Thanks to the British Weights and Measures Act of 1824, we Americans inherited a collection of units known as the Imperial system. Imperial units are unbelievably accurate and superior to the metric system in every way–and I can prove it with a singular question:

What is 17-17/32″ divided by three?

And you thought a six-star Sudoku puzzle was hard.

Fortunately, woodworkers are constantly dividing things in half, a much easier task than the gasket blowing problem above (5-27/32″ is the correct answer–took me a day and a half, or .15 payroll period to figure this out ). Try it yourself–dividing 17-17/32″ by two only took me four hours.

Approximately 520 payroll periods ago, we introduced the CS-1 Center Scribe, a cool tool to help Inch Land woodworkers find the center of things without time-consuming calculations. Inchlanders often struggle with the efficiency of Imperial measurements and our CS-1 Center Scribe quickly became one of our most sought after tools to this day.

About 104 payroll periods ago, improvements to the CS-1 came upon me. Fully charged for the redesign, the muse arrived unannounced bearing news of the VP-60 Adjustable Pitch Plane. Immediately thereafter, who should reappear with a radical new design for shoulder planes? And for the past year, I have been obsessed with the Jointmaker Pro–likely the most scrutinized new tool introduction I’ve known.

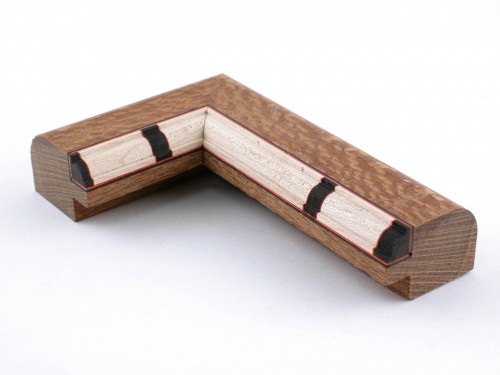

The image below is of our new, improved Center Scribe.

Briefly, here are the improvements;

- Zero backlash or slippage–no gears.

- Holds a pencil

- Finds centers on square, round or rectangular stock lightning-fast.

- Does not react with humidity

- Field adjustable if needed

- Smoother feel

- More precisely scribed centerlines (not pencil lines for obvious reasons), accurate to within .002″

To learn more, visit the CS-2 Center Scribe pre-production page. And if the CS-2 looks like something you can use, click the panel that states “Notify me when this item is back in stock.” By adding your name to this database we have a much better idea of our manufacturing quantities–you are not placing an order.

Thanks to a suggestion by a good engineering friend, this tool is crazy smooth and accurate. I hope you like it because… well, it’s a payroll thing.

-John