $150 I thought to be extraordinarily priced and somehow, in the always familiar way, makes everything I have ranted about go away… this is the piece I want to crow about.

And thanks for listening.

Best-

John

The Bridge City Caption Contest Winners…

April, 27th, 2010

Like the paternal voice I should be but rarely am, it is time to mine this exercise for deeper meaning…

I think it is safe to say that all who participated in this process had fun–some of these suggestions were damn funny. What is not funny is the dent in productivity this caused around here… who would’ve thunk it?

Linus Pauling once stated that the best way to have a good idea is to have lots of ideas, and this little contest is testament to the powers of distillation. And therein lies the message! (Linus Pauling was once a professor at Oregon State which reminds me, college football starts in four months–it is no irony that I am in the woodworking tool business and my favorite team is the Beavers!)

When I am asked to jury a show or my thoughts on a piece I almost always would like to see the ideas that were rejected prior to the final design. All to often there were no prior ideas–not good.

What we all did over the last couple of days is participate in a group brain-storming event. Hopefully you found this enjoyable and fun and perhaps the corollaries to your own work might be beneficial–it is what you reject as a designer that makes your work strong.

Speaking of rejects… (Oh goodie–the fun John is back!) well, we have quite a few ideas that need polish, but they helped elevate our three winners! But first, let’s discuss the judging because there might be lawyers lurking around this totally awesome and worthless blog.

Since I proffered a couple of ideas I recused myself–otherwise I am certain that I would have swept the awards… yes/no? Just kidding folks, but I did recuse myself from this contest, diets and fast Hollywood women.

That said, I managed to select two people off the street as judges. Imagine my surprise when I found out they both work here! So, if you don’t like the results, blame Cassia and Michael.

We have a three-way tie for first place–here ya go!

“Does this knurling make my knobs look big?”

.

.

.

“Tenonmaker? Big deal. My boyfriend’s an Elevenmaker!”

.

.

.

“Separated at birth, the twins stood wide-eyed, mouths agape when they met

for the first time as adults. Charlie, the older of the two (by three minutes),

had been born uneventfully. But there had been some complications during

Ben’s delivery, and he never quite grew to his full potential. On the other

hand, Ben’s adoptive parents had paid for the extensive orthodontic work

required to correct the severe malocclusion that ran in the family. Both men

had lost all of their hair by this time, and Charlie’s ill-fitting toupee was a

bit…embarrassing.”

Thanks to all of you who helped set a new record for posts in this totally awesome and worthless blog. To stevekay, pfranks and Steve_OH, you have your choice of a totally free $50 gift certificate OR one totally free Tenonmaker when they become available.

Now, I have got to get to work–my biggest fear is knowing the size of your wallet is growing and I am not doing anything to lance it…

–John

PS: To all the losers–when depressed, sad and feeling worthless visit this site. Works like a charm–I know it works for me!

New Tool, New Contest from Bridge City…

April, 21st, 2010

Last year we introduced the Kerfmaker and if you don’t have one by now… maybe you can win this little contest and get one for (drum roll please) FREE!

But first you have to wade through the latest post on this totally awesome and worthless blog and then enter the contest below.

Let’s recap; the Kerfmaker will allow you to to make P-E-R-F-E-C-T bridle joints, cross laps and other tight fitting joints without measuring SQUAT! How tight you ask? Tighter than a tube top on Dolly Parton–tight enough?

We will soon be introducing the Tenonmaker, which will allow you to make P-E-R-F-E-C-T tenons without measuring SQUAT! How tight you ask? Tighter than a prairie dog’s butt in a Nebraska dust bowl–tight enough? (Aren’t you glad I bypassed the obvious sophomoric analogies…?)

Because you are likely a guy (wild guess on my part) we are forced to make a movie of the Tenonmaker so that you understand it–every guy knows manuals don’t work. And once you understand the Tenonmaker YOU WILL succumb to an overwhelming urge to send us $89 for your own personal version. Don’t believe me? Check out this testimonial;

John-I have had a run of bad luck lately that led to a pretty wild night a few weeks back. My boss at the pitchfork factory rejected my idea of a one tine pitchfork, said it was already invented and it is called a javelin. So I came home and swallowed three bottles of sleeping pills, stabbed myself in the neck with an oyster fork, jacked my car up, crawled underneath and kicked the jack handle. I really wanted to leave this earth but the pills turned out to be flea medicine for my dogs, the oyster fork hurt like hell (FYI), and that damn jack never worked anyway. My wife said if I tried all of this on the same day again, she would turn off the heater on my salt water aquarium. I think she is my problem–she just doesn’t get mouth breeders.

