Remember the pandemonium surrounding Y2K? Well, brace yourself for July 20th because that is the deadline for ordering The Tool You Will Want Real Bad.

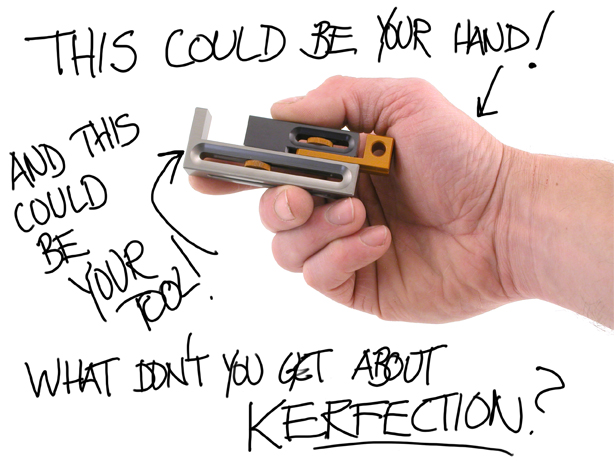

If you have not ordered a Kerfmaker (two or more would be preferable) you have to ask yourself this simple question; “What is wrong with me?” For a measly $59 bucks I can have a tool that will not allow me to make mistakes.

And we agree (it’s unanimous too) there is something wrong with people who have yet to order the Tool You Will Want Real Bad.

Maybe this will help the fence sitters; With our marketing effort in hypeoverdrive (I just made that word up) could we afford to lose face by delivering a product that disappoints? Of course! But we won’t.

Oh, for those of you wondering what happens after July 20th when you realize that not ordering the Kerfmaker was a HUGE MISTAKE? Well, you get to put your name on a list and when the list grows to 500,000 names, we will make the second batch.

What don’t you get about KERFECTION?

Don’t be a bozo–July 20th is it. No exceptions. $59.

–John

Behind the Scenes

Behind the scenes at Bridge City Tool Works!

What the BLEEP is THIS?–The Movie!

June, 30th, 2009

G-day Mate! (I am pretending to be on an exotic vacation)

John here-your favorite Tool Potentate with another dose of piffle.

Just read that Transformers: The Revenge of the Fallen (it’s a movie) has pulled in over 200 million bucks since it opened last week. This sum is a mere rounding error compared to the soon-to-be-released revenue figures from The Tool You Will Want Real Bad.

Furthermore, the enormous profits from The Tool You Will Want Real Bad will be impossible to conceal when my European accountants leak that I am buying my own island continent (forgot to think big for a moment). One simply cannot ignore the phalanx of customers worldwide who want this tool real bad and don’t know it yet. How do I know this to be?

For only $6.50 and 50 extra calories, I received the following secret message at lunch today;

Life is good. And yours is about to get better–here’s the movie that will usher in a new epoch!

–John

What the BLEEP is THIS? The backstory…

June, 24th, 2009

It is not easy inventing a tool that every woodworker in the world will want–but we have done it again (the others you don’t know about yet). Which prompts me to ask this question; Does anybody know of a bauxite mine for sale? We are interested–particularly if the owner is setup to take the Discover card. We are, after 25 years, finally thinking big here–real big.

Our new mystery tool, the tool that you WILL want REAL BAD is pretty cool. Here’s the story.

If I sound a bit amped it’s because I have started making things out of wood (after a 25 year exile) thanks to the JMP (Jointmaker Pro for the acronym impaired). I am also off my meds. Just discovered coffee too.

So one day I am making parts on my Jointmaker Pro and the joints were so small I had a hard time measuring (and seeing) to get light-tight results. And then an idea pooped into my head.

NOTE: There are no typos in the above paragraph.

