For all of you who are till suffering from the sleepy after-effects of tryptophan, here’s a little movie of the new Jointmaker SW (single wing for inquiring minds).

We will fill you in with all the details next Tuesday.

And I promise the new Jointmaker Pro v2, the Pro v2 Upgrade Kit and the Jointmaker SW will all be available for pre-sale ordering next week–or my name is Herman Sir Fransky.

–John

Behind the Scenes

Behind the scenes at Bridge City Tool Works!

The Jointmaker Pro v2, the NEW Jointmaker SW and More…

November, 18th, 2009

Sometime tomorrow or Friday (Nov. 20th) we will update our website to accept pre-orders for the new JMP v2 and the new Jointmaker SW. In addition, we will also be able to take orders on upgrade kits (JMP to JMP v2) for existing JMP owners. Here’s a little behind the scenes info…

The original design criteria of the JMP was to create a tool that was capable of gallery quality cuts without dust collection, and with so little noise one could listen to music. And the original JMP could do this and more. However, no product is perfect and no designer/engineer can rest until all little details are addressed…

The original JMP linear motion tables used sliding dovetails and one aspect of sliding dovetails are the incredibly tight tolerances–the parts are expensive to make and the sliders need lubrication. In addition, the sliders were ever so slightly hygroscopic which means combined with tight tolerances, the tables needed to be adjusted with humidity swings. The JMP v2 addresses these areas.

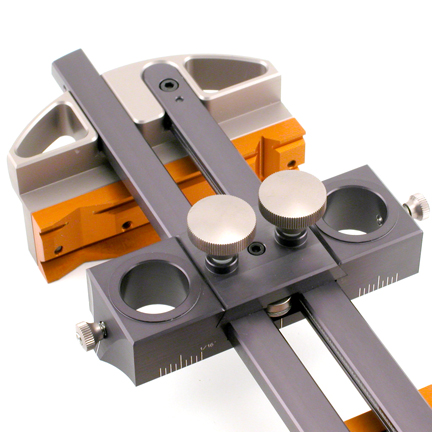

The Jointmaker Pro v2 is identical to the JMP in every way with the exception of the linear table design–the JMP v2 features a recirculating linear bearing system (the bearings follow a closed loop). They do not need adjustment (factory assembled) and they do not require lubrication. The main advantage is they are easier to use (much less friction) at the expense of a bit more noise. The bearings are acetyl which are much quieter than steel bearings–we are thrilled with the results. This version feels effortless and is easily used with one hand working the tables.

About the upgrade kits: They will cost $395 (delivered) and include new rails, adapter plates, tables, and fences. They fasten perfectly to all existing JMP’s. Installation involves removing the screws that hold the original dovetail rails in place, lift out the old rail system and replace with the new–a ten minute chore. Add another ten minutes to align the two new tables planer with each other. We will post a detailed video of this process on the JMP forum on our website.

I would like to add that NOBODY needs to upgrade–the cuts and results are identical on both versions. That said, we are only going to make this upgrade kit available once.

The JMP v2 will retail for $1295 and we are forecasting delivery in April, 2010. The inclined stand (a great accessory) will remain $195.

The JMP SW (Single Wing) is big news. Rather than utilizing two sliding tables that are bridged (for most cuts), this saw works similar to most sliding table saws–there is one sliding table and one static table.

The JMP SW blade will tilt 45 degrees in one direction, and 15 degrees in the other (for dovetail work). It will make all the cuts of the JMP and the JMP v2. The difference is in the jigging–edge miters for example, can only be cut accurately with the long face down. And there is a bit more thought for some cuts where the falloff needs to be supported. The video we are going to release should address most of these cuts. The JMP SW has the exact same cutting capacity of the JMP but occupies a smaller footprint.

We are targeting the JMP SW for $795 delivered (unassembled). The accessory stand is DIFFERENT than the JMP but will be available for $195. All will be delivered next April.

My candid impressions comparing the two versions? Thanks for asking–having lived and breathed with this device over the past three years, I really like the JMP v2 for all the obvious reasons, not the least of which it carries our “Pro” designation (less jigging hassles, better opportunities for sub-tables). However, for the casual user, the JMP SW is clearly 90% of the JMP v2 and $500 bucks less expensive. I suspect we will sell 3-4 JMP SW’s for each JMP v2. Both do gallery quality joint cuts (ZERO chisel paring or router plane work). The blades are the same.