I ended up in therapy where it was suggested that I buy a Kerfmaker from Bridge City Tool Works. Hell, for $72 bucks I gave it a try.

I want you to know that this amazing tool ,which allows me to do P-E-R-F-E-C-T joints has turned my life around. Thank YOU!

As a token gesture of gratitude, I have included a stack of Bearer Bonds totaling $2.4 million dollars. Do with this as you see fit–you deserve it.

–Cooter Ditchman

PS: I think any woodworker who does not own a Kerfmaker is dumber than a bag of hammers.

Well now, that is quite the story yes/no?

The movie will soon be done (the TM-1 movie that is). Meanwhile the pic below showcases the KM-1 (on the left) and the soon to be TM-1 (if you guessed “on the right” you are really smart) side-by-side.

Study this picture carefully because it can be your ticket to free tools (thanks to Cooter, I am now set for life and giving stuff away doesn’t bug me like it used to…).

How you ask?

Don’t you think this picture needs a caption, one that can be shared in a family-centric blog such as this one?

Not convinced? Top three captions will win something.

This is a “No Limit” caption contest. Tell your friends NOW. Proudly hold your clarion aloft and tell the world! Do join in on the fun because I guarantee this will be fun.

What are you waiting for?

–John

CT-17 Block Plane; The Back-story…

April, 19th, 2010

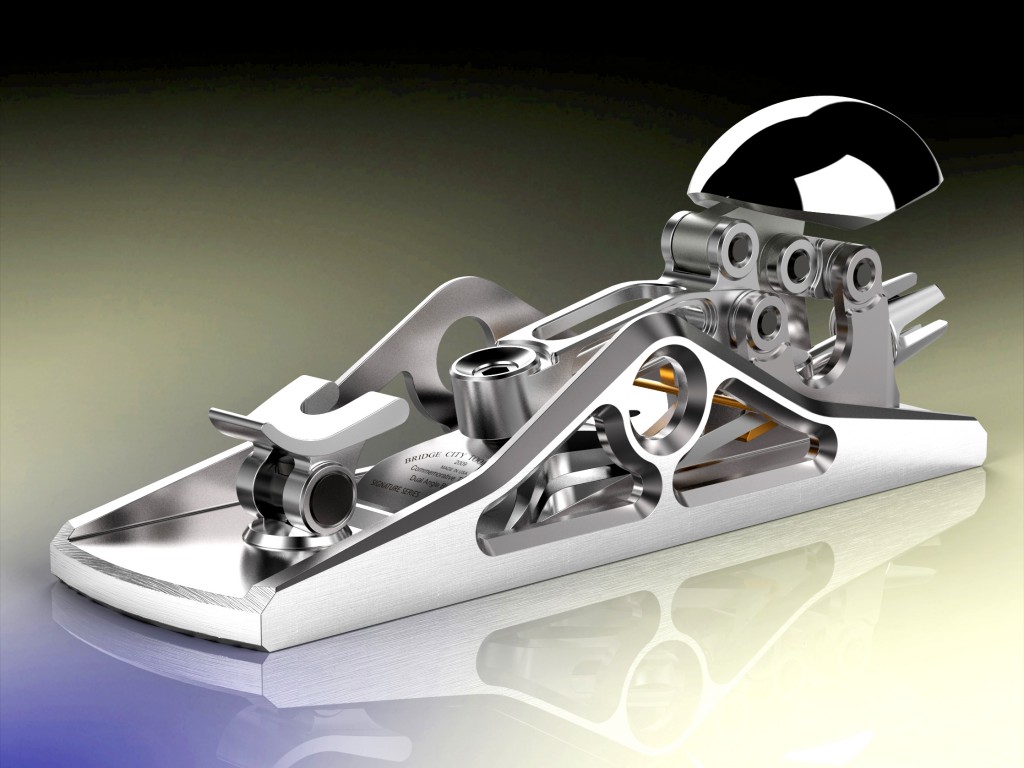

As promised last week, here are further specs on the CT-17 Dual Angle Block Plane;