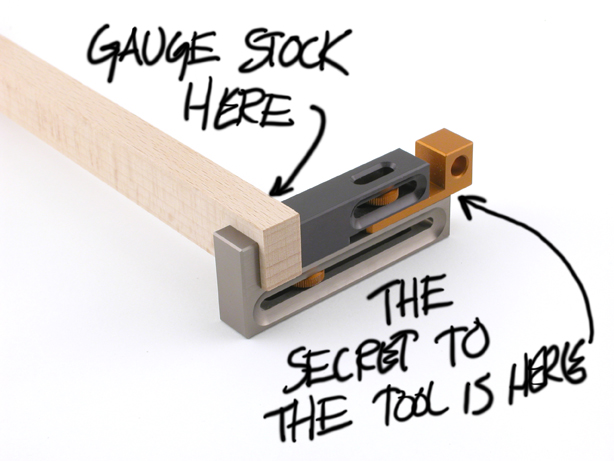

What if there was a tool that instead of measuring all you needed to do was gauge? So we built a prototype and all I can say is you will want one, maybe two, and this want will hurt real bad until the little Bridge City box shows up on your doorstep. Here’s why…

If you have a table saw, router table, radial arm saw, chop saw, band saw, JMP, or any other tool that makes a kerf 1/2″ or less, this device will blow your mind. Please don’t try to send us any money–they are not for sale yet!

Is this cool or WHAT?

REAL LIFE EXAMPLE #1: You are making drawers with veneered ply bottoms. Plywood is like snowflakes–no two sheets are the same thickness. So you cut your bottoms and it is time to cut the grooves in the four drawer pieces. Depending on your drawer, you will likely use a router, router table, table saw or–our HP-6 hand plane. Either case, our new secret weapon will work wonders. Here’s how.

REAL LIFE EXAMPLE #1: You are making drawers with veneered ply bottoms. Plywood is like snowflakes–no two sheets are the same thickness. So you cut your bottoms and it is time to cut the grooves in the four drawer pieces. Depending on your drawer, you will likely use a router, router table, table saw or–our HP-6 hand plane. Either case, our new secret weapon will work wonders. Here’s how.

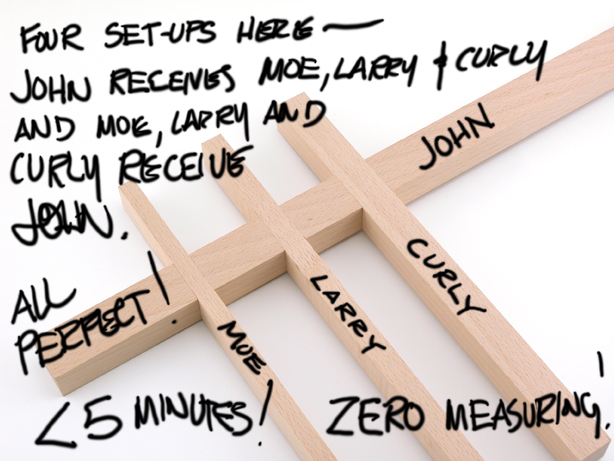

All you need to do is gauge the thickness (you DO NOT MEASURE SQUAT) of the plywood with the tool (it’s so easy even YOU could do it), tighten the knob and this creates an offset at one end of the tool that represents the outer boundaries of your kerf within one or two thousandths of an inch of your ply thickness! The tool then lays on it’s side and acts as a flip stop against a reference. The days of widening a kerf by test cuts is OVER. As in F-O-R-E-V-E-R.

We will demonstrate this via video in the coming days. If your drawer sides are cross-grain grooved at the rear to accept the tenons of a rebate cut on each end of the drawer back, it doesn’t matter what the thickness of the tenon–you gauge and cut–no measuring and I GUARANTEE YOU CANNOT SCREW THIS UP!

This is no pre-game seven Stanley Cup boast made by an overpaid, loudmouth athelete–this is a REAL LIFE boast made by an underpaid loudmouth toolmaker–furthermore book it–I guarantee a gallery quality cut. Did I mention you cannot screw this up–ever?

Is this cool or what?

REAL LIFE EXAMPLE #2: Many think I am nuts, and they are getting warmer. That said, I am actually making a gallery piece out of coffee stirrers that I rescue. OK, I steal them–and I ask first even though I am a charm school flunky. This material is approx. .050″ thick and the joint possibilities are limited–primarily cross and half laps. Not easy. Oops, it is now. Film to follow.