That’s all for now–if you have questions or comments, feel free to ask them here but we would prefer you use the JMP forum for the benefit of those who don’t follow my incredibly hilarious blog.

Thanks–

–John

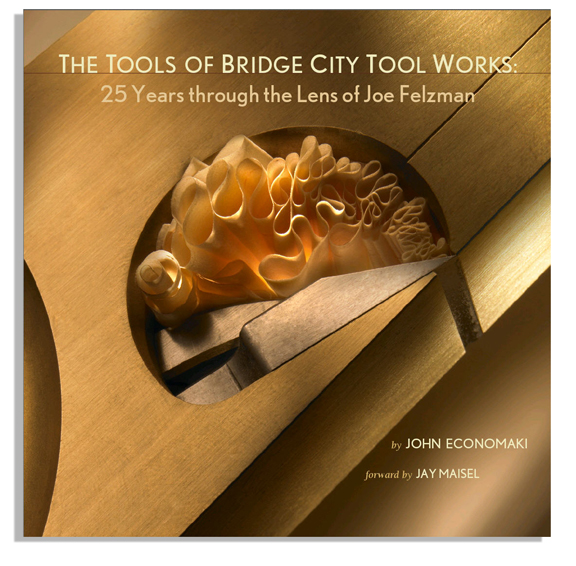

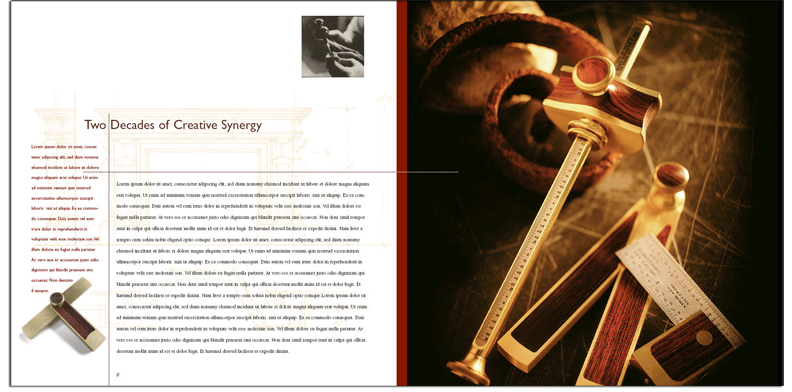

Bridge City Tools: The Book

November, 2nd, 2009

“He who approaches the temple of the Muses without inspiration in the belief that craftsmanship alone suffices will remain a bungler and his presumptuous poetry will be obscured by the songs of the maniacs.” – Plato

I started this project a year ago to coincide with our 25th anniversary, but the economy got in the way—In the spirit of eternal optimism here is the back story…

Way back in the mid 70’s I met Joe Felzman, a freshly minted young photographer from the Brooks Institute. I was teaching high school at the time but I really wanted to be a furniture maker and of course I had no money. I needed a portfolio to enter shows and this was way more difficult than I imagined… today I am proud to say that I turned out to be one crappy photographer.

Joe shot my furniture portfolio from 1976 to 1983 (some of his images of my pieces are posted in our Design Showcase) and when my furniture making days morphed into tool making, Joe shot all of the Bridge City catalogs—several of which have won meaningful awards. It only seemed logical to celebrate his talent and the synergy we experienced by producing “The Tools of Bridge City Tool Works: 25 Years Through the Lens of Joseph Felzman”.

Like our tools, this book will be different—it not only is a chronicle of Bridge City tools, is is also a celebration of photography by an extraordinarily talented photographer. For this effort, I have pulled from my personal collection every tool we have produced over the past 26 years (plus a couple that have never seen the light of day) and Joe is shooting all new imagery. We will include all the catalog covers, ancillary stories and other assorted tales from the past 25 years. From brass and rosewood to black chrome…it will all be included.

Karen Matheson is doing the graphic design and Jay Maisel (who was recently declared by a leading photography journal the greatest living photographer on the planet) has penned the forward. Chris Schwarz, of Popular Woodworking has signed on to fix all of my syntax and grammatical errors and all that is left is my part–writing and funding.

The purpose of this post is to offer you an opportunity for suggestions that we may have overlooked. This project is 6-10 months away, maybe longer considering my history of promises…

Meanwhile, here is a pic of the cover and an inside spread and we look forward to your suggestions.