Weight: 748 grams/1.65 lbs

Overall Height in Use: 61.2 mm/2.41 inches

Sole Length: 162.5 mm/6.4 inches

Sole Width: 48.75 mm/1.92 inches

Iron Width: 34.92 mm/1.375 inches

Iron Finish: Back, Optical Lap < 4 RMS

Iron Thickness: 4 mm/.16 inch

Iron Material; A2 Tool Steel, Rc 60-62, Cryo treated

Iron Bevels: Low Angle: 30 Degrees (25 primary +5 deg. micro bevel), Regular: 35 Degrees (30 primary +5 deg. micro bevel)

Iron Tension: Adjustable

Depth of Cut, Change per Revolution: .025mm/.001 inch

Throat Opening Range: 0 – 4 mm/.15 inches

Maximum Blade Cant : 2.5 Degrees

Sides to Sole Squareness: plus/minus .05mm/.002 inch

Materials: 304 Stainless, Steel Pivots

Blade Guard: Anodized Aluminum, Resides in Plane during use, attaches to back edge of iron for sharpening (affixed via 2 rare earth magnets)

Finish: Interior of body & components; glass bead finish, sides abrasively grained, pivots black oxide. Cap is polished. There is no black chrome on this piece.

Traditionally, most metal block planes use a cross-pin to anchor the chip breaker/cap to the body which holds the iron in place. By eliminating this pin, we were able to address the ergonomics of the tool with new light. The pic below, utilizes one of the stereo lithography models to illustrate the hand position where the index finger rests directly behind and above the cutting edge in a contoured pocket–this I am excited about because it feels great;

The design of the body is “circle centric” as circles were the predominate theme in the tool–they are everywhere and accentuated when possible to reinforce the theme. As illustrated below, the main holes in the body make grasping the tool securely easy and without much effort–it feels like it belongs in the hand…

The pic below illustrates the most traditional hand position using a block plane;

Although not illustrated here, the front “tote” pivots for two hand use and the inclination can be adjusted to suit your tastes.

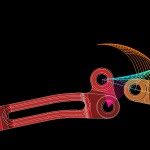

For the past couple of years I have been wallowing in the money pit of radio controlled helicopters–while on my work retreat I realized they have had quite a subtle influence in my work over the past year or so. With the CT-17, I consciously used the influence as a design criteria as you can see below…

Regarding the clues in this totally awesome and worthless blog;

Clue # 1 was a close-up/abstract of the “tail pipe” depth adjuster.

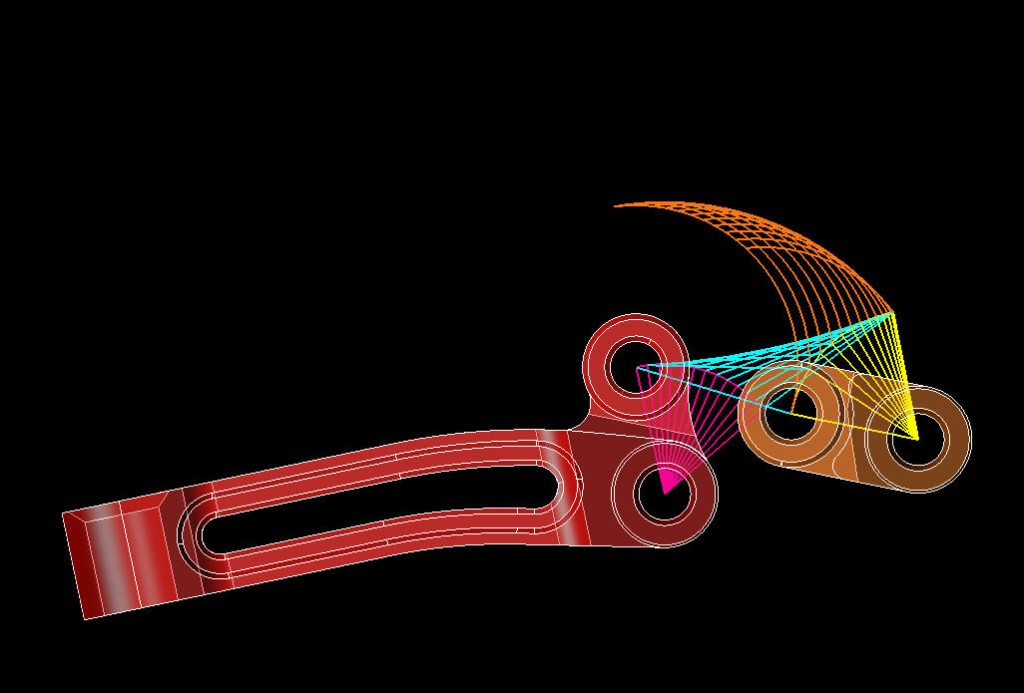

Clue # 2 involved the making of the video. The blade lock mechanism is not linear and at thirty frames per second, I needed to know the exact location of the clamp arm, cap and link throughout the range of motion when opening and closing. This involved a sequence of 12 individual frames to open and 12 to close–the animation software we use is not constraint or interference based so I had to do it manually. This illustration below should bring clarity…

The rest of the clues should make sense now.