There are other examples but the video will spare you from me. Coming soon. –John

What the BLEEP is THIS?

June, 23rd, 2009

It’s summer and we are supposed to be having fun. Let’s begin…

The video elves at Bridge City are busy compiling footage of our newest tool which by no coincidence is pictured below.

Can you guess what it is?

Here is a free clue; the mystery tool will sell for $59 (the equivalent of 12 snow cones at the county fair, one bucket of movie popcorn or one bag of dog food for Louie) and we are almost certain you will want one. Or two. How do I know? I’ll tell you later.

Yet another free clue; the image below contains all the information needed to complete your detective work. There are also a couple of dead-end visual clues. Time to awaken your inner Agatha Christie.

In my excitement for the discovery of this little device, I demonstrated it at at the Marc Adams School of Woodworking several weeks back. You people know who you are and remember, you are sworn to silence so zip it, lock it, and put it in your pocket! This means you too Zane.

Also, one of the editors at Popular Woodworking (name rhymes with Chris Schwarz) has seen this in action. Oops–was that a clue? Oh, he wants one too! Just ask him!

Now, I am no stranger to tool hooplah so you just need to believe me when I say that those that have seen this work want it! Want it bad. Have we had people offer us their first born for this? Sure, but that ain’t right–it’s wrong and needs to stop.

Since you haven’t seen it yet, your uncontrolled desire for this new tool is suppressed–this will pass.

In the meantime, post your guesses and I will respond with one of five words; cold, colder, warm, hot or Bingo! I will try my best to tell the truth too. Sorta.

In the spirit of fair play, I will help you with 10 more free clues. No need to send money now.

1. This device has nothing to do with animal husbandry, parachutes or rock climbing.

2. This device will not increase gas mileage, monitor tire pressure or help you find your car keys. (Got myself on a little roll there with all those automotive clues…)

3. A zeppelin repairman might use this device. It’s a stretch but if I was a zeppelin repairman I would want this tool. Really.

4. We haven’t figured out how to open a beer with this–yet. BREAKING NEWS! We can open a beer with this new gizmo. Attention Marketing Department: Revise sales forecast upwards!

5. This device could be used as an impromptu garlic press.

6. It has a name.

7. We invented it.

8. You will want one.

9. You will want one real bad.

10. We won’t stop you if you want two.

–John

Stainless Steel Shoulder Plane…Going…Going…

June, 22nd, 2009

This is a courtesy post regarding one of biggest surprises we have seen around here in a long time.

Last week we announced plans to build a limited edition of the plane pictured below.

With the run limited to 50, we thought this would sell out in 3 months, not a week or two — as of this writing (Monday, June 22, 4:10 pm) we have 8 remaining. I don’t believe they will last the week. As such, we are moving the delivery date from October to September–maybe earlier. Further details of this plane can be obtained by scrolling down to my original blog post from last week.

I don’t want to sound overly optimistic, but maybe this is a harbinger of a change in the economic climate–we sure hope so!

–John

A respite worth sharing.

June, 20th, 2009

Today is just one of those retrospective days where I can’t seem to do much–just pinned Sam Maloof’s memorial program to my bulletin board on one of the coldest, damp, June days I can remember. It’s hard to think about tools, wood or woodworking. Even Louie dog is leaving me alone–probably has one of my shoes torn to shreds by now…

I was deeply touched by Sam Maloof’s memorial, particularly the music. Cucumrrucucu Paloma, sung by Perla Batalla was simply otherworldly–everybody in attendance knew we were part of a special moment and if there was a a pair of dry eyes in the house, well, I would not have been able to spot them. Not only could I not see, it was hard to breathe.

I was thrilled to learn about Perla Batalla on the internet today and overjoyed to find her singing Cucumrrucucu Paloma in a YouTube video. I apologize in advance for the non-woodworking post but am compelled to share this beautiful song. She is incredible and I hope you share similar sentiment.

Although I don’t speak a lick of Spanish (or any other language sad to say), perhaps somebody does and can enlighten me as to what the lyrics mean and if not, it doesn’t matter. Be warned, tears are a universal language.

Thanks for listening.

