Yesterday I spent the afternoon playing with our Jointmaker Pro prototype. Here’s a short video of a couple of ideas I pursued–as you can see, the accuracy of this tool is incredible. We are all marveling that I can work in our office doing these things without disturbing anybody. It was one of the best days I have had in a long time!

Here’s a direct link to the YouTube video; http://www.youtube.com/watch?v=UTVKQgOqZSo&fmt=18

Also, the Bridge City forum is now open. This is a moderated forum where you can ask woodworking questions or share information regarding our products. The location for entering the forum is at the bottom of our home page. Click on “Community Forum”.

New Tools

Newly engineered woodworking tools at Bridge City Tool Works

The Center Scribe after 520 payroll periods…

June, 26th, 2008

Thanks to the British Weights and Measures Act of 1824, we Americans inherited a collection of units known as the Imperial system. Imperial units are unbelievably accurate and superior to the metric system in every way–and I can prove it with a singular question:

What is 17-17/32″ divided by three?

And you thought a six-star Sudoku puzzle was hard.

Fortunately, woodworkers are constantly dividing things in half, a much easier task than the gasket blowing problem above (5-27/32″ is the correct answer–took me a day and a half, or .15 payroll period to figure this out ). Try it yourself–dividing 17-17/32″ by two only took me four hours.

Approximately 520 payroll periods ago, we introduced the CS-1 Center Scribe, a cool tool to help Inch Land woodworkers find the center of things without time-consuming calculations. Inchlanders often struggle with the efficiency of Imperial measurements and our CS-1 Center Scribe quickly became one of our most sought after tools to this day.

About 104 payroll periods ago, improvements to the CS-1 came upon me. Fully charged for the redesign, the muse arrived unannounced bearing news of the VP-60 Adjustable Pitch Plane. Immediately thereafter, who should reappear with a radical new design for shoulder planes? And for the past year, I have been obsessed with the Jointmaker Pro–likely the most scrutinized new tool introduction I’ve known.

The image below is of our new, improved Center Scribe.

Briefly, here are the improvements;

- Zero backlash or slippage–no gears.

- Holds a pencil

- Finds centers on square, round or rectangular stock lightning-fast.

- Does not react with humidity

- Field adjustable if needed

- Smoother feel

- More precisely scribed centerlines (not pencil lines for obvious reasons), accurate to within .002″

To learn more, visit the CS-2 Center Scribe pre-production page. And if the CS-2 looks like something you can use, click the panel that states “Notify me when this item is back in stock.” By adding your name to this database we have a much better idea of our manufacturing quantities–you are not placing an order.

Thanks to a suggestion by a good engineering friend, this tool is crazy smooth and accurate. I hope you like it because… well, it’s a payroll thing.

-John

HG-1 Honing Guide in Action

June, 2nd, 2008

It is always fun around here when an idea becomes reality. Later this week our new honing guide will be in stock. Although I designed this tool with the specific needs of sharpening our HP6 profiled irons in mind, it will work on just about every tool in your shop. Here’s a peek of the tool in action…

As you can see, the rear roller is flat. We have had several inquiries regarding a roller that is crowned to facilitate relieving the corners of wide plane irons. Although this sounds like a good idea, the math makes no practical sense. For example, if one wants to relieve the corners of a plane iron by .002″-.003″, the crown in the honing guide roller would be around .001″. This is just not a practical idea (in our opinion) when the same results can be achieved with finger pressure applied to each corner during honing. If a more severe crown is required, a barrel shaped roller might make sense, and if you have that need, you can easily remove the stock roller and insert a shop made roller (wood will work) for your needs.

Lastly, it is not clear in this clip but the clamping bridle pivots and will accommodate aggressively tapered tools–the most common of which are Japanese chisels.

Thanks for watching.

-John

Jointmaker Pro In Action

May, 8th, 2008

Here’s a little clip that shows some amazing capabilities of the Jointmaker Pro.