Regarding the video, it was put together by Michael who also wrote the music beat. Editing by yours truly, hosted by YouTube. You are probably thinking, I would love to see that again! Here ya go;

For those of you curious about the software we used in this project (not in any particular order); Cobalt, SharkFX, HyperShot, HyperMove, Premier Pro, PhotoShop, Excel and FantaMorph.

On a personal note, I have been deeply troubled by the story of Phoebe Prince (the Massachusetts high school freshman who took her own life after relentless bullying by classmates). Why, we as a culture allow this kind of thing to happen is beyond my ability to comprehend. I was once told that bad people exist because good people do nothing.

So, on a much less serious scale–completely insignificant in comparison–but nevertheless related, we here at Bridge City deeply appreciate those of you who take the time to correct some of the inaccuracies and mean spirited posts circulating on the internet regarding this tool. It is a huge step in making the internet a much more useful tool.

More questions regarding the CT-17? You know where to find me.

Thanks to all for making this project so much fun. For those of you who earned a $50 Gift Certificate, you can expect an email sometime in the next 10 days–Natasha, aka. “The Gift Certificate Queen” is on vacation this week.

–John

CT-17 First Peek…

April, 15th, 2010

I want to thank all of you crazy people for participating in the CT-17 guessing game–although nobody won the $100,000,000,000 prize, EVERYBODY who contributed to this thread (up until noon 4/15) has a $50 Gift Certificate coming–I thought this was fun. AND, I have at least two new ideas to pursue!

Should we do this again next year? What if I bumped first prize up to $100,000,000,000,000?

Oh, I almost forgot; here’s a little clip of the CT-17…our website/store will be updated later today.

Thanks again-for making this all possible.

Now I get to go home and do my taxes. I know I am not getting a refund but we are hoping you do!