–John

Special Limited Edition 25th Anniversary Plane

June, 17th, 2009

Last year when we introduced the CT-14 Shoulder Plane, we made a couple out of solid stainless steel with no intention of ever producing a stainless version–the machining costs are astronomical.

I have hauled one around with me at several of the Lie-Nielson Hand Tool Events and it is definitely a head-turner–works great too. Recently we had a customer who wanted to buy the plane and it was explained it was not for sale.

“Name your price.” he said. I have heard this before and it is hard to ignore.

We held our ground. Until last week.

In a staff meeting it was suggested that we make a very small run of these and include them as part of our 25th Anniversary celebration. What is a small run? 50.

Each of these planes will be hand signed and serial numbered. Delivery will be in October, the price; $2500.

If this interests you, give us a call (1-800-253-3332). As of this writing there are 17 remaining. Phone orders only–serial number will be assigned at time of order.

If you are looking for a something that is truly unique, perhaps a great investment, this may be worth considering. There is nothing like it.

Did I mention I have developed a tool fetish for stainless steel? This stuff is awesome!

–John

Sam Maloof: Woodworker

June, 15th, 2009

Last week I attended Sam’s memorial service. It was the finest memorial I have attended—which likely comes as no surprise to those who have crossed paths with Sam. The service was rich with music—extraordinary music actually. The testimonials were heartfelt, deeply moving and richly informative. But most important, it was celebratory—Sam liked parties.

After the service we migrated to Sam’s residence to find an IN-N-OUT food truck serving burgers and chips—turns out this was Sam’s favorite fast food. Although I do not eat beef, I ate two IN-N-OUT cheeseburgers in Sam’s honor Tuesday evening. Good thing one of those outlets is not in Portland because I would have to add this as yet another influence this man has had on my life…

In the early 1970’s the Portland Public Schools maintained a film depository for teachers. I quickly learned that most of the woodworking related offerings were film strips. My woodshop “classroom” was a series of tiered benches surrounded by windows reinforced with chicken wire, a needed safety measure to protect students from the occasional explosions which occurred in the adjacent welding lab.

The room was too small to show film strips—the heat from the projector caused immeasurable discomfort I was told—and it was explained to me by one student that they “messed “with glue set-up times. Truthfully they were dorky.

Sometime in 1974 I noticed a new film title; Sam Maloof: Woodworker and ordered it for review.The next day after classes were over, I rolled a projector into my classroom, turned out the lights and watched a movie about a woodworker unbeknownst to me. It is probably important to mention I was 23 years old and as a condition of my employment I was forced to coach freshman baseball.

Time erodes my memory—beer too—but I believe the film was around 30-40 minutes in length. That late afternoon I watched the film five times in a row. It was the most humbling experience of my life. Here I am, teaching woodworking and realized I knew nothing about woodworking.

Produced by Maynard Orme (whom later served 19 years as the president and CEO of Oregon Public Broadcasting) Sam Maloof: Woodworker was impossible for me to ignore. I remember having a raging internal debate as to whether I should show this to my students for fear of exposing my own ignorance. My training prevailed; “The role of the educator is to open minds, not close them.” So I say now, to the professor who shared this mantra; “See! I was listening!”

I have seen Sam Maloof: Woodworker well over 50 times and have learned something with each viewing. At that time I did not know about pattern shaping, never had seen a rolling pin sander, and it never occurred to me that wood could be sculpted in such fashion.Hate to admit it, but at that time I was Forrest Gump dumb in regards to woodworking—probably everything else too.

Within a year another film made the catalog. Wendle Castle’s music rack (can’t remember the title) was a cool how-to film set to Mussorgsky’s Picture at an Exhibition. Then in 1975 I received the first issue of Fine Woodworking (which I still own).I did not know it at the time but my life was being molded in ways that leads directly to this overly long blog entry.

Sometime in early 1978 I noticed an ad in Fine Woodworking for the Anderson Ranch in Snowmass, Colorado. Listed was a three-week summer hands-on workshop with… Sam Maloof! Had to go.