–John

Insomnia has its rewards…

May, 5th, 2008

I don’t know why, but I wake up in the middle of the night so frequently I wonder why I go to bed in the first place. Last August, while you were likely asleep, I was wide awake fretting how woodworkers tend to put their fingers at risk when sawing small stock. Then an idea came upon me…

With patents pending, we will soon introduce a completely new way to crosscut wood and make joinery entirely by hand. And although this saw really shines with small stock, it will cut hardwood or softwood up to 6″ in width and 1-5/8″ thick, which is the vast majority of crosscuts for most. It is quiet, accurate, and the cut is so smooth no further work is necessary for cleanup. It is rather remarkable because accuracy like this has never been possible without power. There is also no need for hearing protection, dust collection and it is very safe.

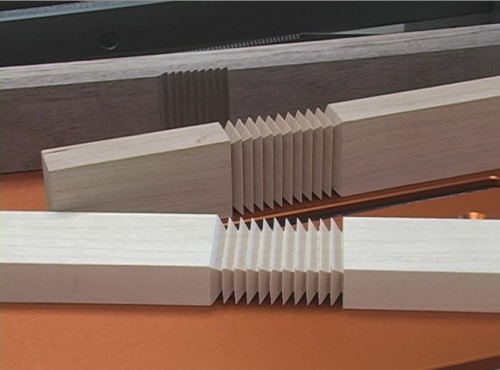

Many woodworkers view new ideas with a bias towards their own skills and techniques and are slow to embrace change–woodworking is the most anachronistic hobby in America. So, over the past four months I have given demonstrations to several different groups of woodworkers to determine interest in this new way of cutting wood. We also demonstrated the saw in Cologne, Germany in March. I will write more later, but until then, check out the two images below – all of these cuts were hand sawn! We think you will agree, these images are strong indicators of a tool that rivals, and exceeds in many cases, the capability of power-hungry alternatives.

-John

These two boards were cut entirely by hand with a new handsaw from Bridge City. The cuts are smooth, accurate and depth is consistent within .002″ on every cut. Each board took about 10 minutes and is comprised of 88 individual cuts.

In an effort to fully understand the capabilities of our new saw, we quickly cut angled cuts into two pieces of wood and nested them. This is amazing when one considers no power was used. Each piece was cut in approximately 5 minutes and consists of 42 individual hand cuts.

Ideas are everywhere when you’re hungry…

May, 1st, 2008

Last fall I crossed paths with a sandwich board on my walk to lunch (O.K., I tripped). As I walked around the sign I had one of those moments where I saw something that wasn’t there (typically I imagine IRS agents—they’re everywhere you know…) The offending culprit is pictured below.

Empirically we understand concrete is a painful abrasive (knees never forget) and while regaining my balance I imagined the sidewalk as an endless… abrasive… honing stone… and I was tripping over a… crude honing guide! Sounds weird, but a ray of light leaked into my cranial garden and in that instant, an idea germinated.

I returned from lunch, grabbed a chisel and mocked up the idea using my Razr cell phone. That was all the validation I needed to pursue the development of our HG-1 Honing Guide. And we are thrilled with the results. (In a pinch, a cell phone makes a crappy honing guide, but as you can see, schematically it worked out very well. Don’t be surprised if the “Woodworking Taliban” embraces this ridiculous cell phone alternative …)

The HG-1 is completely different than previous designs. Most significant is the built-in squaring guide which will keep cutting edges that have to be square to the sides in perfect alignment (shoulder plane irons are one example). The other new development is the infinitely adjustable micro-bevel system controlled by the knob at the back of the plane. This was a crucial development for this tool because of the profiled irons our HP-6 Mini Multi-Plane employs.

We will formally announce this new product (and the reference set-up guide for precise primary bevels) in a couple of weeks, with many more details and pricing. Needless to say, it will work well for chisels, irons and really shines when used on our aluminum profiled stones for HP-6 molding irons. Below are a couple of pics to see how the guide unfolded.

Oh, and I forgot, the yakisoba was delicious.

-John