–John

The Next Generation of the Jointmaker Pro and Random Bridge City News…

October, 27th, 2009

The intuitive mind is a sacred gift and the rational mind is a faithful servant. We have created a society that honors the servant and has forgotten the gift. —Albert Einstein

Over the past six months or so we have been developing the second version of the Jointmaker Pro. Most of the things we have addressed are transparent to current owners with the exception of our work on various linear motion options for the tables. Here’s a brief progress report;

We developed a recirculating linear bearing system for the sliding tables that fell flat on its face within 2 hours at the recent WIA conference. Although disappointing and embarrassing, this is the fuel that lights fires in the brains of engineers. I am pleased to announce this failure has been fixed. Here are the pros and cons of the new design;

PRO: The cost is identical to the current dovetailed rail design

PRO: No lubrication is required

PRO: Attaches to all existing JMP’s

PRO: Much more efficient

CON: Not as quiet as the original version (uses acetyl ball bearings)

From our perspective, there are more pros than cons but we are interested in your thoughts. Below is a video of a prototype retrofit version–the final production versions will be slightly different visually but it is easy to see the efficiency of this system. For those that are interested in converting to this system we are forecasting the cost for new rails, new tables and new fences to be around $395–delivered. Again, the video is of a prototype!

JOINTMAKER SW

We are building prototypes of a new version of the JMP that has only one sliding table opposing a fixed table—similar to all sliding table saws—and it’s working title is the Jointmaker SW (single wing). If this passes our tests, we believe this version will have a street price around $795. The cost savings emanate from the elimination of one linear motion table, and a reduction in metal/machining/anodizing expenses by allowing the blade to tilt 45 degrees in only one direction. It will tilt approx 18 degrees in the other direction for dovetail cuts.

If you have an opinion/suggestion/comment regarding this version, please chime in. We will post a video of a working prototype within the next couple of weeks.

KERFMAKER NEWS

All of the Kerfmakers will be out of our warehouse this week and we are reopening orders for the second run–our website will be updated in the next day or so to accept orders. I warned everybody that “The Tool You Want Real Bad” is aptly named. We have another batch in the oven so if you want one before the holidays, now is the time to order.

COMMEMORATIVE TOOL # 16

We will formally announce the CT-16 Palm Brace this week via email (and I will let you know here as well.) I have been playing with this tool for a couple of months now and I am completely stoked as to what it does in my quest for silent woodworking. It is not a panacea but what it does, it does very well and I am sticking to my guns that this is best screwdriver I have ever used.

The DJ-1 Drilling Jig, Round 2

We are completely sold out of the first production run and will announce pre-orders for round 2 this week as well. If you missed the first go, you may want to consider getting your name on the list for the next batch–this is one incredible tool.

That’s enough for now. We look forward to your comments.

—John

Bridge City Announces Commemmorative Tool #16

October, 19th, 2009

One of my favorite quotes dates back to the turn of the 20th century and has been the foundation for all of our Commemorative Tools;

“It must be useful, it must work dependably, it must be beautiful, it must last, it must be the best of it’s kind”. –Alfred Dunhill

Once each year we announce a very special tool that we pledge never to make again–and we try to honor Alfred Dunhill’s maxim with each edition. We are pleased to share that the the 2008 Commemorative Tool is the CT-16 Palm Brace.

Unless you own our original PB-1 Palm Brace introduced back in 2000, it is unlikely you have ever used such a tool–here’s the back story…

While on a trip to the east coast, I found myself in a dank basement surrounded by old engineering books (it’s a long story) when I stumbled across a user’s manual for a Model-A Ford (could have been a Model T, I can’t remember). The illustrations caught my eye, they were all woodcuts and the work involved to illustrate this manual seemed staggering to me. The mildew stench was a bit much too, but an image of a hand tool designed to hone the engine block valve seats caught my eye. This tool was not made to make full revolutions, apparently you swung the arm to and fro and the tapered abrasive cone honed the seat. It was the scale of the tool that really intrigued me–it appeared to be about six inches in length.

Once back in Portland I played with a couple of ideas and hit many dead ends regarding the scale of a new tool and the scale of available 3-jawed chucks–I could not make this work visually. I took a quick trip to Taiwan to visit a chuck manufacturer but that too was a dead-end. Only when the epiphany of “why use a traditional chuck at all” did the project come together.

The original PB-1 was a big hit amongst our customers as it was designed to use most bits/drivers with 1/4″ hex shanks. Not only did it do a great job drilling all the small holes required in project making, it is likely the best screwdriver I have ever used. The CT-16 Palm brace is superior in many ways–and like many well made hand tools, once you can count on reliable and consistent results, you find great joy in knowing that you are the motor.