It was dusk when I pulled into the Anderson Ranch and while driving through the campus I noticed a barn with doors wide open. Alone inside was Sam Maloof oiling one of his rocking chairs.I was such a chicken I quickly sped past to the check-in counter for chickens.

The Anderson Ranch woodworking classroom was two columns of workbenches. I took the very last bench because I would not like to look around, or over, a 6’3” view hog.And besides, I was awestruck.

On the third or fourth day an interesting thing happened. Sam’s glasses broke at the bridge and for the rest of the class, they were held together with white tape—Hanson brother style for you hockey fans.

The significance of this event was transformative for me because I then realized Sam was just as susceptible to life’s quirks as the rest of us. I also noticed that he worked fast. Really fast.

On the last day of class there was a picnic. Sam sought me out and apologized for not spending much time with me. It was a grand gesture, sincere and he really did feel bad. I told him I was not there to talk but to learn and that I was going to go home and quit my job to be a furniture maker. It was the easiest decision I ever made. Everybody else thought I was crazy, which strangely enough, persists to this day.

Before we parted company Sam asked to see my portfolio. All I had were a couple of pictures of a try-square I designed for my beginning woodshop classes—I was really embarrassed. In his customary way, he told me he thought the try square was beautiful.

Within a couple of years my work—strongly influenced by Sam’s forms—was being accepted by juries. At some point Sam called to congratulate me and I confessed how hard it was to design without thinking about how Sam would do it. He told me not to worry, that this will pass and I will find my own voice. It was not long and I had a three-year backlog of work and just as he predicted, my later work bore no resemblance to Sam Maloof.

Unfortunately, I have an abundance of dumb genes. I never once saw Sam wear a dust mask, and neither did I. My furniture making career came to a quick halt in 1983 with a hyper-allergic reaction to wood dust.

A couple of times a year there would be tool shows in the Los Angeles basin and I would stay with Sam and Freda on the lemon grove property. We would talk until Freda made Sam go to bed.It is here that I learned that objects should be worthy of the space they occupy—he was surrounded by the visual richness of others in addition to his own work.There was a canoe hanging from the ceiling—how cool.

Sam was an avid customer of Bridge City and during one trip I asked him where all the tools were that he had purchased. Oh, they are right here behind the sofa and he pulled out a box and opened it. I said “Why don’t you use them?” He said “I do. I tell everybody about these beautiful tools.”

My last visit with Sam was a year ago—I took Sam and “the boys” to lunch.Sam asked to see our latest tool, which was the CT-14 Shoulder Plane. When told the price, Sam commented, “$800 is a lot of money for a plane.”I retorted, “$35,000 for a rocking chair is a lot of money for a piece of furniture.”

One of the boys interrupted, “Sam, you are not going to win this one.”

And with a wink, he put the hand plane on his lap and asked if I could send him an invoice.

I don’t believe Bridge City would exist without Sam Maloof. So on behalf of all of the Bridge City family, particularly the big oaf at the helm, I offer a collective “thank you”.It was a grand thirty-one years.

Thanks Sam—

–John

Introducing “Bridge City Essentials”, Celebrating 25 Years of Toolmaking

May, 28th, 2009

The later half of the ’70’s and the first couple of years of the 80’s I was a studio furniture designer/maker–and there is no doubt that I would still be making furniture had I not become hyper allergic to wood dust. For me, being a craftsman is simply an honorable profession for those who love working with their hands.

Bridge City is the direct result of my forced wood aversion and ironically Bridge City has made it possible for me to begin making things again–thanks to the low dust output and accuracy of the Jointmaker Pro. This is an exciting time for me creatively and the concept of “Silent Woodworking” really resonates with how I want to pursue woodworking. I know it is not for everybody but I also know it is growing in appeal. In a way, we are creating the shop of my future with this 25th anniversary celebration.