–John

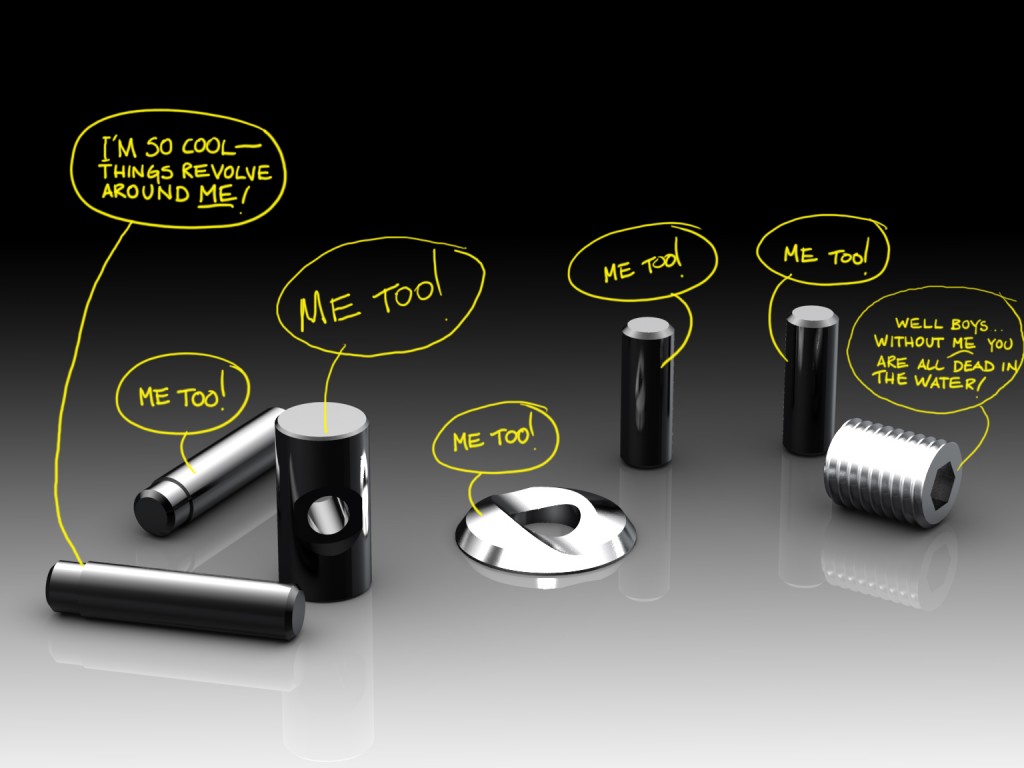

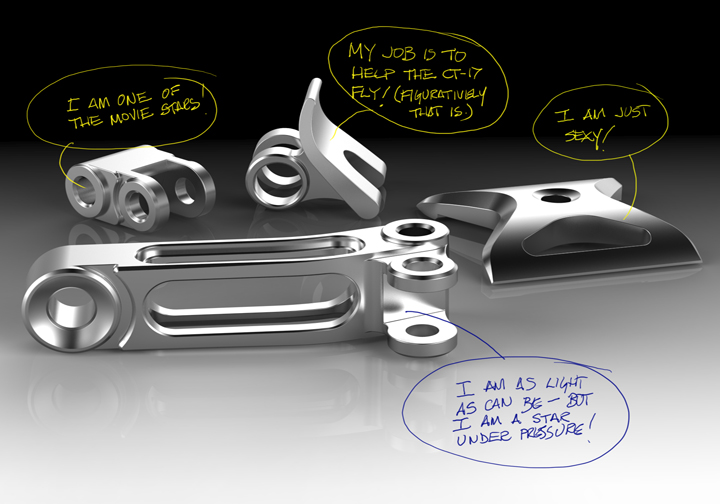

CT-17: Talking Tool Parts… Last Clue!

April, 14th, 2010

Tomorrow (sometime) we announce Commemorative Tool #17. We are optimistic you will find it to be a compelling tool–the internet? We are bracing ourselves for the buckets of crap to come. (I should be more professional but even Tool Potentates have a weak moment or three…)

From my perspective, I think it will be one of the best in the series, maybe top two (the eggbeater drill is still my favorite), but ultimately you will decide. That said, here is the final clue;

-John

CT-17: Talking Tool Parts… Clue #8

April, 13th, 2010

Rarely do I keep track of my hours on a tool but the CT-17 has been easy–I haven’t worked on much else since my work retreat in January. This adds up to about 300 hours of fun for me. Some of the components of the CT-17 were designed, and redesigned, almost 30 times. Why? Because of Dunhill’s Maxim:

“It must be useful, it must work dependably, it must be beautiful, it must last, it must be the best of it’s kind.”

This is, I believe is the best set of guiding principles one could ever adopt.

As many of you know, for the past couple of years I have spent much of what little free time I have learning how to perfect the art of crashing model helicopters. What makes this fun is the solitude of sitting at my little repair table and fixing what broke on my latest three second flight.

During this process I became a fan of helicopter parts–all have been reduced to their essence–no excess weight, materials appropriate for the function, aerodynamics when applicable and engineering that is just plain sexy– a Hiller rotorhead (amongst others) is a kinetic work of art.

Starting with the CT-14, where we skeletonized the body of a shoulder plane, we have embraced “helicopter ethics” in our work (when possible). For me, I am continually asking myself, “Is this the least amount of material to work and remain functional both physically, emotionally and aesthetically?” The CT-15 was also designed with minimalism in mind as was the DSS-6 Double Square and the DJ-1 Drilling Jig. After all these years (27 and counting…barely most of the time), I think these pieces are amongst our best work.

There are two reasons for sharing this information; one, prior to making a single chip in metal, a great deal of resources (time and prototypes) were dedicated to the form and function of the CT-17–this is a lesson easily and frequently skipped by hobbyists (and some pros). I have always asked students in my design classes; “How many of you figure out what you are making while you are making it?’ The show of hands is almost always unanimous–not good. Interestingly, if I were to only make one of these, the total time from idea to finished product would be ratio of about 10:1 in favor of the design time.

Second, by sharing that I have an undeniable influence in this case (model helicopters) I am suggesting that influences are everywhere. I almost got killed one day walking across the street because I stopped to marvel at the design cast into a manhole cover (cell phone cameras have given me a new lease on life). One of my furniture pieces in our “Original Design” forum was inspired by the landing lights of the Portland International Airport. There is such a huge difference between “looking” and “seeing” that you never know what direction your work will take as you progress in the world of design.

Personally, my work is seriously fun and I can’t wait to share the CT-17 with you. And speaking of fun, Clue #8 is pictured below.

–John