First, the chuck has a positive lock–drills back out of holes and stay in the chuck–an occasional annoyance of our first chuck design that has now been fixed.

The swing handle of the PB-1 was awkward for those of you with bear-paw hands–that has been rectified.

The CT-16 Palm Brace is made from stainless steel, black chromed aluminum and black chromed steel (the swing handle is aluminum which keeps the majority of the mass centered over the drilling axis) and is one of the nicest tools we have produced over the past 25 years. And for those who had a chance to play with the CT-16 prototype at WIA last month, feel free to share your thoughts.

Pricing will be announced in a day or two and when complete we will update our website. Meanwhile, I hope you enjoy the sneak peek of the short video Michael put together–we think Alfred would be pleased.

–John

Inspiration Comes in Many Forms

October, 14th, 2009

I will be the first to admit that sometimes I just don’t understand what motivates woodworkers.

Recently, I had an opportunity to demonstrate the HP6v2 to a group of woodworkers and the ensuing discussion was centered on texture (one of my favorite design topics). I explained how it is the role of the designer to create depth and intrigue, in a non gratuitous manor, to add interest and richness to a piece when this little diddy popped out of the group;

“That plane is the dumbest thing I have ever seen.”

“Why?” I asked.

“All woodworkers want to do is make things flat.” was his reply.

Several others nodded their heads in agreement and I immediately felt the early pangs of a headache.

I have a hunch that in sheer numbers, he is likely correct. However, for those of you who are interested inspiring work, I am happy to share the genius of Brian Chan, a recent PhD graduate from MIT.

Brian’s art is origami and the rules are simple; the paper cannot be cut, glued or altered in any way other than folding. I found his work to be a rousing celebration of the human spirit and an exhilarating tour de force of texture. If you can spare 5 minutes, watch how Brian folded the MIT logo, Mens et Manus.

Below is Brian’s hissing roach–besides the mind-numbing difficulty, it is the texture that creates depth (through shadows) and that is what makes this interesting to our eyes.

Perhaps a few vectors can be bumped if one looked at that perfectly flat board as nothing more dramatic than a piece of paper…

–John

PS: Brian’s father is California woodworker/teacher Yeung Chan.

PPS: I think Brian should undertake the allghoi khorkhoi next, which everybody knows as the Mongolian Death Worm.

WIA ReCap–One Toolmaker’s Perspective

October, 6th, 2009

First the bad news;

Michael and I got stuck on the smoking floor of our hotel–my room smelled much worse than his, but he disagrees. The last time I remember walking into death like this was when I forgot to bring in my duffel bag after a hockey game–that bag stayed in my trunk for about a week–you get the idea–and in case you don’t there were mushrooms growing on my shin pads. Moving us to a non-smoking room was not possible–a direct punishment for making reservations on a discount site.

In addition, we had a direct flight from Philadelphia to Portland and we both got stuck in middle seats–I would rather get bitten by a Mongolian Death Worm than ride in the middle seat–again, punishment for purchasing discount airfare I am sure.

Lastly, whoever thought of the idea of opening the exhibit area at 8 am each day needs to be bitten by the Mongolian Death Worm. When it was slow on the floor, this is ALL WE TALKED ABOUT.

There. I feel much better.

It sure appeared that the attendees had a grand time–it is fun to be around positive vibes. Orders were tough, but it has been this way for a while in this business so that is no surprise.

On Friday, I assembled for the first time, a new rail system for the Jointmaker Pro. It worked great–for about a half-hour. I give myself a great big “F” for that idea. However, like all engineering problems, failures are solvable and I can’t wait to lick this one. More on this later.

I really enjoyed talking to the other toolmakers and several inquired into our business model–meaning how do we survive without inventory? The math is basic–with credit lines diminished or gone completely, inventory is worse than the bites of a thousand Mongolian Death Worms. We make-to-order and are constantly refining this process–as of this writing, I don’t see us ever going back to the days where we have millions of dollars of cash tied up in inventory.

On Friday evening, we joined several other tool makers at a clients house (whose name shall remain anonymous since his basement is the Ft. Knox of hand tools) for a hand prepared meal. Check this out–the pesto for the handmade pasta was made in San Diego, put on dry ice and flown in specifically for this feast! How cool. Oh, and how tasty!