I am pleased to share that over the next seven months we will be introducing the Bridge City Essentials. This is a series of tools, all made to order, that embody a harmonious union of form and function. Each tool will represent a solution for an essential function found in all woodshops, large or small, silent or noisy. Each will be designed and crafted in such a way that reflects all we have learned over our 25 years of tool making. Each tool will also celebrate something unique and innovative that Bridge City has introduced into the woodworking marketplace–and all will be made from stainless steel as I have this unyielding fetish…

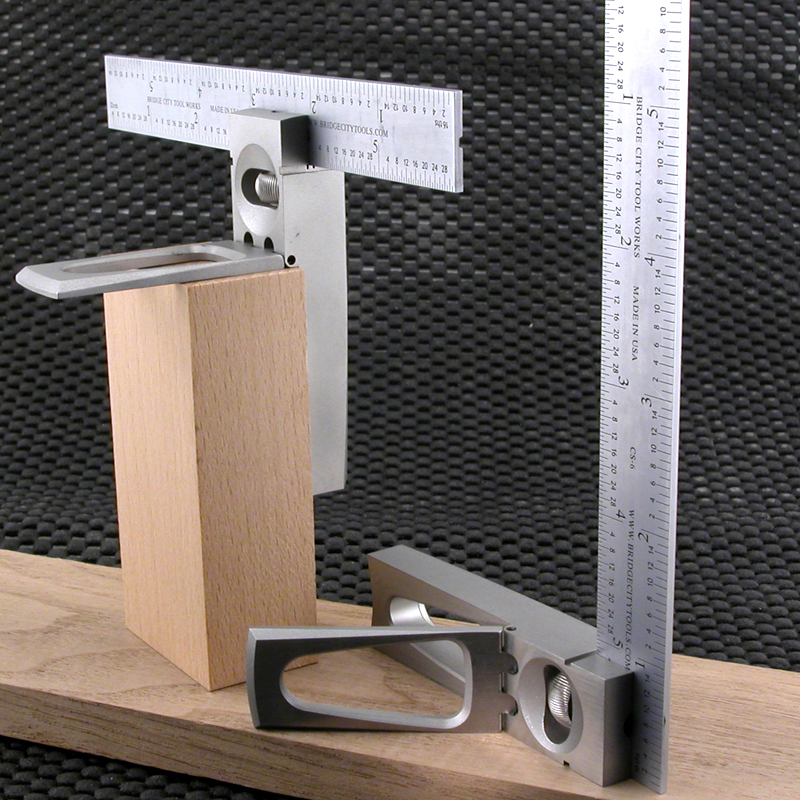

Please meet the first Bridge City Essential, the DSS-6 Double Square.

This little square, once in hand, is impossible to ignore. The heft, the feel and the function represents our very best effort. In addition to a fully functional 6″ double square, the DSS-6 also features a 2″ saddle square–an innovation we introduced about 10 years ago. The combination is an obvious improvement over traditional designs and the tool packs a wallop functionally in such a small footprint. And yes, it is square.

The design borrows from our HP-7 Shoulder Plane in that the radial knurled locking knob resides in a spherical pocket–it is our way of keeping circles and squares in tune.

Small enough to fit into your apron pocket and yet accurate enough for large projects, the DSS-6 will be my square of choice for 99% of what I make moving forward. It is meticulously machined from a stainless steel billet and comes with three satin chrome blades options.

The DSS-6 is available for immediate delivery. We will only make them again if there is sufficient demand.

Thanks for taking the time to read about the ‘Bridge City Essentials’. The next member will be introduced in late June.

–John

Celebrating 25 Years of Tools and Blunders…

Although our first ad appeared in the 1983 Nov/Dec issue of Fine Woodworking, our first full year of operation was 1984 and that makes us officially 25 years young. It does not seem that long ago until I realize that I was 32 when this started. .. Yikes!

What an incredible ride–here are a couple of fun facts and statistics that you may find interesting–

- We have sold tools to over 450,000 unique Bridge City customers over the years. This is actually a small number for a direct marketing company. However it is an amazing number when 100 percent of the woodworking catalogs I contacted in 1983 told me that American woodworkers would never pay for quality.

- The TS-2 Try Square we introduced in 1983 for $45 would cost $100.39 today.

- When it came time to design a combination square, all of my field research dictated that it would be a mistake to eliminate the scribe pin that Leroy Starrett included in his invention. Not one bound by conventional wisdom, our CS-12 Combination Square (sans scribe) was the single most successful tool introduction in our history. We sold 6,500 units in three weeks. It took us 6 months to make them.

- It is hard to forget the theft ring that operated out of our warehouse. An employee informed me that there were new BCTW tools at a pawn shop in downtown Portland. In fact, new tools were subsequently found in all the pawn shops in Portland. An inventory of our warehouse indicated no discrepancies. All tools were boxed, stacked and sitting on shelves. We discovered that counting empty boxes was the problem–the loss on this one event was around $50K.

- Our single biggest sales day was $255,000.

- We never had a zero sales day until 9/11 and we had six in a row.

- In the direct marketing business one way you can judge growth potential is by the pool of available names. These names are from other woodworking businesses, magazine subscribers and a couple of other sources. The pool of available names today is almost 1/2 of what was available in 1990.

- The largest check I ever signed was for $360,000 to the US Post Office to deliver 1,400,000 catalogs.

- In 25 years we have never missed a payroll*.

*I hired an MBA to help me run the company years ago. It was his idea to delay payroll for the manufacturing team one day to impress how important it was to increase productivity. Instead of being paid on Friday, they were paid on Monday. Five people quit that day. It was the last time I allowed my gut to remain silent.

- Fifteen years ago we moved paydays from Fridays to Wednesdays. Absenteeism on Mondays decreased by 80%.

- About four days after signing the largest check I have ever signed, our manufacturing manager walked into my office and told me sit down. The 1.4 million catalogs that were hitting the street had the wrong toll free number on every page and the order form. I knew this was the end. I called the phone company and requested the wrong number knowing that most issued numbers have uncommitted numbers on both sides–but not in this case. The wrong number belonged to a prescription drug company in New Jersey and low and behold, my next call was the most foul, angry call I have ever fielded from a CEO–furthermore it was from a woman. After her spleen burst, all I could say was, “Why would I do this on purpose?”. Knowing that every problem has a solution, I called her back a couple of hours later and proposed that her staff take orders for us for the next 12 weeks and for so doing, we would pay 10% of each order as a bonus to her staff. Each day we received a FedEx package of orders from her staff and each week we mailed out the “bonus” checks to the phone staff . We managed to make it through the biggest blunder I could imagine. About six months later I received another call from the CEO thanking me for making her company better–apparently in a race to answer the phones, her customers noticed a marked improvement in customer service and her average order increased over this same period! Go figure. Oh, the bonus checks were in excess of $100K.

- The first trade show we attended was at the Cow Palace in San Francisco, March, 1984. I had no booth, signage or display material. I simply sat on a table and showed our first two tools, the TS-2 Try Square and the SA-2 Scratch Awl. The booth cost me $500 and I wrote $2500 in orders. The following week I went to Pasadena with the same meager presentation and wrote $5000 in orders. That year, our total revenue was $37,000.

- We never failed to double our revenue for the next six years. The jump from 1.5 million to 3.4 million in 1990 was when I realized that I needed serious management help.

- Up until about 10 years ago, we had an unconditional guarantee on all of our tools. Then one day I walked through our shipping department and noticed a pallet of returns (we normally receive one or two returns a week, 50% are screw-ups on our part and the other 50% are from buyer’s remorse after the wife sees the credit card bill). The same day I get a call from a customer directing me to a post on a woodworking forum. This genius outlined, “How to Get Free Bridge City Tools”. This involved buying our tools from estate sales at less than face value and then deliberately damage the tools so they were beyond repair. In one day we received a package with 17 tools within. The try square blades were all bent, as if someone stepped on the blade and pulled the handle upward. This type of behavior would never occur to me but this guy violated the spirit of good faith in such a way that I voided his warranty. He was informed and then he called me to share that he was a lawyer, my warranty was explicit and that he would see me in court. I told him I could not wait for the day where he had to explain to a jury what he did to these tools for new replacements. We sent all of his junk back and never heard from him again.

Well, there are more fun facts but I will save them for another day. Sometime today or tomorrow I will share how we plan to celebrate all of my mistakes by doing what I do best, which as you now know, is not running a business.

–John