THIS JUST IN: I just received an email from a customer admonishing me for showing the prototype of the CT-16 without posting it here first. We will formally announce this new tool next week with a couple of videos. Meanwhile, here are a couple of pics of black chrome and stainless steel;

Two well received tools at WIA were the MG-5 Marking Gage/Gauge (both are correct) and the DJ-1 Drilling Jig. We were particularly thrilled with the DJ-1–the demo where Michael drilled a perfect hole on the corner of square stock–while hand holding both the stock and the drill–dropped more than one jaw and opened several wallets.

The MG-5 surprises people with its ergonomics and ability to sit where put. And, the verdict is in, all those that voiced an opinion thought my fetish for black chrome is worth pursuing.

The exhibit hall had many lulls which, as weird as this sounds, I welcomed. I don’t get many opportunities to play with our tools and these moments provided many new seed ideas.

UNRELATED TO WIA DEPT: I was thrilled to read in the New York Times today that as of December 1, the FTC is requiring any blogger/Twitterer or other social media sites which post product reviews to disclose any connection to the advertiser, including the receipt of free products and other forms of compensation. This is a slimy practice in my opinion and any attempt to fix it is most welcome.

THE BEST NINETY-NINE CENTS I EVER SPENT DEPT: I happen to be one of many, I am sure, who are addicted to the smell of WD-40. There is just something about smelling like WD-40 that makes me feel productive and that is just part of the story… I have been spraying this stuff on my ankles for over 50 years and have never been bitten by a Mongolian Death Worm–so there.

I am sad to report that smelling productive just may be over. WD-40 has recently released a new dispenser that is fantastic. It is a felt-tipped pen that puts the smell right where you want it. We bought this at a local box store in Philadelphia because Michael forgot to bring the JM-P lubricant and this turned out to be a great mistake on his part. DISCLAIMER: Although it is not December 1 yet, I have no affiliation with WD-40 other than as a customer who likes to smell like petroleum distillates. What I really like is the benefit to the environment–how many times have I needed to silence a squeaky door hinge and ended up painting a 2 square foot area with lube? Those days are over. It’s ninety-nine cents folks and tell them John, your Tutelary Lubrication Angle sent you.

I can’t close before mentioning that the staff of Popular Woodworking did an outstanding job (except for that 8 am stuff) and are very gracious hosts. I have not heard where the next WIA event will take place but I am sure it will be another stellar event.

–John

Woodworking in America, Oct 2-4

September, 23rd, 2009

This is a friendly reminder that Bridge City will be exhibiting at the Woodworking in America conference October 2-4. Location is at the Valley Forge Convention Center.

This should be fun because we will be exhibiting prototypes of the following;

- CT-16

- The Tool Too Sexy for Mass Production

- The Tool You Will Want Real Bad (KM-1)

- The MG-5 Black Chrome Marking Gauge

- A working prototype of the Jointmaker Pro v2

- The DJ-1 Drilling Jig

- And a bunch of other cool stuff.

The exhibit hall will be open to the public we are told, so come on by and visit with either Michael or myself–we hope to see you there!

–John

Bridge City Essentials; Black Chrome and Stainless Marking Gage

September, 16th, 2009

As we continue to celebrate our 25th anniversary I am pleased to give you a peek into what is coming next.

Sometime in the next day or so, we will be announcing the pre-production run of the next Bridge City Essential–an updated version of our MG-4 Marking Gage and calling it the MG-5. Stainless steel, black chrome…OK, I will fess up–this black chrome is the coolest stuff–I am hooked.

Frankly, the world does not need another marking gage but this one is notable because it has two “business ends” one, a beveled cutter for straight work and a scribe pin for following curves. It is small, fits the hand great and the black chrome just feels oh so sexy.

We are working on pricing but the MG-5 will be well under $150 so it won’t break the bank…hell, what I am thinking, all the banks are broken! Don’t know how many we are going to make yet and don’t know if we will make it again (We are in the anti-inventory business) so give it a ponder.

Here’s a Sneak Peek of the prototype;

–John

Stainless Steel on Black

September, 14th, 2009

Can’t say I was overly productive today but I did manage to sign all 50 of our 25th Anniversary Stainless Steel Shoulder Planes. They really came out great. I wish I could be around in a 100 years to see what these things are worth but after last week’s bout with salmonella–glad I am on the downhill side of life.

Thought you might enjoy this pic of our round-up;

These should all be in their rightful owners’ hands within the next 8-10 days.

–John